Screw-free mounting type wood-plastic floorboard

A wood-plastic floor and wood-plastic board technology, applied in the field of wood-plastic flooring, can solve the problems of inconvenient assembly and high cost, and achieve the effects of reducing assembly time, ensuring the quality of bearing capacity, and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

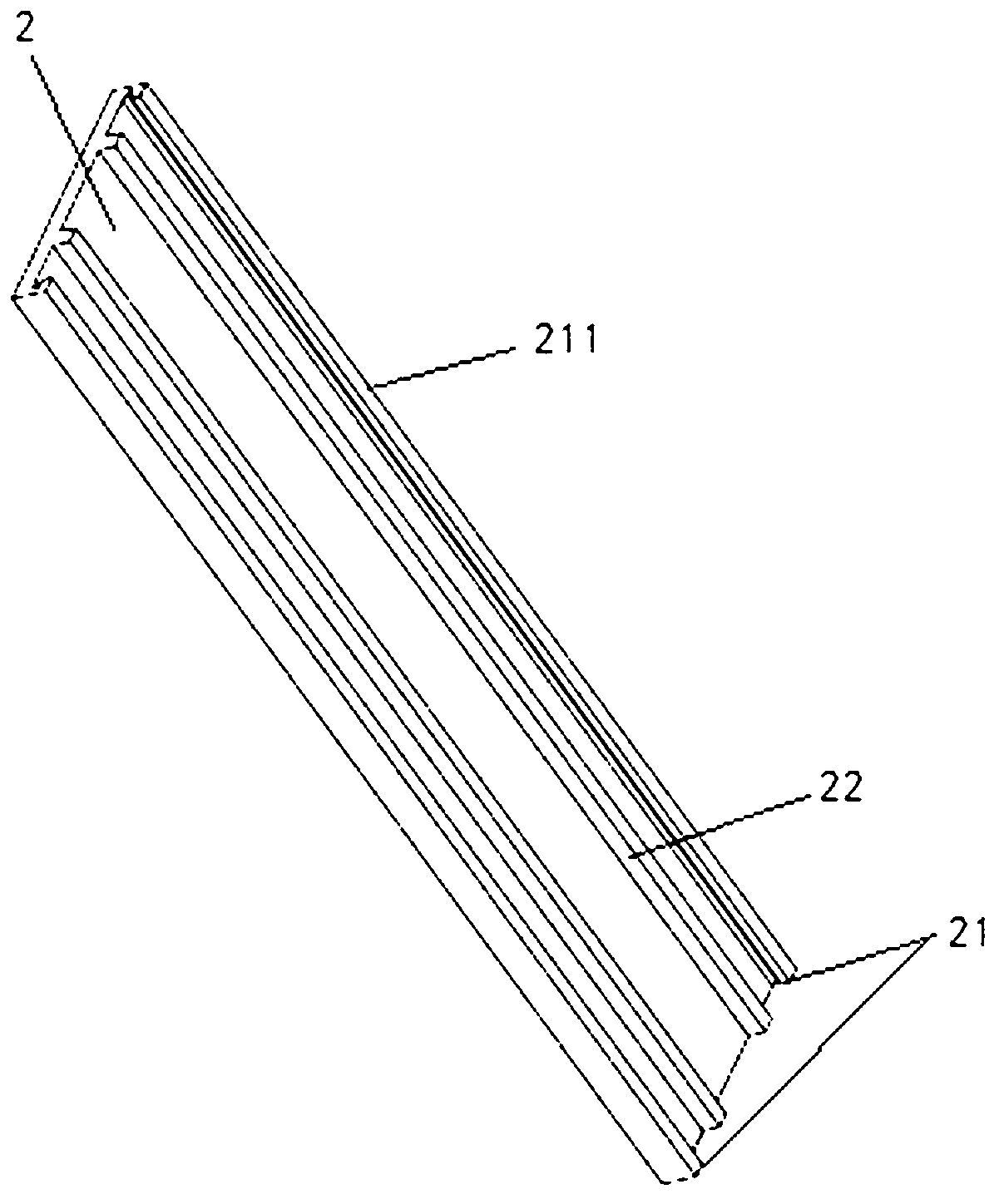

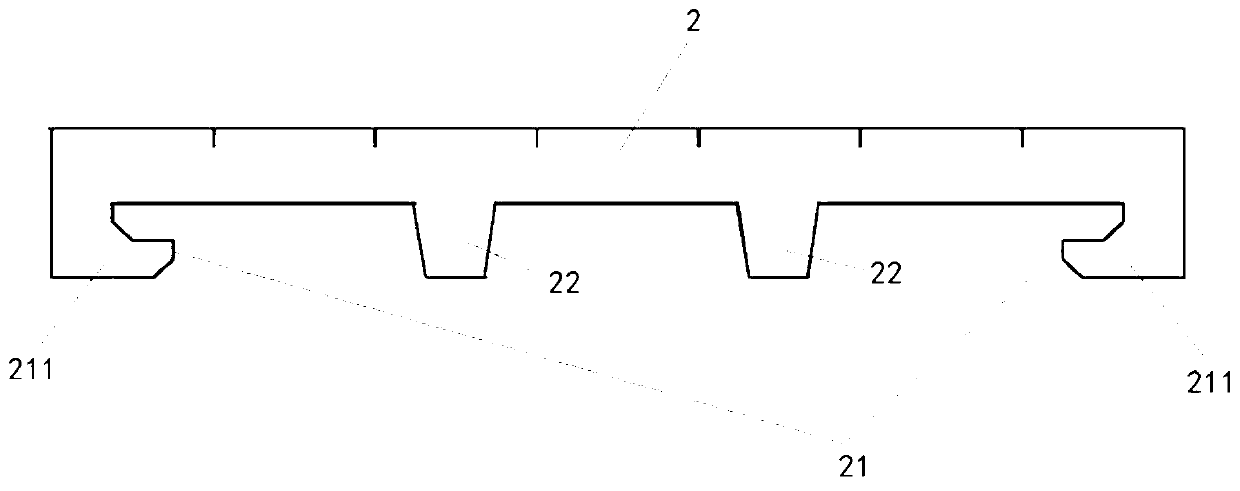

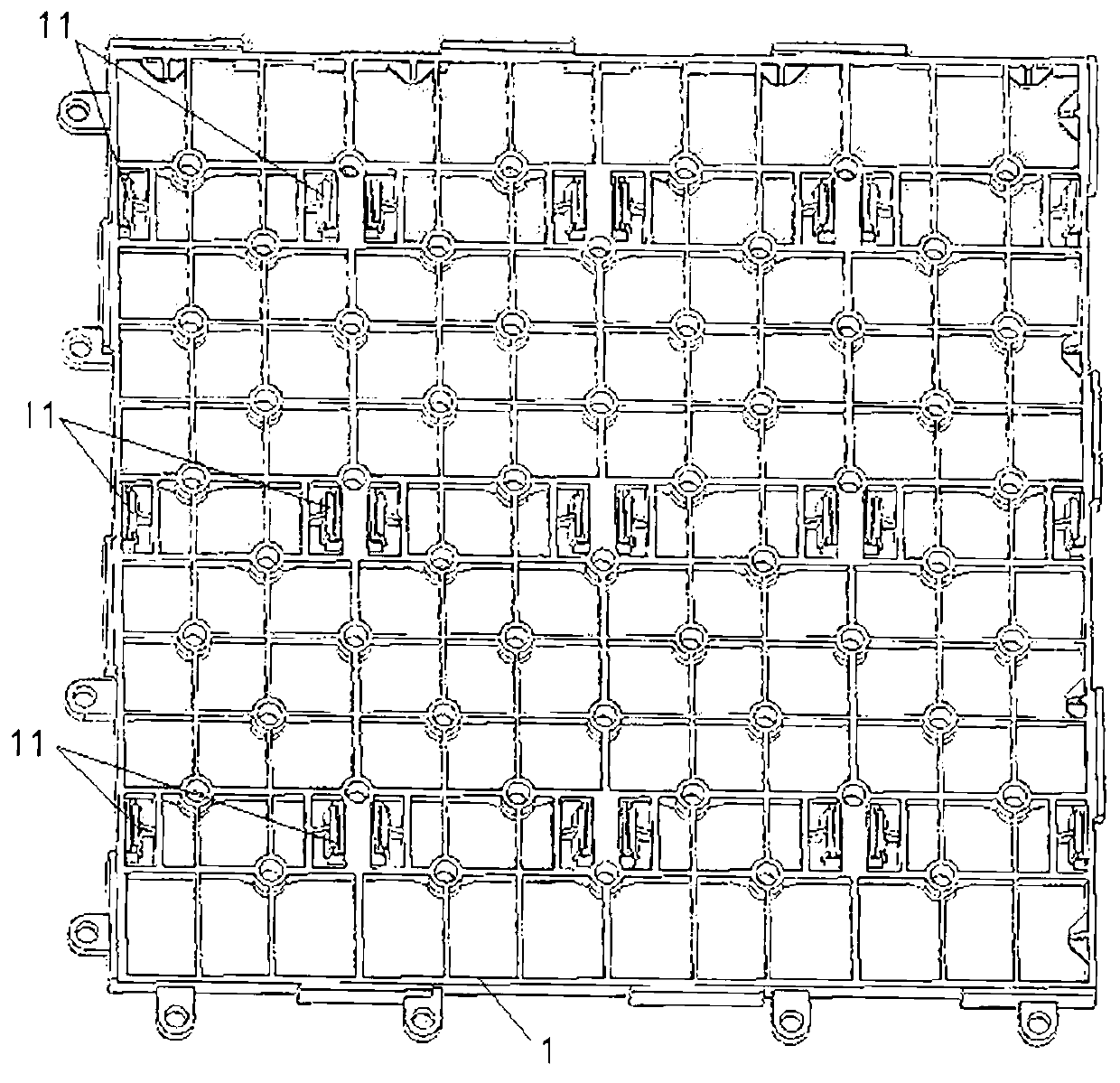

[0022] Example: such as figure 1 , figure 2 and image 3 As shown, the same as the traditional wood-plastic floor, the nail-free installation type wood-plastic floor provided in this embodiment also includes a plastic base 1 and several wood-plastic slats 2 on the plastic base. .

[0023] The key improvement of the present invention is that: the bottom of the wood-plastic slat 2 is provided with a card slot 21, and the upper part of the plastic bottom bracket 1 is fixed or integrally provided with a tab 11 that is inserted into the card slot 21. The slats 2 and the plastic bottom bracket 1 are fixedly connected together only through the slot 21 and the tongue 11 , instead of the traditional screw connection.

[0024] Such as figure 1 and figure 2 As shown, in this example, the slot 21 is jointly formed by two L-shaped slot sides 211, and the two slot sides 211 are respectively arranged on the left and right sides of the bottom of the wood-plastic slat 2, and the slot T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com