Patents

Literature

85results about How to "Won't warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

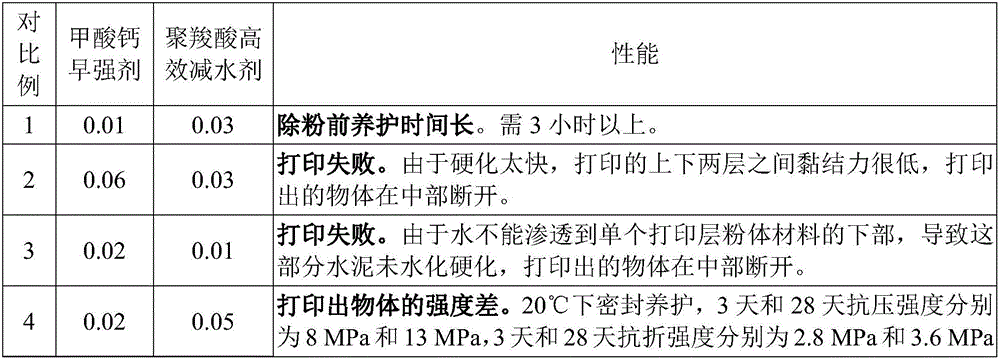

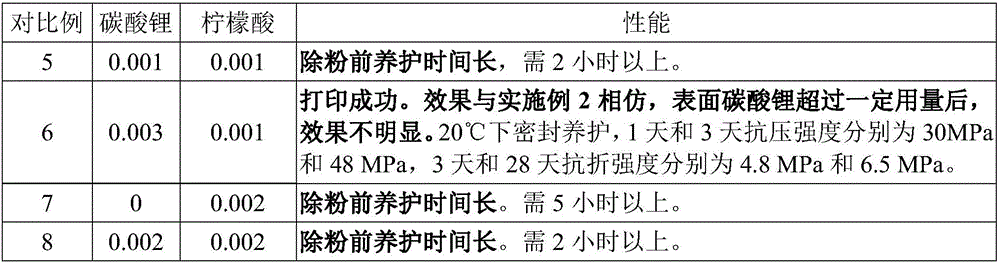

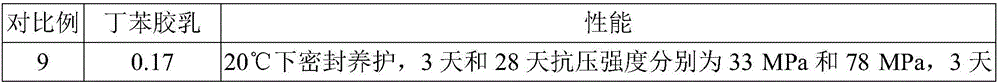

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

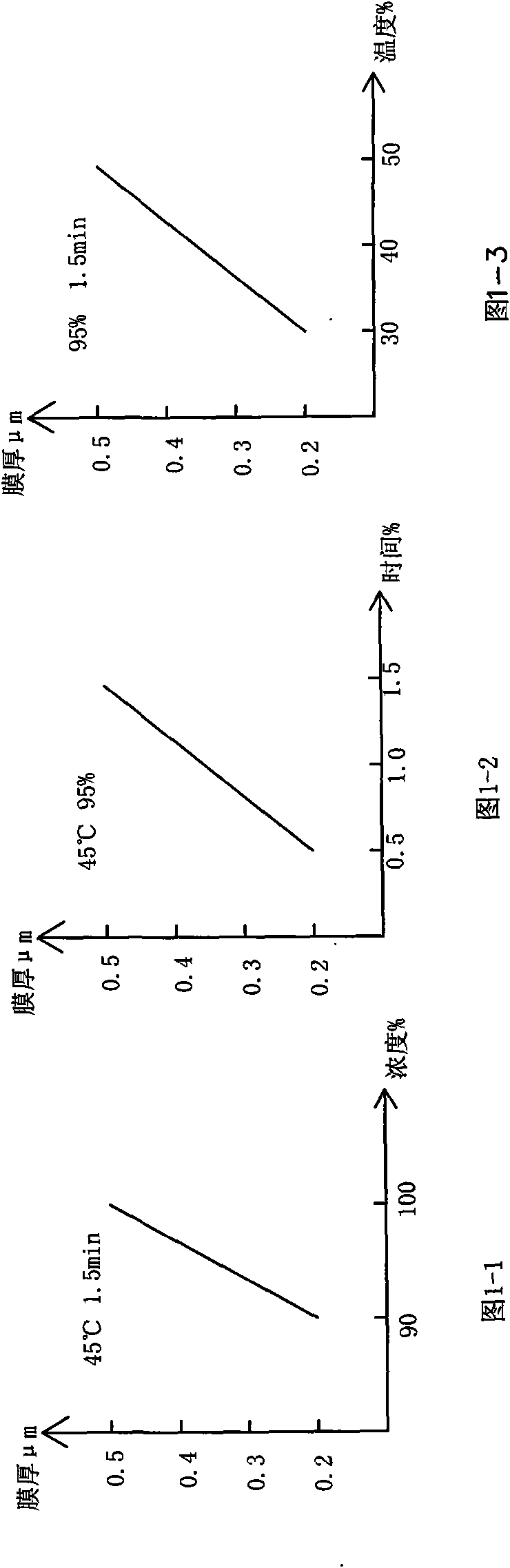

Lead-free printed circuit board copper surface protecting agent and preparation method thereof

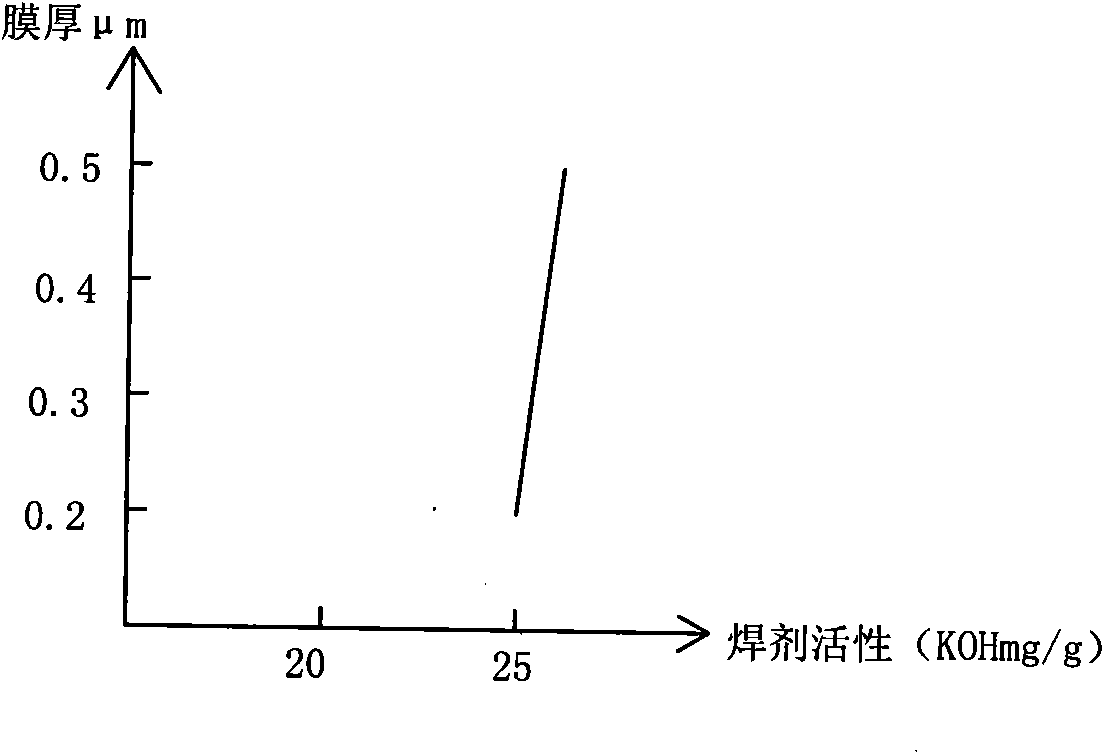

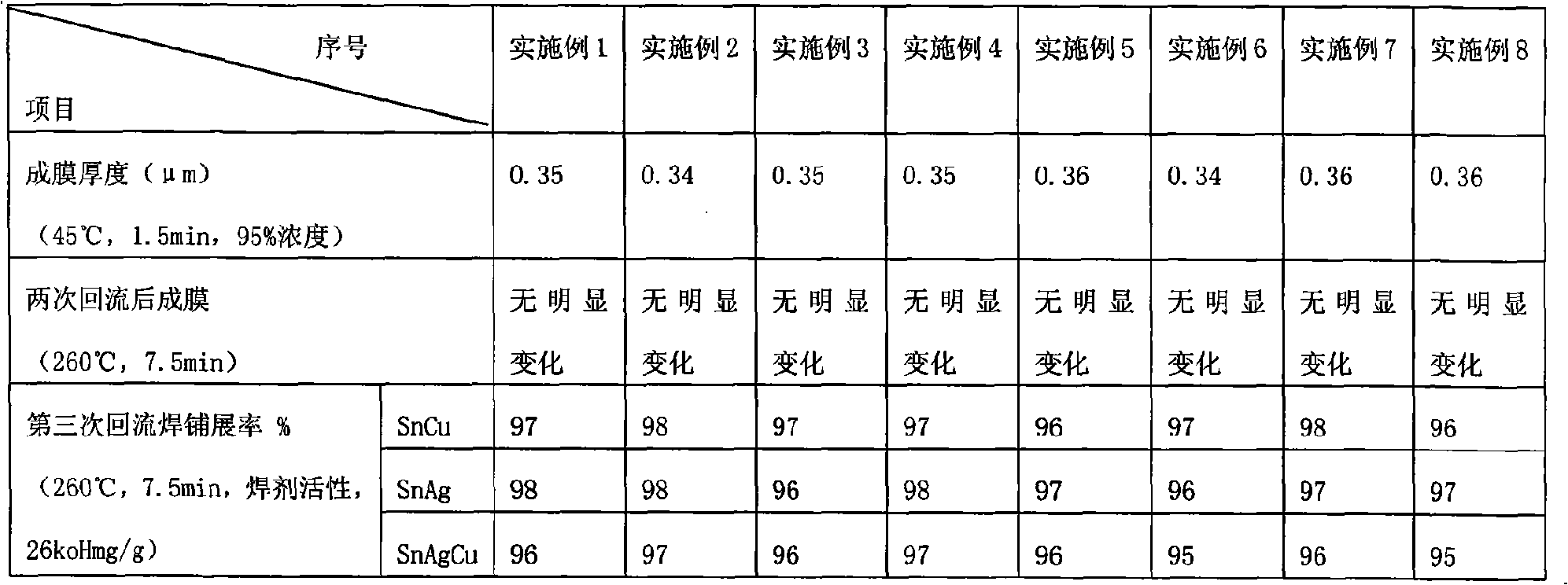

InactiveCN101560656ALower operating temperatureWill not deformMetallic material coating processesOrganic acidTectorial membrane

The invention discloses a lead-free printed circuit board copper surface protecting agent and a preparation method thereof. The lead-free printed circuit board copper surface protecting agent is a mixture prepared by the following materials with parts by weight: 1-15 parts of organic acid, 0.1-2 parts of metal salt, 0.1-3 parts of imidazoles compound, 0.01-0.15 part of non-ionic surfactant and 79.85-98.79 parts of deionized water. The invention also provides a preparation method of the protecting agent and is applied to the naked copper surface processing technology of the printed circuit board (PCB) of electronic industries. The protective film generated after the dipping treatment of the protecting agent has flat, non-crispy, anti-oxidation, heat shock resistant and humidity resistant properties. The invention has low production cost, simple production process, convenient and quick use and extremely broad market shares.

Owner:广东中实金属有限公司

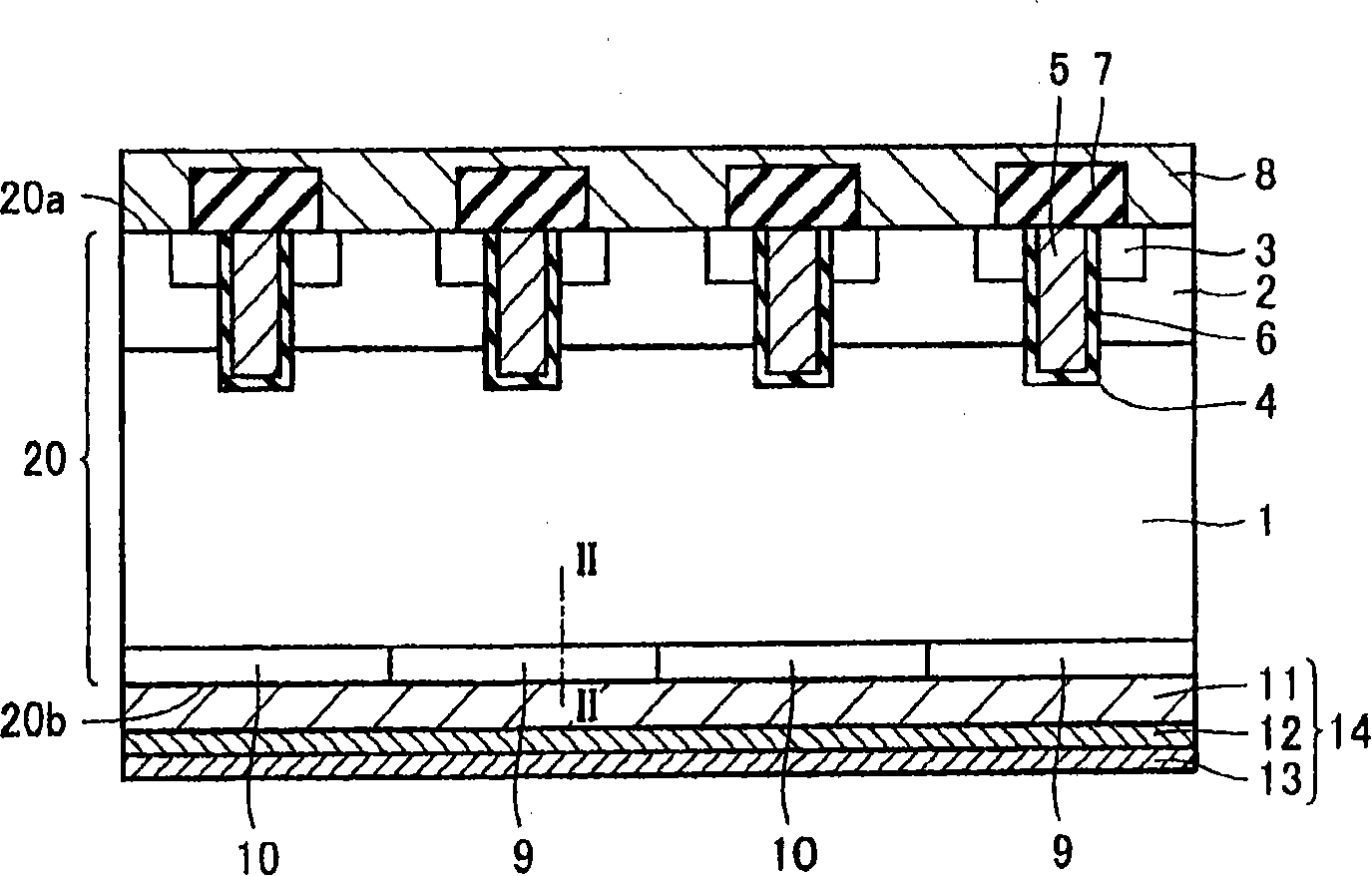

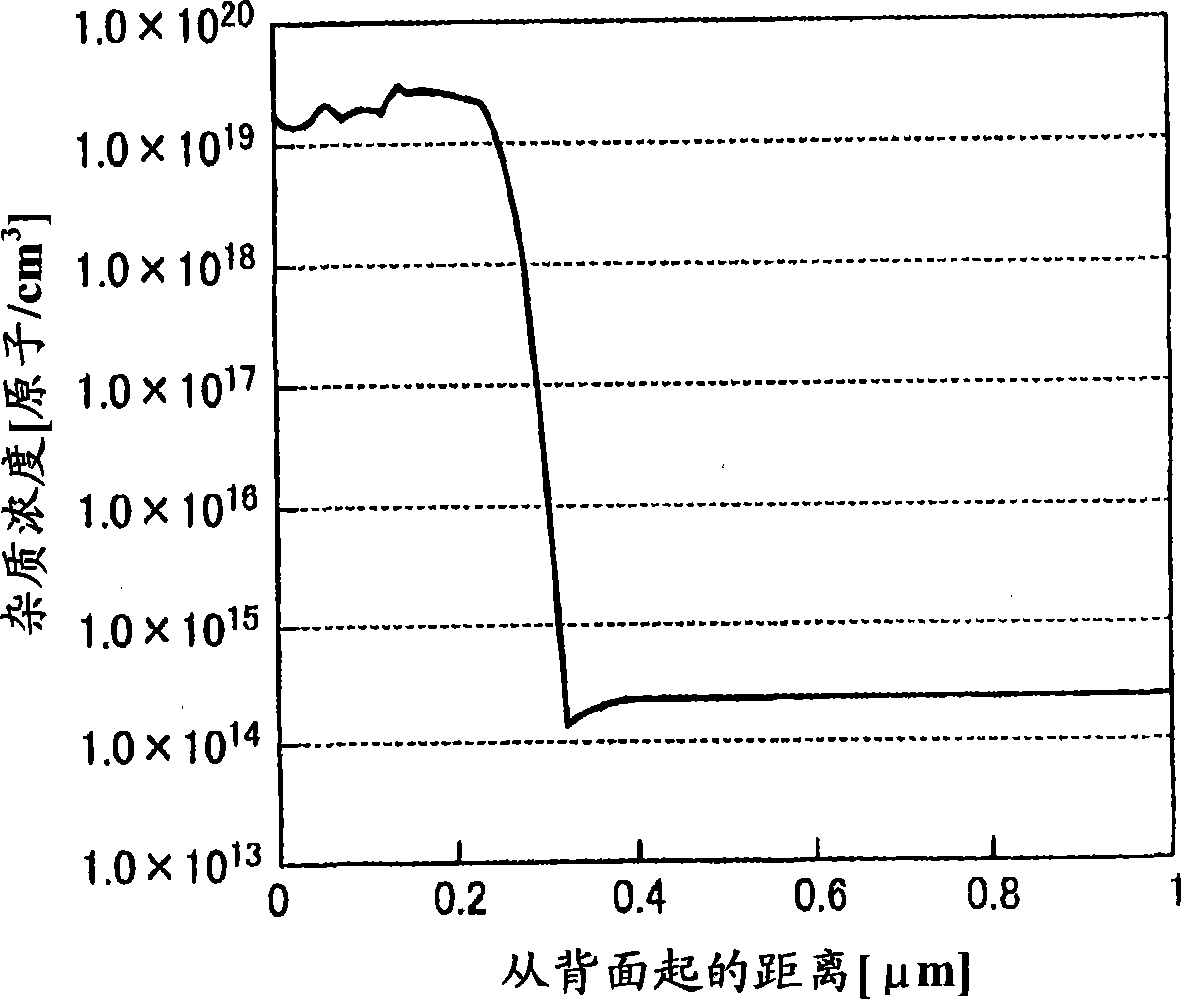

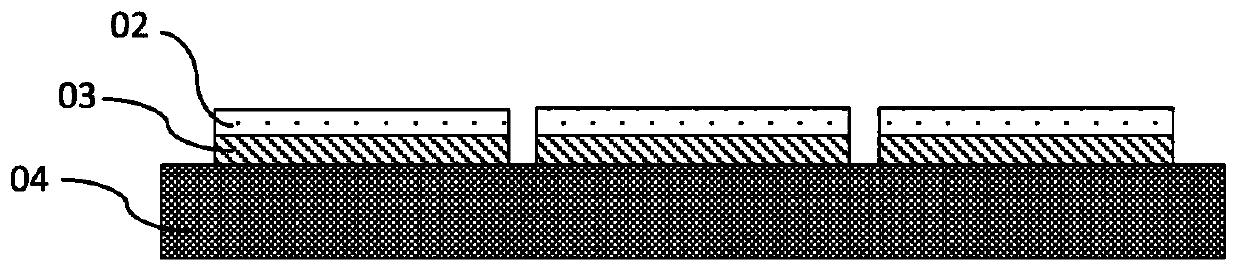

Semiconductor device and manufacturing method thereof

InactiveCN101170109AGood turn-on voltageWon't warpSolid-state devicesSemiconductor/solid-state device manufacturingFlyback diodeTitanium

A p-type collector region (9) of an IGBT and an n-type cathode region (10) of a free wheel diode are alternately formed in a second main surface (20b) of a semiconductor substrate (20). A back electrode (14) is formed on the second main surface (20b) so as to be in contact with both of the p-type collector region (9) and the n-type cathode region (10), and has a titanium layer (11), a nickel layer (12) and a gold layer (13) that are successively stacked from the side of the second main surface (20b). A semiconductor device capable of obtaining a satisfactory ON voltage in any of conduction of an insulated gate field effect transistor and conduction of the free wheel diode as well as a manufacturing method thereof can thus be obtained.

Owner:MITSUBISHI ELECTRIC CORP

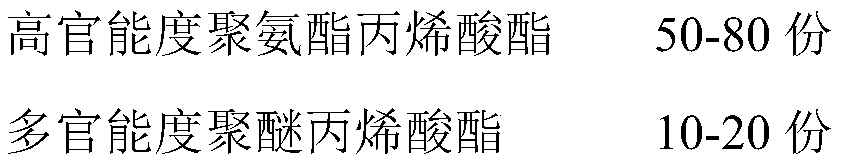

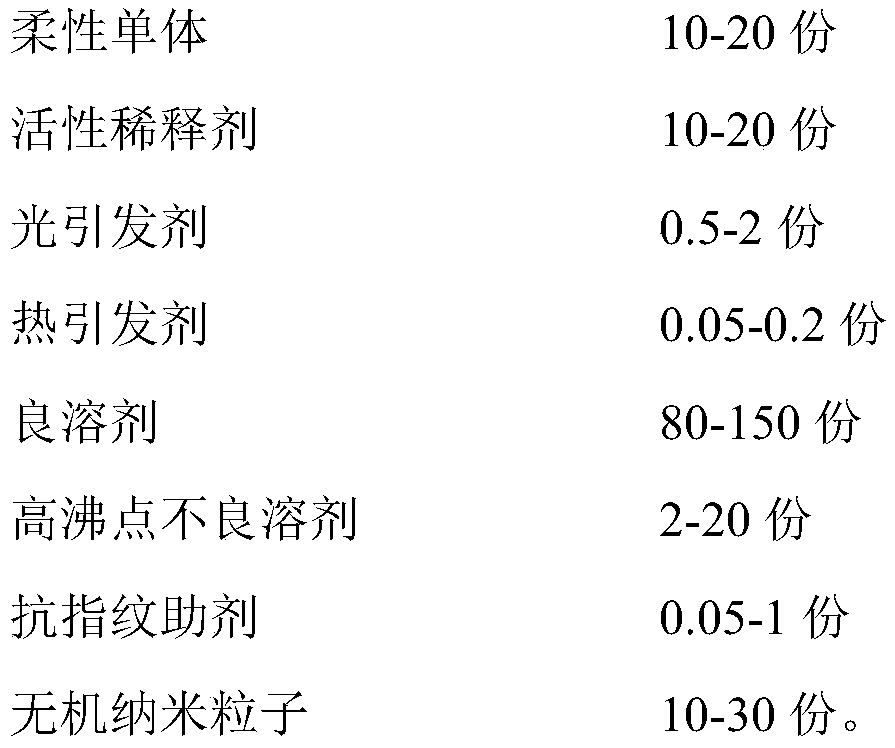

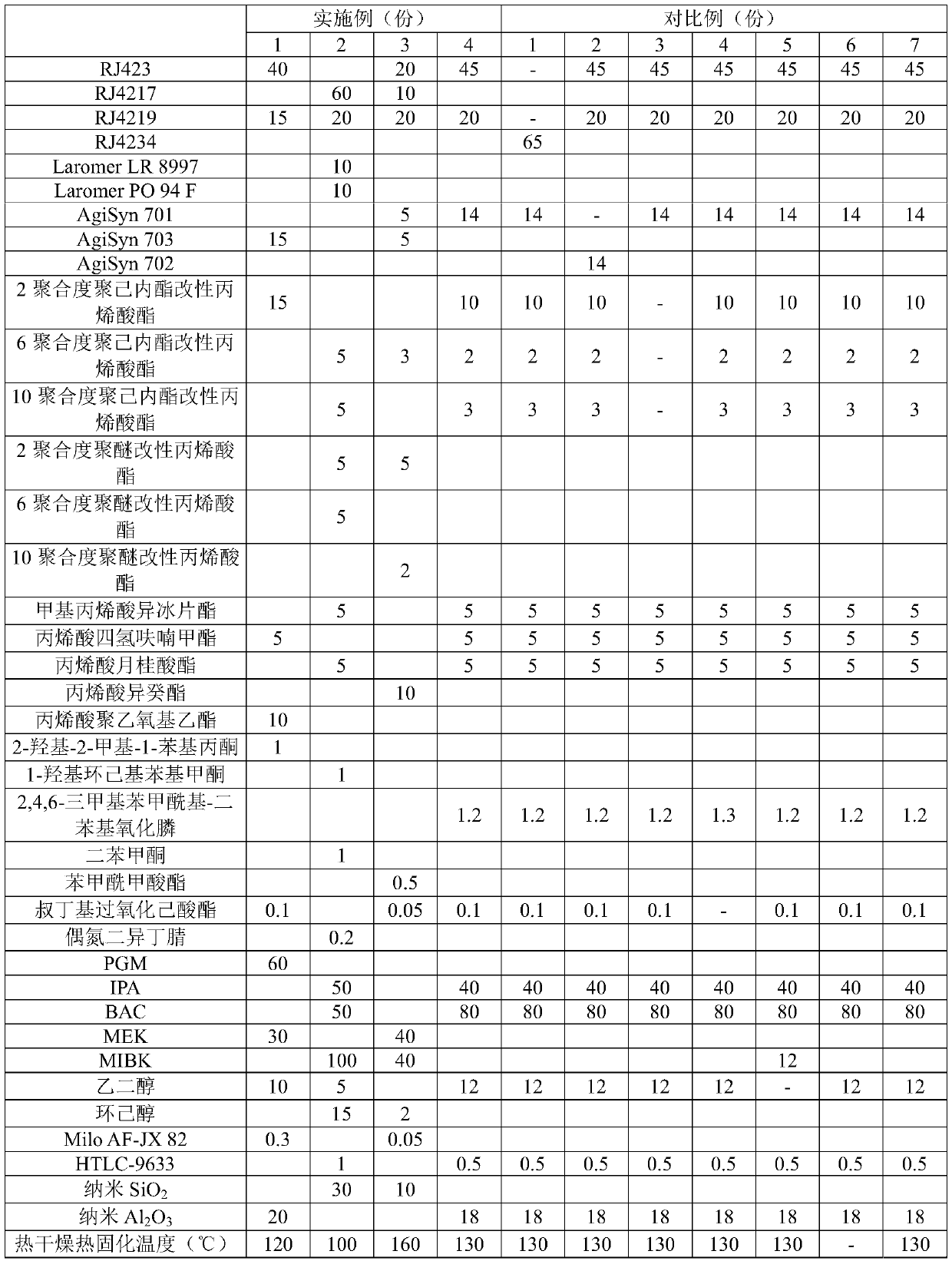

Transparent polyimide hardened film with low shrinkage, high hardness and high wear resistance

ActiveCN110358439AHigh hardnessImprove toughnessAntifouling/underwater paintsPaints with biocidesSolventLow shrinkage

The invention specifically relates to a transparent polyimide hardened film with low shrinkage, high hardness and high wear resistance, belonging to the technical field of transparent polyimide hardened films. A hardening solution used for preparing the transparent polyimide hardened film comprises, by weight, 50-80 parts of high-functionality urethane acrylate, 10-20 parts of polyfunctional polyether acrylate, 10-20 parts of a flexible monomer, 10-20 parts of a reactive diluent, 0.5-2 parts of a photoinitiator, 0.05-0.2 part of a thermal initiator, 80-150 parts of a good solvent, 2-20 parts of a high-boiling-point poor solvent, 0.05-1 part of an anti-fingerprint agent and 10-30 parts of inorganic nanoparticles. According to the invention, the high-functionality urethane acrylate and the polyfunctional polyether acrylate are adopted to improve the hardness of the hardened film, and the toughness of the hardened film is enhanced by the flexible monomer; and the thermal initiator and thephotoinitiator are added at the same time, and through cooperation between thermal curing and photocuring, shrinkage stress caused by polymerization during curing process is properly released, so warpage is avoided.

Owner:新纶光电材料(常州)有限公司

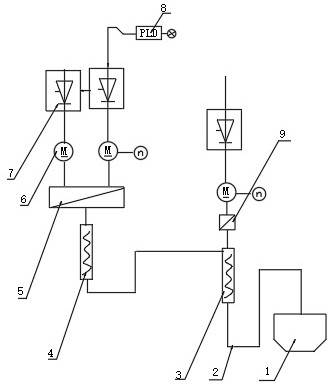

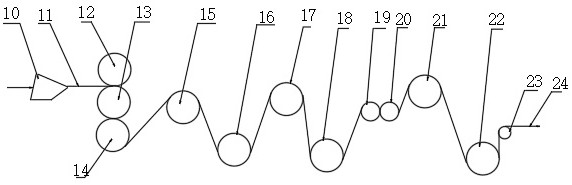

Production technology for silicone oil paper

ActiveCN106958167AImprove bindingGood quality and safetyPaper coatingPhysical paper treatmentPaper sheetEmulsion

The invention discloses a production technology for silicone oil paper. The key point of the technical scheme includes the following steps: S1) preparing a coating material, namely mixing and uniformly homogenizing emulsion silicone oil, a catalyst and a cross-linking agent at certain ratio; S2) coating, namely uniformly coating the coating material onto a paper surface through a coating machine; S3) drying, namely inputting a paper sheet after press polishing into a drying box, and heating and drying at the drying temperature of 80 DEG C to 150 DEG C; S4) re-wetting, namely wetting the dried paper sheet; S5) secondarily drying, namely drying the wetted paper sheet in the drying box again at the drying temperature of 80 DEG C to 150 DEG C; S6) press-polishing, namely press-polishing the dried paper sheet with a press-polishing machine; S7) cutting: cutting the paper sheet after press-polishing with a cutting machine; S8) coiling. The food-grade baking paper prepared according to the invention has a uniform and glossy surface, has a good anti-sticking effect, is free from edge warping and is high in yield.

Owner:MINFENG SPECIAL PAPER

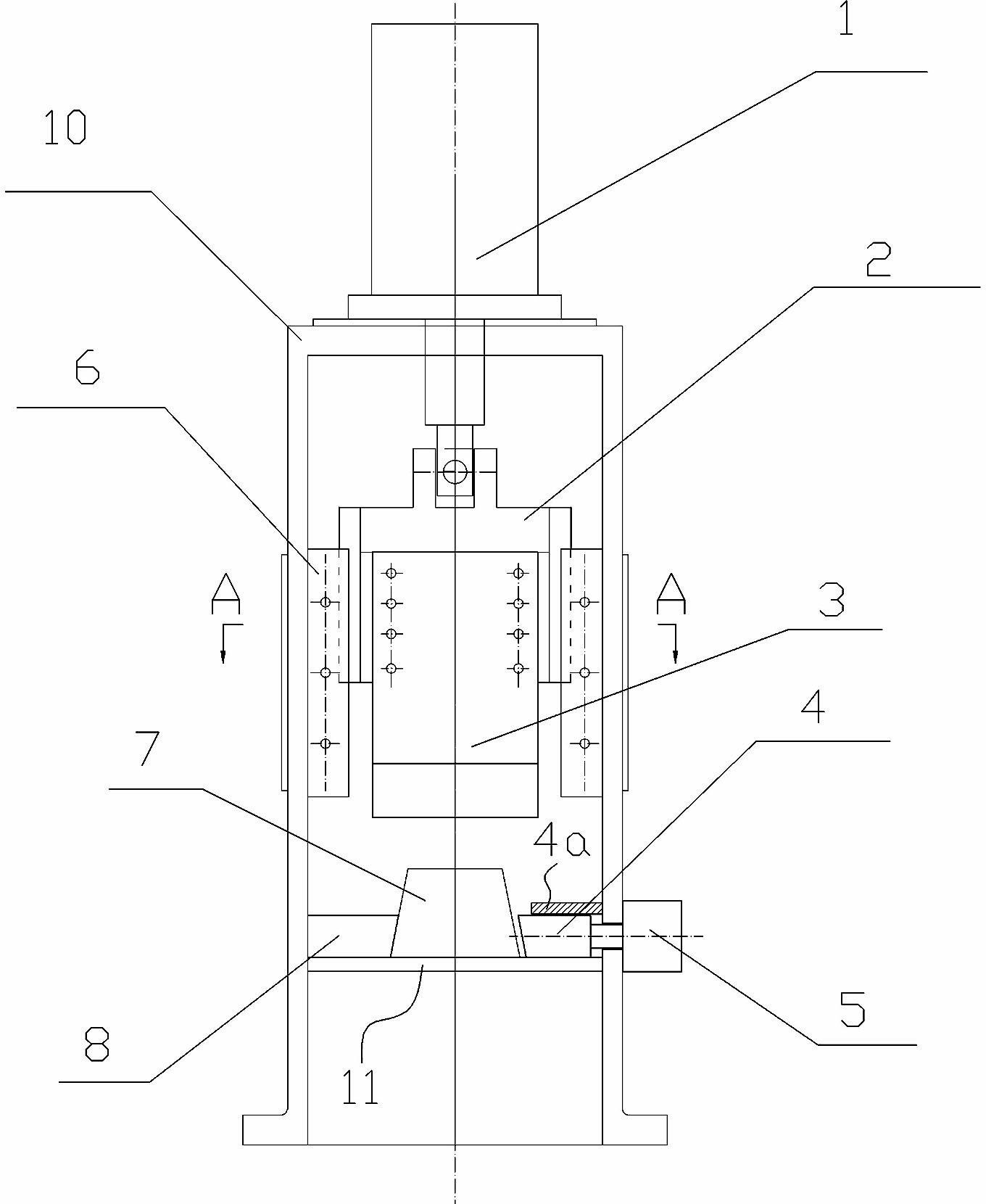

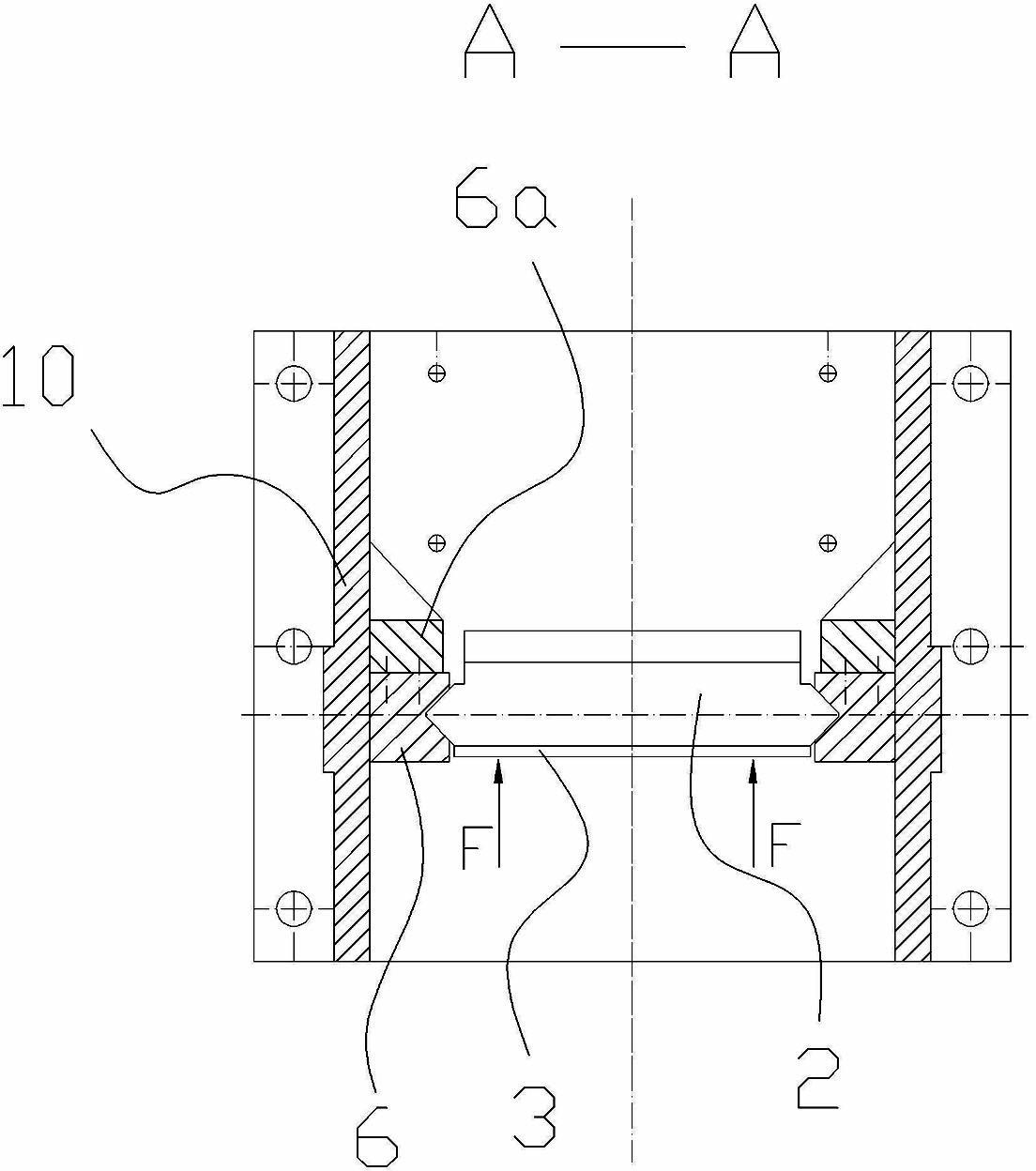

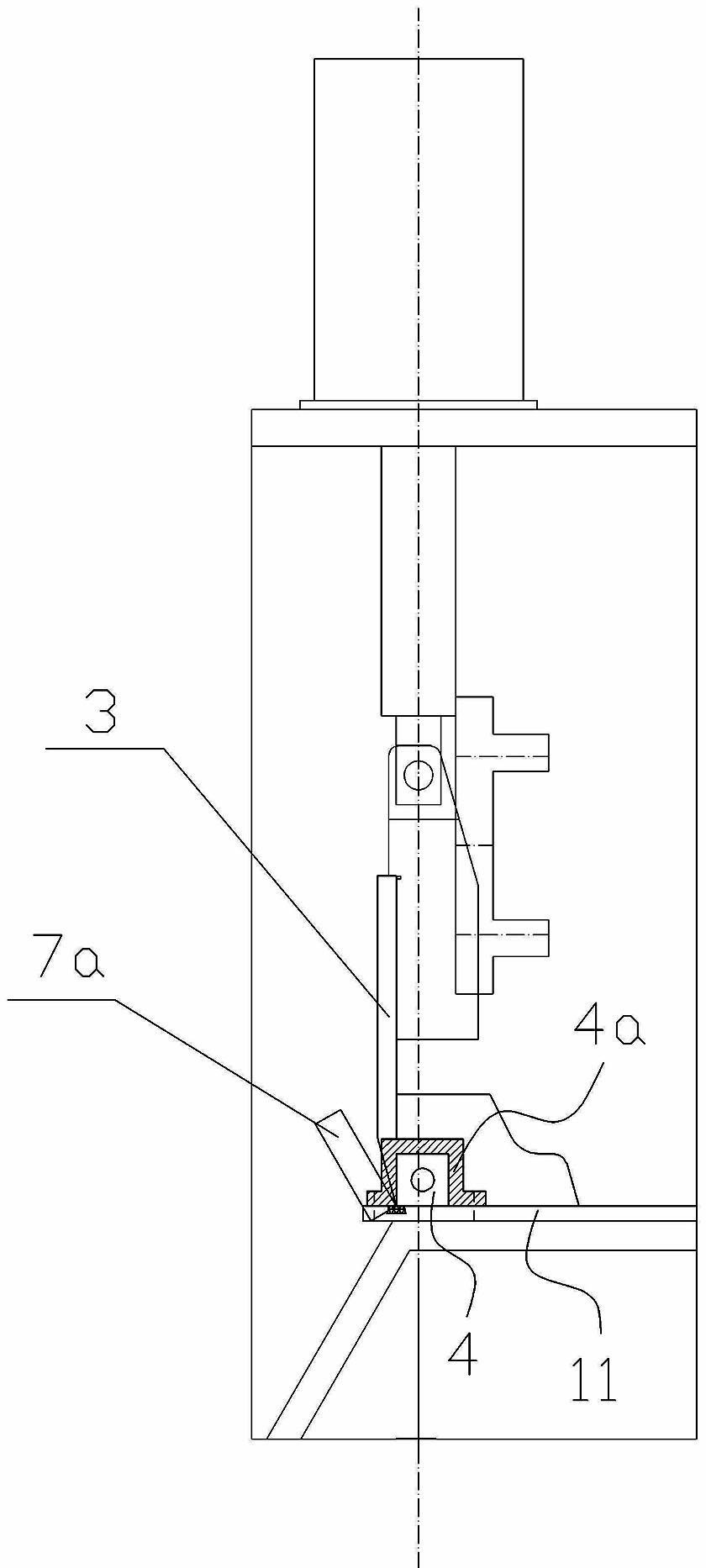

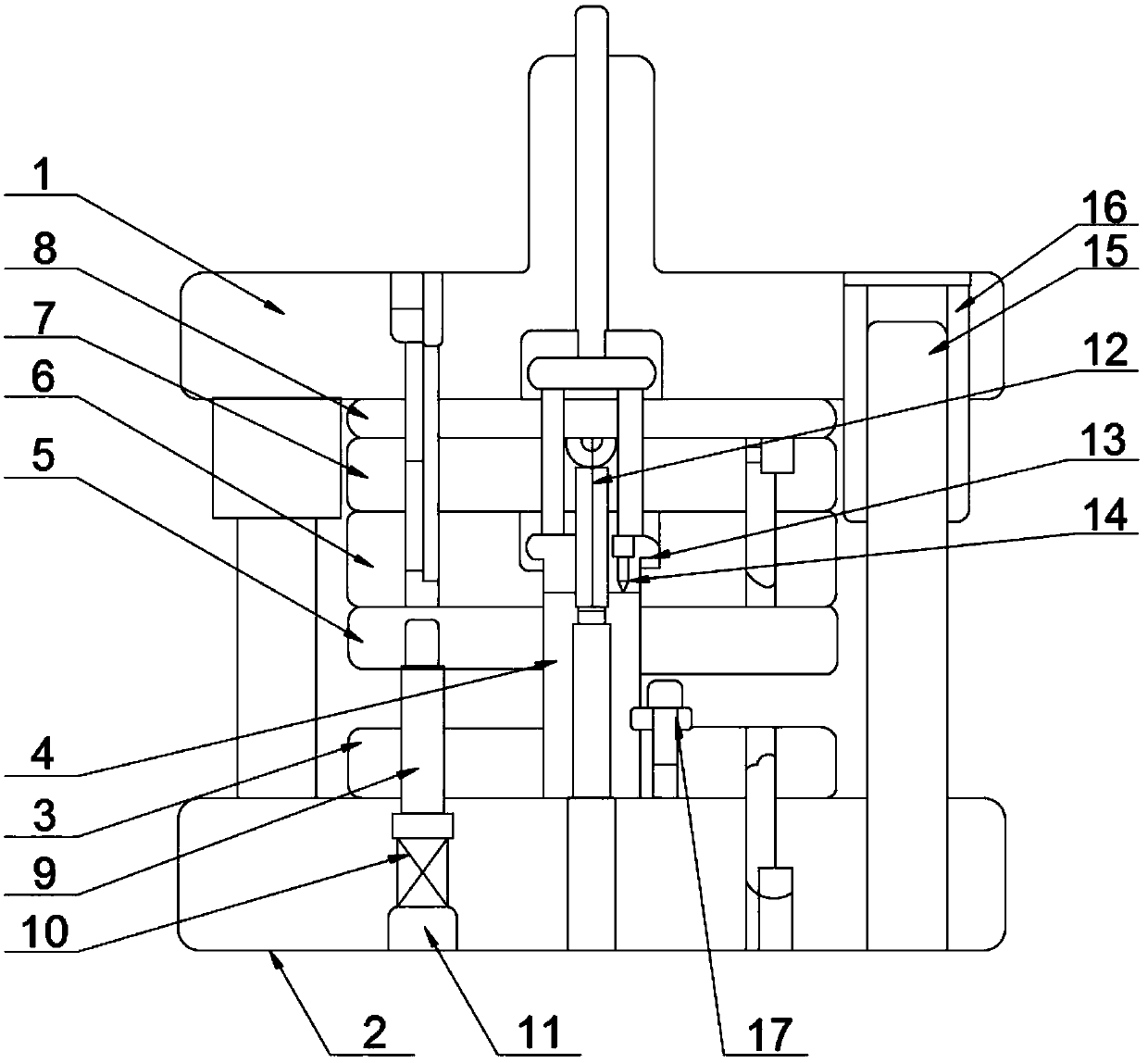

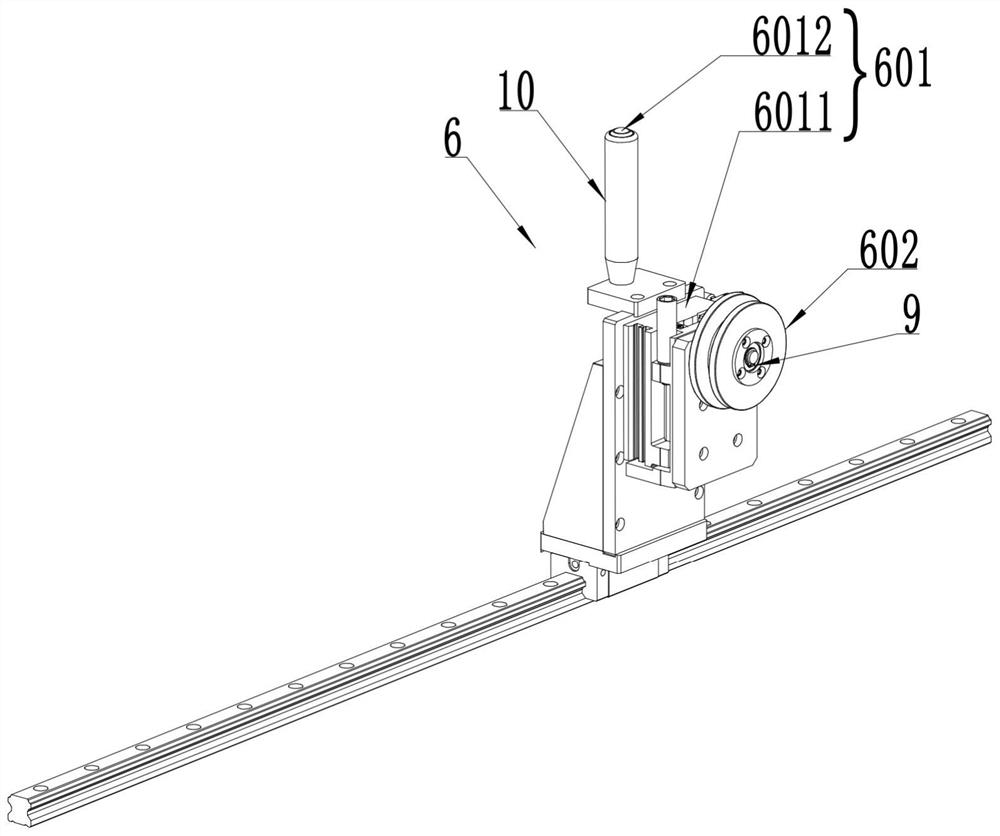

lead ingot slicer

InactiveCN102275007AWon't warpWon't snapNibbling shearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention relates to a lead ingot slicing machine. A guide rail (6) is arranged on both sides of a frame (10). A sliding block (2) is arranged in the guide rail (6). The upper end of the slider (2) is connected to the set The hydraulic cylinder (1) at the upper end of the frame is connected, and a cutter (3) is connected to the slider. The lead ingot conveying platform (11) is arranged on the frame below the cutter (3), and the conveying platform on one side of the frame A fixed positioning block (8) is arranged on (11), and a cylinder (5) is arranged on the other side of the frame to connect with a movable positioning block (4), which slides and fits with the guide sleeve (4a). The advantages of the present invention: when the lead ingot is transported to the shearing position, the cylinder pushes the movable positioning block to move laterally to clamp the lead ingot, and the lead ingot will not warp during the shearing process, and the lead ingot can be cut completely. There is less waste and the cutter will not snap. Therefore, the present invention has the advantages of high efficiency, high material utilization rate, long service life and the like.

Owner:乔欣

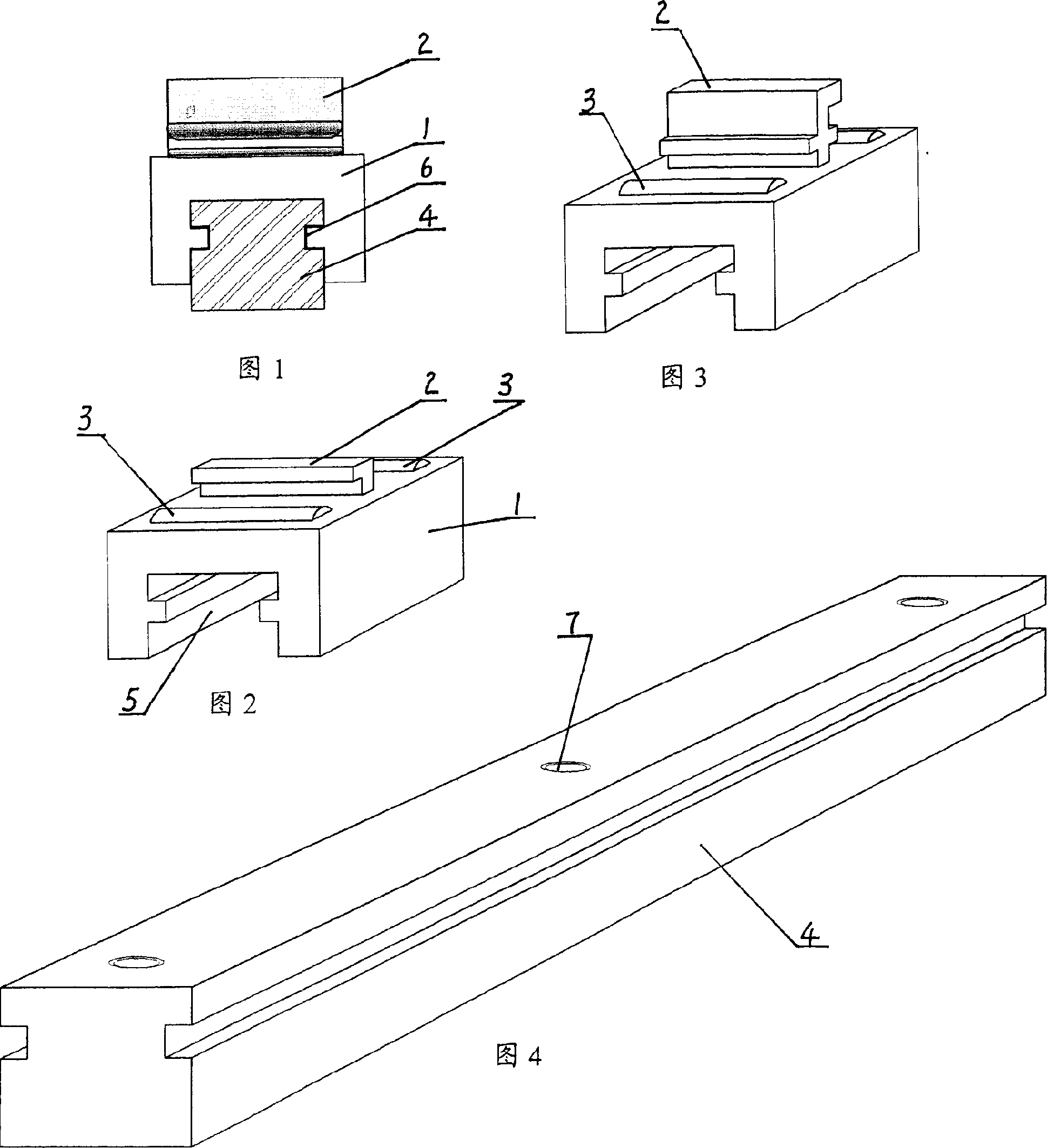

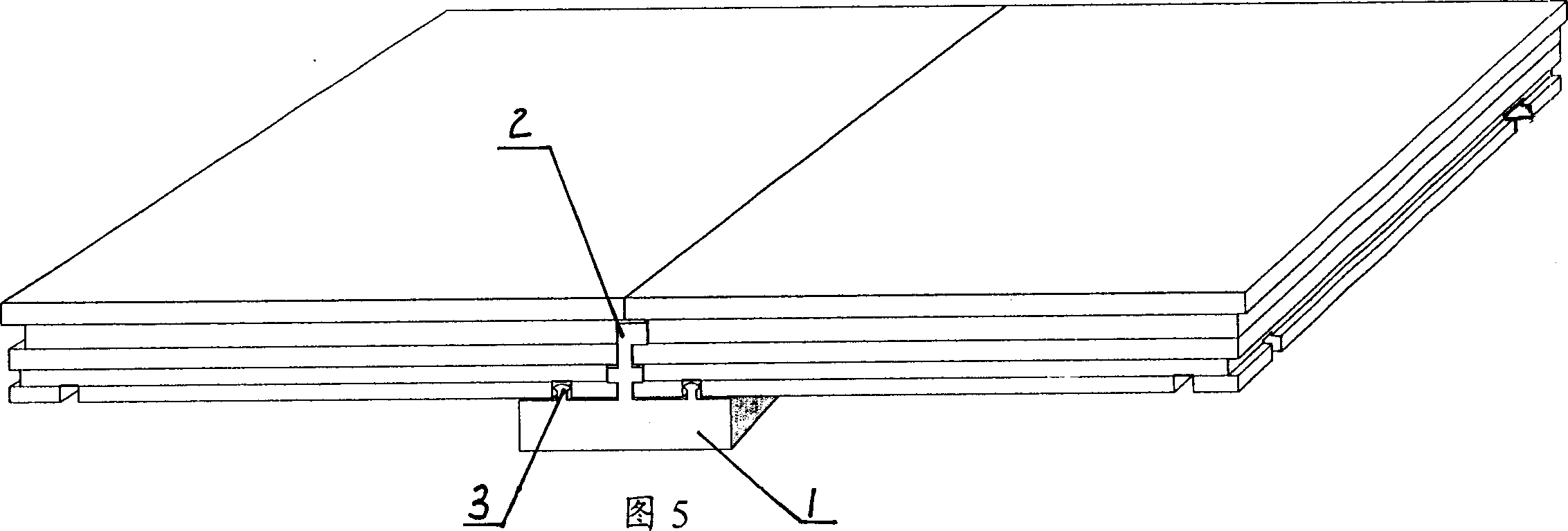

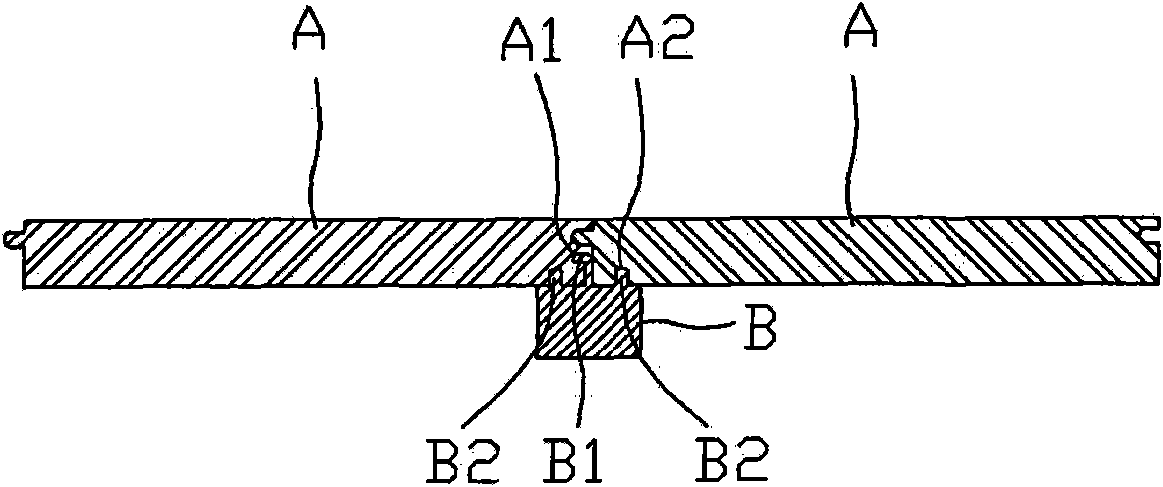

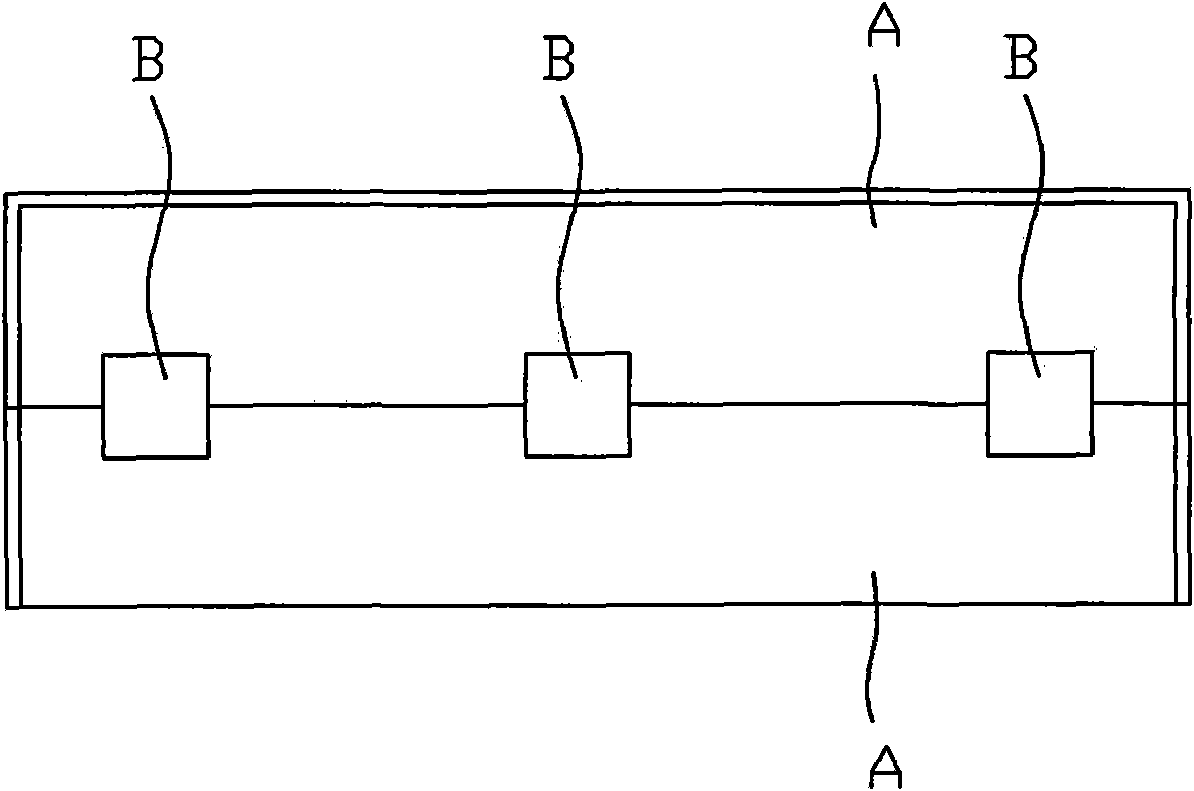

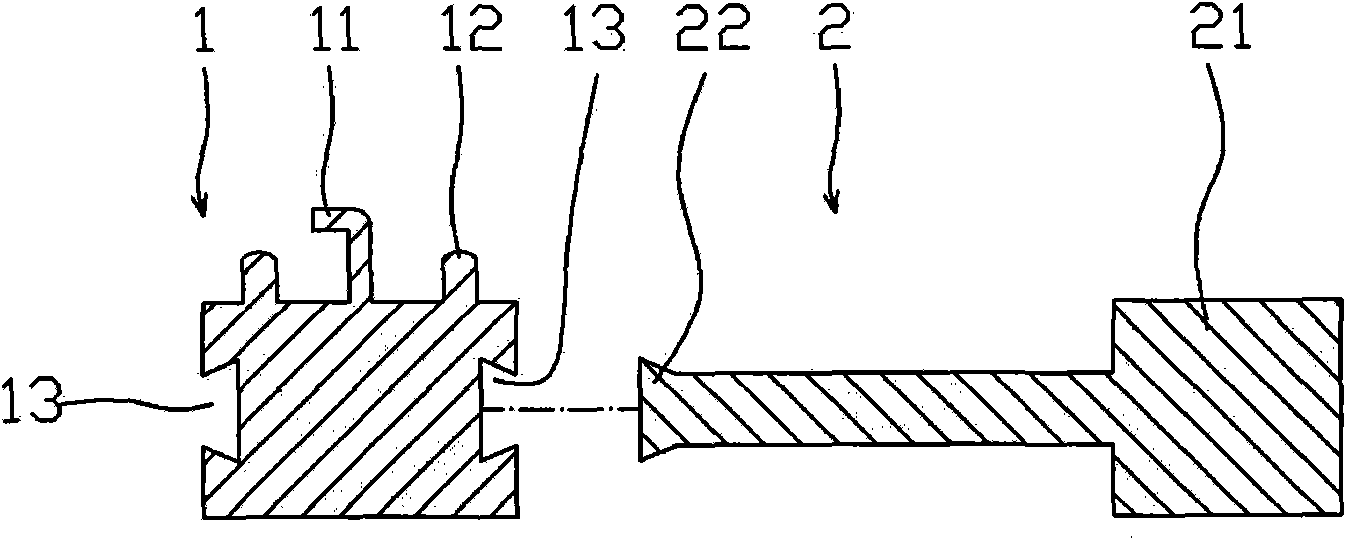

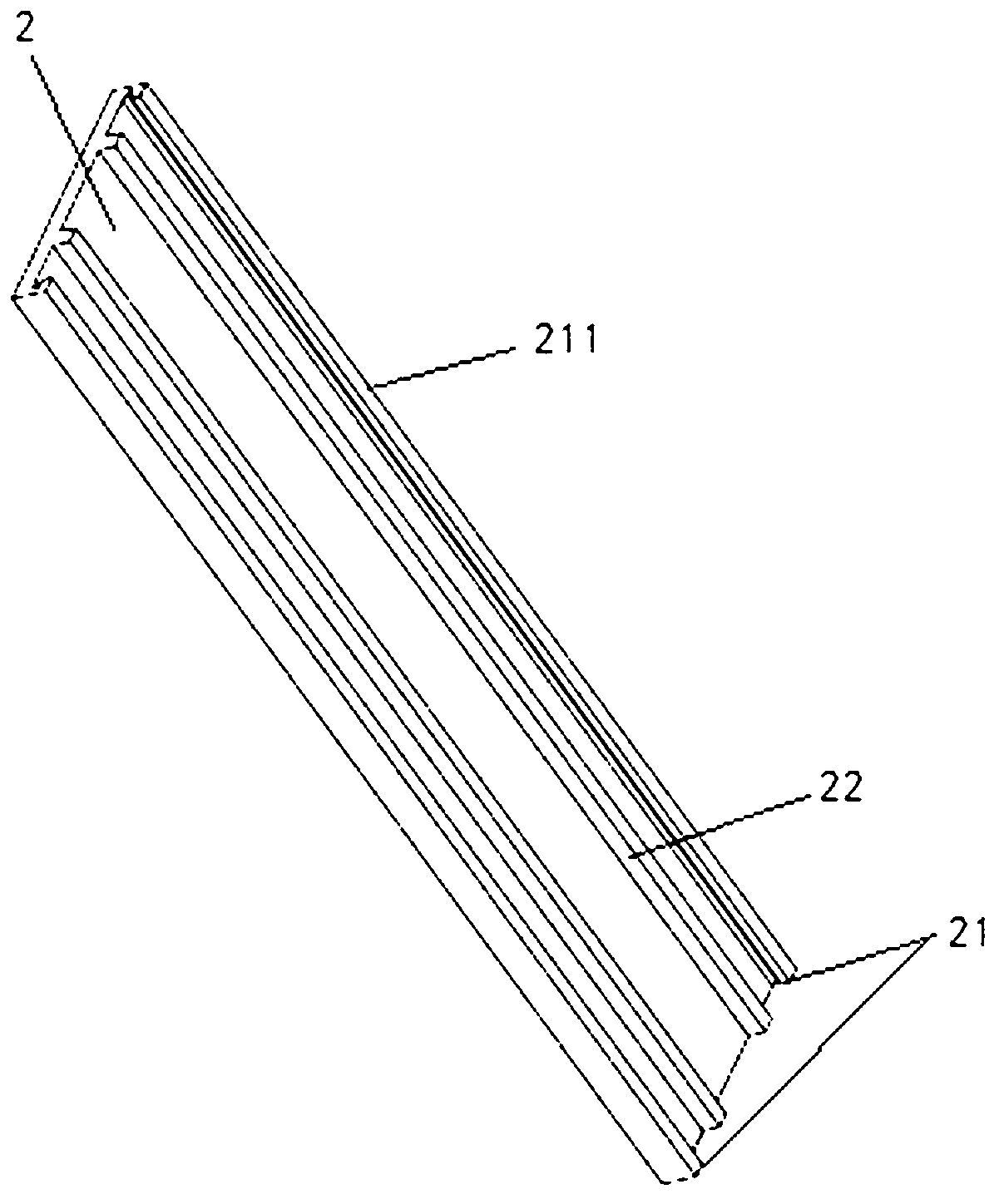

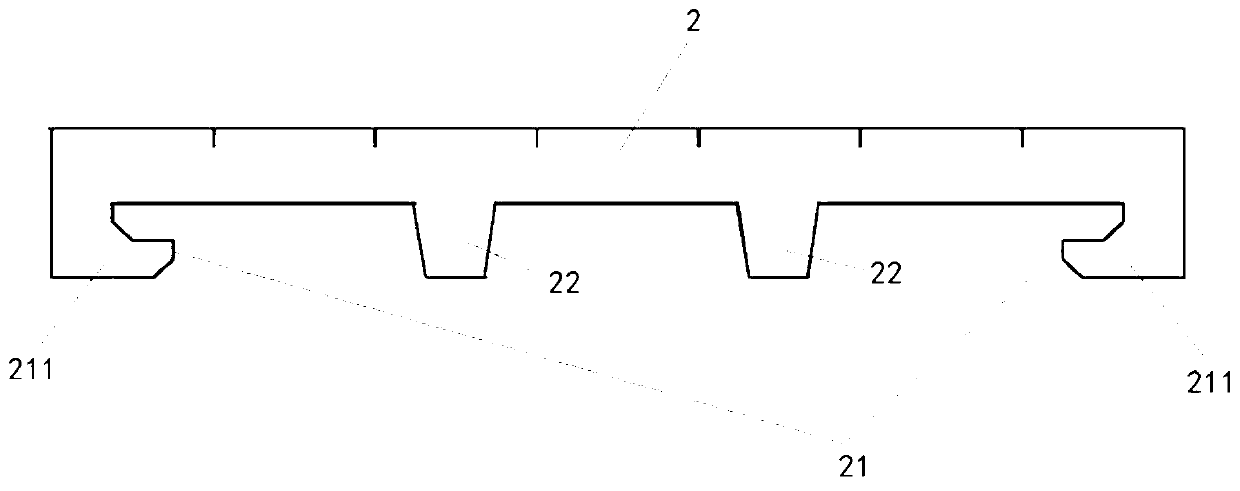

Combined joist

This invention relates to a composite keel, characterized in that it comprises the bar and lump keel, wherein on the lump keel is arranged a strip main bar, and the side wall of the main bar is arranged the prominence; on the lump keel surface near the main bar set at least one assistant bar parallel to the main bar; behind the lump keel is arranged a beard corresponding to the bar keel, between the beard and the corresponding bar keel is arranged the lunisolar slot. Said keel can lock the longitudinal joint of two adjacent boards, and it is suitable to mating use with the floor, wall plate and the ceiling.

Owner:李新发

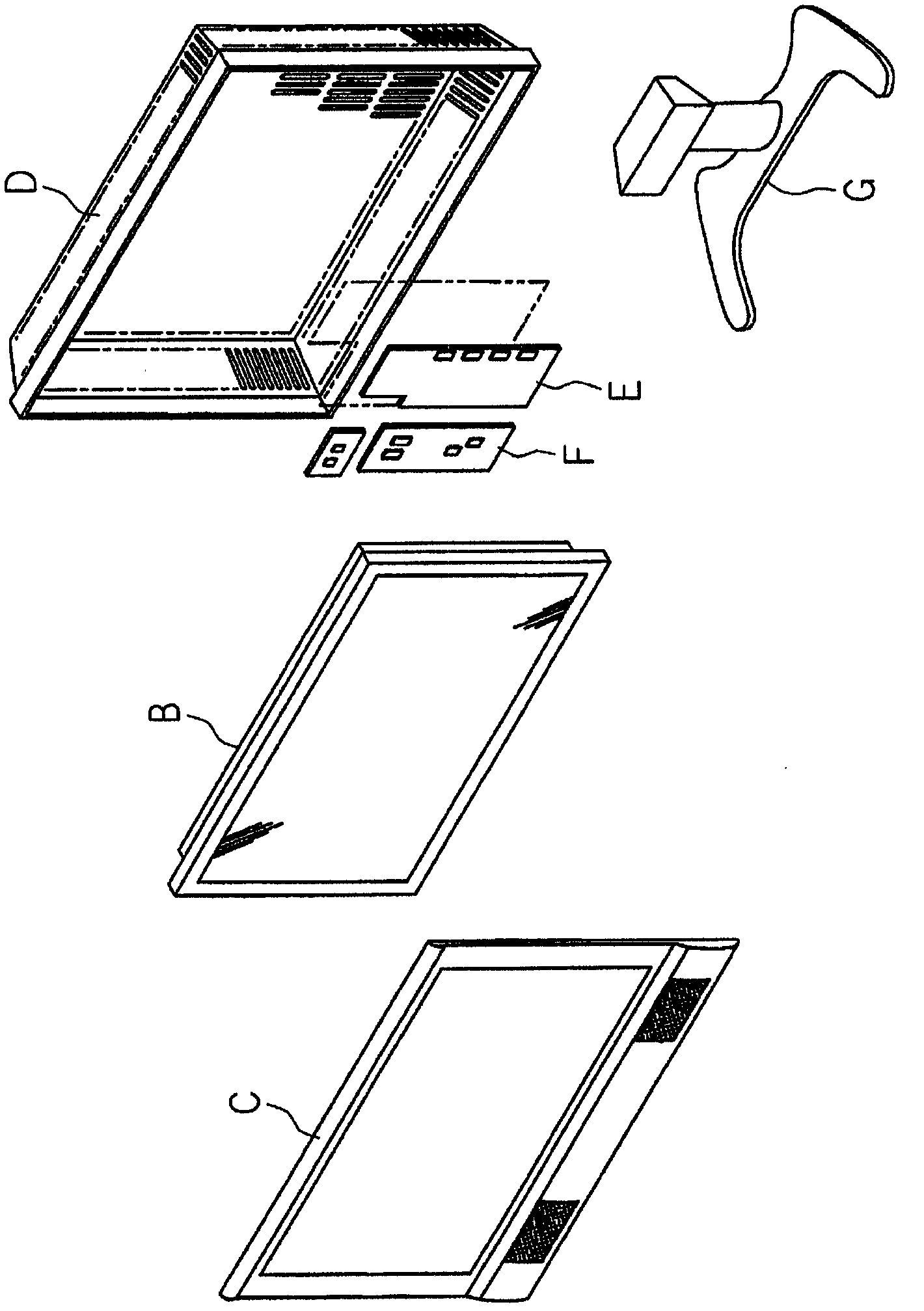

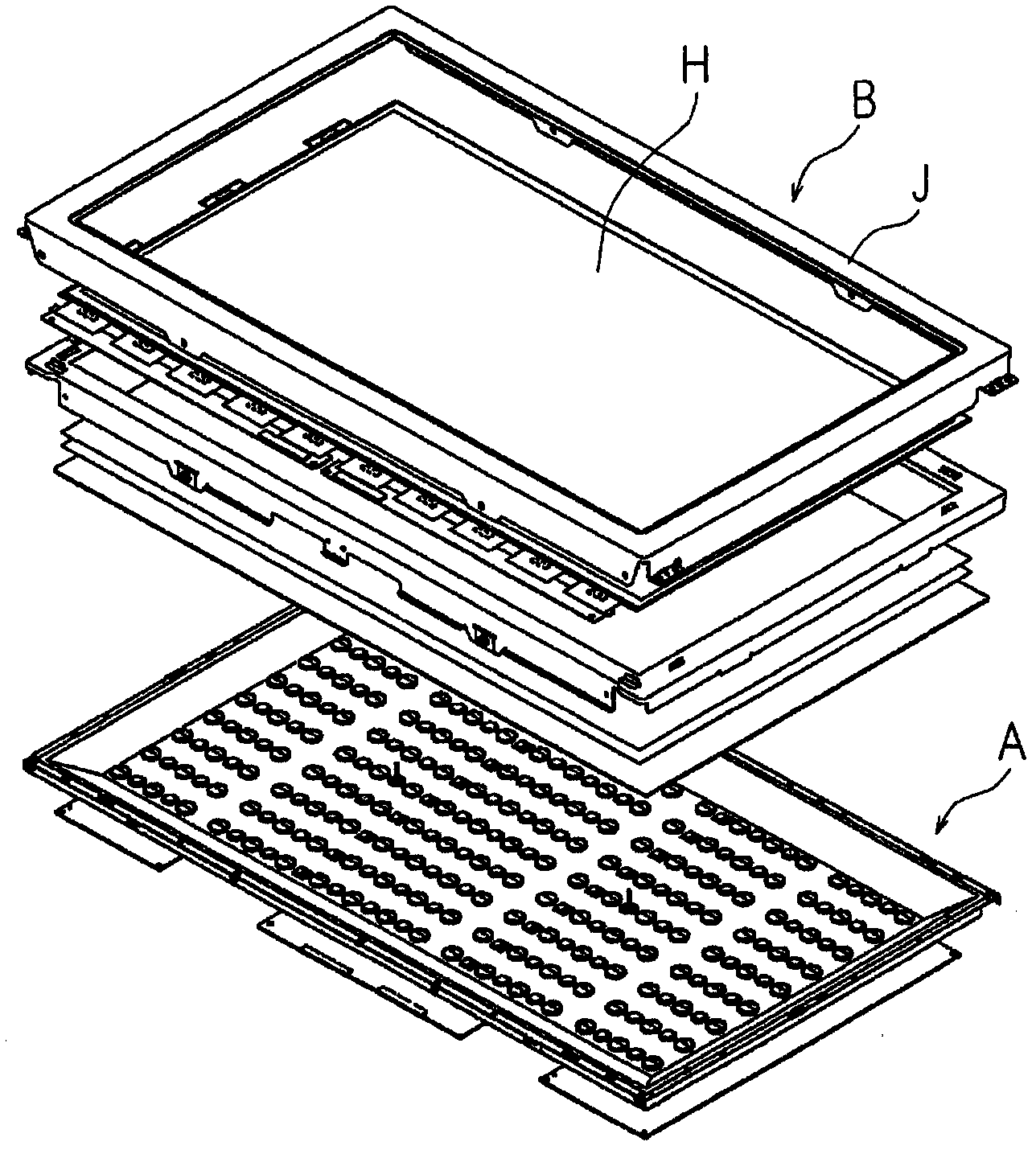

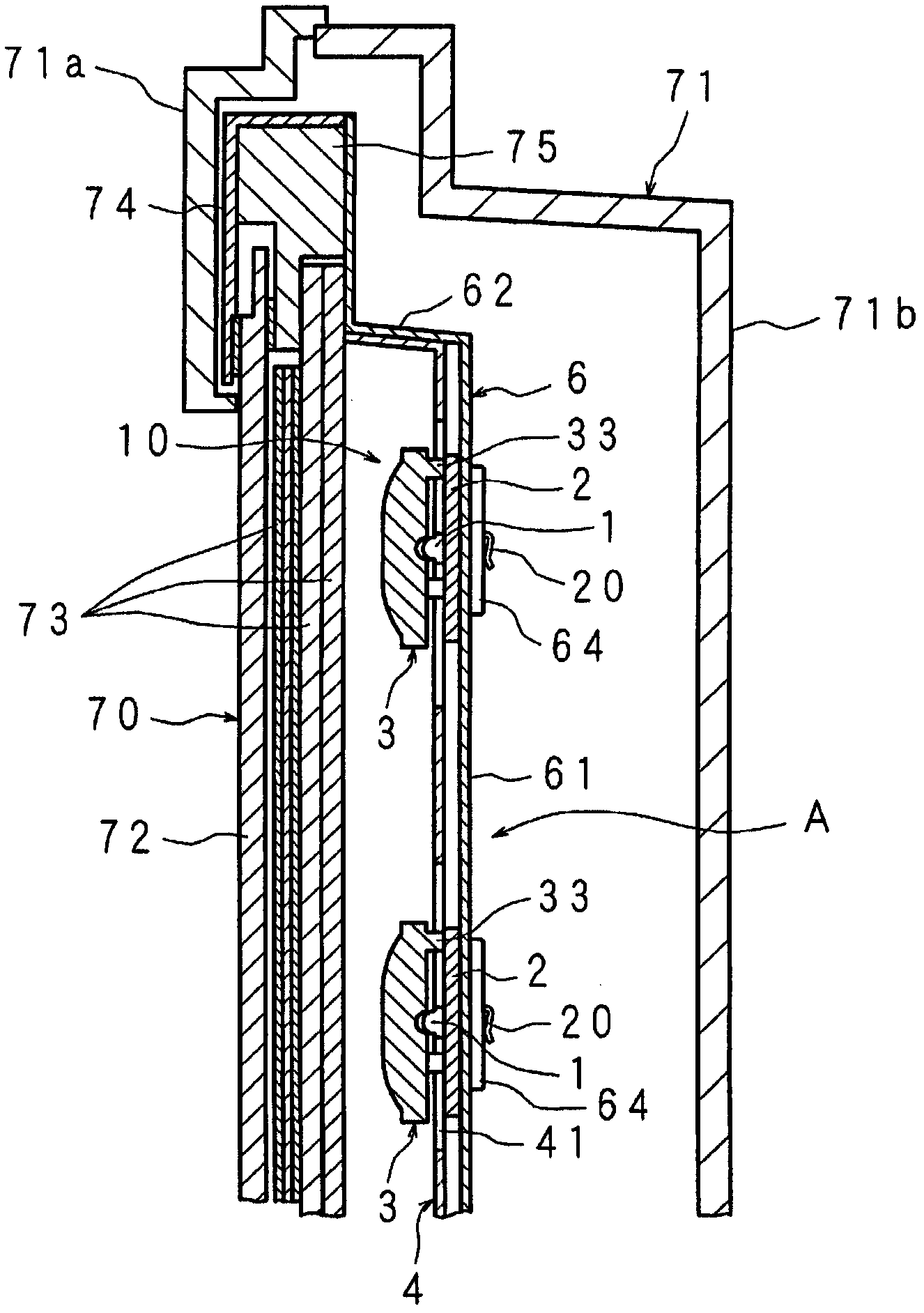

Light source device, image display device and television receiver device

InactiveCN102459997AImprove cooling effectIncrease contact areaPoint-like light sourceLighting heating/cooling arrangementsElectricityTelevision receivers

Disclosed is an image display device, a television receiver device, and a light source device such that substrates can be electrically connected even if said substrates are separated by more than a prescribed distance, or are in closer proximity than a prescribed distance. A light source unit with light emitting diodes arranged in rows on one surface of a light emitting diode substrate (2) is provided with latching sections (20) on the other surface (2b) of the light emitting diode substrate (2). The locking sections (20) are latched onto latching slits (63, 63... 63) in a holding body (6) for holding the light source unit, allowing the light source unit to slide along one surface of the holding body (6).

Owner:SHARP KK

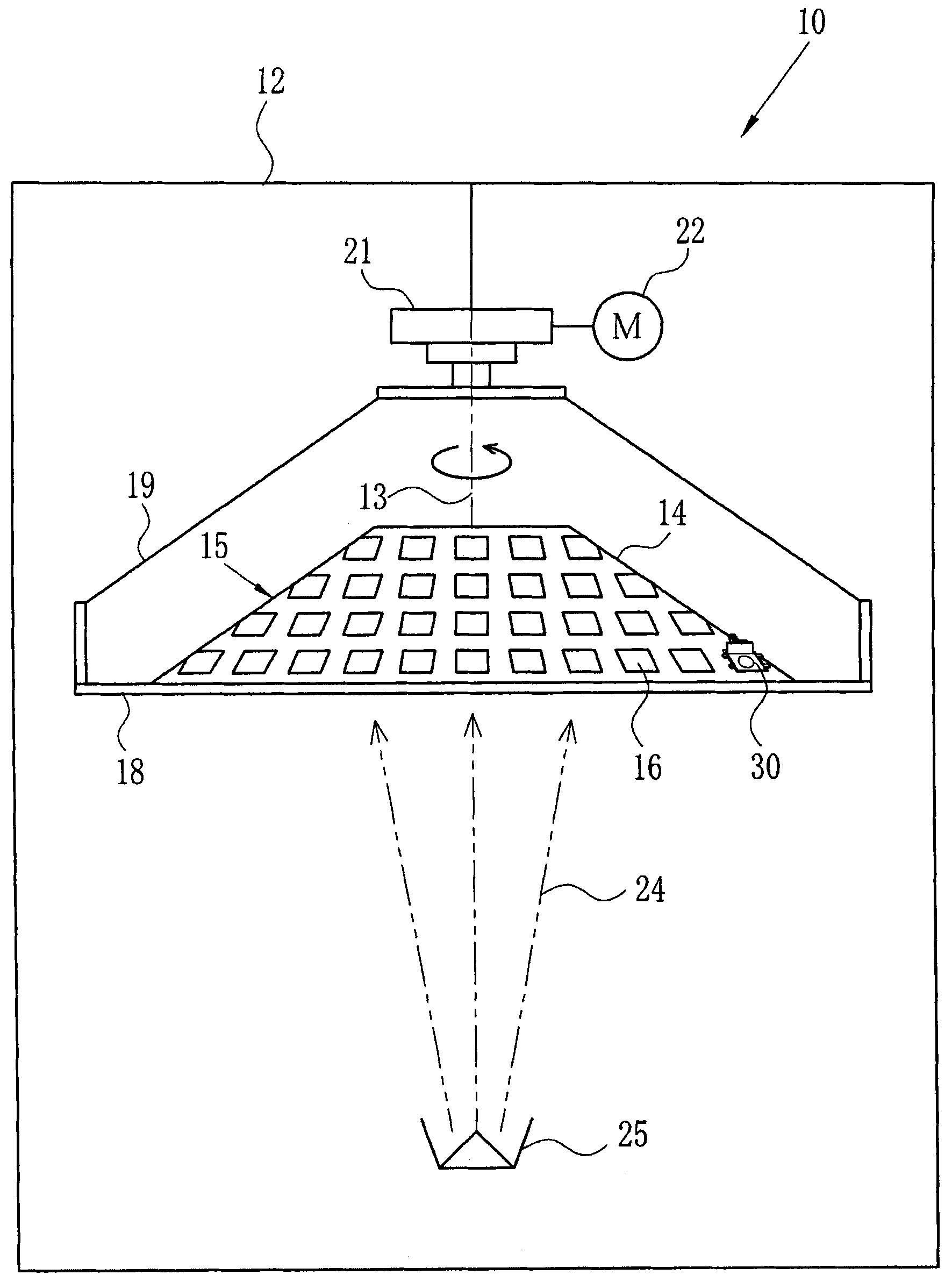

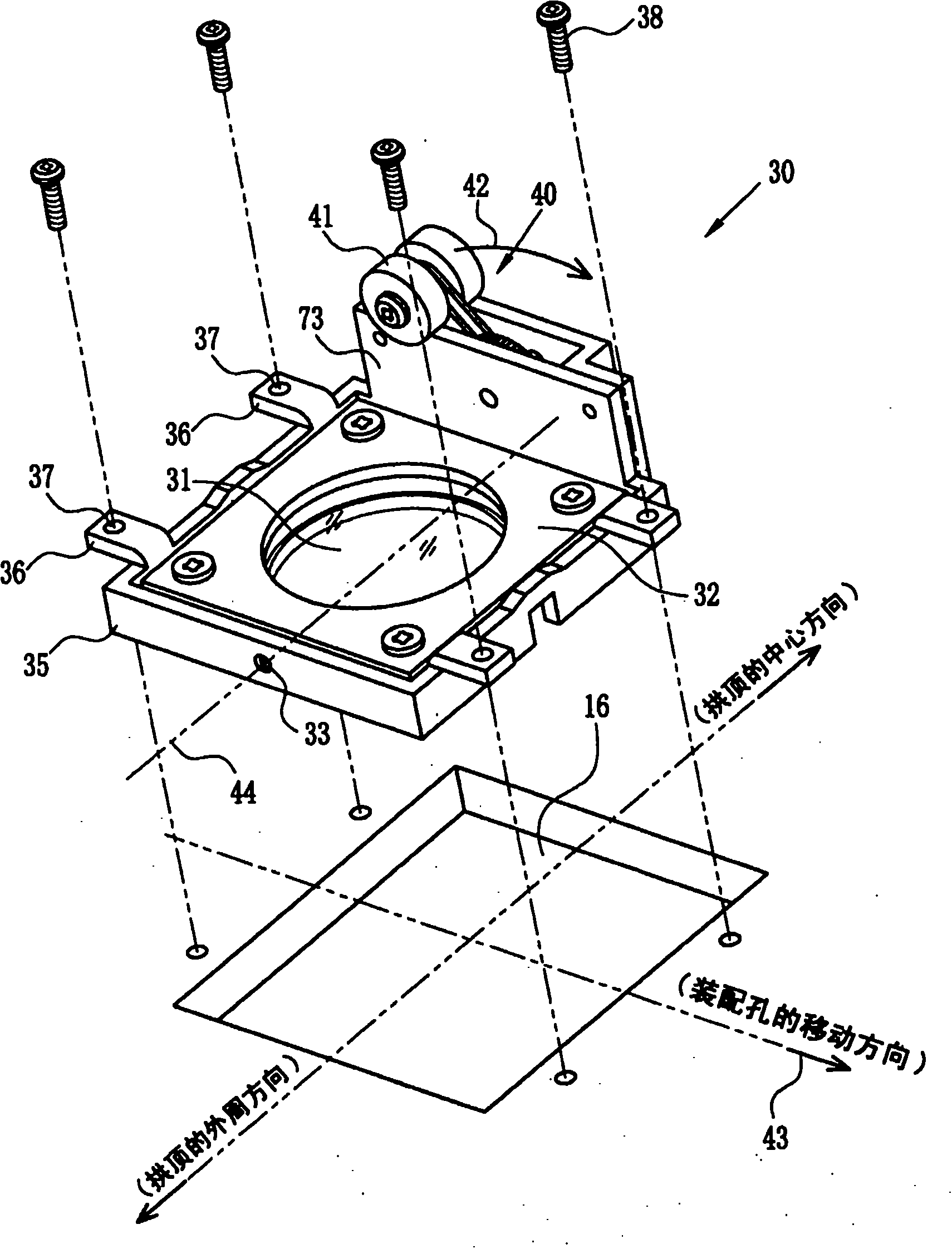

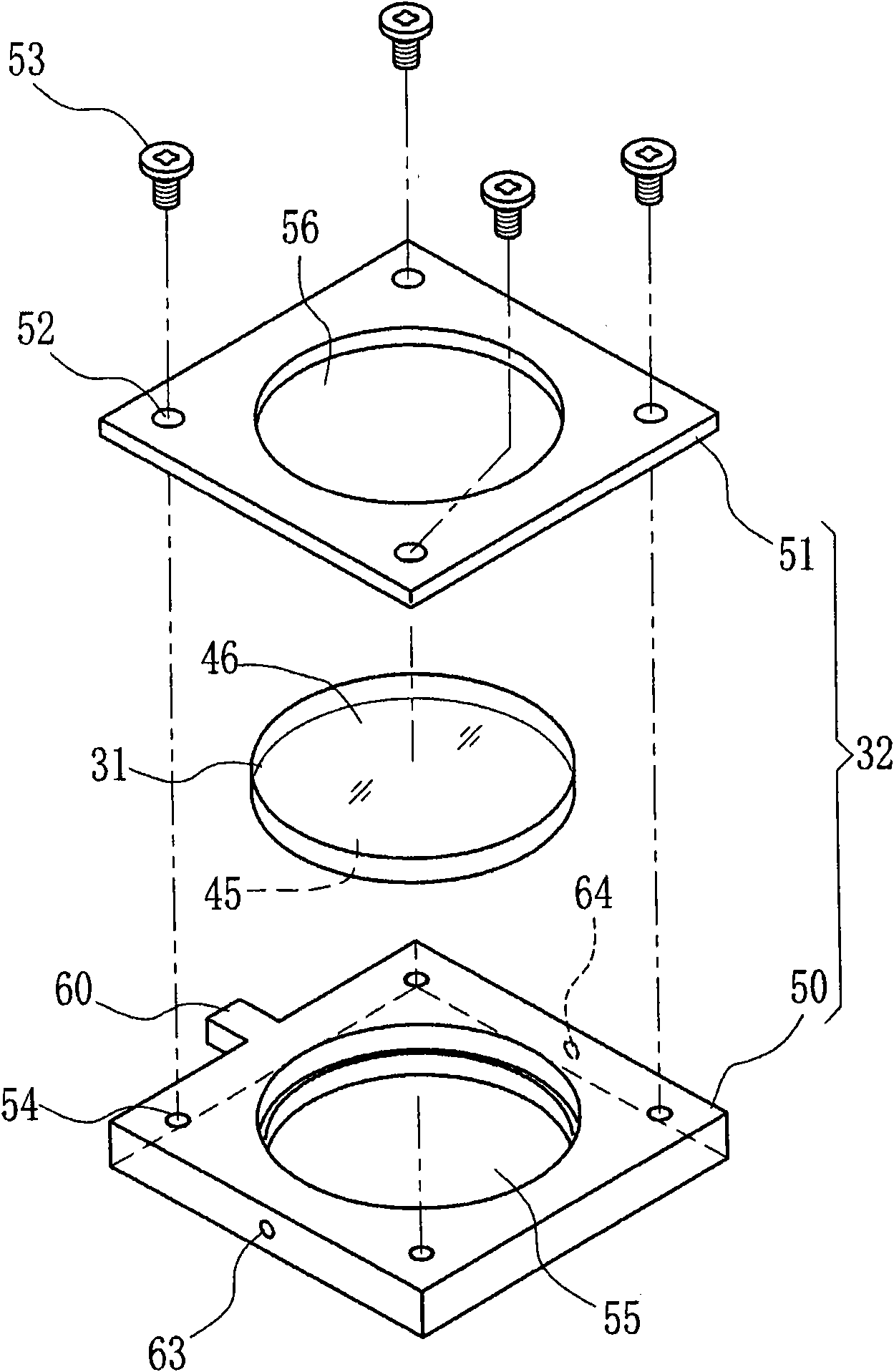

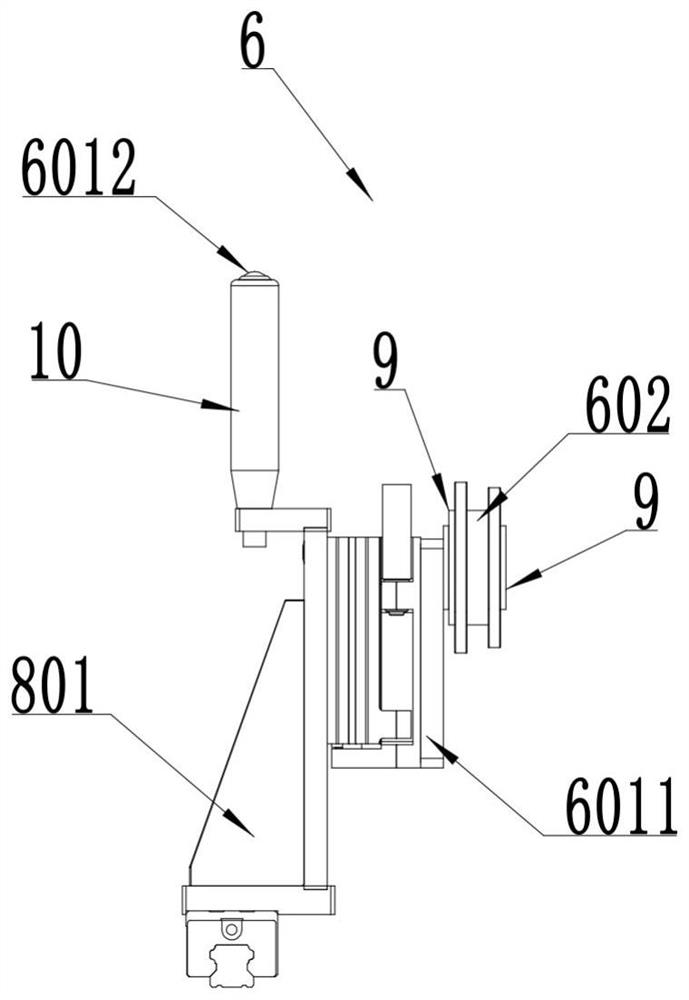

Workpiece turnover unit, vacuum film-forming device and workpiece assembly unit

InactiveCN101899648AWon't warpVacuum evaporation coatingSputtering coatingEngineeringCentrifugal force

The present invention provides a workpiece turnover unit, a vacuum film-forming device and a workpiece assembly unit, wherein the workpiece turnover unit is capable of keeping a cavity of the vacuum film-forming device to be vacuum so as to film by turns on two faces of the workpiece. The vacuum film-forming device is capable of forming film on two faces of the workpiece continuously and directly that the cavity is of a vacuum state. A workpiece assembly unit (20) is arranged on a plurality of workpiece assembly parts (18) which are formed on a dome sloped surface in the cavity of the vacuum film-forming device. The workpiece assembly unit (20) includes a clamp support frame (25) for rotating-freely supporting a workpiece clamp (22) fixed with a glass plate (21) by a pair of rotating shafts, and a ball guiding frame (50) having a locking component (60) for locking the clamp support frame (25) from rotating. The ball guiding frame (50) is provided with a ball (58) held at a loading position through a rib (56). If a rotating speed of the dome is increased, the ball (58) may collide with a ball collision part (62) of the locking component (60) across the rib (56) by a centrifugal force, here, a locking claw (63) moves from a locking position of the workpiece clamp (22) and the workpiece clamp (22) is turned over.

Owner:FUJI PHOTO OPTICAL CO LTD

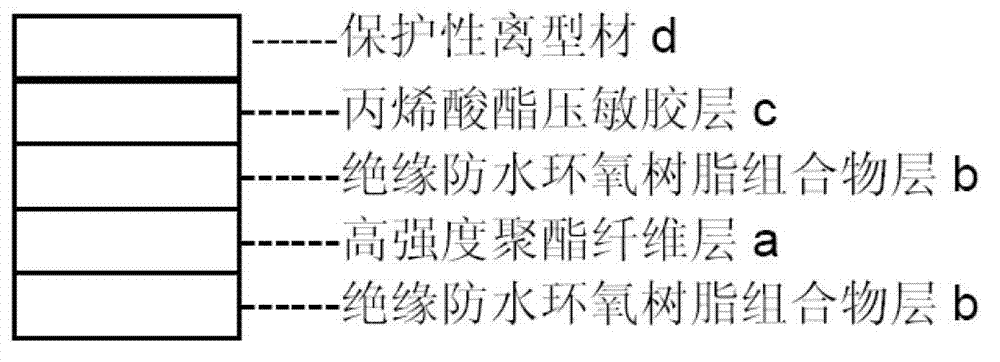

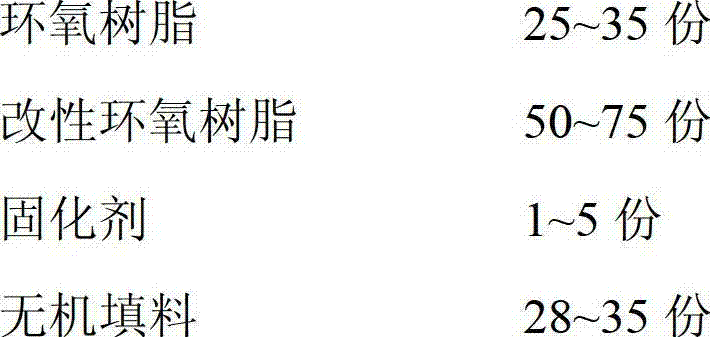

Waterproof insulation epoxy resin composition, adhesive tape and preparation method thereof

InactiveCN103044859AGood flexibilityImprove low temperature resistanceFilm/foil adhesivesEster polymer adhesivesEpoxyHeat resistance

The invention discloses a waterproof insulation epoxy resin composition, an electrician insulation adhesive tape prepared by using the composition and a preparation method for the composition and the adhesive tape, wherein the composition comprises the following components in parts by weight: 25 to 35 parts of epoxy resin, 50 to 75 parts of modified epoxy resin, 1 to 5 parts of curing agent and 28 to 35 parts of inorganic fillers. The waterproof insulation epoxy resin composition has good flexibility, can be recovered after being cured at the high temperature, has high impact strength, stripping strength and stretch shearing strength, and has good low-temperature resistance and heat resistance; the flexibility of the composition is not influenced by the seasonal climate, so that the problem of excessively brittle in winter and excessively soft in summer in the existing products is solved; the preparation cost is low; and the finished product yield is high. The electrician insulation adhesive tape has the excellent performances of tightness, insulation, heat resistance, water prevention, high mechanical strength and good gloss, has excellent early bonding performance and restripping performance, has good bonding following characteristic, and can be widely applied in the coil winding protection and associated industries.

Owner:NINGBO SOKEN CHEM

Forming die of thermoplastic sheet material

The invention relates to a forming die of a thermoplastic sheet material, comprising an upper backing plate, a lower backing plate, and a molding frame, wherein, the molding frame is arranged between the upper backing plate and the lower backing plate, the surfaces of the sheet material of the upper backing plate and the lower backing plate are flat, and the mouding surface is coated with a teflon coating or a mold lubricant coating. By using the die disclosed in the invention, the material formed in hot pressing cold pressing unit has a density of 0.3-12, and the surface of the material is flat without warp.

Owner:NINGBO HUAYE MATERIAL TECH

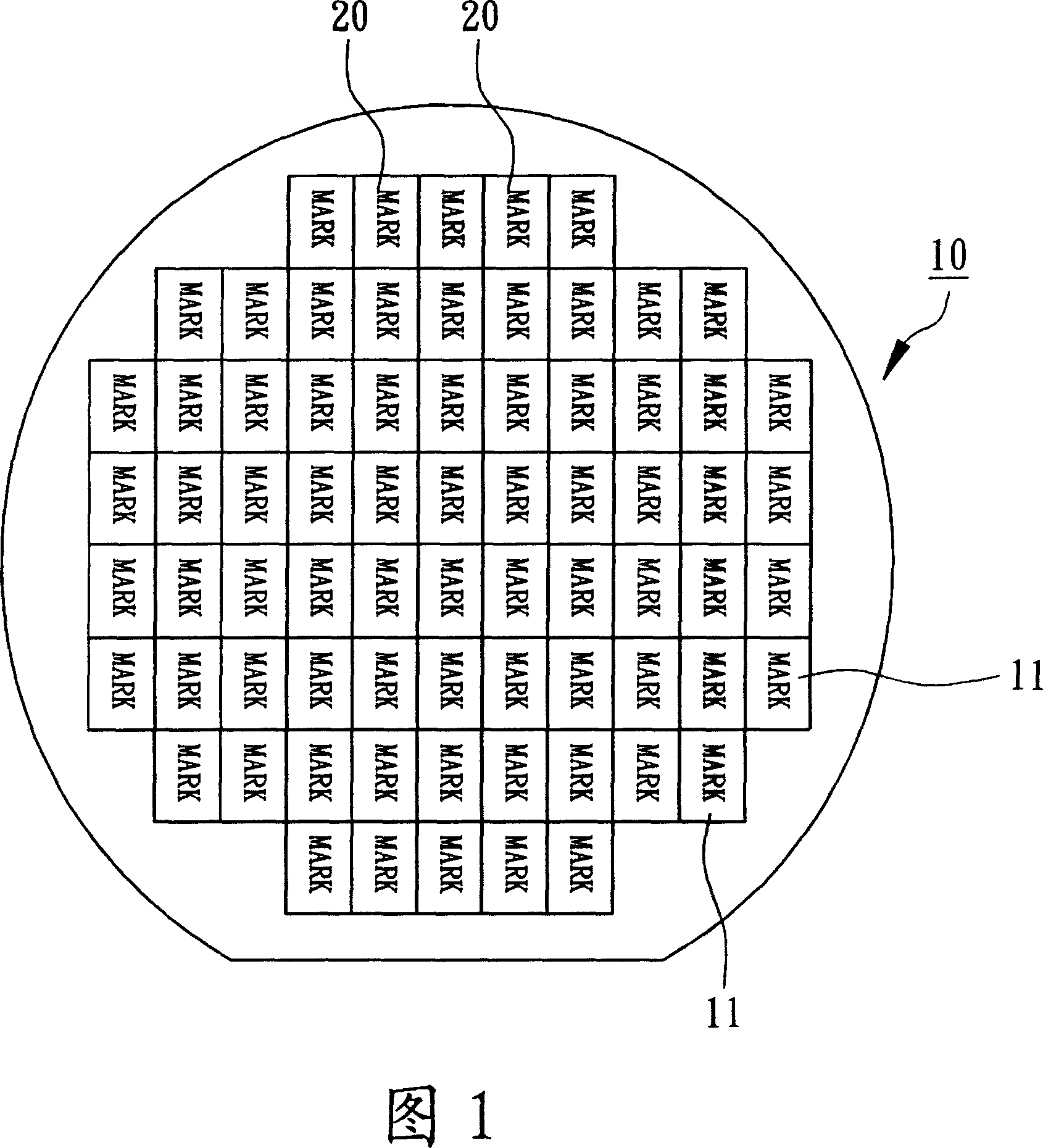

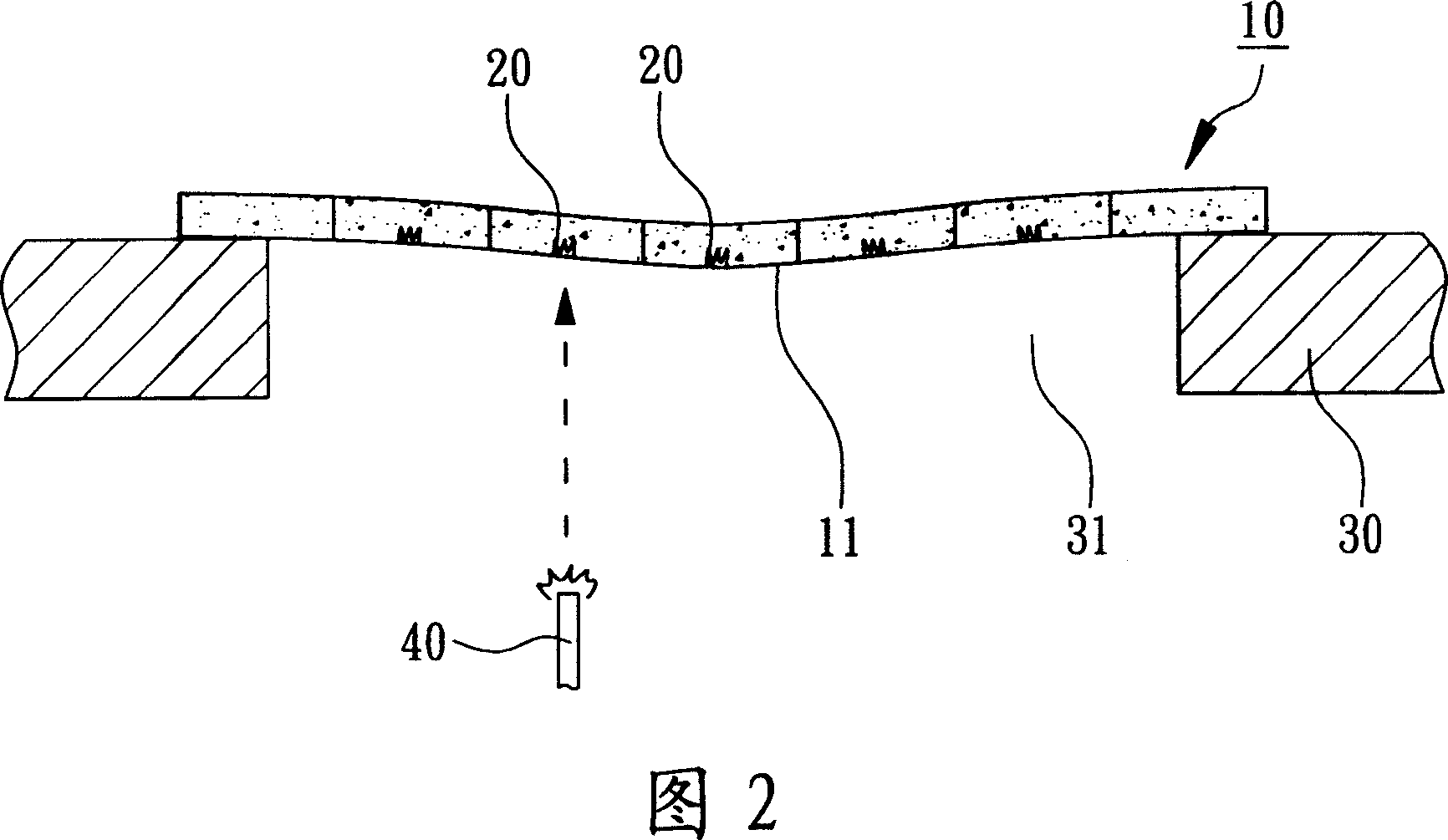

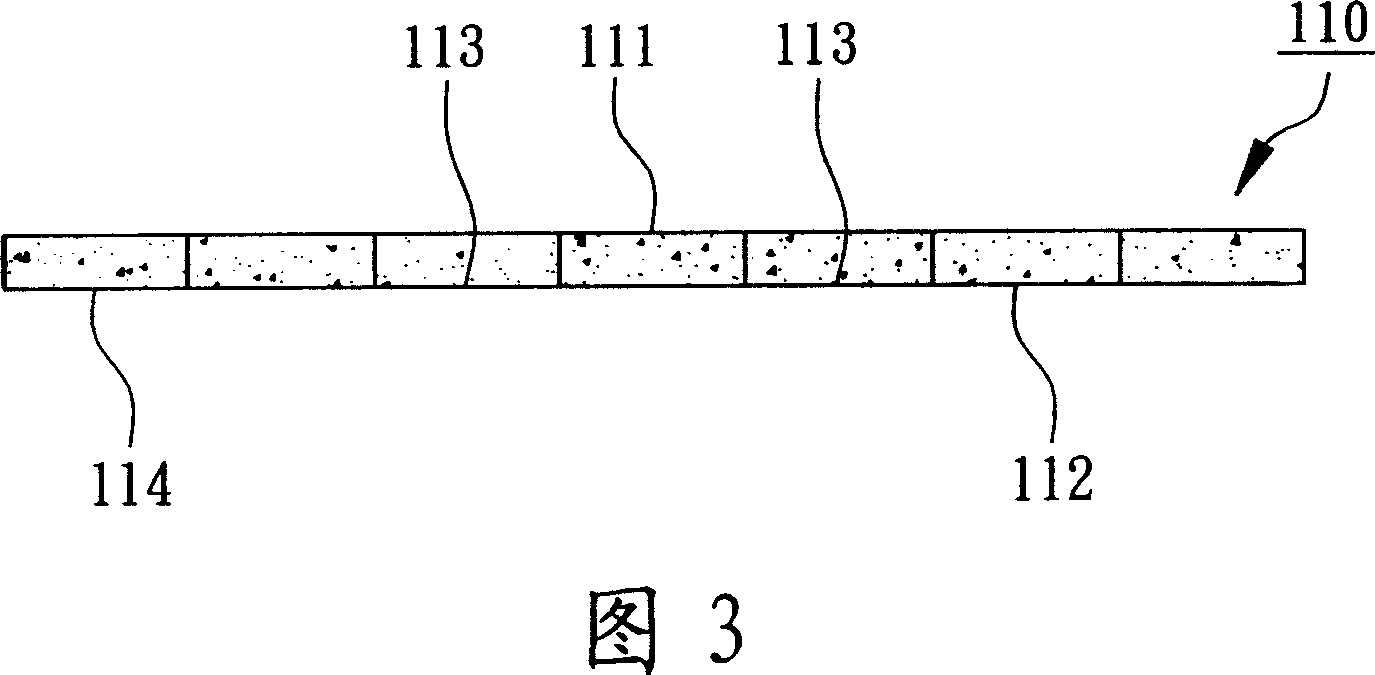

Wafer laser marker method and its wafer

InactiveCN1921066ASolve the problem of not being able to laser markWon't warpSemiconductor/solid-state device detailsSolid-state devicesActive surfaceLaser

The invention relates to a laser mark method of crystal chip and relative crystal chip. Wherein, it comprises: providing a crystal chip on the transmission carrier, while its back contacts parallel the carrier; when there is laser mark, the laser passes the transparent carrier to emit the back of crystal, to form at least one laser mark. The inventive crystal has one active surface and one back surface, while the thickness between them is 1-12mil, and the back surface has at least one laser mark.

Owner:CHIPMOS TECH INC

Detachable carpet

PendingCN110393413ANot easy to fall offExtended service lifeWarp knittingSynthetic resin layered productsCushionEngineering

The invention discloses a detachable carpet. The detachable carpet comprises a carpet surface and an antiskid cushion, wherein the carpet surface comprises three-dimensional net cloth structure layersat a surface layer and a bottom layer; the antiskid layer comprises an antiskid water-resisting layer at the bottom layer and a binding layer at the upper layer; the binding layer is single-sided fabric on which plenty of dacron, or a number of polypropylene fibers or nylon monofilament bumps are arranged; the bumps can be inserted into net gaps of the three-dimensional net cloth structure layers. According to the detachable carpet, the binding layer of the antiskid cushion adopts a single-sided structure layer formed by splitting from the middle part of the three-dimensional net cloth structure layer or a single-sided fabric with bumps made from monofilaments of more than 20D; the 20D-120D dacron, polypropylene fibers or nylon monofilament bumps on the binding surface can be formed intothick and rigid bumps with certain stiffness, and thus can be conveniently and randomly inserted into meshes of the three-dimensional net cloth structure layer at the bottom layer of the carpet surface, also can be conveniently detached, and even can be repeatedly detached for many times without damage, and the service life is significantly improved.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

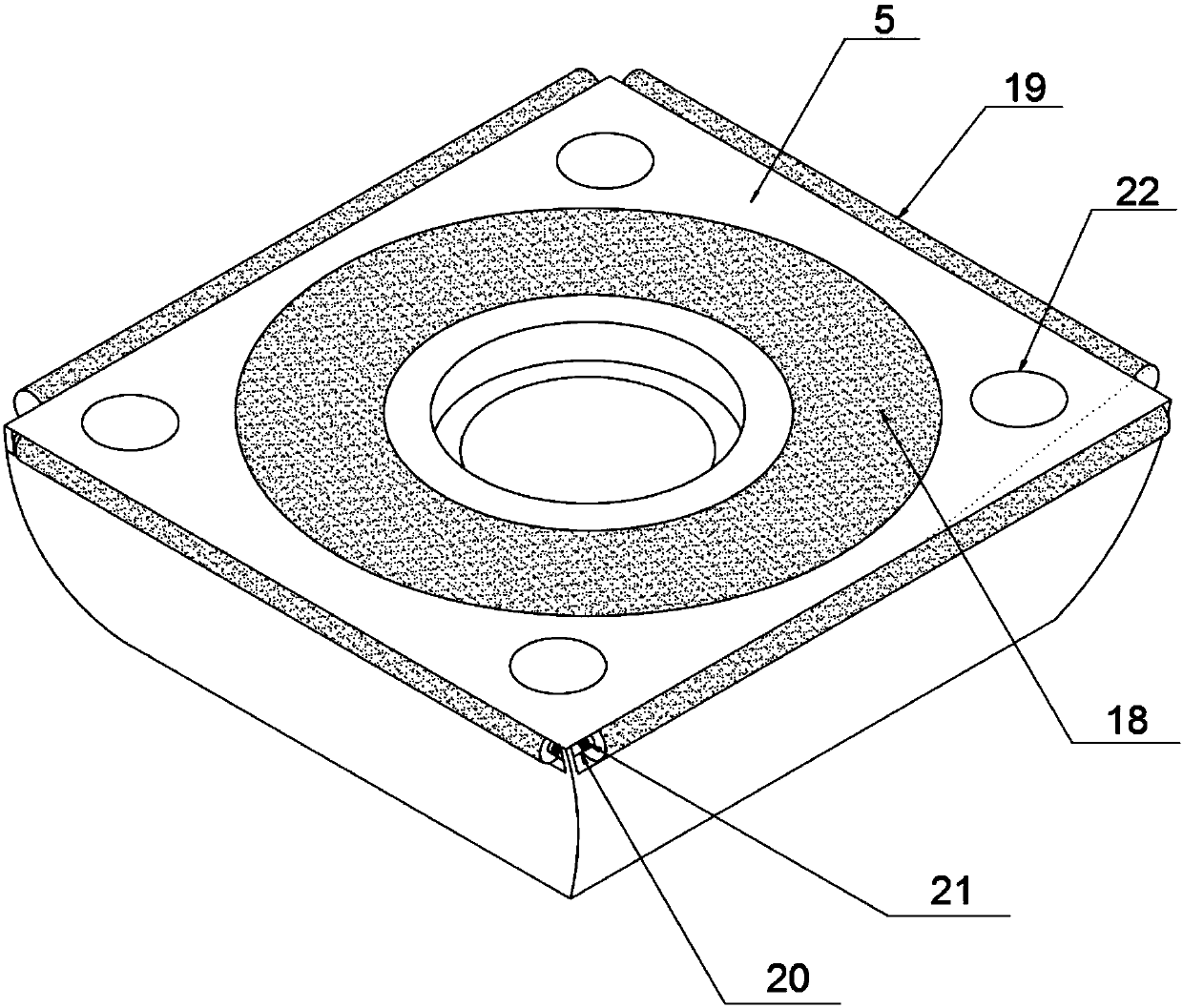

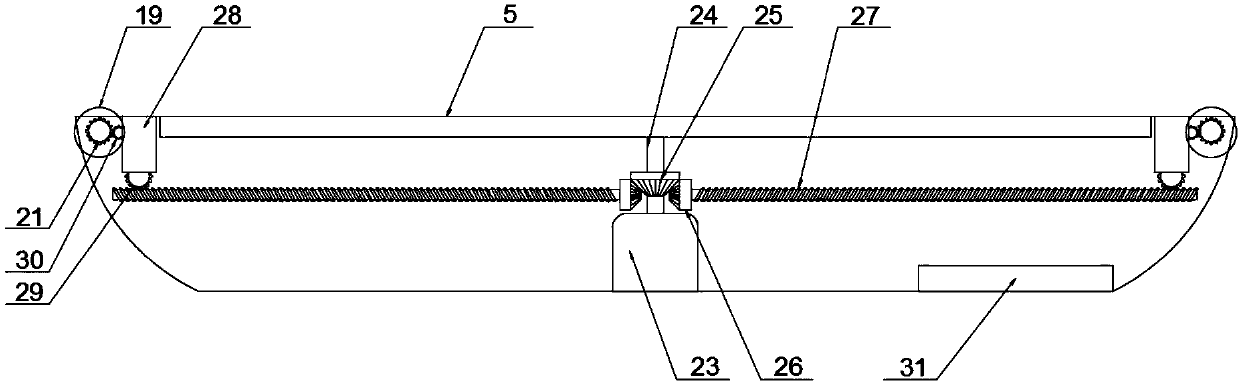

Punching die with polishing function

The invention provides a punching die with a polishing function, and relates to the field of punching dies. The punching die comprises an upper die base and a lower die base. A cushion plate is arranged at the bottom end of the upper die base. A female die fixing plate is arranged at the bottom end of the cushion plate. A female die plate is arranged at the bottom end of the female die fixing plate. A discharging punching composite male die penetrates the center of an unloading plate and is connected with a jacking type male die. The jacking type male die penetrates the unloading block. The unlocking block is provided with a spring plunger. The upper die base and the lower die base are connected through a guide column. The connecting position of the guide column and the upper die base is provided with a guiding sleeve. The unloading plate and an unloading bolt at the bottom of the unloading plate are fixedly connected. A rectangular spiral spring is arranged at the bottom end of the unloading bolt. A screw plug is arranged at the bottom end of the rectangular spiral spring. Screw holes are formed in the four corner positions of the unloading plate. A grinding disc is arranged on the surface of the unloading plate, and four corner grinding rollers with the same specification are arranged on the tops of the four sides of the unloading plate correspondingly. The secondary machining procedures are saved, and the product qualification rate is greatly increased.

Owner:ZHEJIANG ZHONGTONG AUTO PARTS

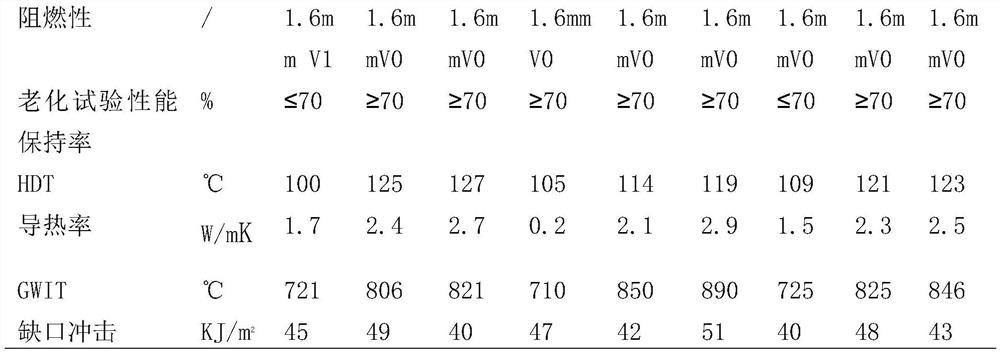

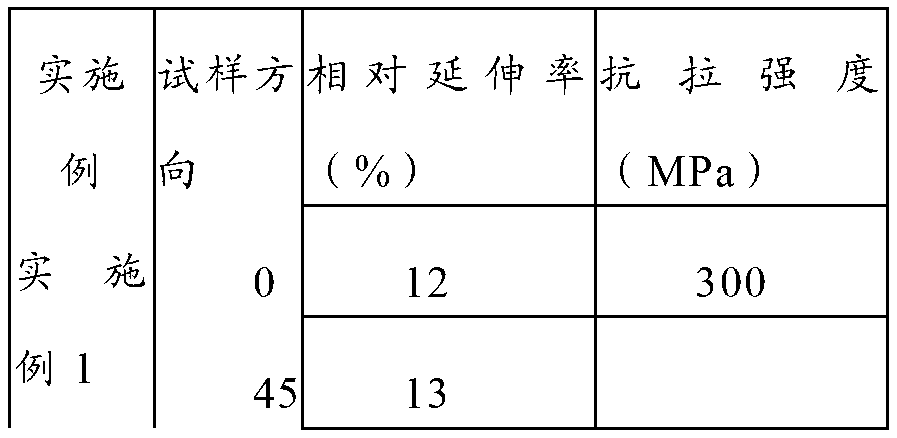

Heat-conducting flame-retardant high-fiber reinforced polycarbonate composition and preparation method thereof

The invention relates to the technical field of polymer functional composite materials, in particular to a heat-conducting flame-retardant high-fiber reinforced polycarbonate composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 30-70% of polycarbonate; 0-10% of silicon copolycarbonate; 2-10% of a flame retardant; 3-10% ofa heat conduction material; 0-5% of MBS; 0-0.2% of a coupling agent; 20-50% of a thermally conductive reinforcement; 0.2-0.5% of an anti-dripping agent; 0.1-0.3% of an antioxidant; 0.1-0.5% of a lubricating agent; 0.1%-0.4% of a toughening agent; and 0.2%-0.5% of a compatilizer. The adopted phosphazene flame retardant is low in addition proportion, resistant to high-temperature processing, high inthermal deformation temperature, good in weather resistance, free of precipitation, halogen-free or extremely low in halogen content; the flat glass fiber can achieve higher filling ratio and has better stretching, bending and impact resistance, a molded product is not warped, the dimensional stability is extremely good, and basically no glass fiber is exposed on the appearance; and the heat conduction material is added, so that the molded product has better heat conductivity, the molding period is shortened, the hand feeling is better during use, and the life cycle of the product is longer.

Owner:宁波合裕新材料科技有限公司

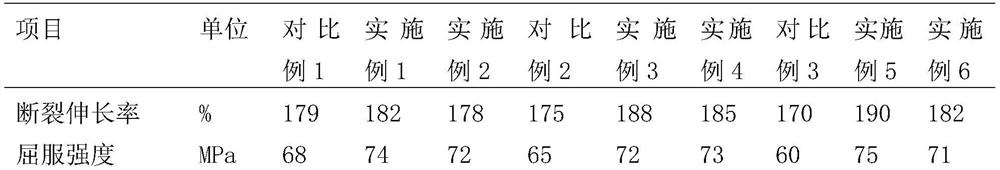

Aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof

ActiveCN103290282AHigh hardnessMeet strength requirementsUpperBootlegsHardnessUltimate tensile strength

The invention provides an aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof, and the aluminium alloy sheet material is 7xxx series aluminium alloy, and concretely comprises the following components by weight percent: 0.50-1% of Fe, 0.40-1.0% of Mn, 0.4-0.80% of Mg, 0.20-0.80% of Si, 0.2-0.3% of Zr, 0.10-0.2% of Ti, 3.5-4.5% of Cu and Al the rest amount. The aluminium alloy contains Zr, Ti, Si, Cu and Mg, and has a high hardness and intensity, and belongs to the superhard aluminium alloy, the invention has a good wear resistance, and after the stress is relieved by processing, the product does not deform and warp, thereby shortening the moulding time and improving the work efficiency. The aluminium alloy sheet material provided by the invention can satisfy the requirements of intensity and hardness, and ensure the thickness of the aluminium alloy sheet material is the lowest.

Owner:SOUTHWEST ALUMINUM GRP

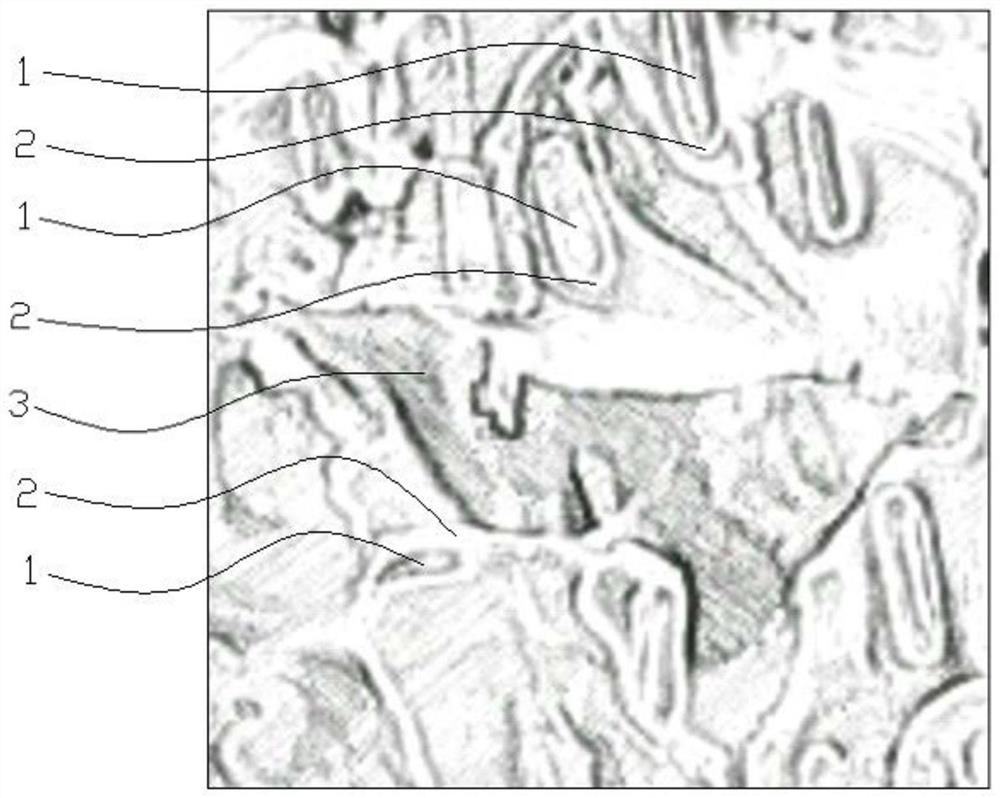

Natural fiber-reinforced thermoplastic composite material prepreg tape, and preparation method and application thereof

ActiveCN104228237ANot easy to mold and deteriorateKeep drySynthetic resin layered productsLaminationPunchingNatural fiber

The invention belongs to the technical field of composite processing, and relates to a natural fiber-reinforced thermoplastic composite material prepreg tape, and a preparation method thereof. The method comprises the following steps of (a) cutting the natural fiber-reinforced thermoplastic composite material prepreg tape and laying; (b) heating the prepreg tape layer into an infrared-ray oven and melting; (c) putting the melted layer into a cold press machine to carry out cold press and cooling to obtain a sheet material; and (d) after the cooling process is finished, cutting the obtained sheet material, punching, polishing, cleaning burs, carrying out precision grinding, spraying paint and applying a surface to obtain a skateboard surface. The prepared natural fiber / thermoplastic resin skateboard surface can be stored for a long time, and after hot press, the natural fibers can be impregnated by the resin thoroughly, so that the material particularly the natural fibers can be kept dry. The natural fibers are not liable to mildew or deteriorate. Products adopted by the invention have no harm to a human body and do not produce adverse reaction.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

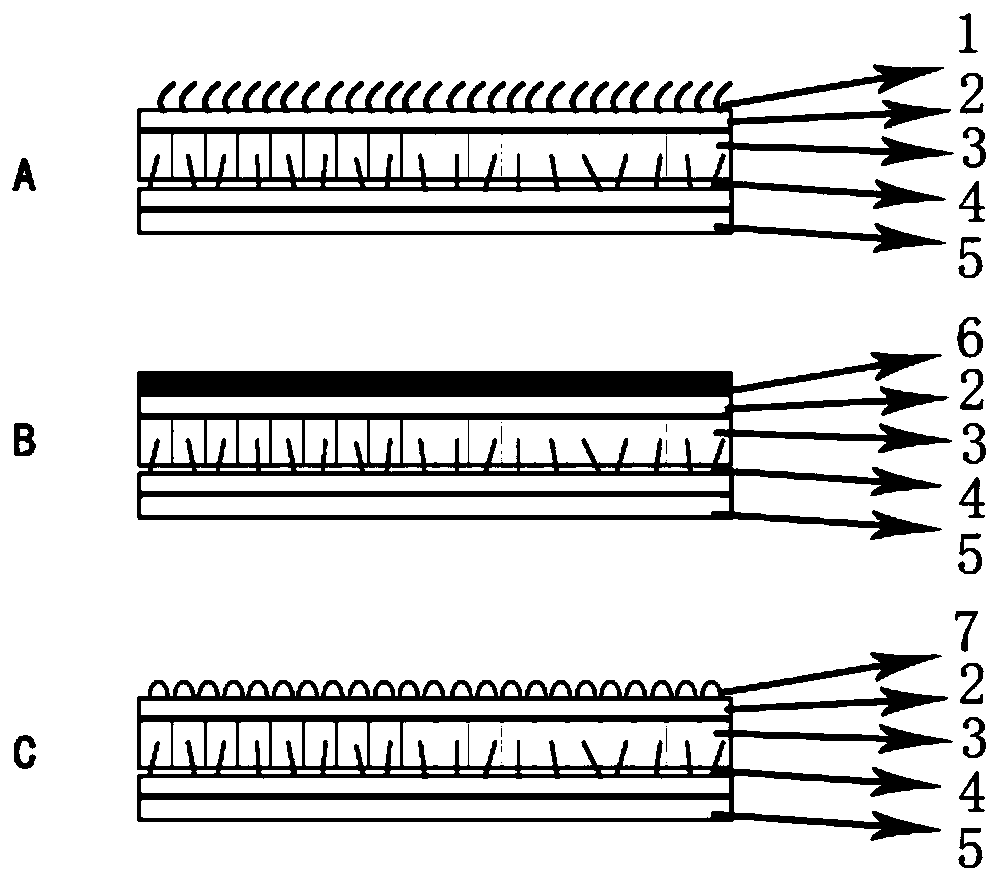

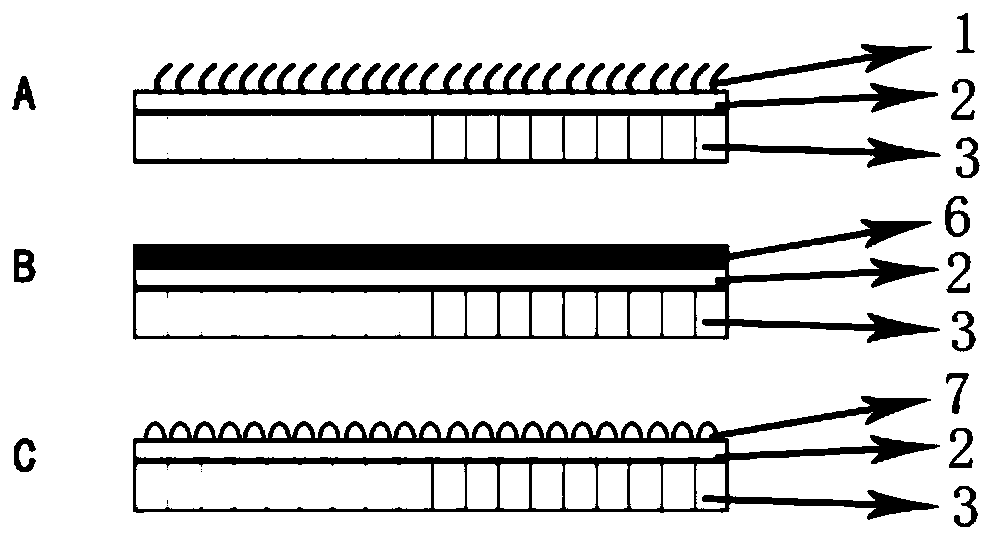

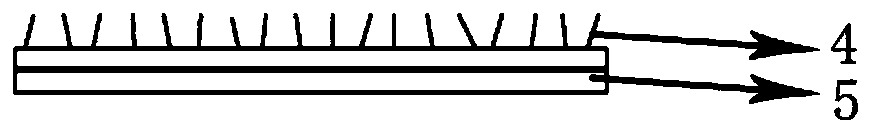

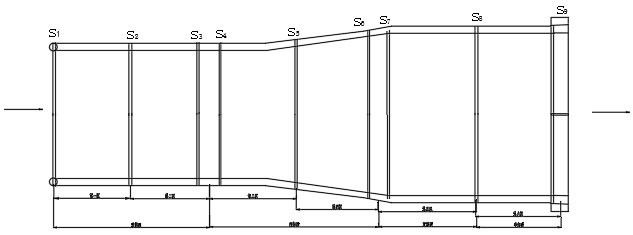

Process for preparing base film for polaroid protective film, and equipment

PendingCN113071122AExcellent optical appearance performanceConvenient appearance testFlat articlesForeign matterPolyester

The invention relates to a process for preparing a base film for a polaroid protective film, and equipment. The equipment comprises a die head, a material conveying pipeline, a metering extruder, a filter, a mixing container, a direct current motor, an electronic element, a control system, a metering pump and a polyester casting sheet. According to the process for preparing the base film for the polaroid protective film, and the equipment, a produced base film product has excellent optical apparent performance, the surface of the protective film is free of defects such as foreign matter, white points, scratching and creases, polaroid apparent testing can be conveniently carried out under the condition that the protective film is not removed, meanwhile, damage and pollution of various defects to a TAC film are prevented, weather resistance and permanent adhesion stability are achieved, the stripping force is not obviously increased after several days or longer, and the protective film is easy to tear off, has no residual glue and no mark on a protected surface, has good adhesion performance on the protected surface, does not tilt or fall off in a material carrying or processing process, and is subjected to antistatic treatment so as to be low in electric quantity and prevent electrostatic dust adsorption from polluting the surface of a polaroid.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

Degradable food packaging film with antibacterial function

InactiveCN108276598ASolve problems such as uneven compounding, poor antibacterial properties, and low strengthImprove drying qualityFlexible coversWrappersMicrowaveComposite film

The invention provides a degradable food packaging film with antibacterial function. The degradable food packaging film with antibacterial function is characterized in that nanocellulose is used as amatrix, and nanometer ZnO particles and the nanocellulose are uniformly mixed to prepare a nanocellulose / nanometer ZnO composite film; then the film is immersed in a chitosan solution with a certain concentration, the chitosan is assembled onto the surface of the composite film through a self-assembly way, and then the obtained composite film is dried through a microwave drying way; and the self-assembly process can be repeated 5-8 times as needed, and finally the food packaging film which can be completely degraded and has a high antibacterial grade is obtained. According to the degradable food packaging film with antibacterial function, the biomass nanocellulose, the nanometer ZnO particles and the chitosan are used as raw materials, and are processed into the degradable food packaging film with antibacterial function through methods of microparticle dispersion, layer by layer self-assembly and microwave drying, so that the problems of non-uniform composite, poor antibacterial property, low strength, and the likes of a current nanocellulose and chitosan film are solved.

Owner:南充三樱药用包装材料有限公司

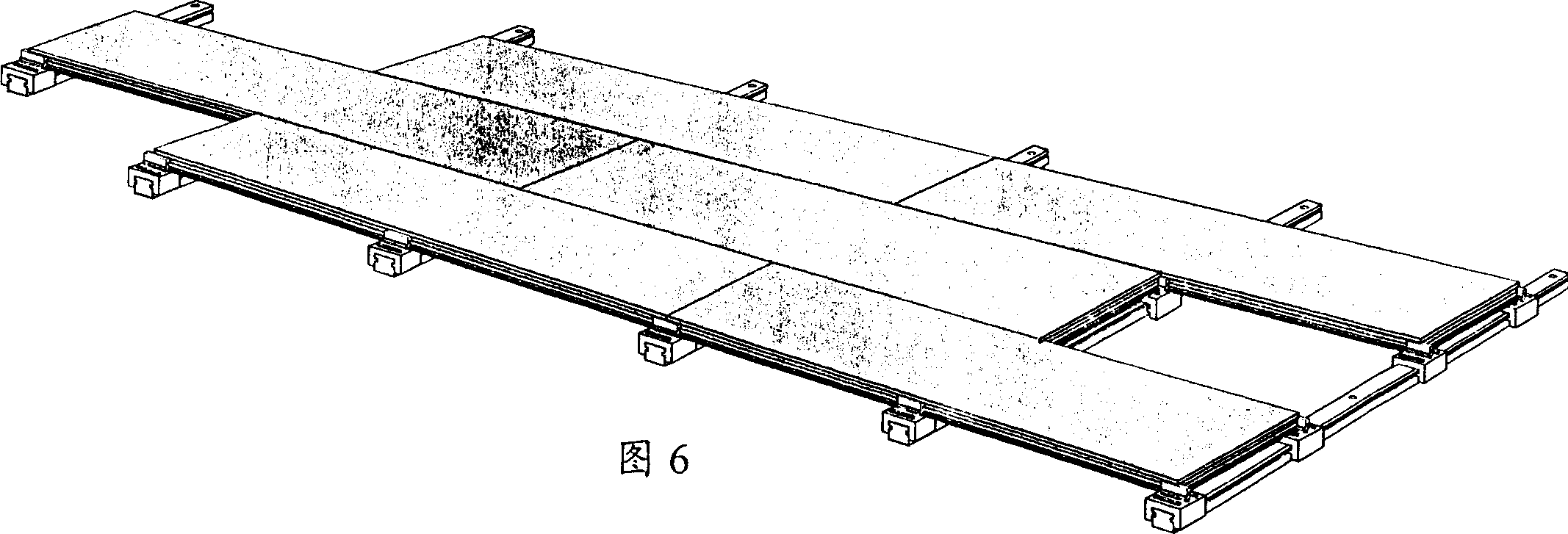

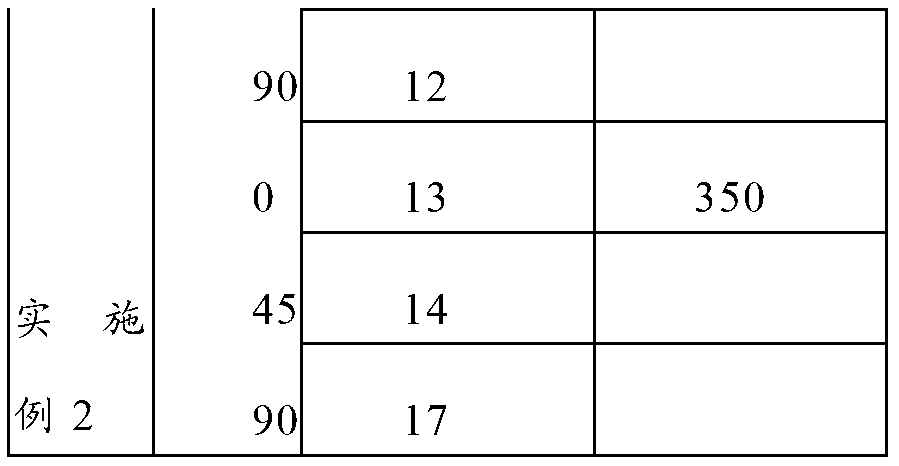

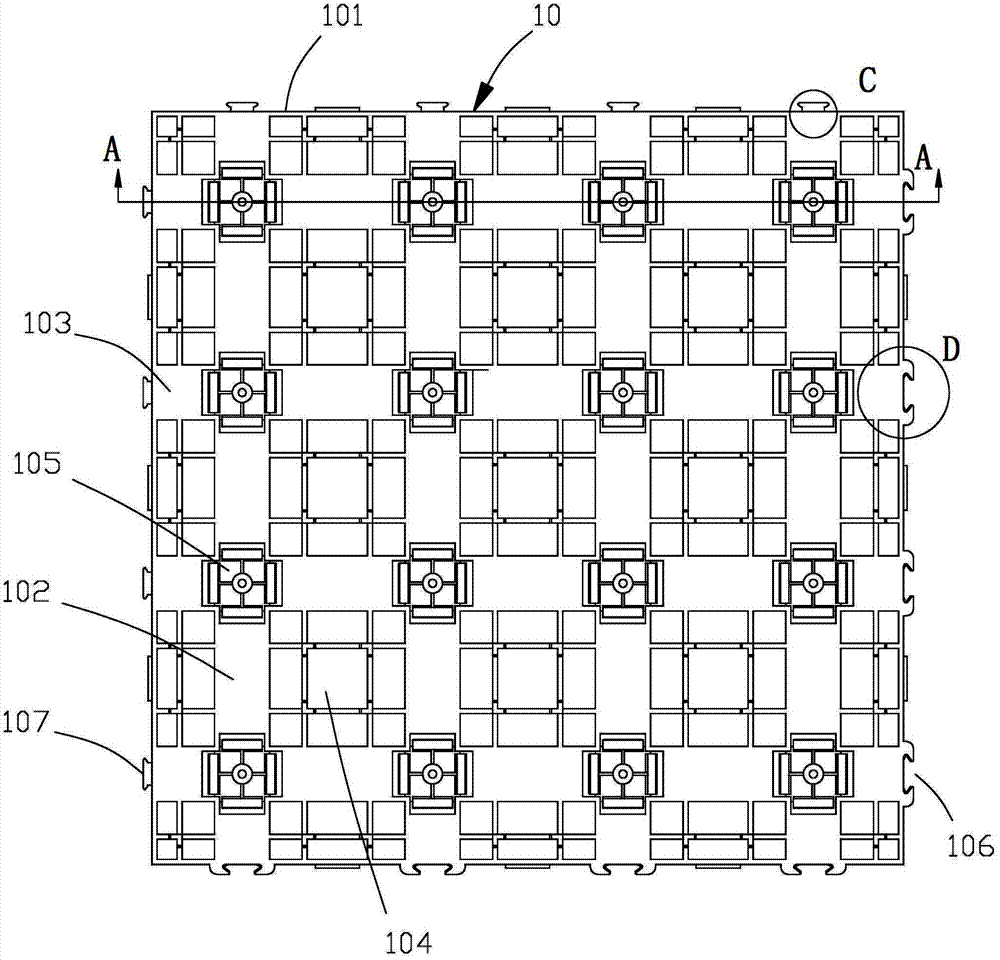

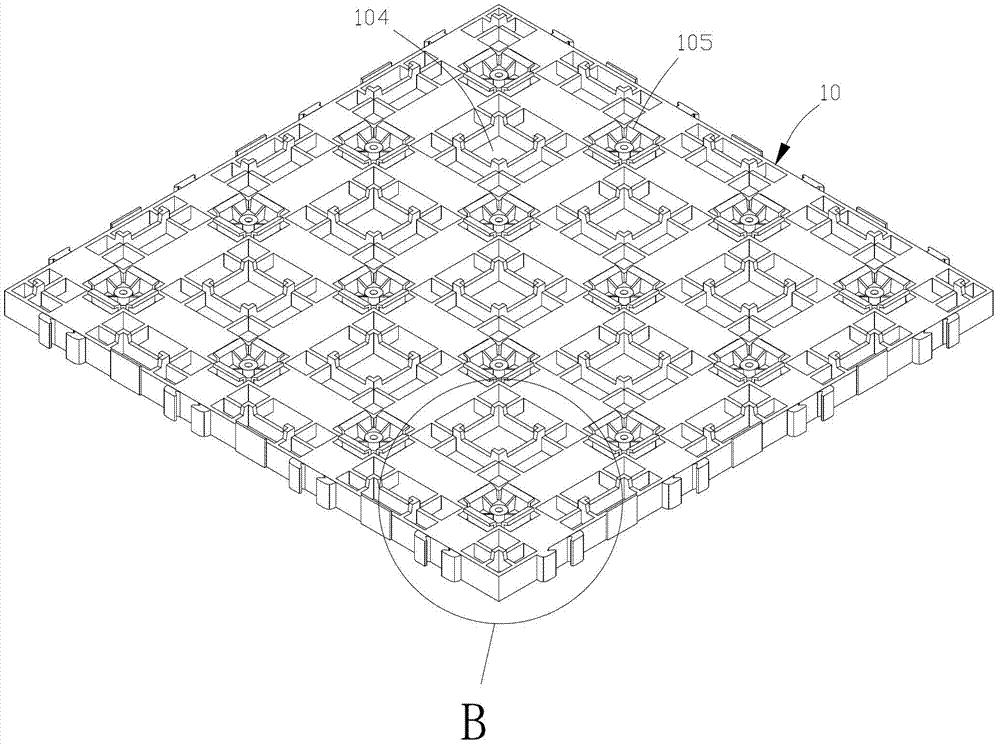

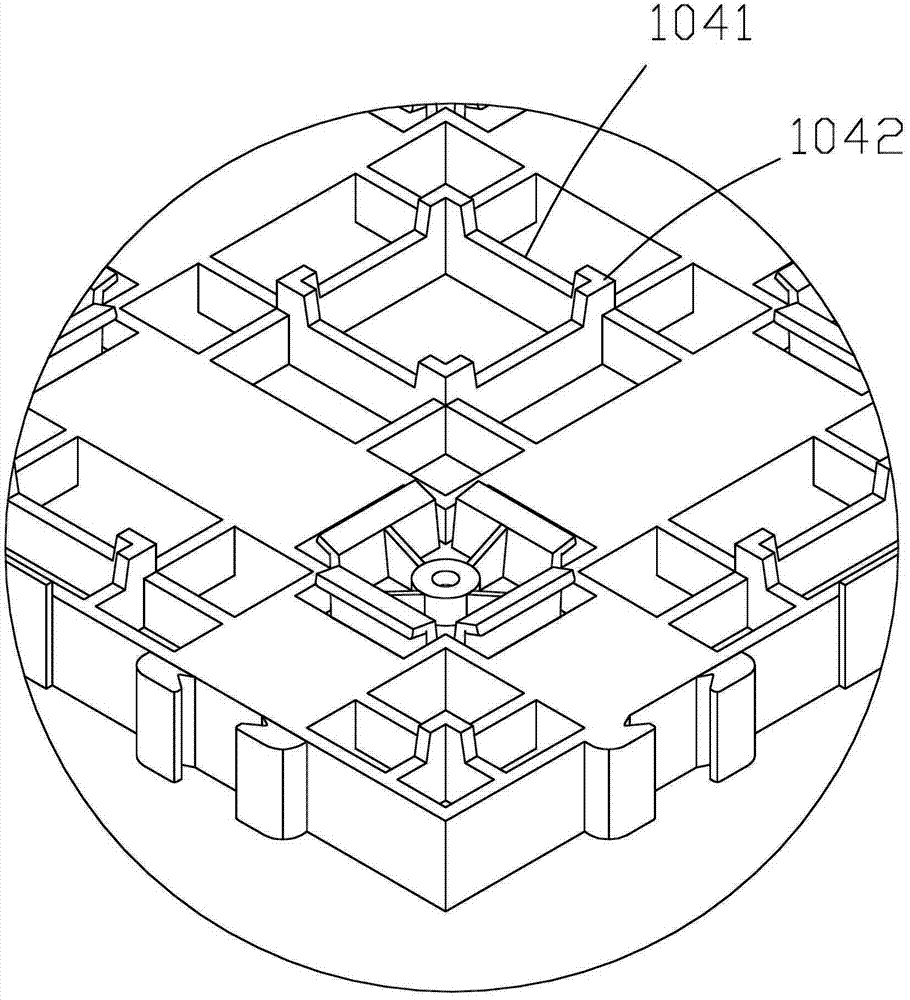

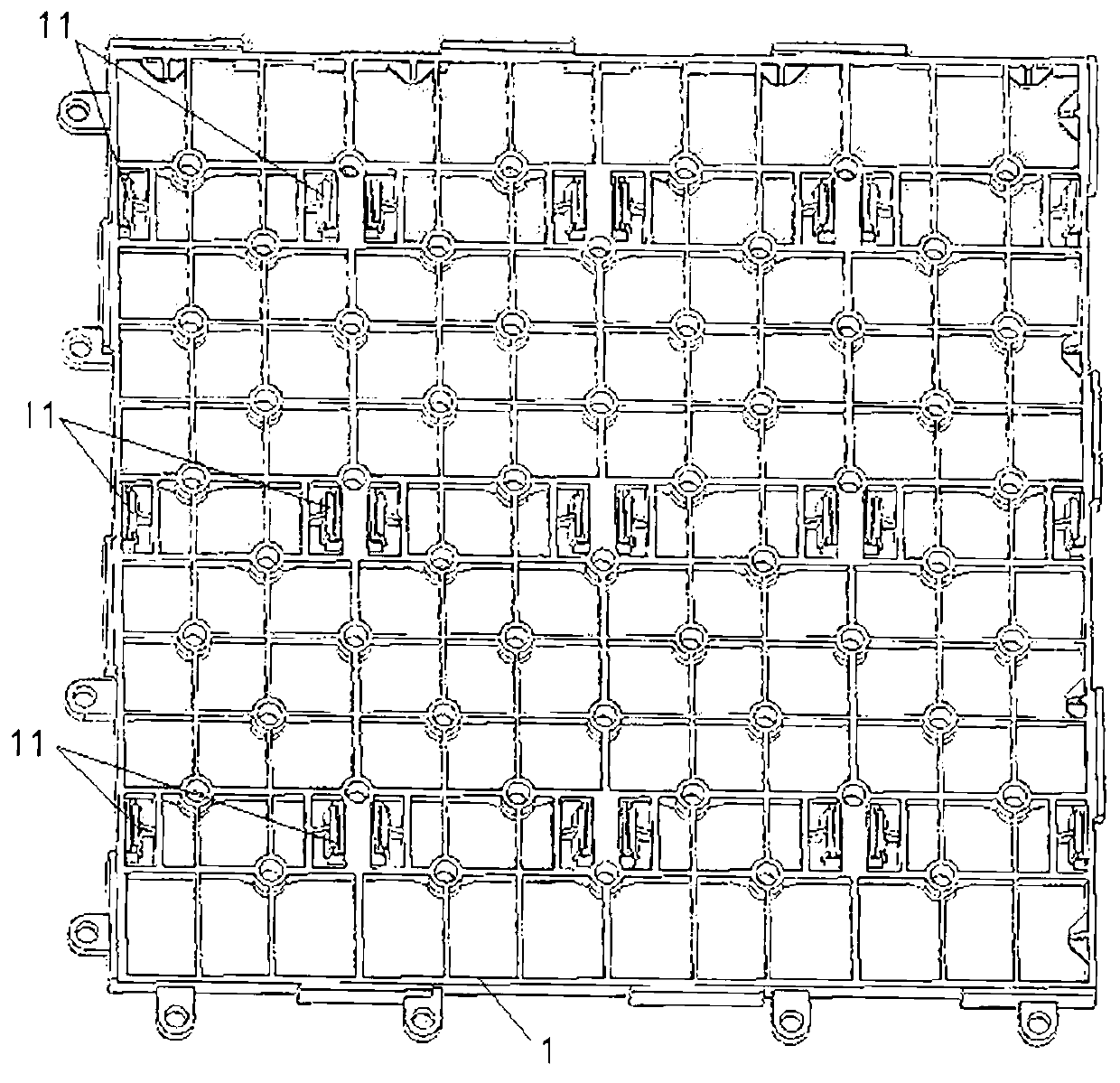

Lower floor board of system without screws

ActiveCN103161290ADirect connection is strong and reliableNo fixedFlooringEngineeringMechanical engineering

The invention provides a lower floor board of a system without screws, and relates to the technical field of floor board connecting parts. The lower floor board of the system without the screws comprises a net bottom which is wholly in a square structure and is used for supporting the floor boards, wherein the net bottom comprises battens which are located around the net bottom and are used for forming a square net bottom frame, a plurality of longitudinal connecting bones and horizontal connecting bones are arranged longitudinally and horizontally among the battens in integration, the longitudinal connecting bones and the horizontal connecting bones connect the battens located around the net bottom together to form the net bottom, the longitudinal connecting bones and the horizontal connecting bones are vertically intersected, a plurality of floor board installation regions with consistent shapes and areas are arranged between the longitudinal connecting bones and the horizontal connecting bones, neck regions used for clamping the floor boards are formed by stretching upward the upper surface of intersection positions of the longitudinal connecting bones and the horizontal connecting bones, dovetail grooves used for connecting the net bottom are formed in the external side walls of two adjacent battens which form the net bottom, and dovetail joints matched with the dovetail grooves are arranged on the external side walls of the other two adjacent battens. The lower floor board of the system without the screws has the advantages of being stable and reliable due to direct connection between the floor boards and the net bottom, and free of screw fixation. Horizontal connection and longitudinal connection can both be achieved between the floor boards and the net bottom, and the screw connection does not exist between the floor boards and the net bottom.

Owner:ANHUI SENTAI WPC GRP CO LTD

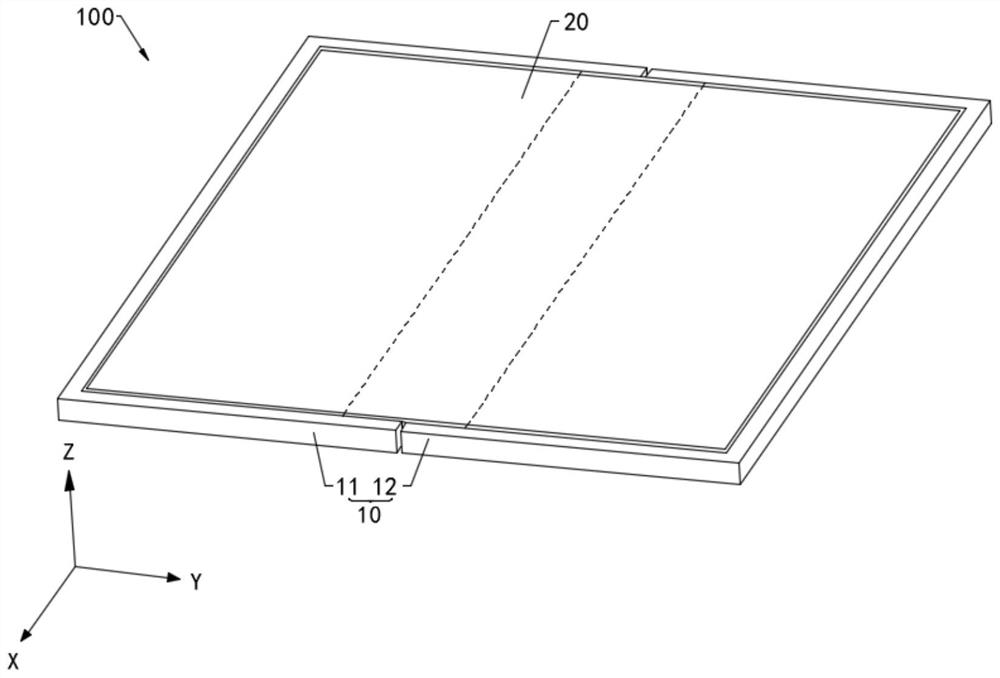

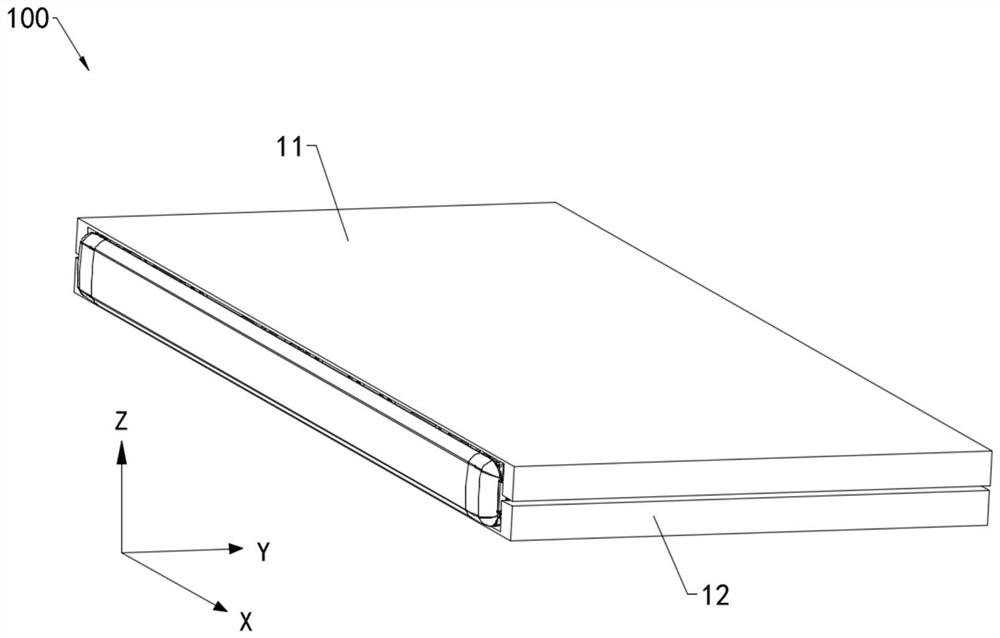

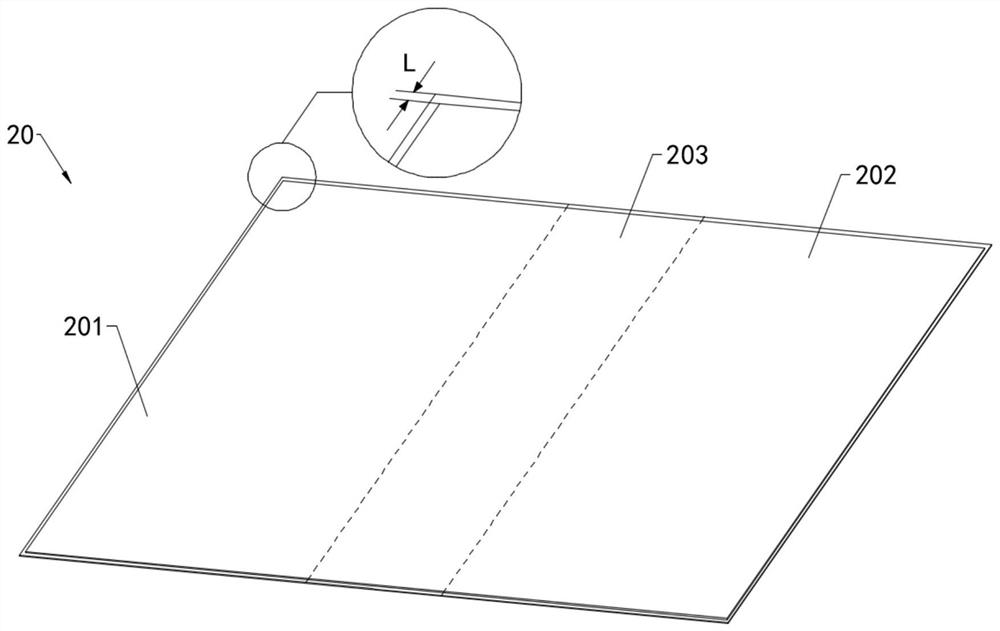

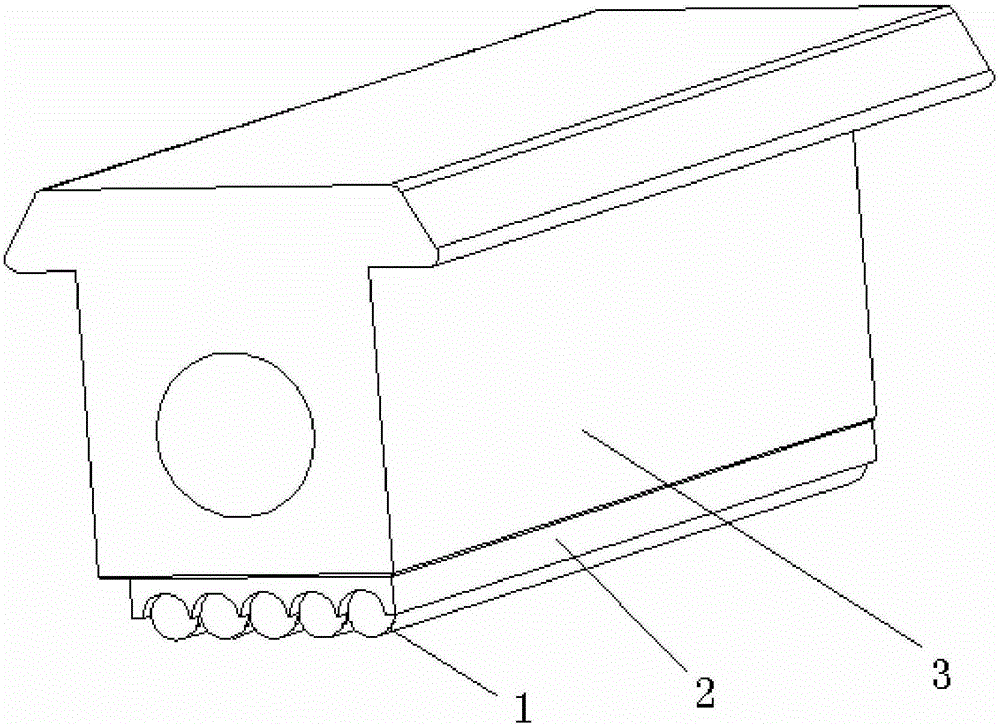

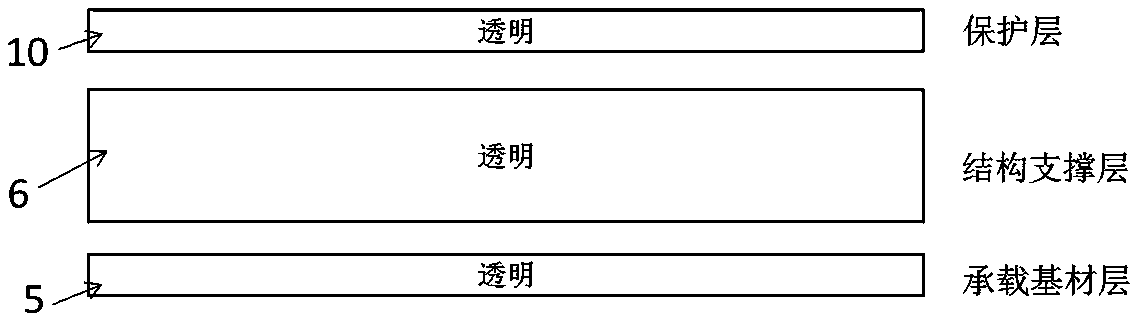

Protective film, protective film assembly, display screen assembly and terminal

InactiveCN113583582AExtended service lifeWon't warpFilm/foil adhesive primer layersTelephone set constructionsStructural engineeringComposite material

The invention provides a protective film. The protective film comprises a bonding layer and a base film layer which are arranged in a stacked mode, the bonding layer is used for being bonded to a foldable display screen, the base film layer comprises one or more high-modulus base films and one or more low-modulus base films, the elastic modulus of the high-modulus base films is larger than that of the low-modulus base films, the high-modulus base film and the low-modulus base film are alternately stacked, and the surface layer, far away from the bonding layer, in the base film layer is the high-modulus base film. The protective film disclosed by the invention can be firmly attached to the foldable display screen and cannot be warped due to rebounding caused by repeated bending of the display screen, so that the foldable display screen is comprehensively and effectively protected. The invention further provides a protective film assembly comprising the protective film, a display screen assembly and a terminal.

Owner:HUAWEI TECH CO LTD

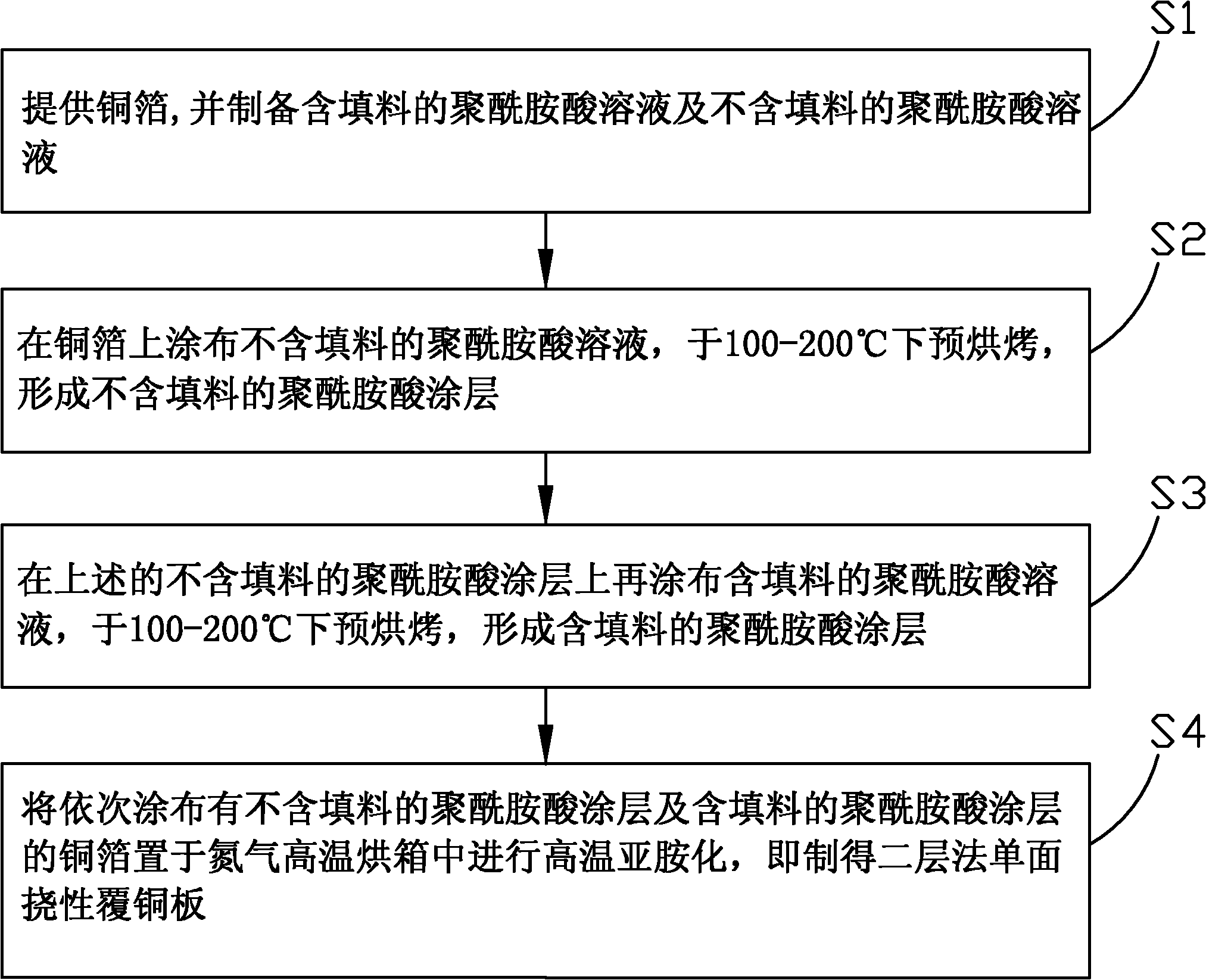

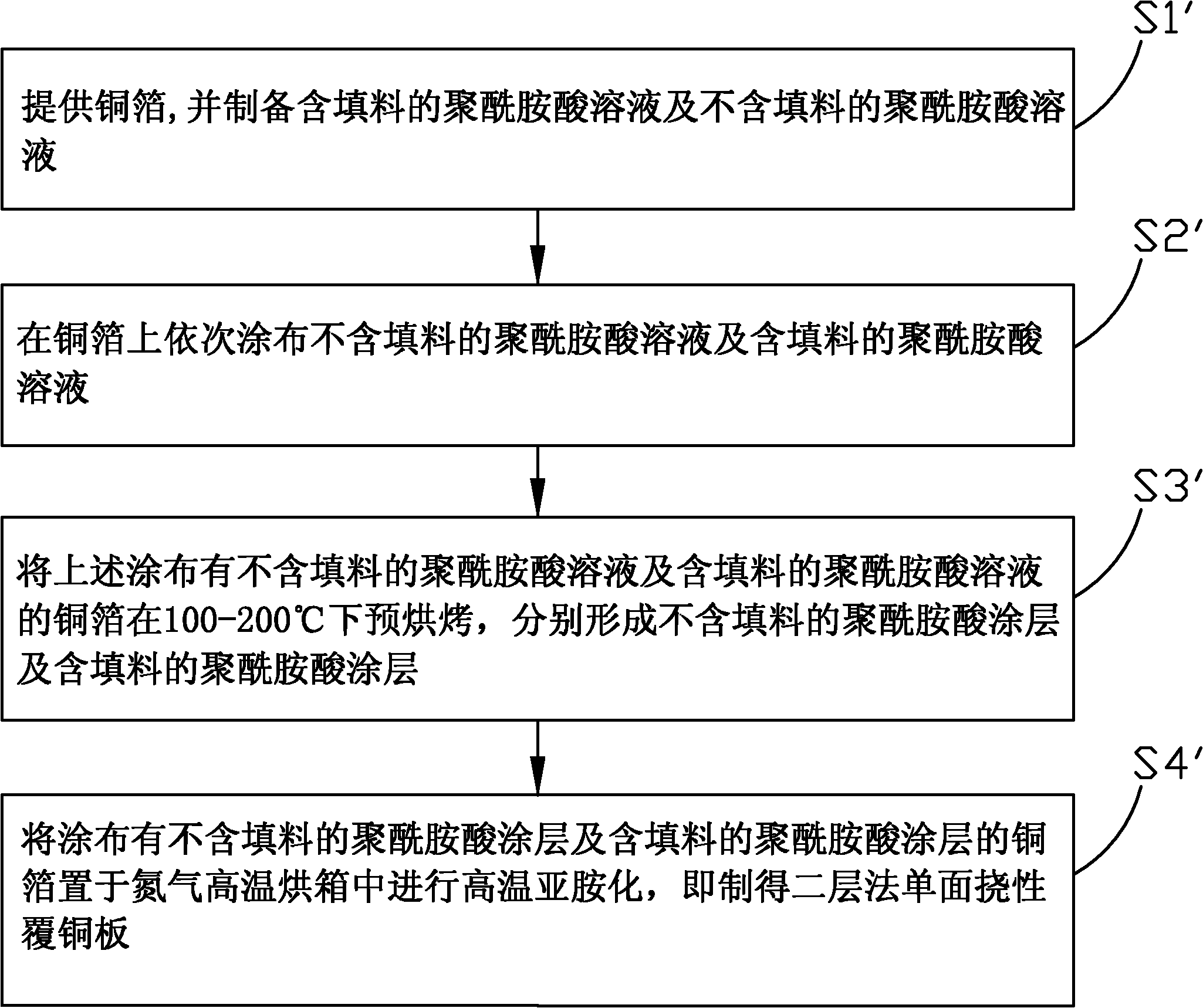

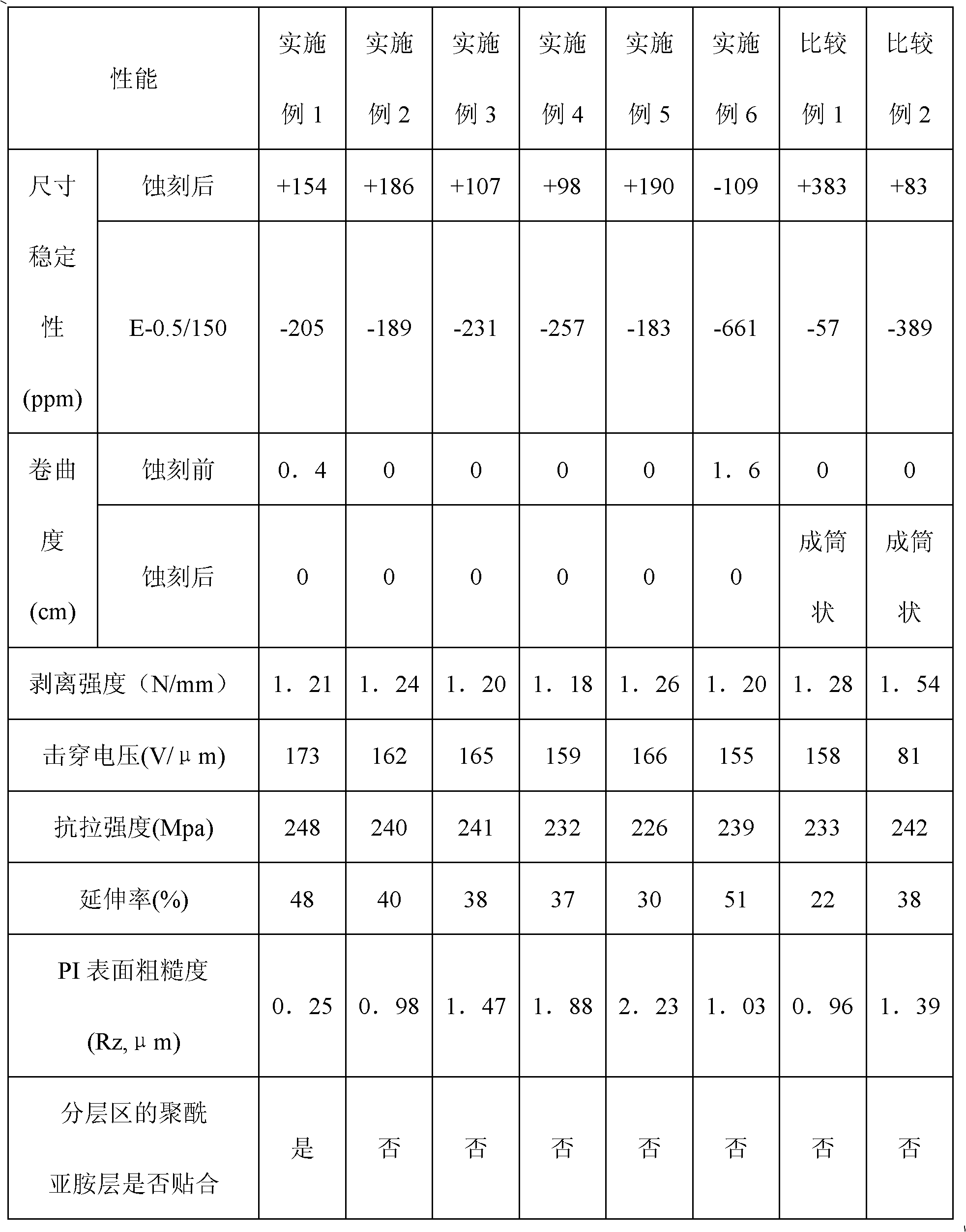

Manufacturing method of two-layer single-sided flexible copper clad laminate

ActiveCN102166853AWon't warpEasy to operateSynthetic resin layered productsMetal layered productsFilling materialsNitrogen

The invention relates to a manufacturing method of a two-layer single-sided flexible copper clad laminate. The method comprises the following steps: providing copper foil and preparing a polyamic acid solution with filling materials and a polyamic acid solution without filling materials; coating the copper foil with the polyamic acid solution without filling materials and pre-baking the copper foil at a temperature of 100 to 200 DEG C to form a polyamic acid coating without filling materials; coating the polyamic acid coating without filling materials with the polyamic acid solution with filling materials and pre-baking at a temperature of 100 to 200 DEG C to form a polyamic acid coating with filling materials; placing the copper foil successively coated with the polyamic acid coating without filling materials and the polyamic acid coating with filling materials into a nitrogen high-temperature baking oven for high-temperature imidization and finally to obtain the two-layer single-sided flexible copper clad laminate. The invention is simple in operation. The two-layer single-sided flexible copper clad laminate prepared by two times of coating is flat and smooth instead of warping before and after etching.

Owner:GUANGDONG SHENGYI SCI TECH

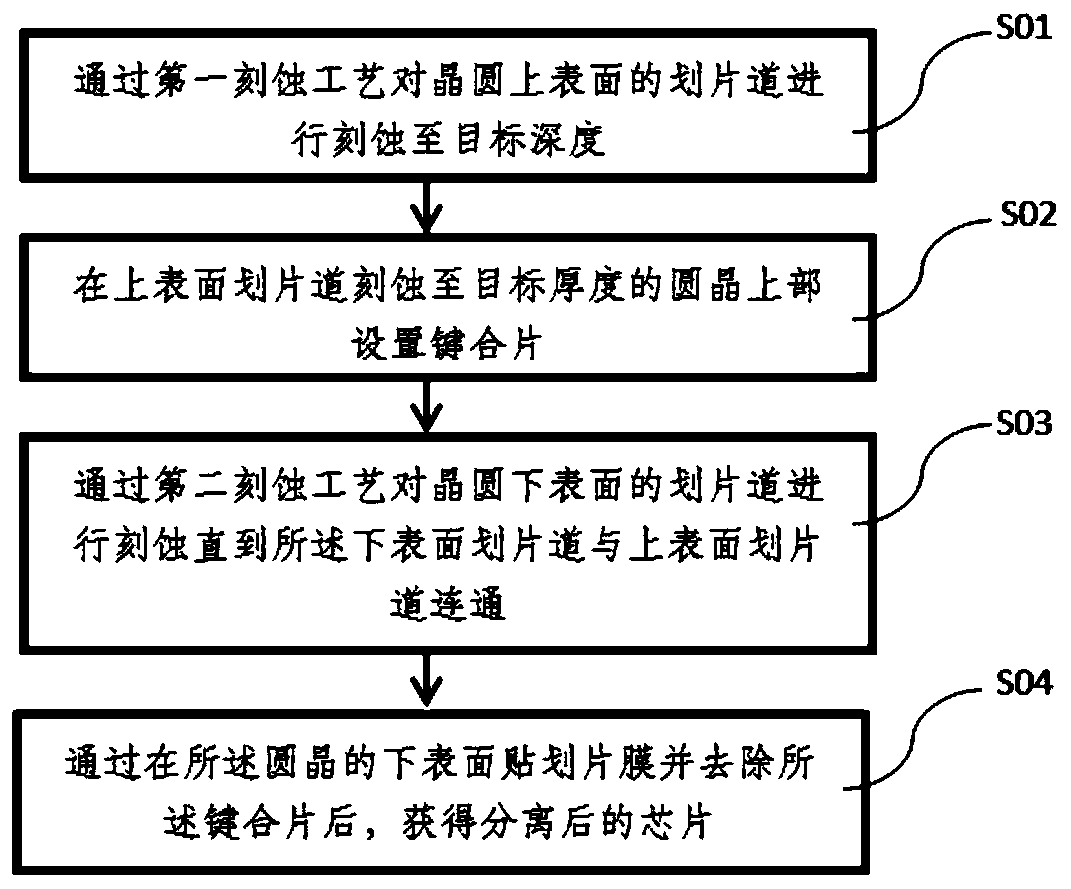

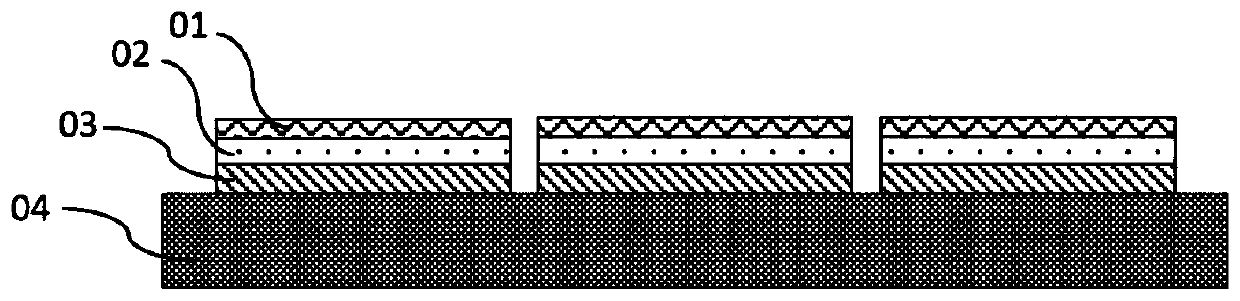

Wafer slicing method and chip

PendingCN110838439AWon't warpIncrease the number of survivorsSolid-state devicesSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a wafer slicing method. The method comprises the following steps of: etching a scribing channel on the upper surface of a wafer to a target depth through a first etching process, arranging a bonding sheet at the upper part of the wafer of which the upper surface scribing channel is etched to the target thickness, etching the scribing channel on the lower surface of the wafer through a second etching process until the scribing channel on the lower surface is communicated with the scribing channel on the upper surface, and pasting a scribing film on the lower surface of the wafer and removing the bonding sheet to obtain a separated chip. The invention further discloses a chip manufactured through the slicing method. According to the technical scheme, the survival number of the chips on each wafer is greatly increased, and the yield of the chips is greatly increased.

Owner:WILL SEMICON (SHANGHAI) CO LTD

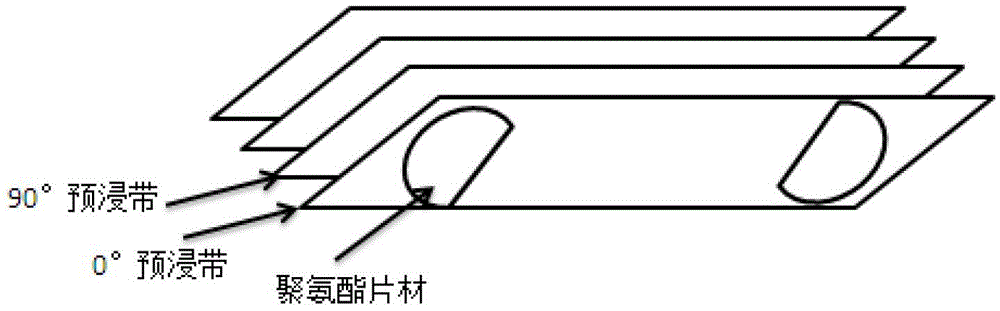

Wear-resistant sliding plate surface and processing method

ActiveCN104097374AImprove water resistanceReduce defectsSynthetic resin layered productsGlass/slag layered productsWear resistantResin composite

The invention belongs to the technical field of processing technology of composite materials and relates to a sliding plate surface and a manufacturing method thereof. The sliding plate surface is composed of a prepreg strip layer and a polyurethane layer. The prepreg strip layer is formed by 100 parts of a glass fiber reinforced thermoplastic resin composite material single-direction prepreg strip in a laminated manner. The polyurethane layer is formed by 5-10 parts of sheet-shaped thermoplastic polyurethane. A sliding plate material manufactured by means of the method in the invention is improved in a water-resistant performance and is not easy to warp and peel after being contacted with water. The manufacturing method is completely free of glue and a glue-coating process is reduced so that pollution during a processing process is reduced. In addition, the sliding plate surface, which is manufactured from the glass fiber reinforced thermoplastic composite material is thinner and is higher in strength.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Locking catch block

The invention relates to a locking catch block, which comprises a keel and a cushion block. The middle of the upper part of the keel is provided with a convex rib with a barb part and convex ribs distributed on two sides of the convex rib with the barb part, at least one inserting groove is formed on the keel, the cushion block consists of a main body part which has equal height with a keel cube and an inserting tenon matched with the inserting groove on the keel, and the inserting tenon on the cushion block is inserted in the inserting groove on the keel. In a fixer used with the locking catch block, one side of a block body is provided with a left groove, a right groove and a middle groove which are matched and sleeved with the left convex rib, the right convex rib and the middle convex rib of the keel respectively; and the left groove and the right groove are provided with flanges. The locking catch block can conveniently assemble a plurality of wood floor blocks together, the assembly is convenient and simple, and the wood floor is not easy to deform after assembling.

Owner:李新发

Screw-free mounting type wood-plastic floorboard

ActiveCN103343606ASave assembly timeReduce manufacturing costFlooringEngineeringMechanical engineering

Owner:EVERWIN IND GRP

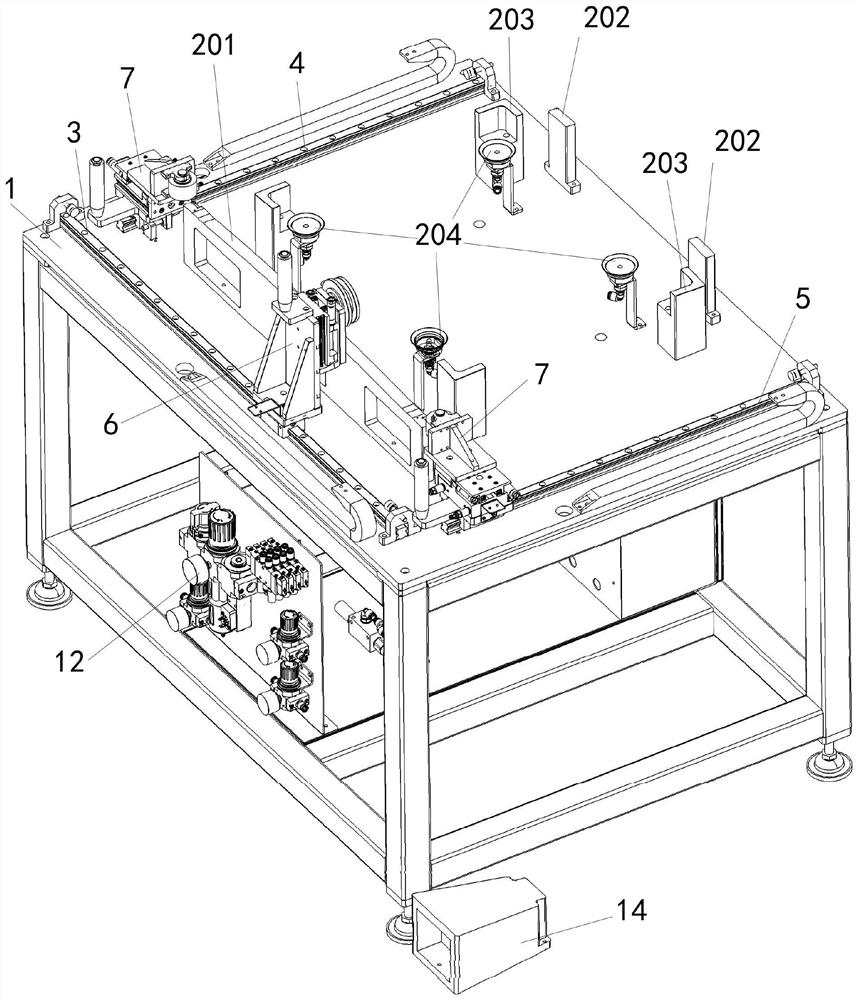

Automobile skylight sealing strip assembling equipment

The invention relates to automobile skylight sealing strip assembling equipment which comprises a workbench, the workbench is provided with a profiling supporting base, a transverse guide rail, two longitudinal guide rails, a vertical press-fitting mechanism and a horizontal press-fitting mechanism, and the profiling supporting base is used for bearing an automobile skylight; the transverse guide rail is located at the front end of the profiling supporting seat, a vertical press-fitting mechanism is installed on the transverse guide rail, and the vertical press-fitting mechanism applies pressure to the sealing strip in the vertical direction to press the sealing strip into the sealing strip inserting groove. The two longitudinal guide rails are arranged on the two sides of the profiling supporting base respectively, the two longitudinal guide rails are each provided with the horizontal press-fitting mechanism, and the horizontal press-fitting mechanisms apply pressure to the sealing strip in the horizontal direction to press the sealing strip into the sealing strip inserting groove of glass. The equipment can meet the installation requirements of sealing strips with two different assembling forms on the same automobile skylight, and is simple in structure, low in labor intensity and high in assembling efficiency.

Owner:科德汽车零部件(山东)有限公司

A cutting process of sapphire crystal rod and its processing jig

ActiveCN103448153BWon't splinterWon't warpWorking accessoriesFine working devicesCrystal orientationWire cutting

The invention discloses a cutting technique and a machining fixture for a sapphire ingot. The cutting technique comprises the following steps of firstly, bonding the machining fixture for fixing the ingot to a base of a multi-wire cutting machine and enabling the bottom surface of the machining fixture to be parallel to that of the multi-wire cutting machine; secondly, after bonding and curing the machining fixture and the base of the multi-wire cutting machine, fixedly bonding the sapphire ingot in an arc-shaped positioning groove in the machining fixture, enabling the end face of the sapphire ingot to be parallel to that of the machining fixture and ensuring the crystal orientation of a cutting-in surface of the sapphire ingot; thirdly, starting the multi-wire cutting machine, sequentially cutting the sapphire ingot and the machining fixture from the crystal orientation of a cutting-in surface of the sapphire ingot by matching a wire saw with a cutting fluid until the sapphire ingot is completely cut off. According to the cutting technique and the machining fixture disclosed by the invention, the sapphire ingot is cut by combining the cutting technique with the machining fixture, so that a plurality of sapphire ingots can be cut at one time; the production efficiency is high and the cutting quality is good.

Owner:LENS TECH

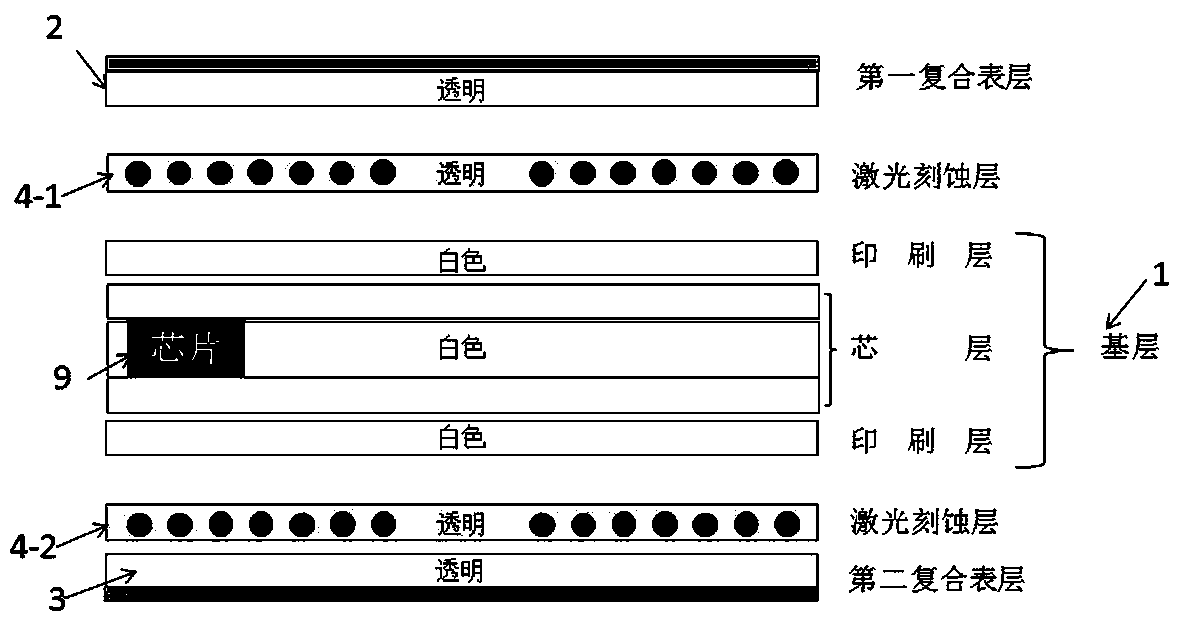

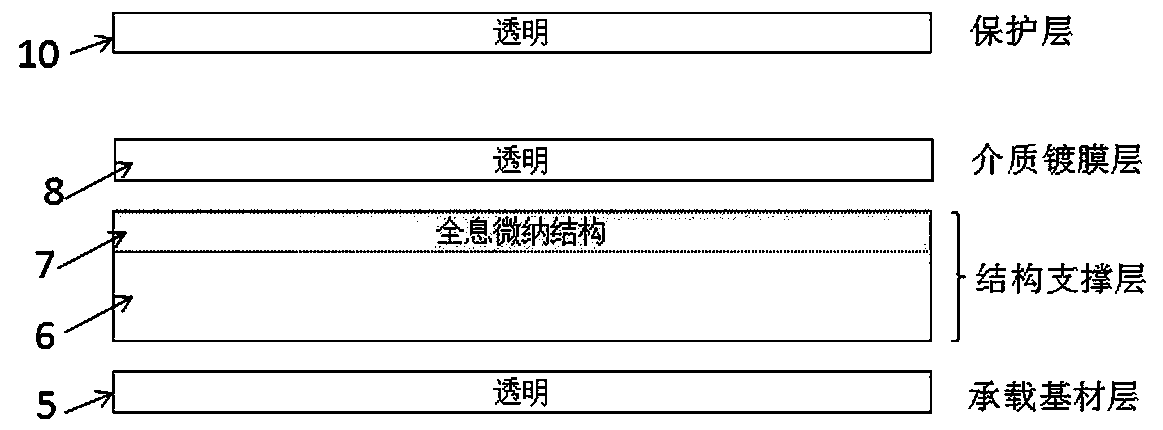

Anti-counterfeiting identification card with asymmetric structure

The invention provides an anti-counterfeiting identification card with an asymmetric structure, can reduce cost of a single-sided anti-counterfeiting identification card on the basis of ensuring realization of a full-page holographic anti-counterfeiting image on a surface of the anti-counterfeiting identification card. The anti-counterfeiting identification card comprises a base layer and laser etching layers, wherein a first composite surface layer and a second composite surface layer are respectively arranged on one side, far away from the base layer, of the two laser etching layers, the first composite surface layer comprises a bearing base material layer and a structure supporting layer, a holographic micro-nano structure is formed on the structure supporting layer in an impressing mode, a structural surface where the holographic micro-nano structure is located is covered with a transparent dielectric coating layer composed of an oxide film with the refractive index larger than 1.8, and a protective layer is arranged, the protective layer and the structure supporting layer are made of the same material, a difference value between a thermal expansion coefficient of the materialand thermal expansion coefficients of the materials of the base layer, the laser etching layer and the bearing base material layer is [+30%, -30%], and the second composite surface layer comprises a bearing base material layer and a base layer. The invention further discloses a manufacturing method of the anti-counterfeiting identification card with the asymmetric structure.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

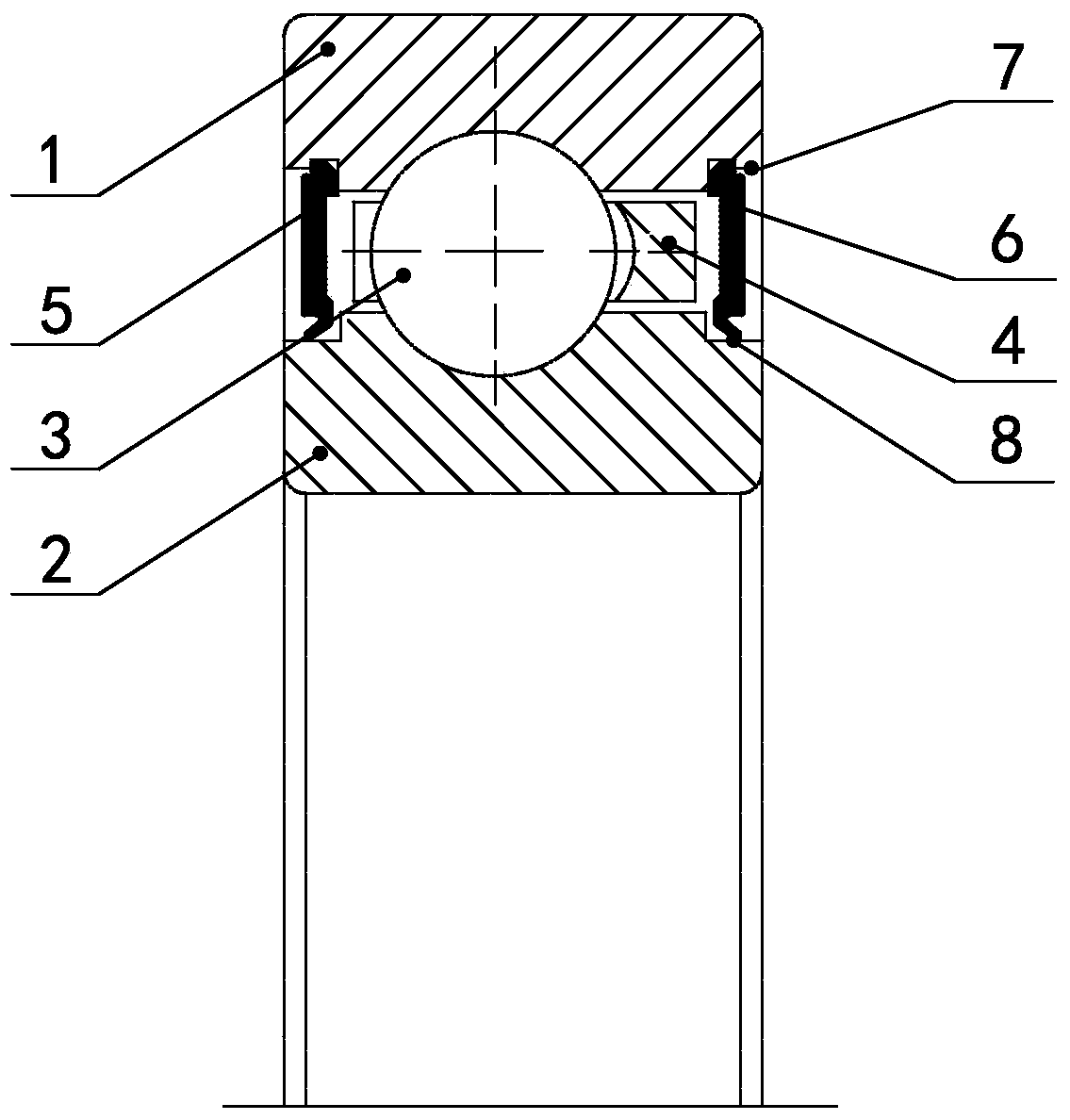

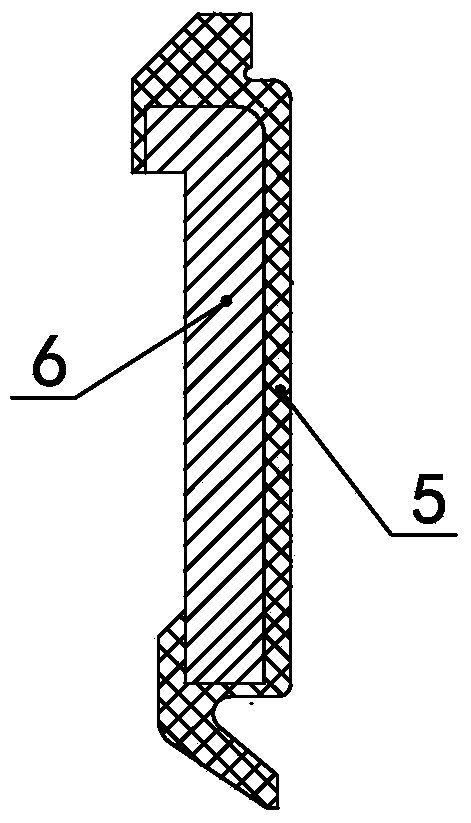

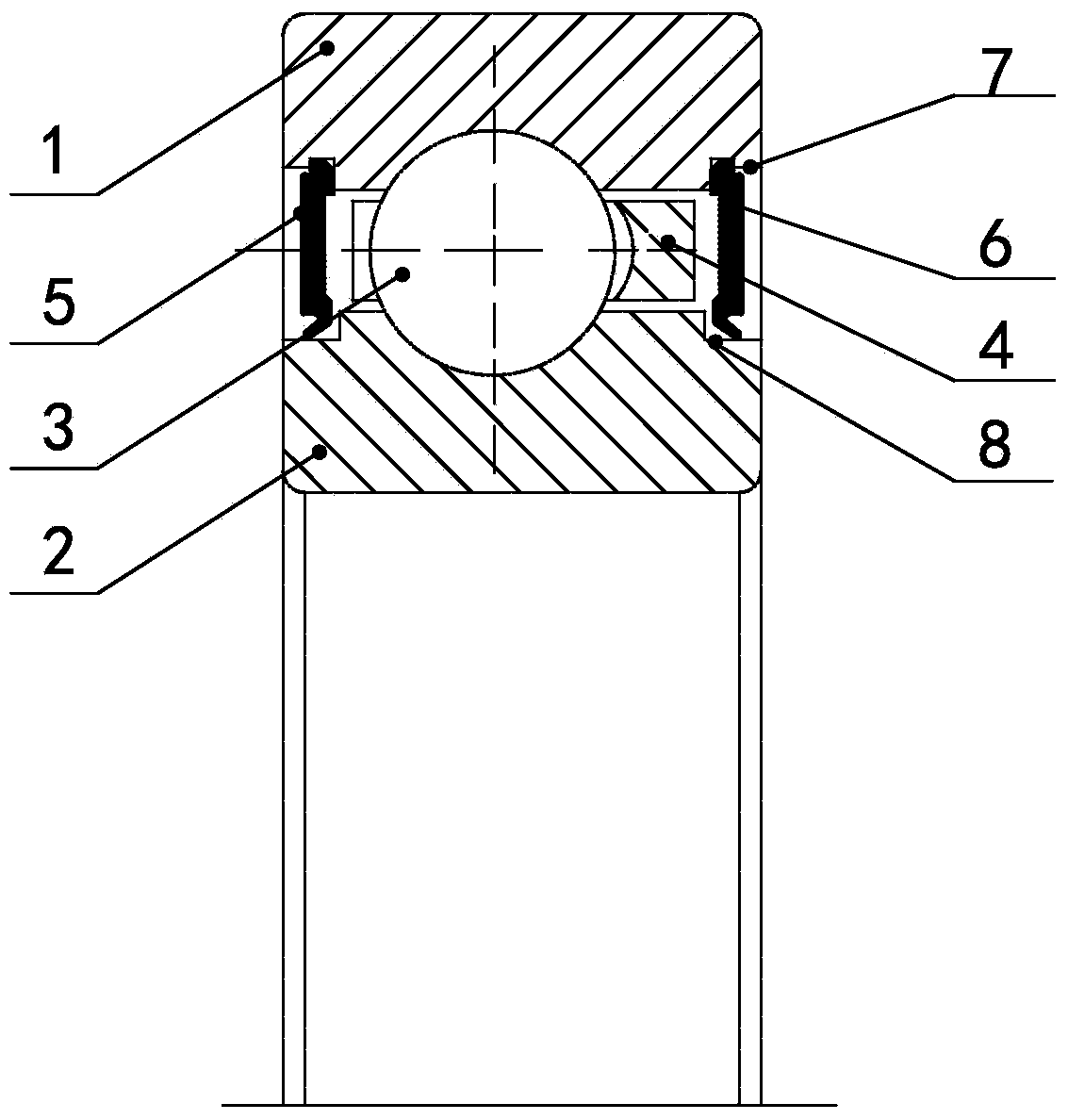

Sealing ring framework structure of ultra-thin-wall bearing with uniform section

InactiveCN104235189AImprove mechanical propertiesWon't warpBearing componentsInterference fitEngineering

The invention relates to a sealing ring framework structure of an ultra-thin-wall bearing with a uniform section. The sealing ring framework structure comprises a sealing ring and a framework, wherein toothed grooves are symmetrically formed in two sides of the inner surface of an outer ring of the ultra-thin-wall bearing with the uniform section, steps are symmetrically arranged on two sides of the outer surface of an inner ring of the ultra-thin-wall bearing with the uniform section, the sealing ring is arranged between the toothed groove of the outer ring of the ultra-thin-wall bearing with the uniform section and the step of the inner ring of the ultra-thin-wall bearing with the uniform section, is in interference fitting with the toothed groove of the outer ring and is in radial contact with the step of the inner ring, so as to achieve the sealing effect; the framework is of a sheet-like hollow cylinder spring steel structure with a rectangular cross section shape; and the sealing ring covers the outside of the framework. The sealing ring framework structure is simple and compact in structure, small in spatial size, high in strength, good in bearing sealing effect and good in revolving flexibility of the bearing.

Owner:LUOYANG VSG BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com