Manufacturing method of two-layer single-sided flexible copper clad laminate

A technology of flexible copper clad laminates and manufacturing methods, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., which can solve the problem of plate warping, affect the pass rate of FPC processing, reduce the breakdown voltage of PI film, etc. problems, to achieve the effect of increasing surface roughness, maintaining breakdown voltage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

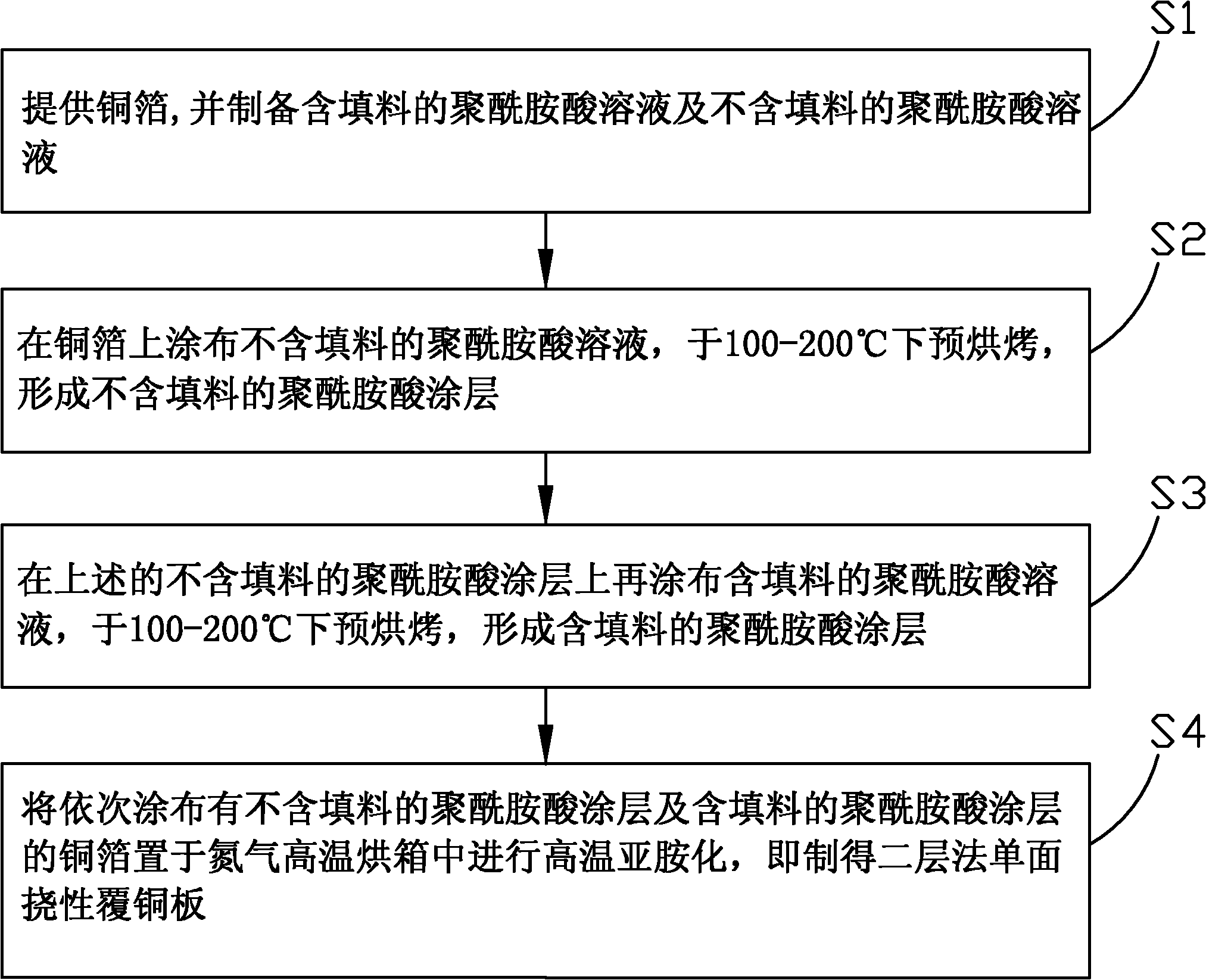

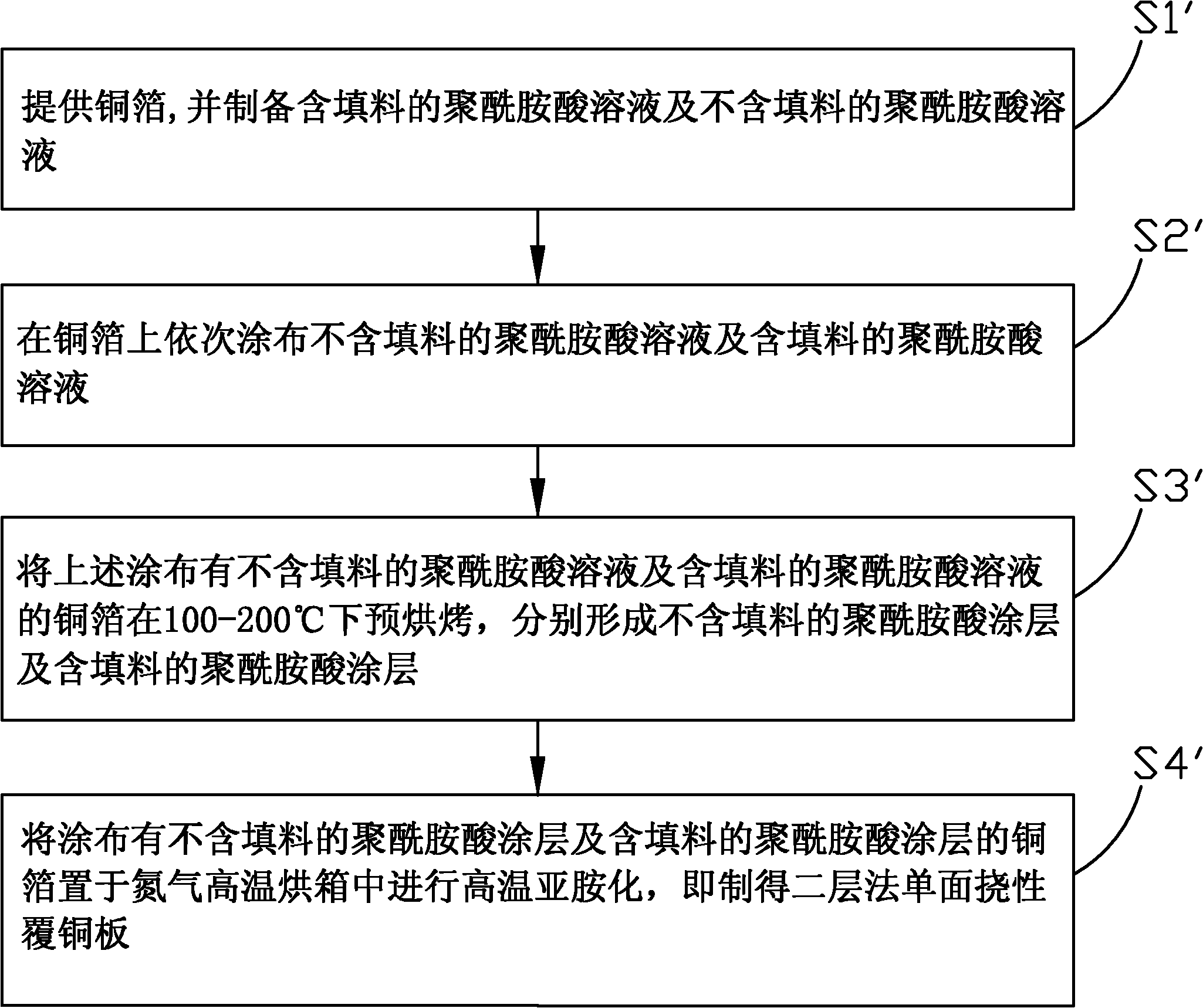

Method used

Image

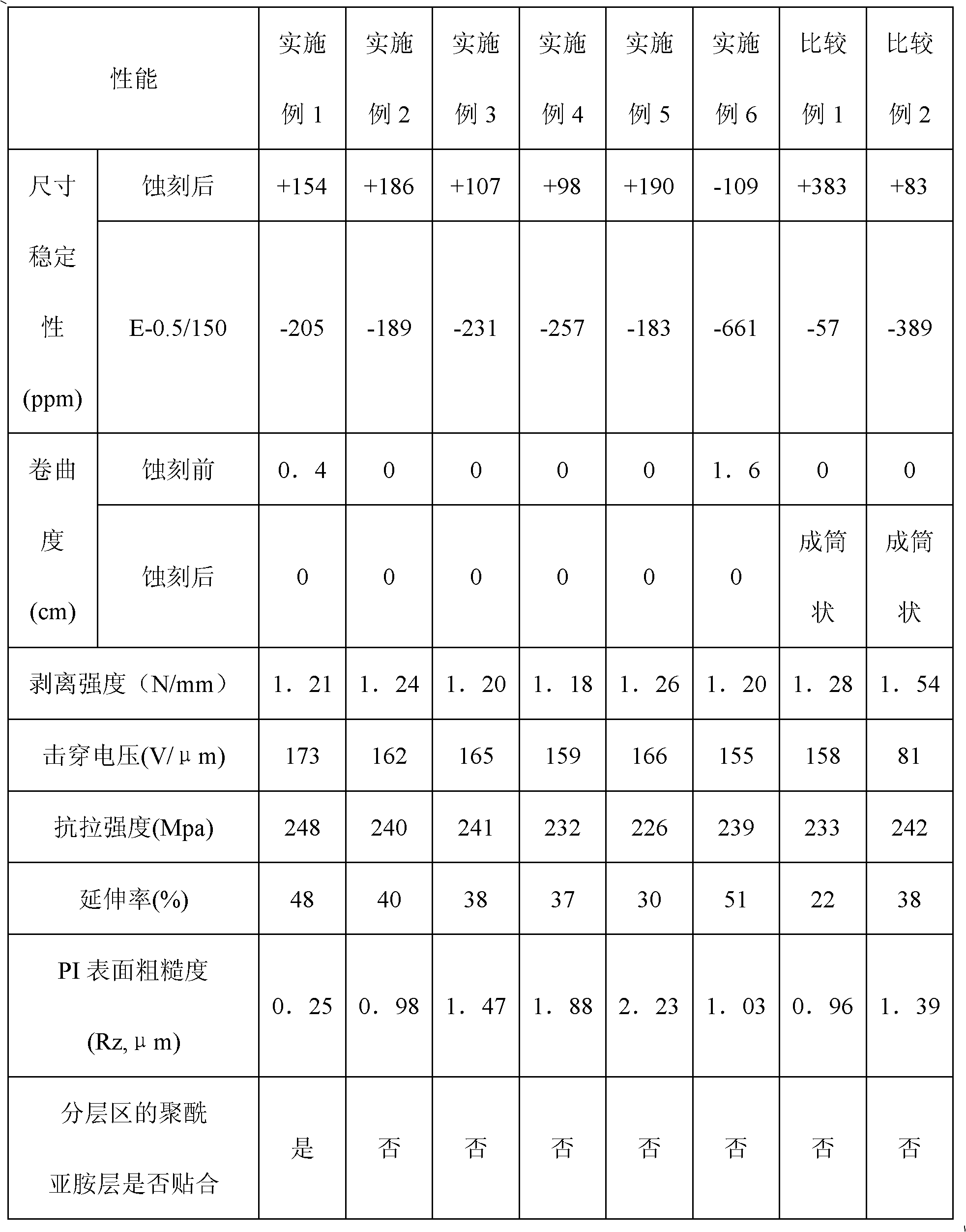

Examples

Synthetic example 1

[0054] Weigh 6.5058g of 4,4'-ODA and 16.0058g of PPDA, dissolve in a mixed solvent of 180g DMAc and 180gNMP while stirring in a 1000ml three-necked flask, then add 1.24 g of 2MZ-A, 34.3281 g of BPDA and 13.7034 g of PMDA were continuously stirred for 4 hours to perform a polymerization reaction to obtain a polyamic acid solution.

Synthetic example 2

[0056] Weigh 7.2287g of 4,4'-ODA and 15.6154g of PPDA, and add them into a 1000ml three-necked flask while stirring, and dissolve them in a mixed solvent of 180g DMAc and 180gNMP. While stirring, 52.4447g of BPDA was added, and the stirring was continued for 4 hours to carry out polymerization reaction to obtain a polyamic acid solution.

Synthetic example 3

[0058] Weigh 3.99g SiO2 2 , add in the mixed solvent of 180g NMP and 180gDMAC, disperse with ultrasonic wave for 5 minutes, then add this predispersed solution in the three-neck flask of 1000ml, weigh 7.2287g of 4,4'-ODA and 15.6154g of PPDA, In the case of a three-necked flask, after dissolving completely, add 52.4447g of BPDA under nitrogen gas and stirring, and continue to stir for 4 hours to carry out polymerization reaction to obtain SiO 2 5% polyamic acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com