Combined joist

A combined and keel technology, applied in the field of keels, can solve the problems that the floor cannot be disassembled and assembled repeatedly, the house structure is easily damaged, and the stress of the wooden floor is large, so as to achieve the effect of quick installation, improved installation quality, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

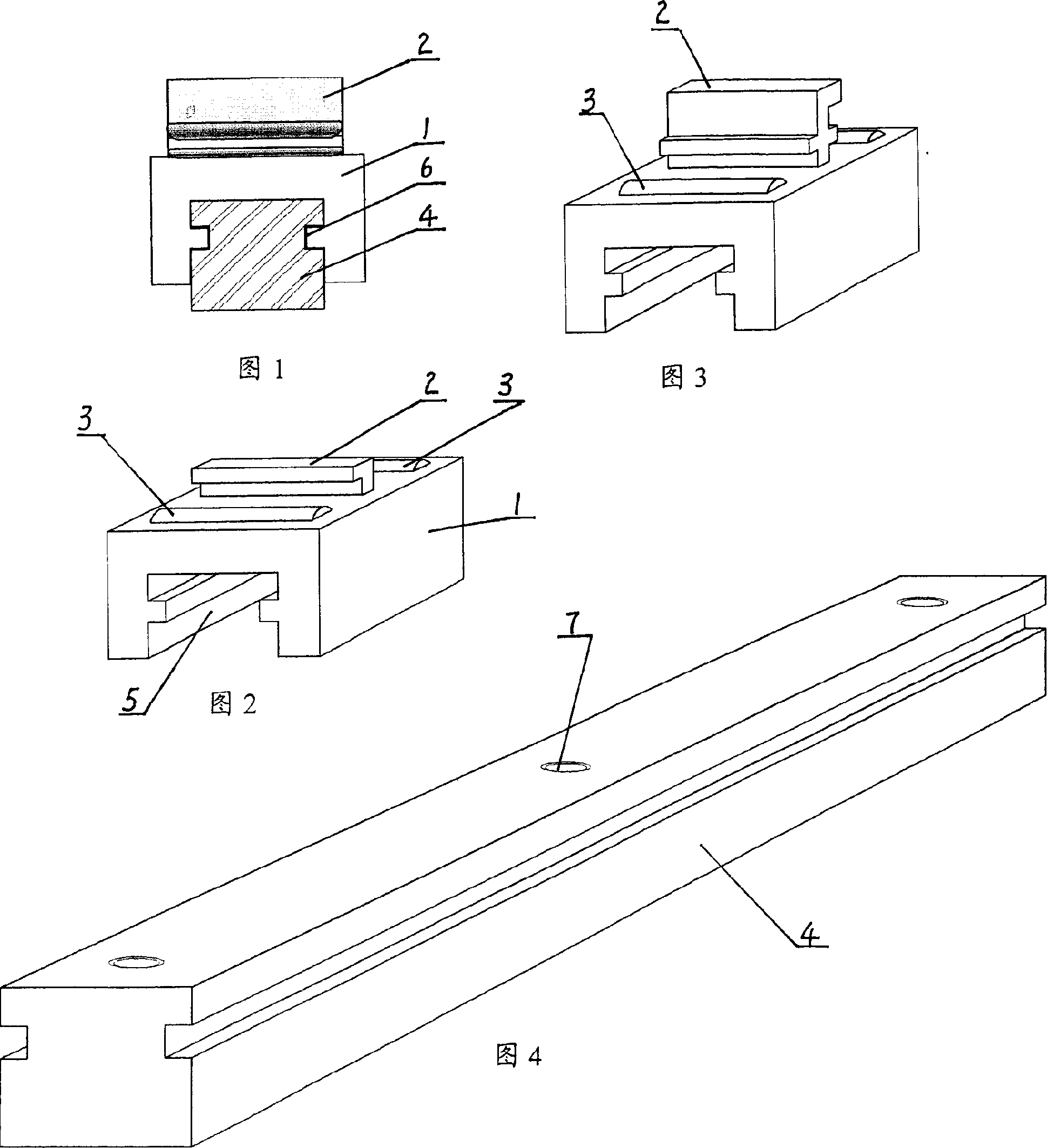

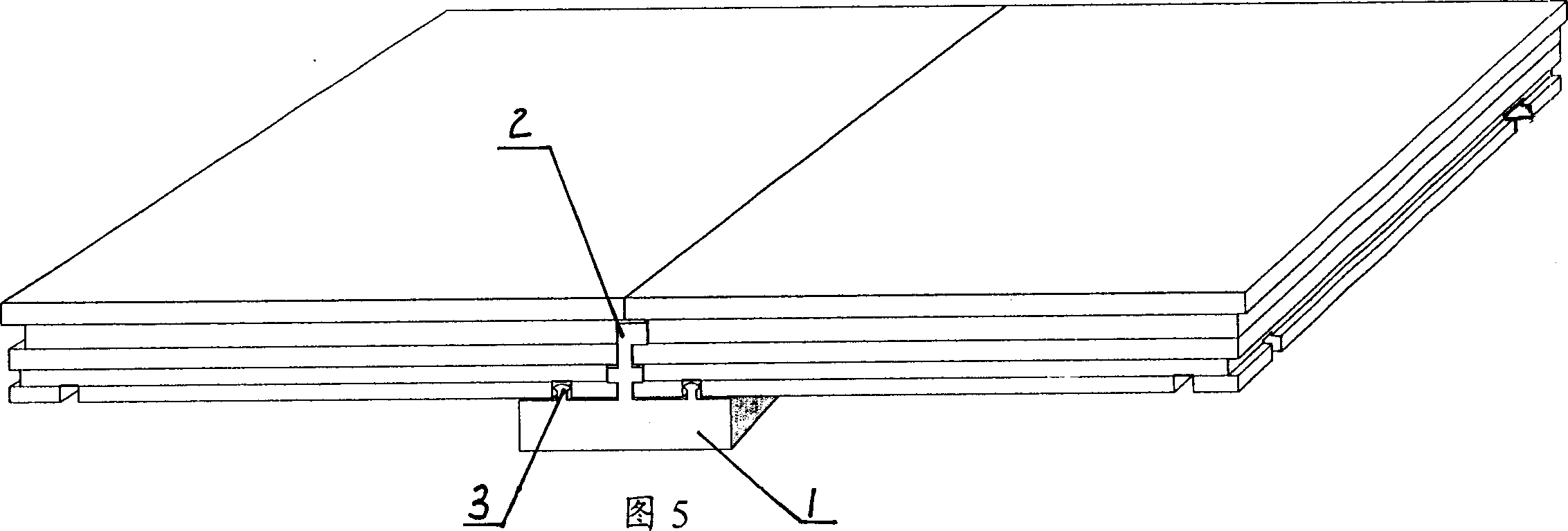

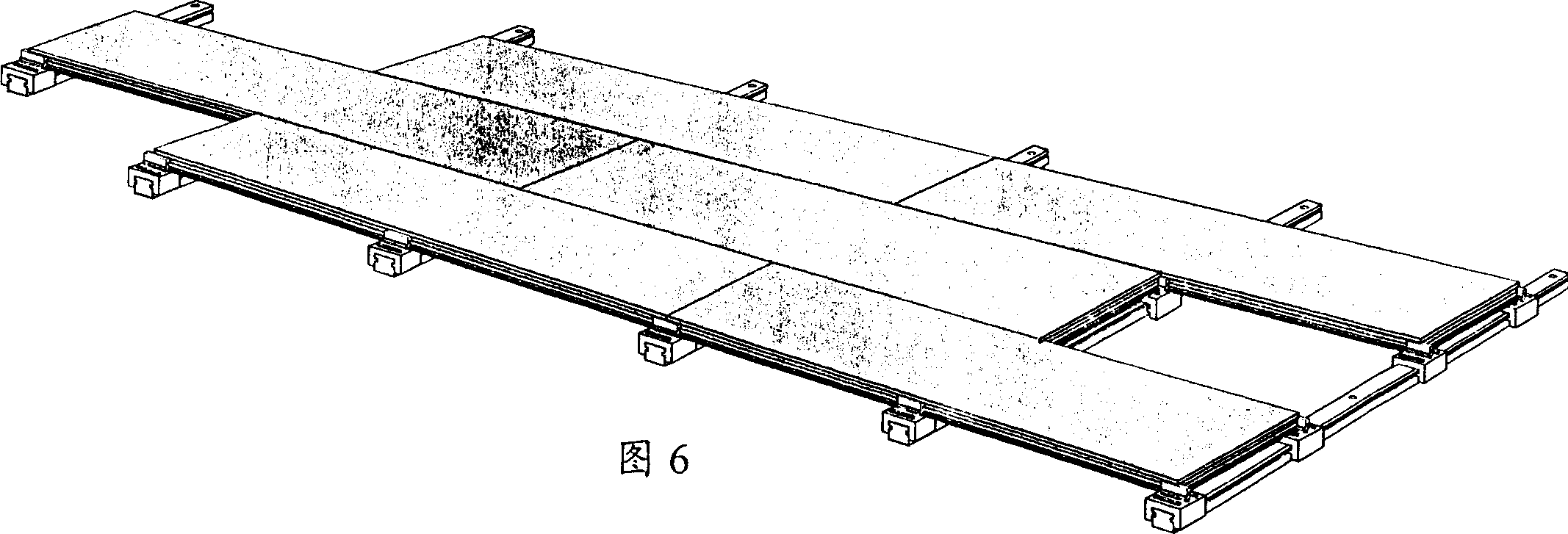

[0017] Refer to Figures 1 to 4. The present invention is composed of a strip keel 4 and a block keel 1, the block keel 1 is rectangular, and a cross section is T-shaped or Γ-shaped, or a combination of a T-shape and a T-shape is provided on one side of the block-shaped keel surface. Or the combination of T shape and Γ shape, or the strip main rib 2 of Γ shape and Γ shape combination, see Fig. 2, Fig. 3. On the surface of the block-shaped keel on both sides of the main rib 2, there is at least one on each side, and two or more auxiliary ribs 3 parallel to the main rib 2 can also be arranged. The cross-section of the auxiliary rib 3 can be T-shaped, Γ-shaped, rectangular, triangular, polygonal, etc., or a raised boss whose surface is arc-shaped.

[0018] On the back of the block keel 1, there is a groove 5 that can be matched with the strip keel 4, and between the two sides of the groove 5 and the sides of the strip keel 4 that match it, there are interfitting yin and yang groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com