Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of semiconductor wafer thickness thinning, mass production performance deterioration, etc., and achieve good conduction voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

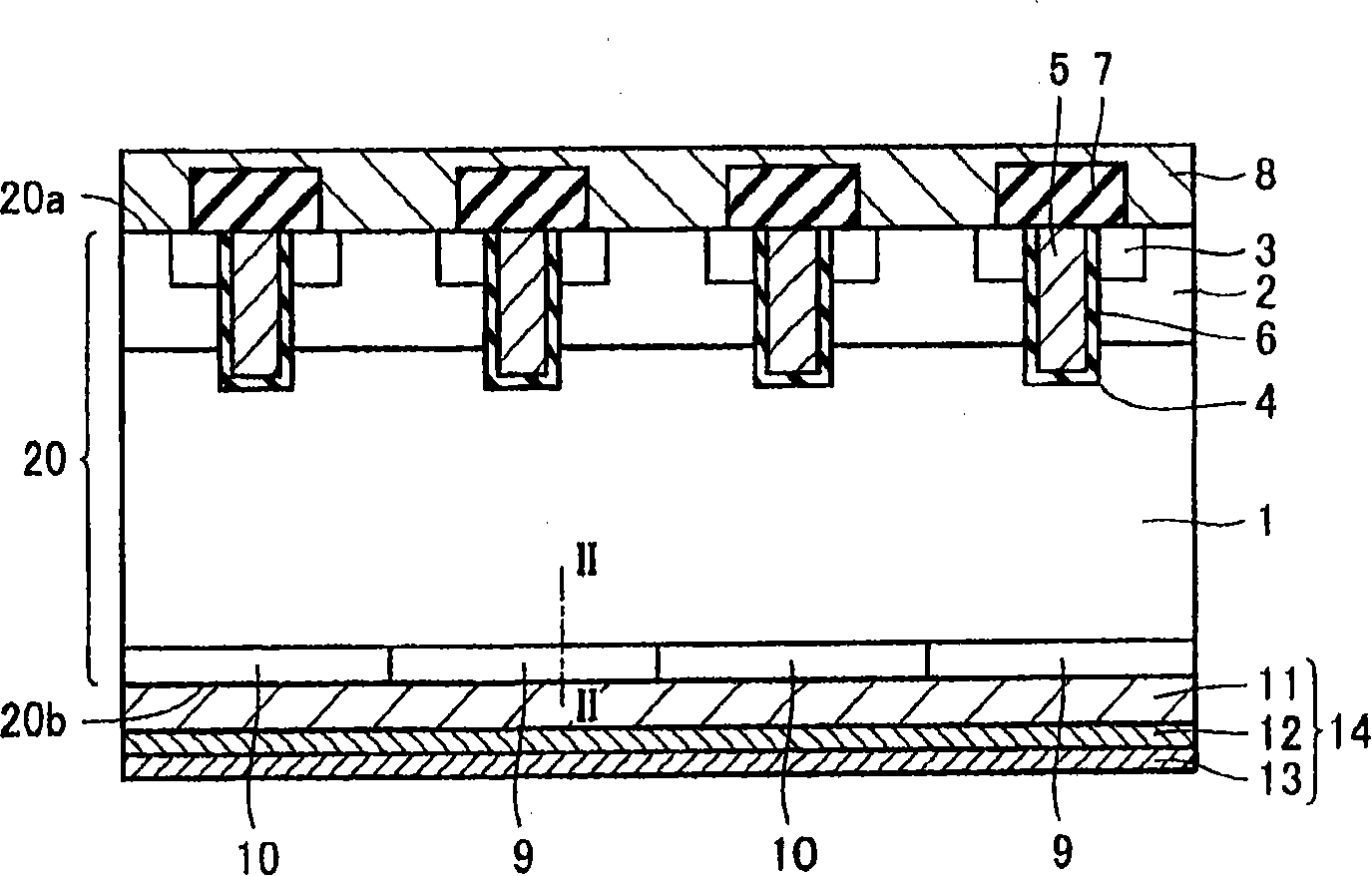

[0022] Embodiments of the present invention will be described below with reference to the drawings.

[0023] see figure 1 , the semiconductor device of the embodiment of the present invention has an IGBT and a freewheeling diode formed on a cell region of a semiconductor substrate 20 . The semiconductor substrate 20 is composed of, for example, silicon doped with n-type impurities, and has a first main surface 20 a and a second main surface 20 b facing each other. The thickness of the semiconductor substrate 20 is preferably less than 150 μm.

[0024] The IGBT mainly has a semiconductor substrate 20 n - Semiconductor layer 1, p-type base region 2, n + Emitter region 3 , trench gate 5 and p-type collector region 9 . On the unit area of the semiconductor substrate 20, in n - On the first main surface 20a side of the p-type semiconductor layer, a p-type base region 2 is selectively formed by diffusing p-type impurities. On the first main surface 20a in the p-type base reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com