Wear-resistant sliding plate surface and processing method

A board surface and skateboard technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem that the bottom is not reinforced, and achieves reduction of gluing processes, high efficiency, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

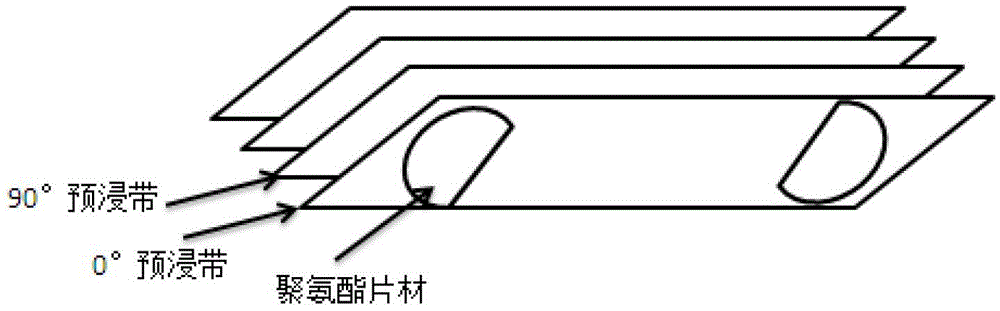

[0049] The skateboard surface is composed of a prepreg layer and a polyurethane layer. The prepreg layer is formed by laying 100 parts of unidirectional prepreg tape of glass fiber reinforced thermoplastic resin composite material. The polyurethane layer is 5 parts of sheet thermoplastic polyurethane. Its preparation method comprises the following steps:

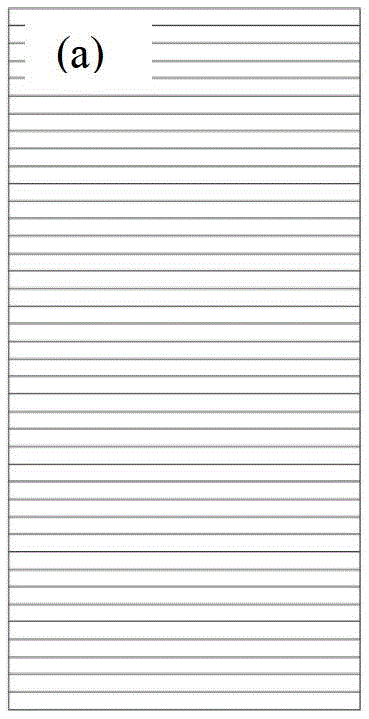

[0050] (1) Take glass fiber reinforced thermoplastic resin composite unidirectional prepreg tape, as shown in Figure 1, including 35 parts of polypropylene, 65 parts of glass fiber, and its density is 1.57g / cm 3 , the single layer thickness of the prepreg tape is 0.25mm;

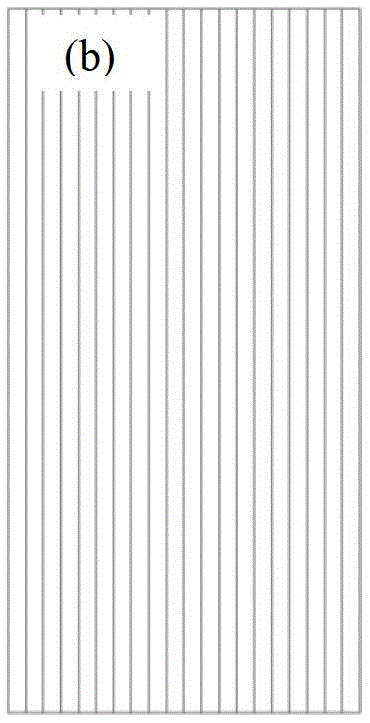

[0051] Take 15 layers of fabrics for laying, of which 1, 3, 5, 7, 9, 11, 13, and 15 layers are all in the direction of 0 degrees, and 2, 4, 6, 8, 10, 12, and 14 layers are laid The direction is 90 degrees, and the total thickness is 3.75mm, as shown in Figure 2(a) and 2(b);

[0052] (2) Take polyurethane material film, its content is 5 parts, its shape i...

Embodiment 2

[0057] The skateboard surface is composed of a prepreg layer and a polyurethane layer. The prepreg layer is formed by laminating 100 parts of glass fiber reinforced thermoplastic resin composite material unidirectional prepreg tape. The polyurethane layer is 7 parts of sheet thermoplastic polyurethane. Its preparation method comprises the following steps:

[0058] (1) Take glass fiber reinforced thermoplastic resin composite unidirectional prepreg tape, as shown in Figure 1, including 40 parts of polylactic acid and 60 parts of glass fiber, and its density is 1.54g / cm 3 , the single layer thickness of the prepreg tape is 0.4mm;

[0059] Take 17 layers of fabrics for laying, of which 1, 3, 5, 7, 9, 11, 13, 15, and 17 layers are all in the direction of 0 degrees, 2, 4, 6, 8, 10, 12, 14, 16 The laying direction is 90 degrees, and the total thickness is 6.8mm, as shown in Figure 2(a) and 2(b);

[0060] (2) Take the polyurethane material film, the content is 7 parts, the shape is...

Embodiment 3

[0065] The skateboard surface is composed of a prepreg layer and a polyurethane layer. The prepreg layer is formed by laying 100 parts of glass fiber reinforced thermoplastic resin composite material unidirectional prepreg tape. The polyurethane layer is 8 parts of sheet thermoplastic polyurethane. Its preparation method comprises the following steps:

[0066] (1) Take glass fiber reinforced thermoplastic resin composite unidirectional prepreg tape, as shown in Figure 1, in which polyethylene is 45 parts, glass fiber is 55 parts, and its density is 1.41g / cm 3 , the single layer thickness of the prepreg tape is 0.3mm;

[0067] Take 19 layers of fabrics for laying, of which 1, 3, 5, 7, 9, 11, 13, 15, 17, and 19 layers are all in the direction of 0 degrees, 2, 4, 6, 8, 10, 12, 14, 16, 18 are laid in a 90-degree direction with a total thickness of 5.7mm, as shown in Figures 2(a) and 2(b);

[0068] (2) Take the polyurethane material film, its content is 8 parts, its shape is a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com