Workpiece turnover unit, vacuum film-forming device and workpiece assembly unit

A technology for assembling units and workpieces, applied in vacuum evaporation plating, metal material coating technology, ion implantation plating, etc., can solve problems such as workpiece warpage, increased burden of space cost, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

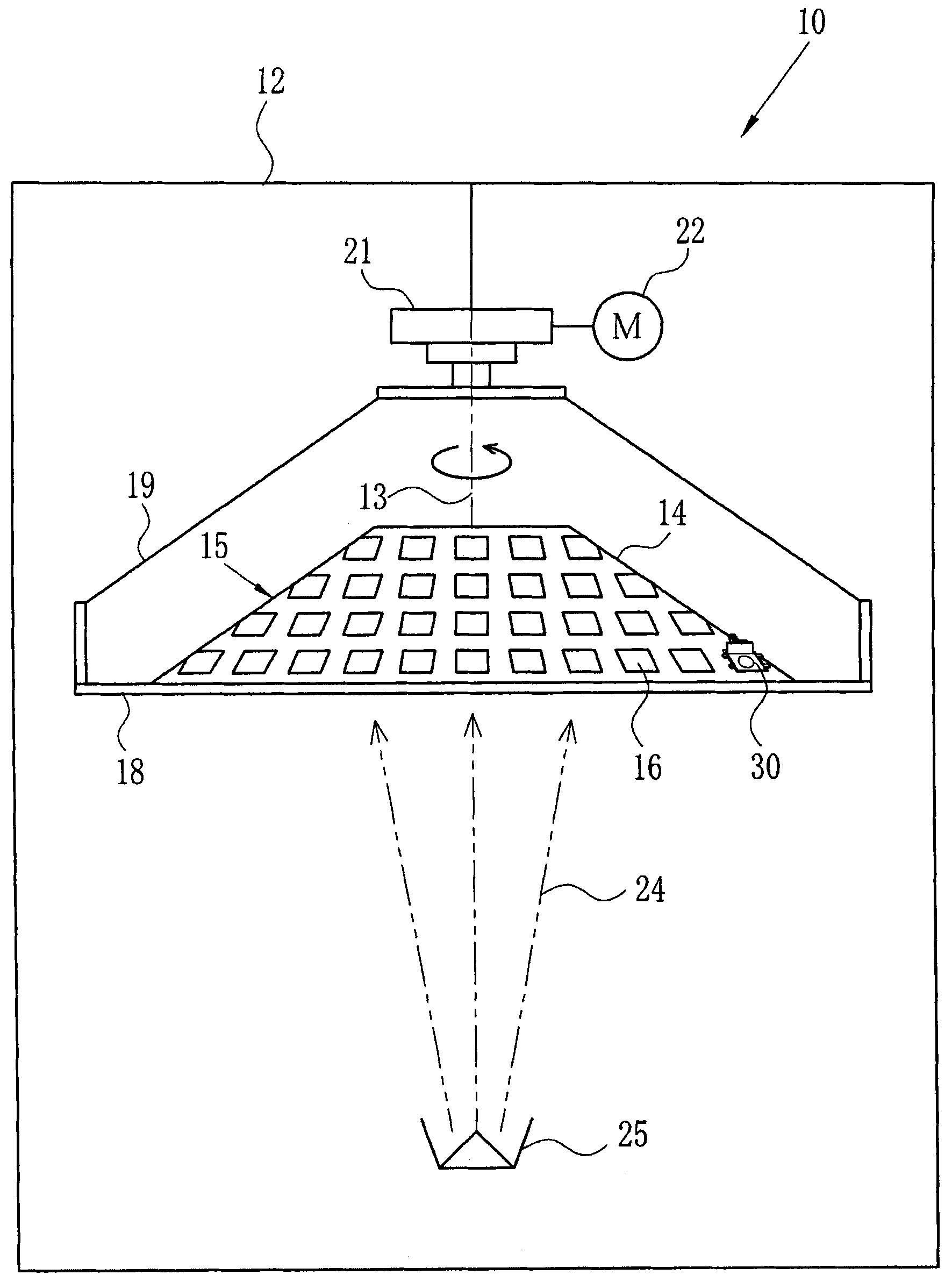

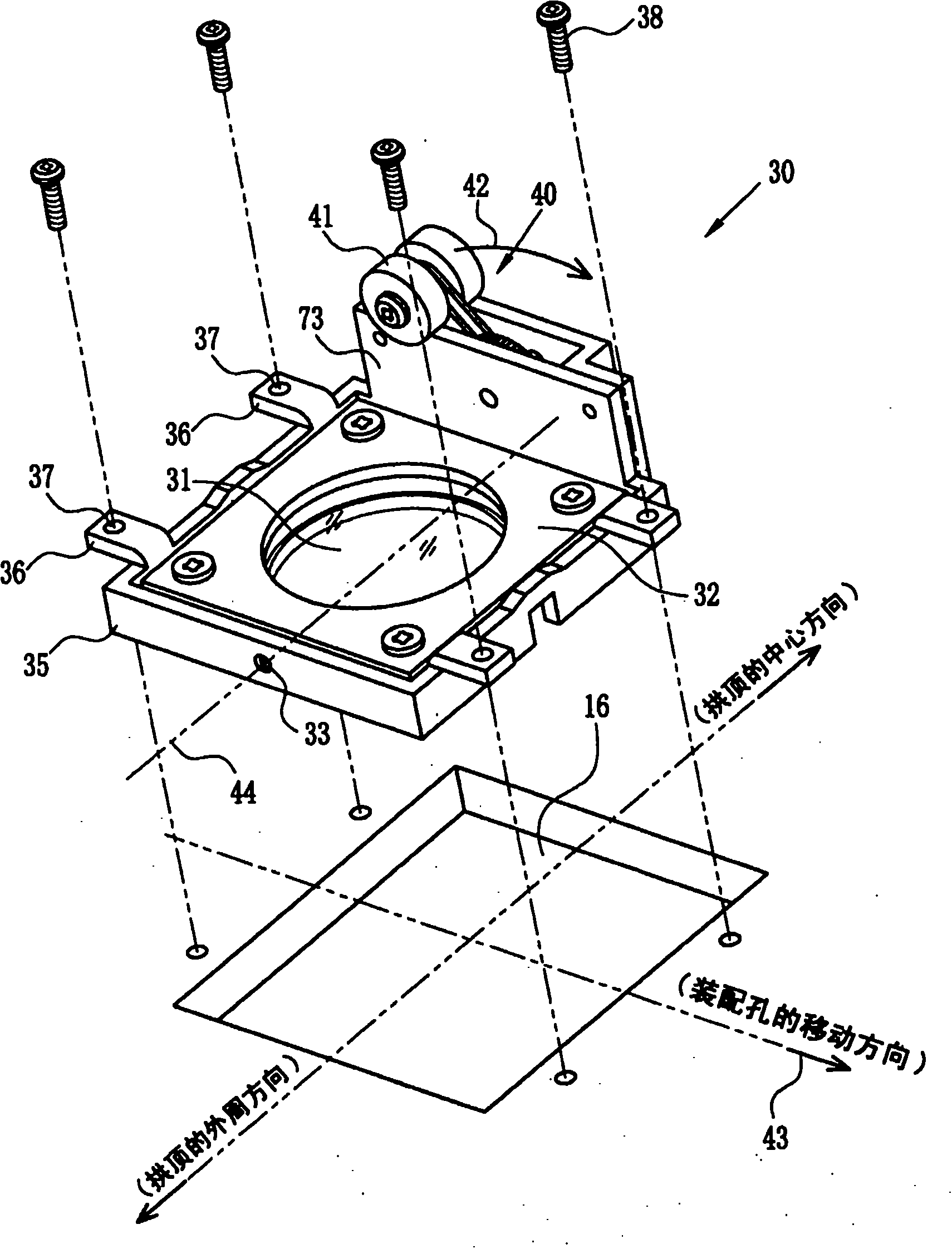

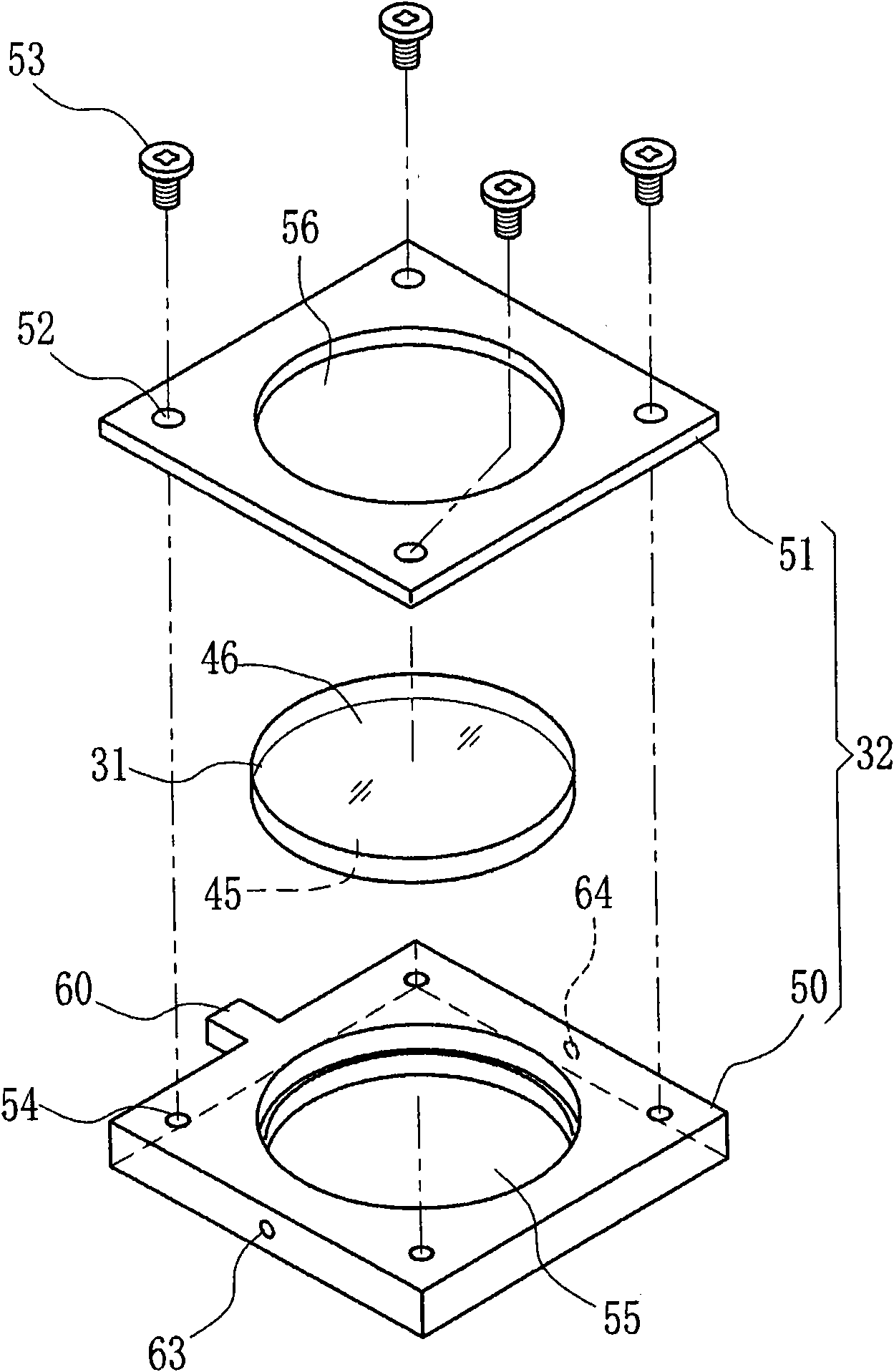

[0074] Such as figure 1 As shown, in the vacuum film forming apparatus 10, a dome (work holding plate) 15 having an umbrella-shaped inclined surface 14 that rotates around the axis of a vertical axis 13 is provided in a chamber (vacuum chamber) 12 whose interior is evacuated. A plurality of fitting holes (fitting portions) 16 for fitting the workpiece inverting unit 30 of the present invention are formed along the inclination (for example, 35°) of the inclined surface 14 . The dome 15 is fixed to a mounting ring 18 and is rotatably suspended from the ceiling of the chamber 12 by three support arms 19 . The three support arms 19 can be rapidly accelerated and decelerated while being rotated at a constant speed by a reduction gear unit (speed change mechanism) 21 and a motor 22 . The reduction gear unit 21 has a braking device (not shown). A film-forming substance generating source 25 for scattering a film-forming substance 24 is arranged at a lower position of the dome 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com