Lead-free printed circuit board copper surface protecting agent and preparation method thereof

A technology for printed circuit boards and protective agents, applied in the direction of metal material coating process, can solve the problems of abnormal electroplating parameters, high cost, difficult to control, etc., to achieve uniform and flat film formation without brittleness, less equipment investment, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

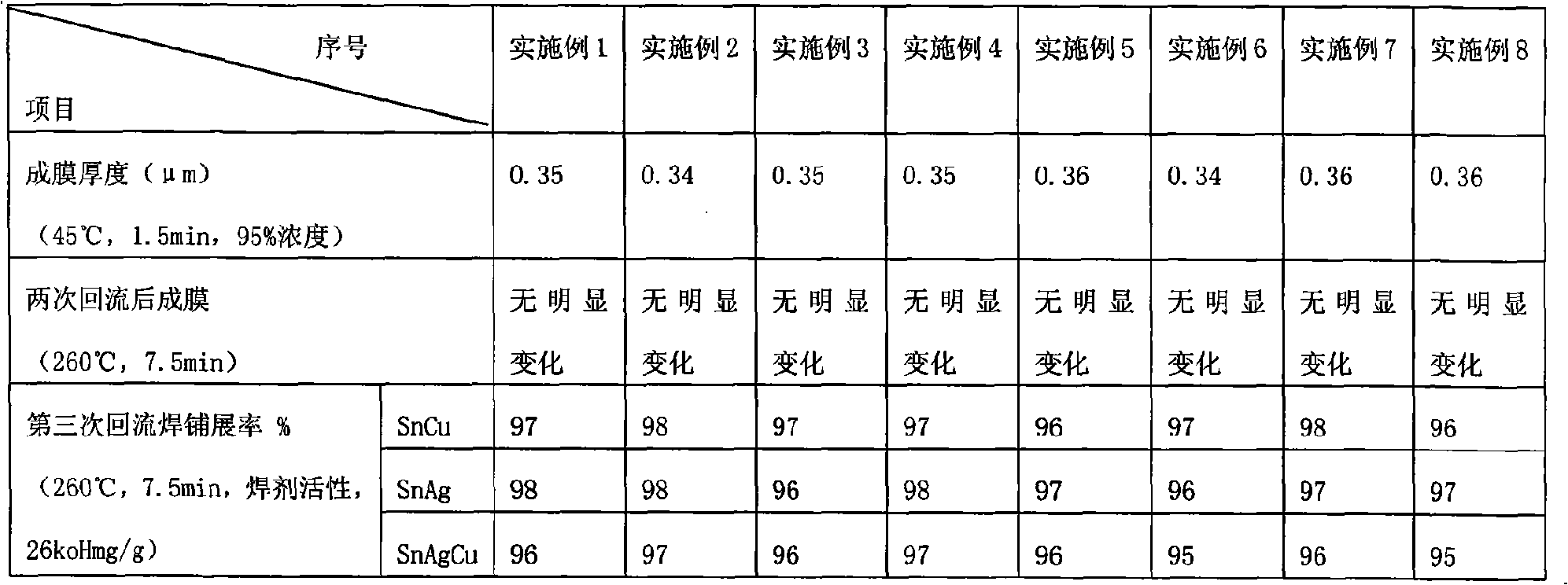

Embodiment 1

[0029] Raw material (Kg): formic acid 1.2, glycolic acid 0.8, copper acetate 0.2, 2-hexyl benzimidazole 0.5, C 12 Fatty alcohol polyoxyethylene (9) ether 0.01, deionized water 97.29.

[0030] The preparation method is as follows:

[0031] 1) Weigh the raw materials according to the above-mentioned protective agent for the copper surface of a lead-free printed circuit board, dissolve the organic acid in deionized water, and stir it to make it all dissolve uniformly to obtain solution A;

[0032] 2) Add the weighed metal salt to solution A and stir until all is dissolved to obtain solution B;

[0033] 3) Add the weighed imidazole compound to solution B and stir until all is dissolved to obtain solution C;

[0034] 4) Add non-ionic surfactant to solution C, stir evenly, and the resulting solution is the protective agent

Embodiment 2

[0036] Raw material (Kg): acetic acid 0.5, propionic acid 8, copper chloride 0.1, zinc acetate 0.6, 2-pentyl benzimidazole 0.3, 2-heptyl benzimidazole 0.4, C 12 Fatty alcohol polyoxyethylene 8 ether 0.08, deionized water 89.3

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] Raw material (Kg) formic acid 5, copper nitrate 0.6, 2-heptylbenzimidazole 0.8, C 12 Fatty alcohol polyoxyethylene (7) ether 0.05, deionized water 92.55

[0040] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com