Steel plate cutting device and steel plate cutting method

A technology for cutting devices and steel plates, which is applied in the direction of shearing devices, devices for cutting by nibbling, and accessory devices for shearing machines, etc. The length is difficult to control and other problems, to achieve the effect of preventing damage, convenient and accurate length control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

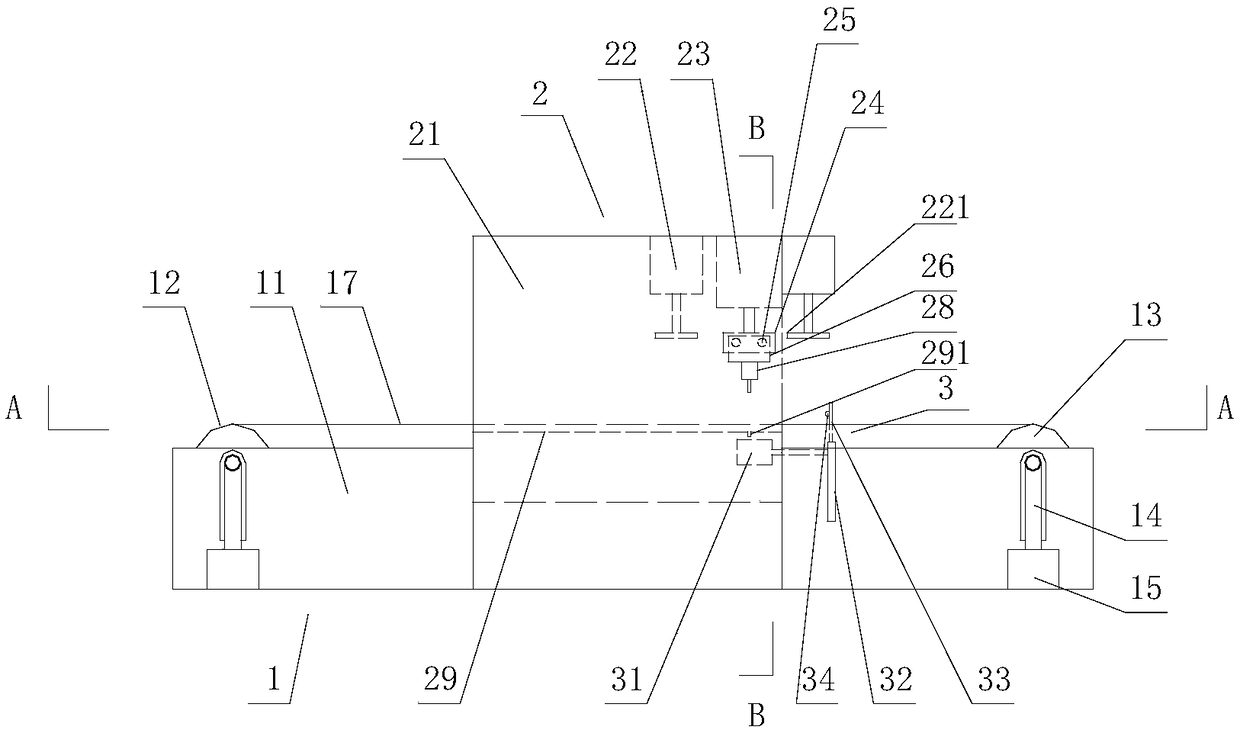

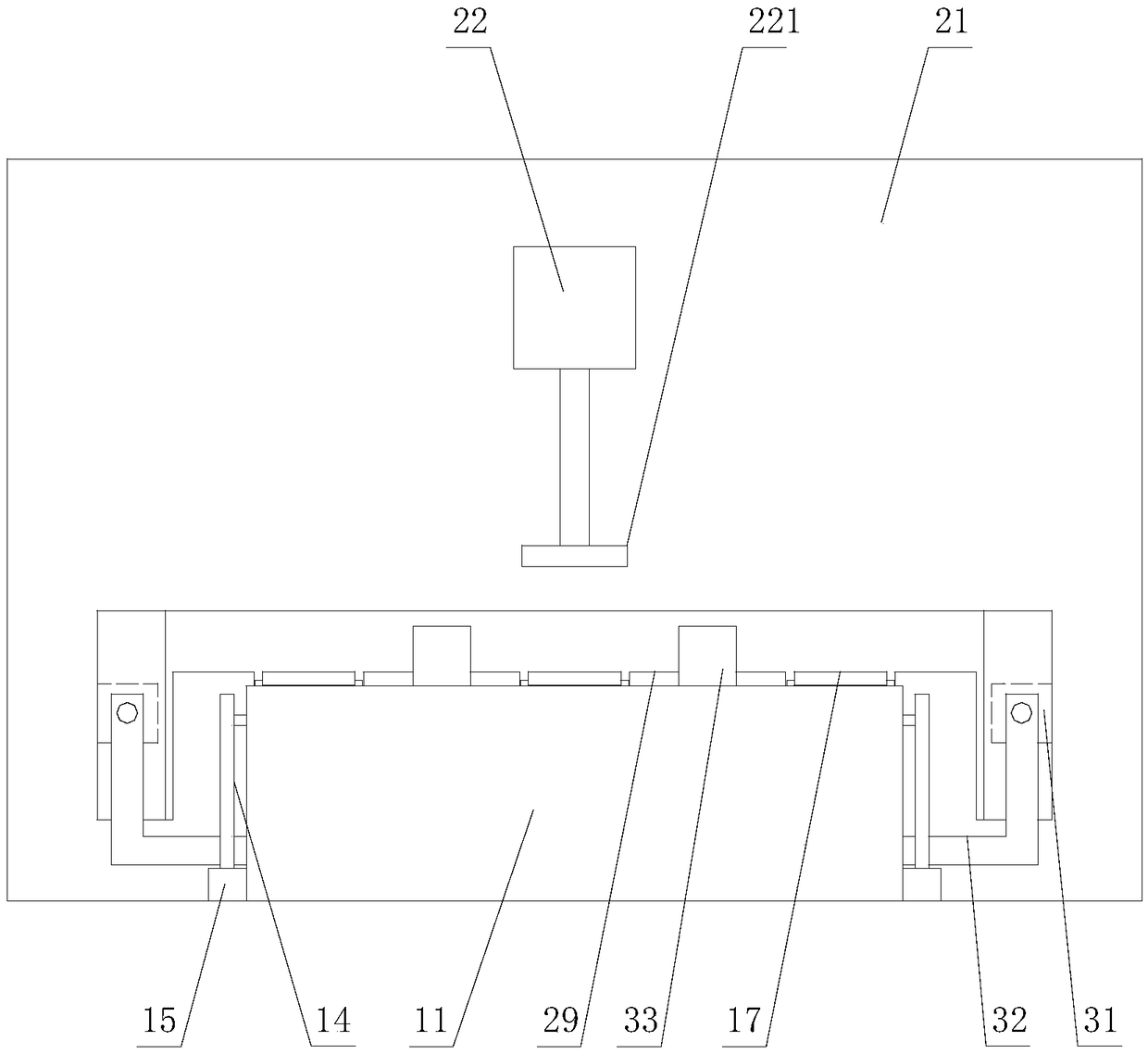

[0030] combined with Figure 1~2 As shown, a steel plate cutting device involved in the present invention includes a steel plate transport mechanism 1 , a steel plate cutting mechanism 2 and a length control mechanism 3 .

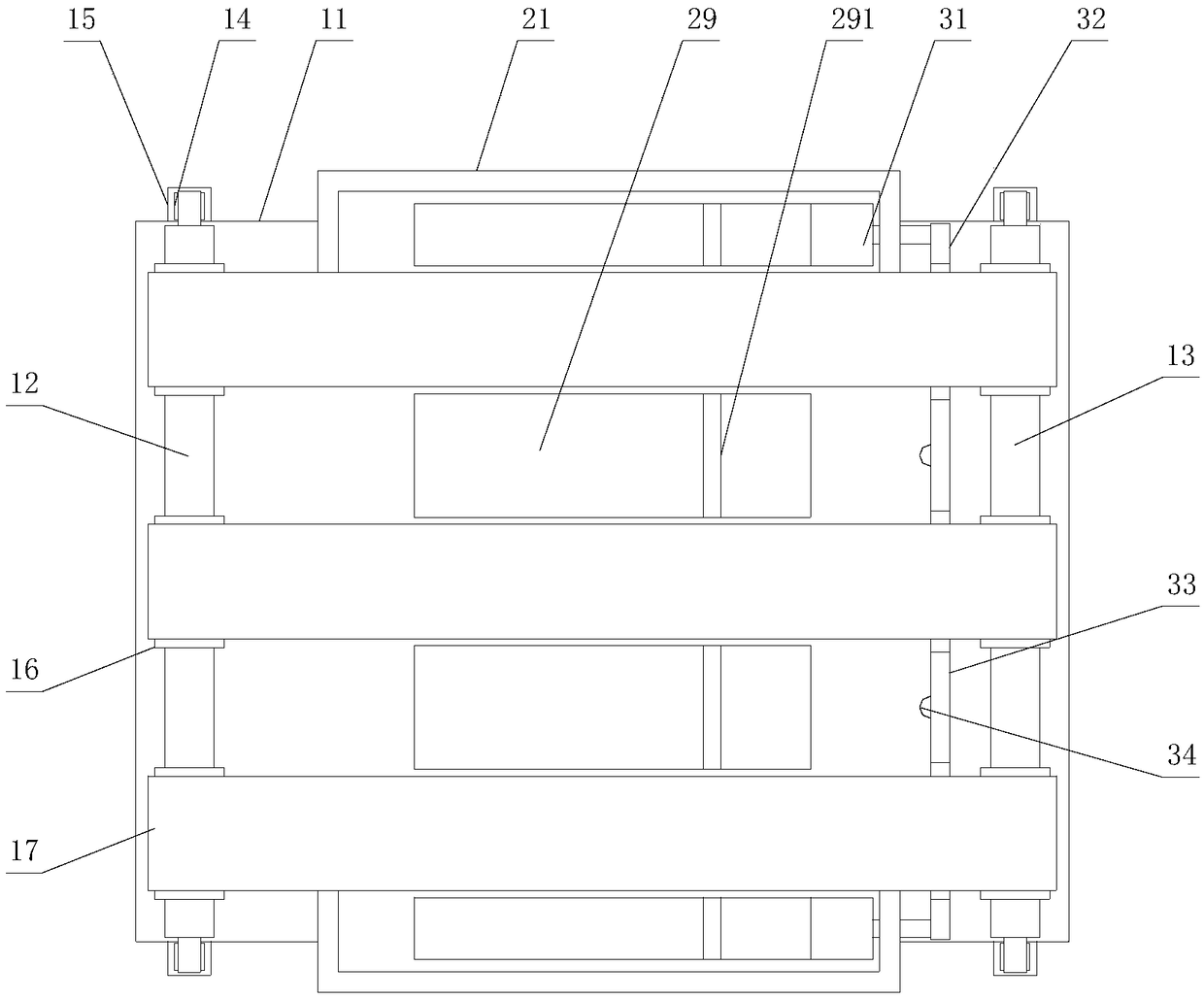

[0031] combined with image 3 As shown, the steel plate transportation mechanism includes a transport frame 11, the left and right ends of the transport frame 11 are respectively provided with a driving wheel 12 and a driven wheel 13, and the driving wheel 12 adopts an electric stick wheel to provide kinetic energy for the transportation of the steel plate. The rotating shaft of wheel 12 and driven wheel 13 all passes through the front and back sides of transport frame 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com