AGV carrying trolley and carrying method thereof

A technology for carrying trolleys and trolleys. It is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc. It can solve the problems of difficult transportation, large volume and weight, etc., and achieve the effect of realizing full automation, realizing automation, and improving the transit transportation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

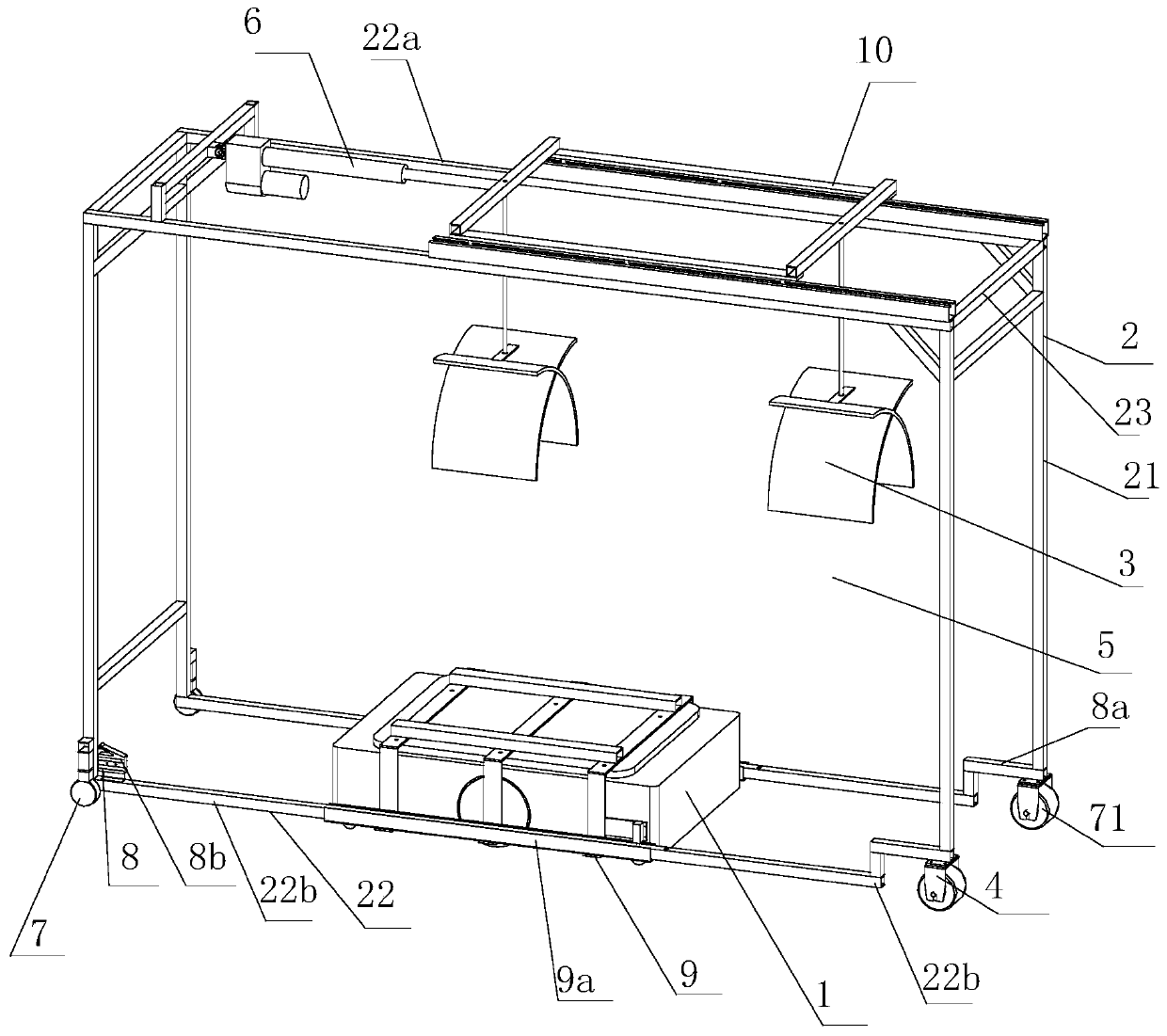

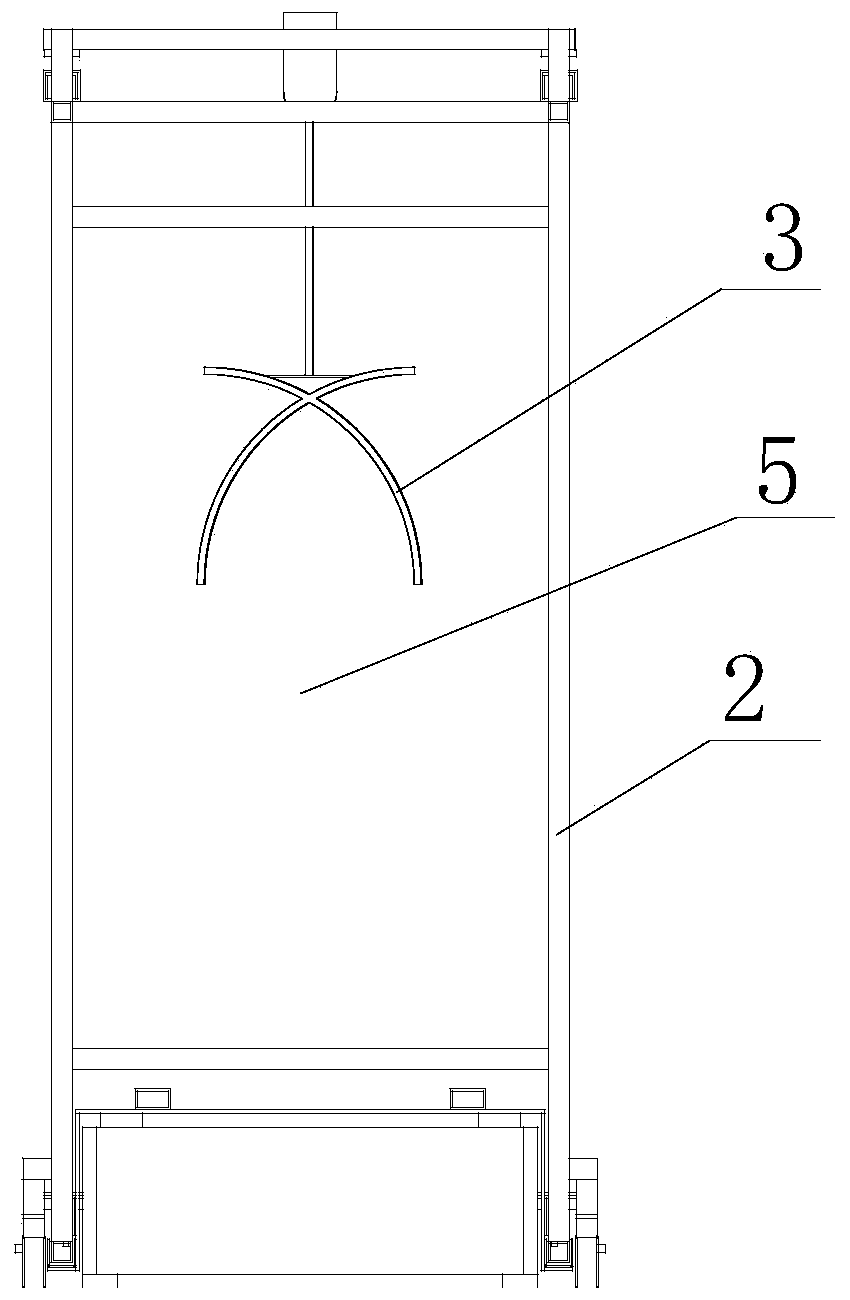

[0036] Such as figure 1 , figure 2 As shown, the AGV carrying trolley in this embodiment includes an AGV trolley 1, a tooling 2 installed on the AGV trolley, and a clamp 3 installed on the tooling. The tooling 2 can move with the AGV trolley 1 and can move horizontally relative to the AGV trolley 1 under the action of the first power unit 4, and the clamp 3 can move vertically under the action of the second power unit. Move horizontally under the effect of the third power unit 6 . The tooling 2 is a frame structure and a space 5 for accommodating the materials is formed in the tooling.

[0037] As a specific embodiment, the tooling 2 is a square frame structure, with four upright columns 21, four horizontal columns 22 and several beams 23, the side of the tooling 2 is square or trapezoidal with the bottom big and the top small, and the horizontal columns 22 is divided into an upper horizontal column 22a and a lower horizontal column 22b; two sets of traveling wheels 7 are ...

Embodiment 2

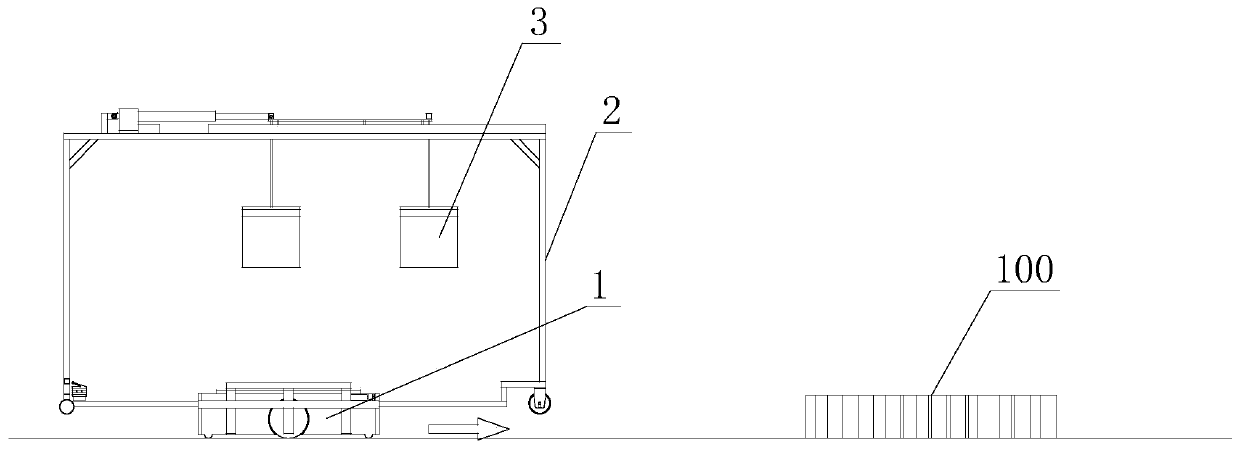

[0044] Such as Figure 3a to Figure 3f As shown, the present embodiment provides a carrying method using the aforementioned AGV carrying trolley, including the following steps:

[0045] S1: The AGV trolley loads the tooling, the jacking device is turned on, the tooling is raised, the AGV trolley loading tooling moves to the material to be transported, the jacking device is reset, and the tooling is lowered;

[0046] S2: The first power device 4 acts, and the tooling moves towards the material to be transported until the material is completely accommodated in the tooling;

[0047] S3: The second power device operates, the clamp 3 descends to the material, the clamp 3 opens, clamps the material, the clamp 3 closes, the second power device reverses, and the clamp 3 holding the material rises;

[0048] S4: The first power unit 4 acts in reverse, and the tooling moves toward the AGV trolley until the material is directly above the AGV trolley;

[0049] S5: The second power device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com