Automatic flow automatic fault indicator assembly line detection system and method

A fault indicator and detection system technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of insufficient testing personnel, unbalanced management of testing information, low testing accuracy, etc., and achieve the goal of improving development quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

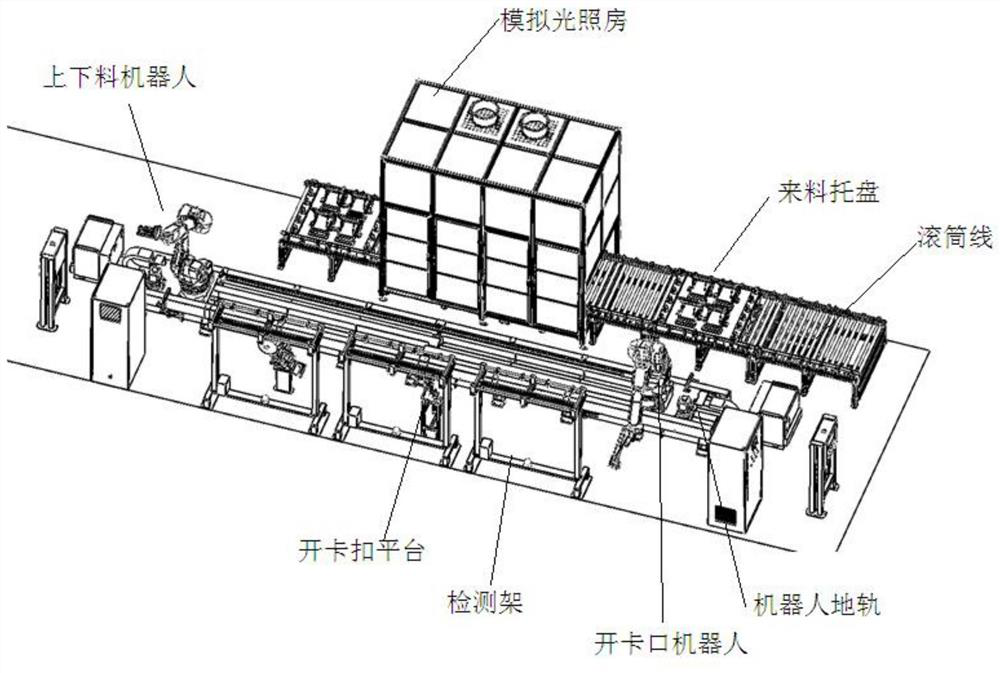

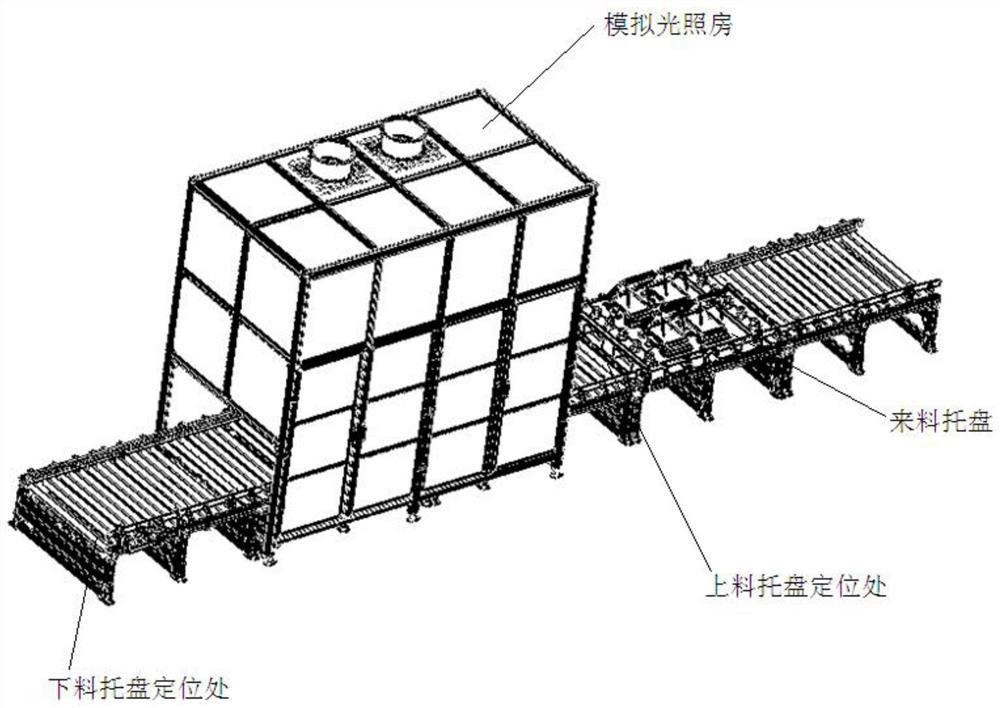

[0059] The invention discloses a fully automatic fault indicator assembly line detection system with automatic circulation, comprising:

[0060] Fault indicator detection pipeline: used to realize the automatic detection of fault indicator acquisition unit and collection unit;

[0061] Intelligent storage system: used to realize automatic storage, transportation and control of fault indicators;

[0062] Detection information comprehensive management and control system: used to realize the monitoring of the fault indicator detection process, storage, analysis and display of detection data.

[0063] The fault indicator detection pipeline includes: a fault indicator acquisition unit detection pipeline body and a fault indicator collection unit detection pipeline body;

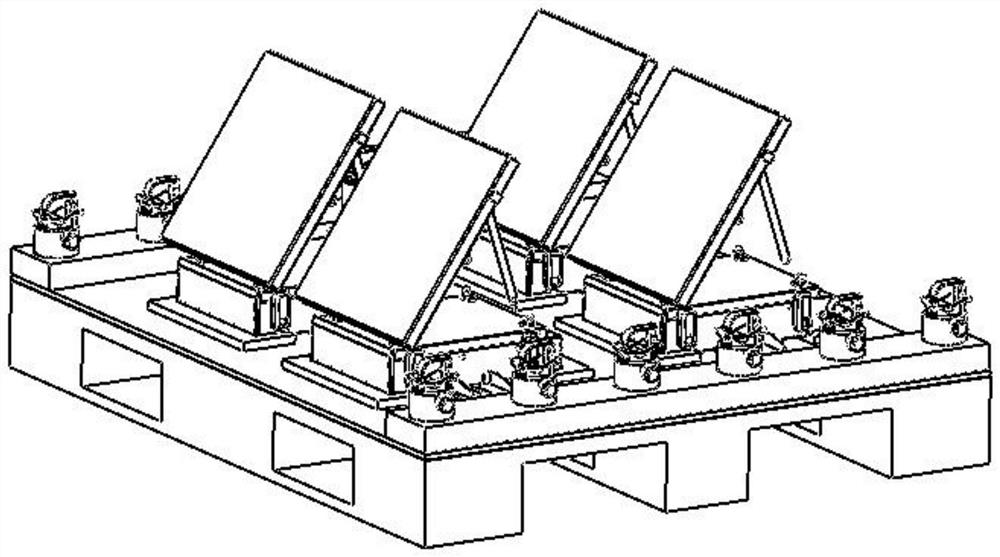

[0064] The fault indicator acquisition unit detects the pipeline body such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com