Fault indicator intelligent automatic assembly line system and method

A fault indicator and assembly line technology, applied in fault location, fault detection according to conductor type, instrument, etc., can solve problems such as shortage of detection personnel, low detection accuracy, lack of manual detection ability, etc., to improve development quality and efficiency benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

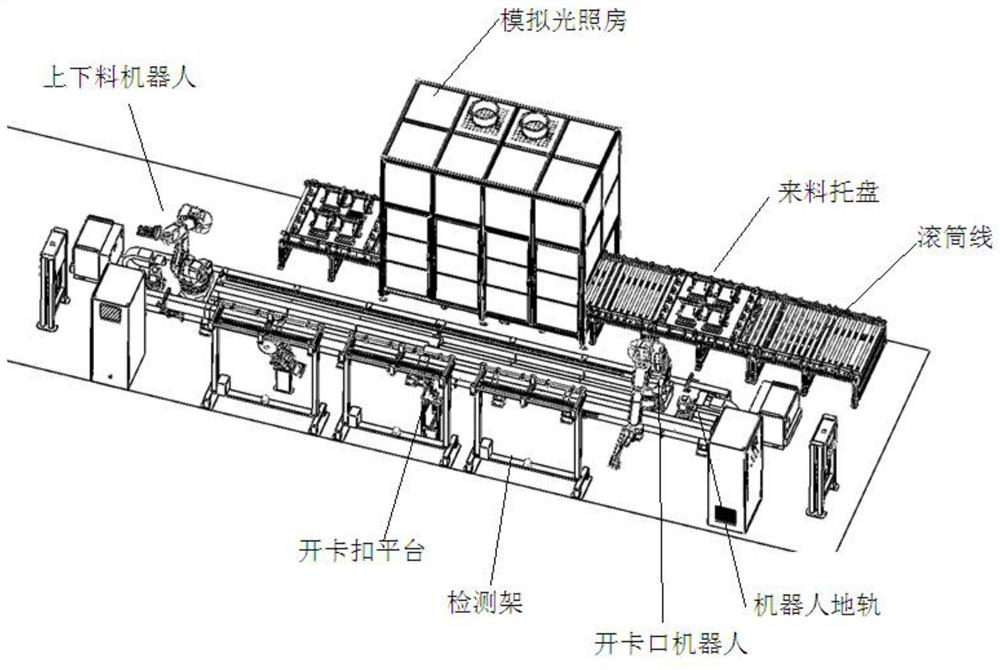

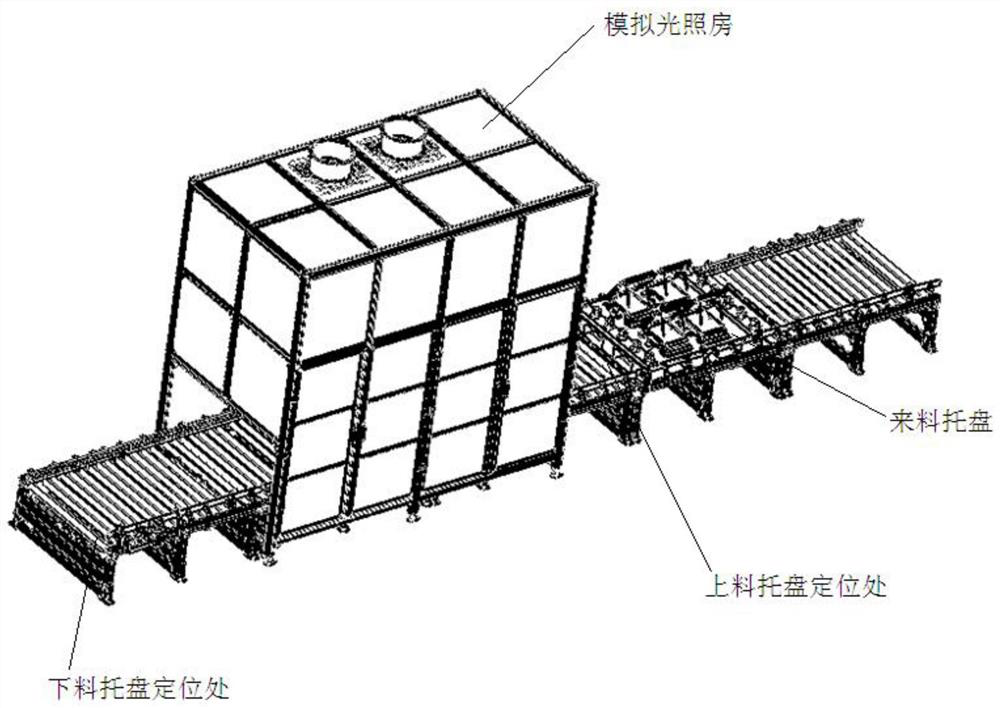

[0048]The invention discloses an intelligent full-automatic assembly line system for a fault indicator, such as figure 1 As shown, it includes: the fault indicator collection unit detection pipeline body, the fault indicator collection unit detection pipeline body, the loading robot and the unloading robot for transporting the collection unit into and out of the fault indicator collection unit detection pipeline body respectively And an unclip robot for unclipping the acquisition unit.

[0049] The implementation of the invention can realize the simultaneous detection of multiple sets of fault indicators and improve the work efficiency.

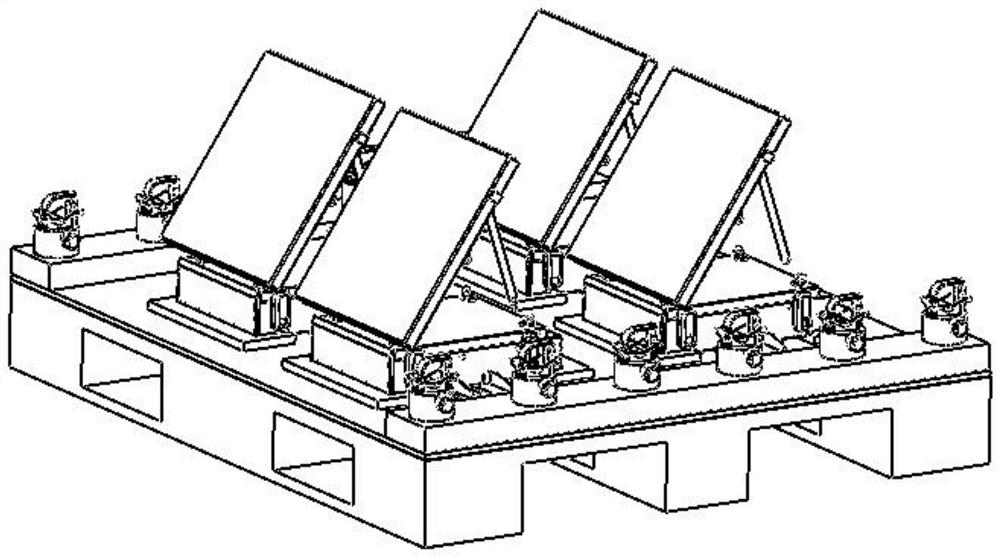

[0050] The fault indicator is composed of two parts: a collection unit and a collection unit. Therefore, the incoming material tray is set, and multiple sets of fault indicators can be placed on the incoming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com