Material taking device of full-automatic sewn-in label machine

A material retrieving device and washing label technology, which is applied in the direction of thin material handling, transportation and packaging, and object separation, can solve the problems of unfavorable production and transportation, high time cost and high cost, so as to shorten the time for replacing washing labels and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

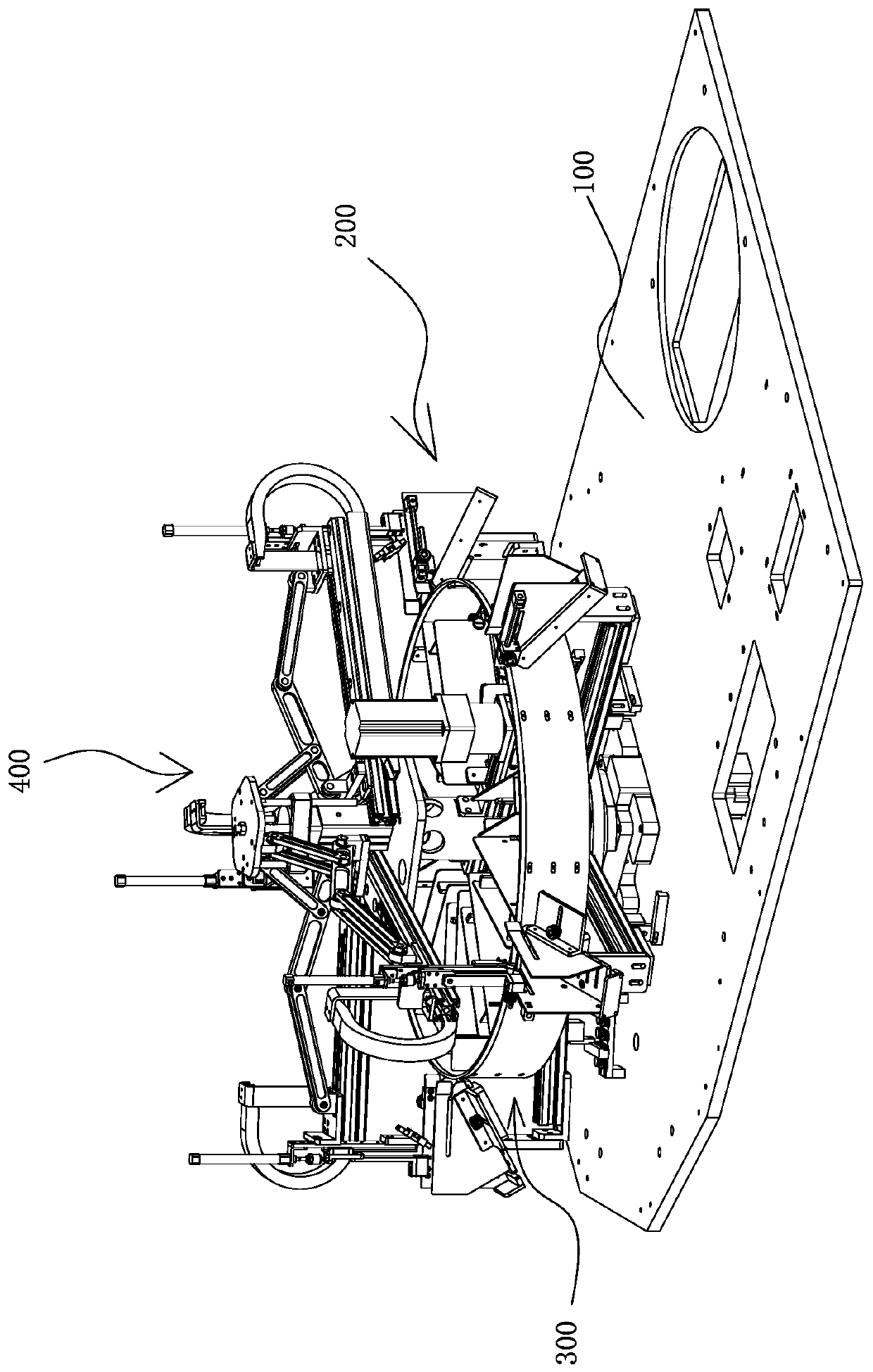

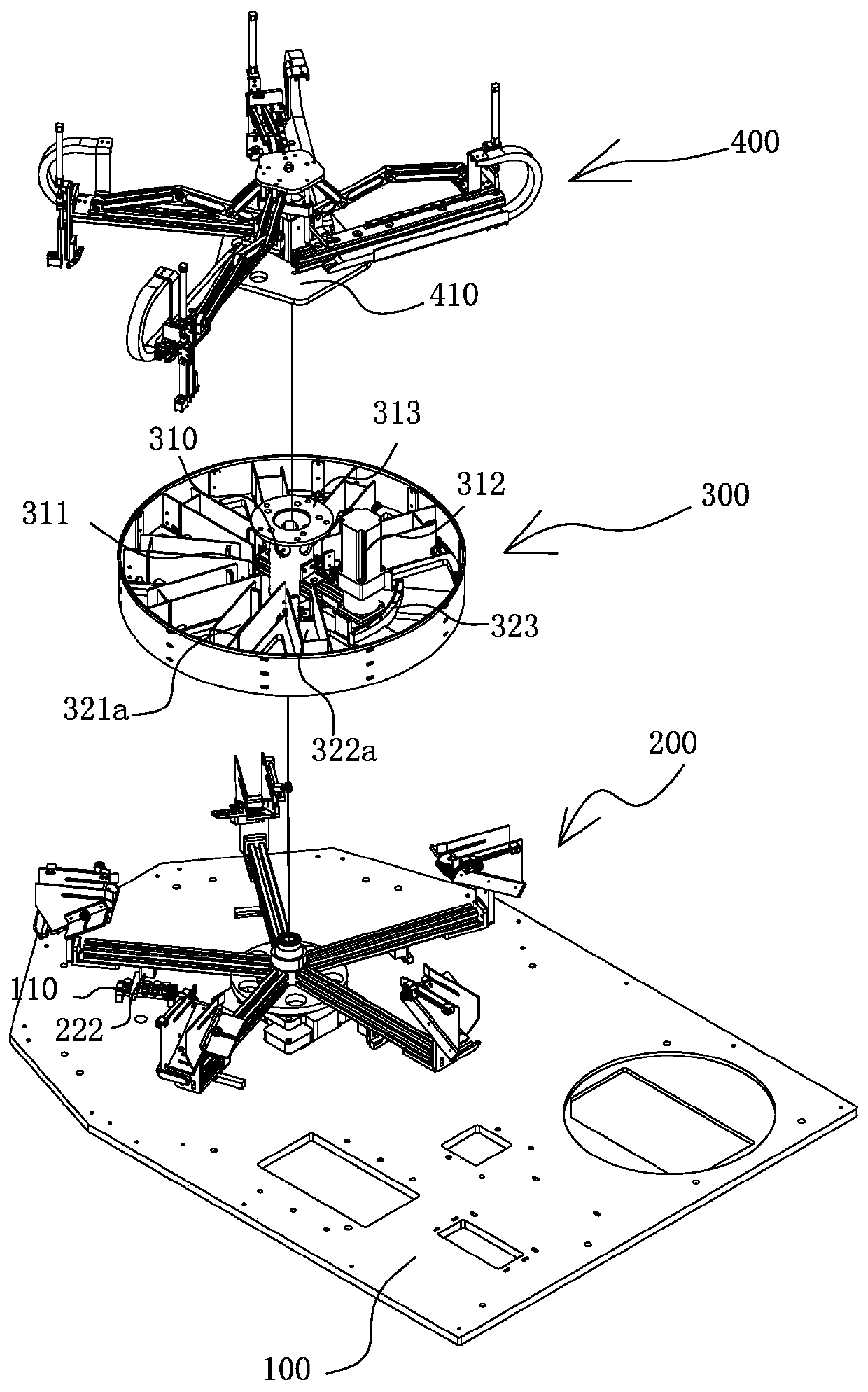

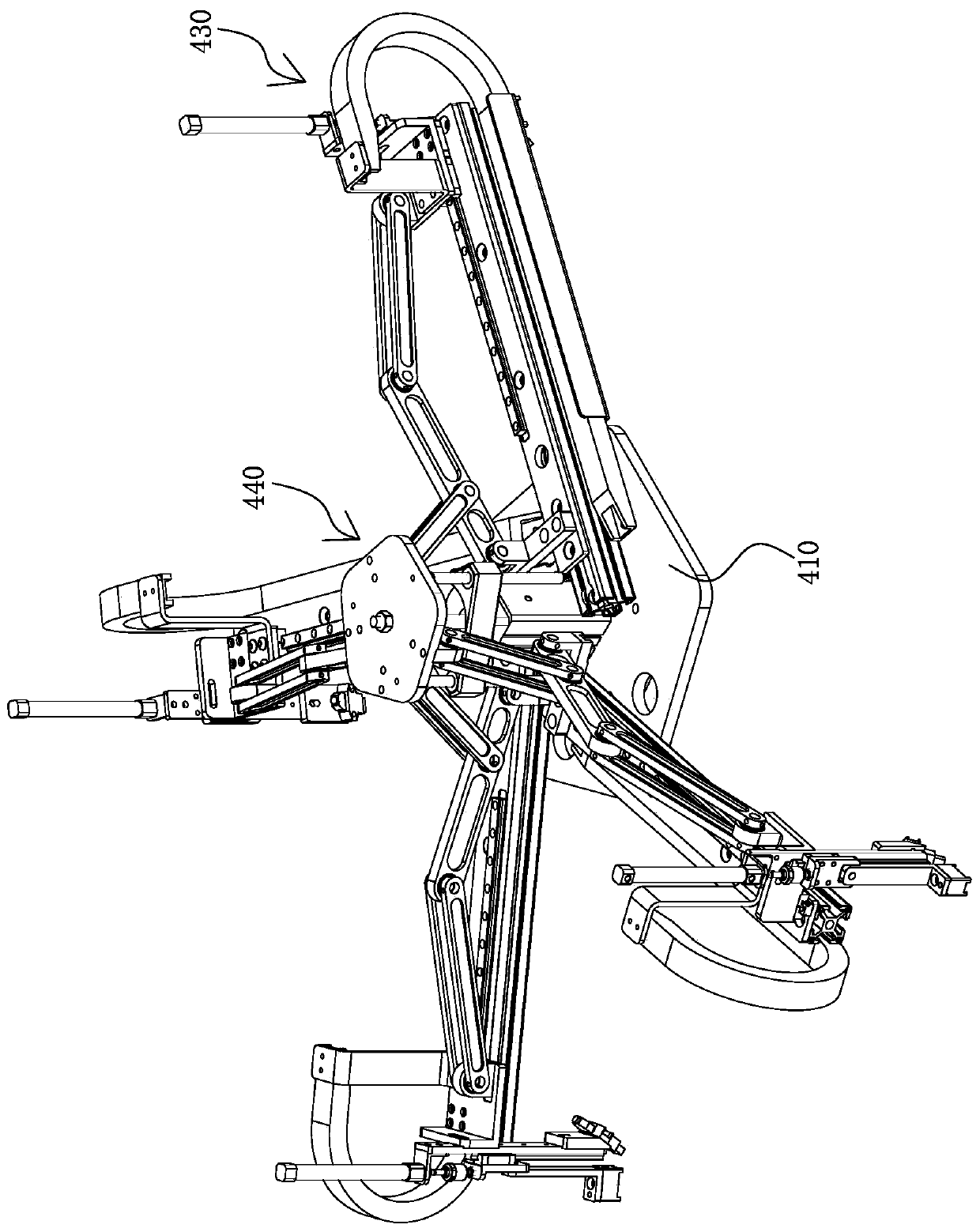

[0031] like figure 1 — Figure 9 As shown, the material retrieving device of a fully automatic water washing label machine of the present invention includes a machine base 100 , a material holding mechanism 200 , a material storage mechanism 300 and a grabbing mechanism 400 .

[0032] like figure 1 — figure 2 , Figure 5 , Figure 7 and Figure 9 As shown, the material holding mechanism 200 is movably installed on the machine base 100, the material storing mechanism 300 is installed on the machine base, and the material storing mechanism is provided with a plurality of main material boxes 321a arranged in a circle, and the material storing mechanism is provided with multiple A material storage box 221 arranged in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com