Shock insulation type copper rod cutting machine

A technology of cutting machine and copper rod, which is applied in the direction of nibbling cutting device, shearing device, metal processing machinery parts, etc., can solve the problems of time-consuming, laborious, low efficiency, etc., and achieve convenient efficiency and good shock isolation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

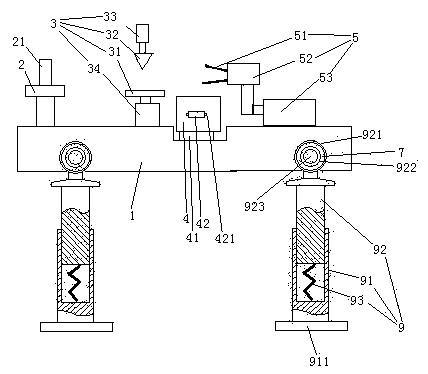

[0028] Embodiment one, see figure 1 , a shock-isolation type copper rod cutting machine, comprising a frame 1. A tray 2, a shearing device 3, a collection bucket 4 and a wire pulling device 5 are sequentially arranged on the frame 1 from left to right.

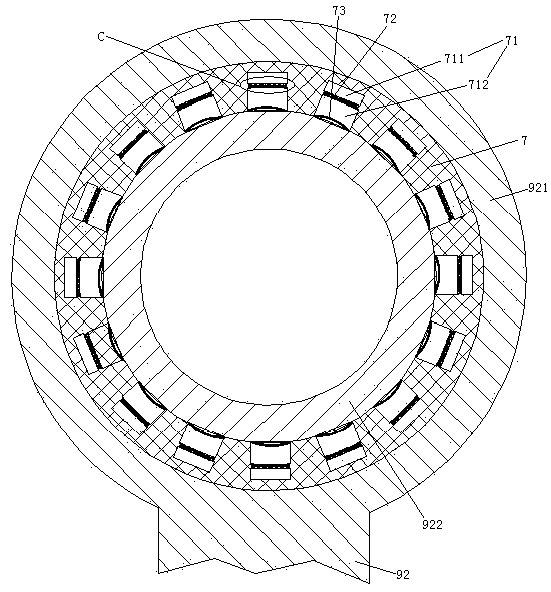

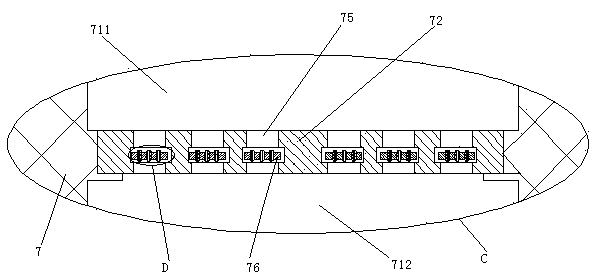

[0029] The frame 1 is provided with four mounting feet 9 . The mounting foot 9 includes a lower section 91 and an upper section 92 . The lower end of the lower section 91 is provided with a mounting seat 911 . The upper end of the lower section 91 is slidably sleeved on the lower end of the upper section 92 . The lower section 81 is provided with a damping spring 93 supporting the upper section 92 . The upper end of the upper section 92 is provided with a connecting ring 921 . An inner ring 922 passes through the connecting ring 921 . The inner ring 922 is connected with the connecting ring 921 through the rubber ring 7 . The inner ring 922 is pierced with connecting pins 923 . The connecting pin 923 is connected with ...

Embodiment 2

[0045] Embodiment two, the difference with embodiment one is:

[0046] see Figure 8 , The mounting foot 9 is also provided with a second driving mechanism 6 . The inner ring 922 is rotatably connected to the rubber ring 7 , and the rubber ring 7 is fixedly connected with the connecting ring 921 .

[0047] The second drive mechanism 6 includes a ratchet 61 , a pawl 62 for driving the ratchet, and a drive rod 63 . The ratchet 61 is coaxially connected with the inner ring 922 . The ratchet 61 is integrated with the inner ring 922 . The pawl 62 is fixedly connected to one end of the driving rod 63 . The upper section 92 is provided with a sliding hole 924 . The other end of the driving rod 63 can slide through the sliding hole 924 two-dimensionally. The lower end of the drive rod 63 is slidably hooked to the lower section 91 along the radial direction of the connecting ring 921 (see figure 1 ) and connected with the next paragraph. The driving rod 63 is provided with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com