Air inlet frame forming machine of tank type ventilator

A fan and air inlet technology, which is applied to cutting devices with nibbling action, other manufacturing equipment/tools, shearing devices, etc., can solve the problems of increased workload, many processing steps, time-consuming and other problems, so as to improve production. Efficiency, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

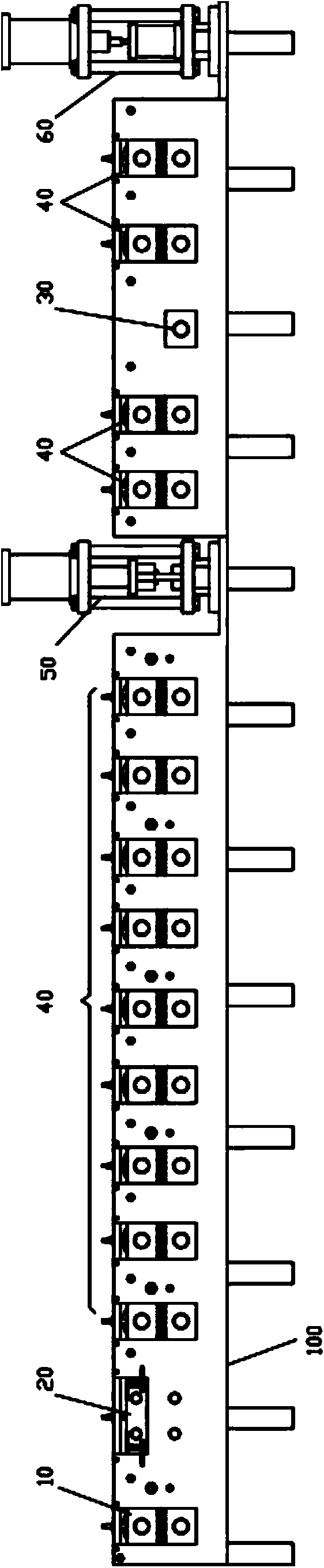

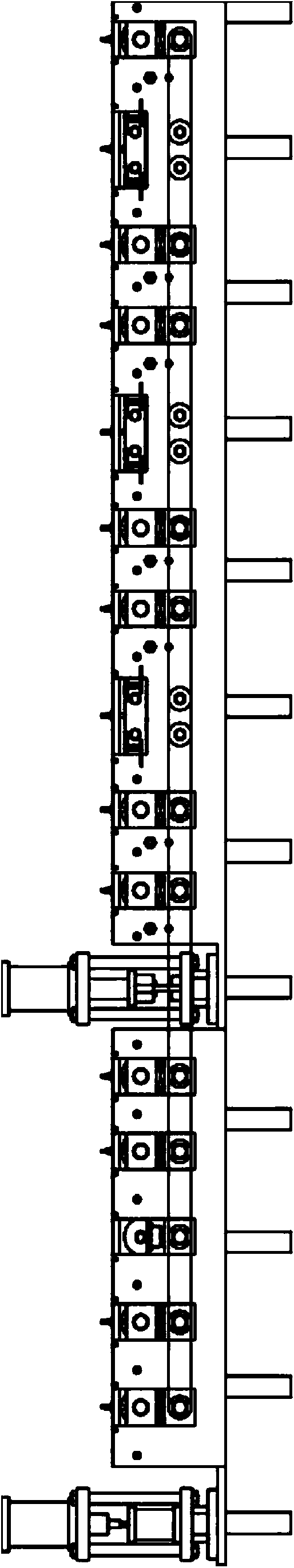

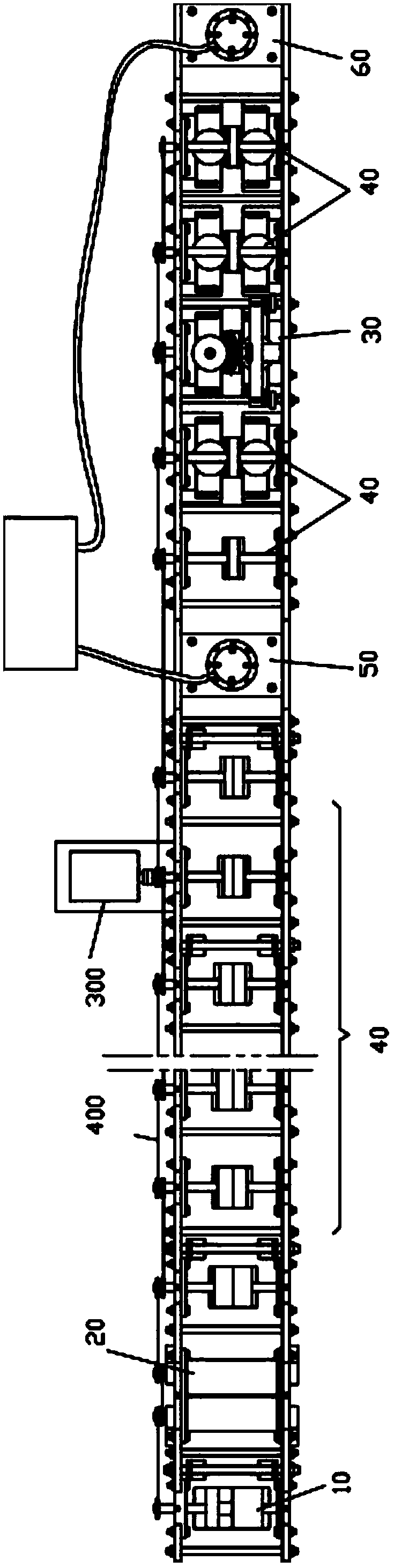

[0034] Example: see Figures 1 to 12 As shown, an air inlet frame forming machine of a box-type fan includes a frame 100 and a drive motor 300, and the frame 100 is provided with a feed roller group 10, an adjustment roller group 20, A shaping roller group 30 and a plurality of forming roller groups 40, a punching machine 50 is provided at the middle part of the frame 100, a cutting and stamping mechanism 60 is provided at the front of the frame 100, and the feed roller group 10 is at the tail end of the frame 100, Adjusting roll set 20 is at the front of feed roll set 10;

[0035] The forming roller set 40 includes an upper pressing roller 41 and a lower pressing roller 42, the upper pressing roller 41 is above the lower pressing roller 42, the middle part of the lower pressing roller 42 is formed with an annular groove 421, and the middle part of the upper pressing roller 41 is fixed with a cylinder The bump 411, the cylindrical bump 411 is inserted in the annular groove 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com