Tube baiting device used for stamper

A punching machine and pipe technology, which is applied in the field of pipe blanking devices, can solve the problems of roughness at the pipe cut, reduce production efficiency, and low blanking efficiency, and achieve the effects of improving working environment, improving production efficiency and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

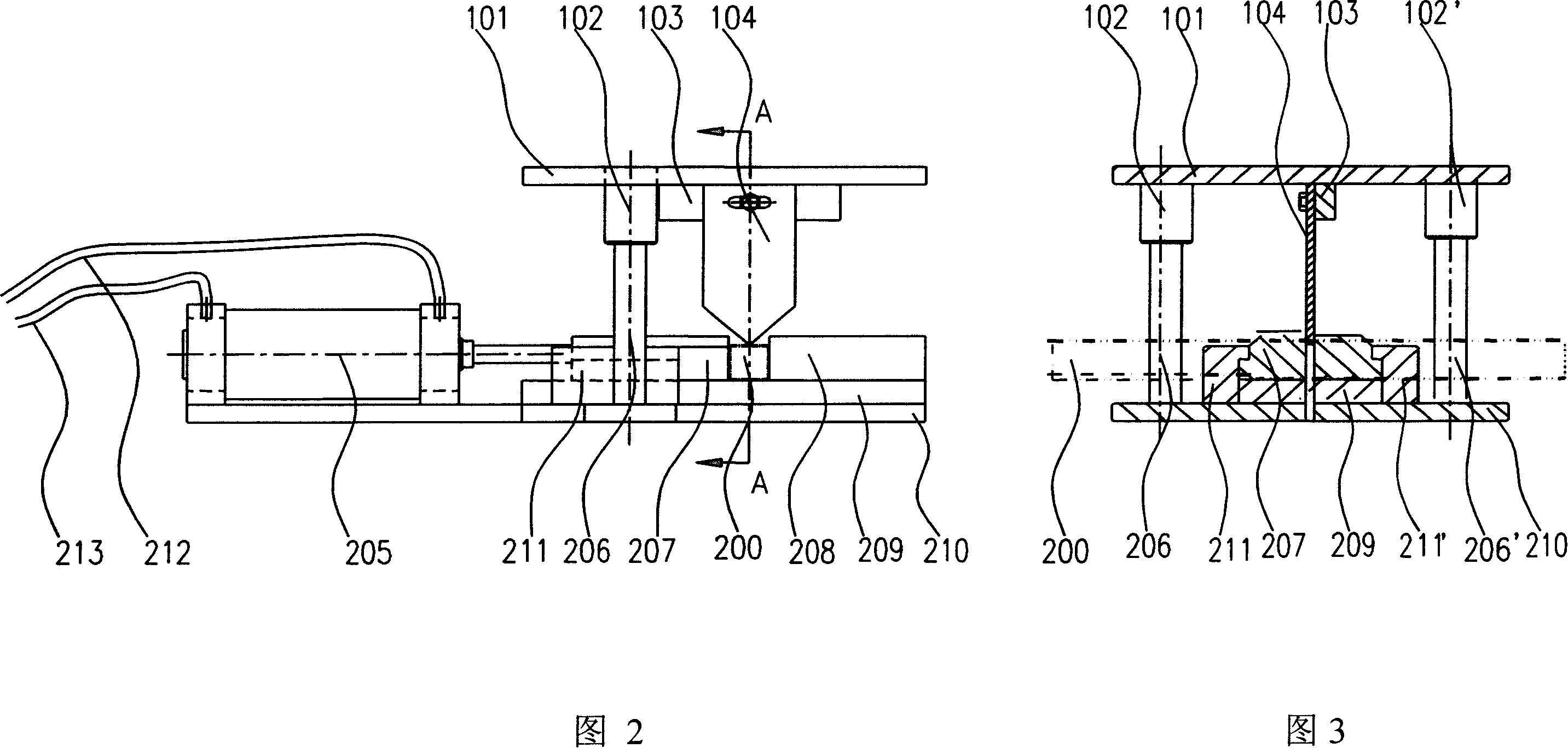

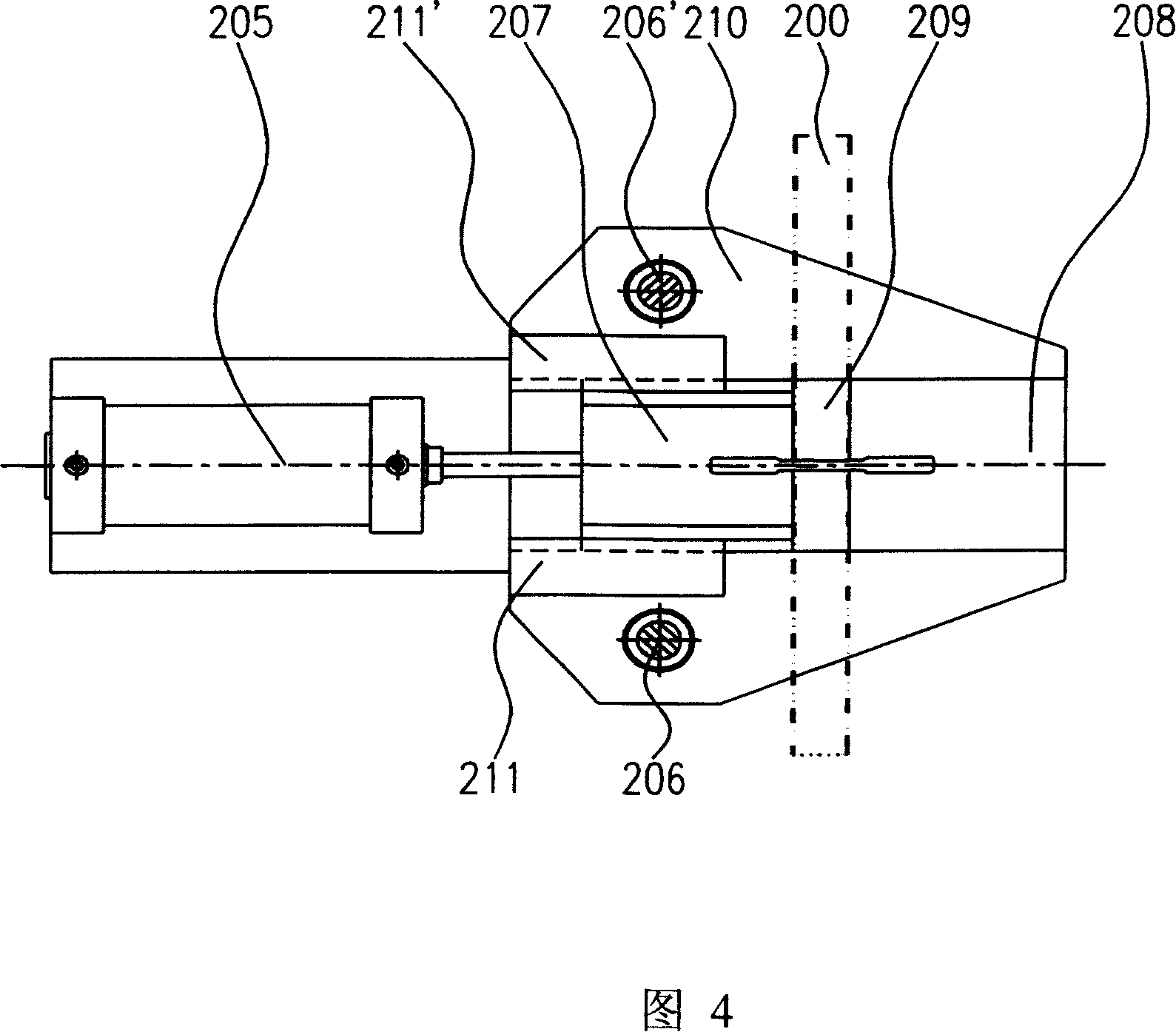

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

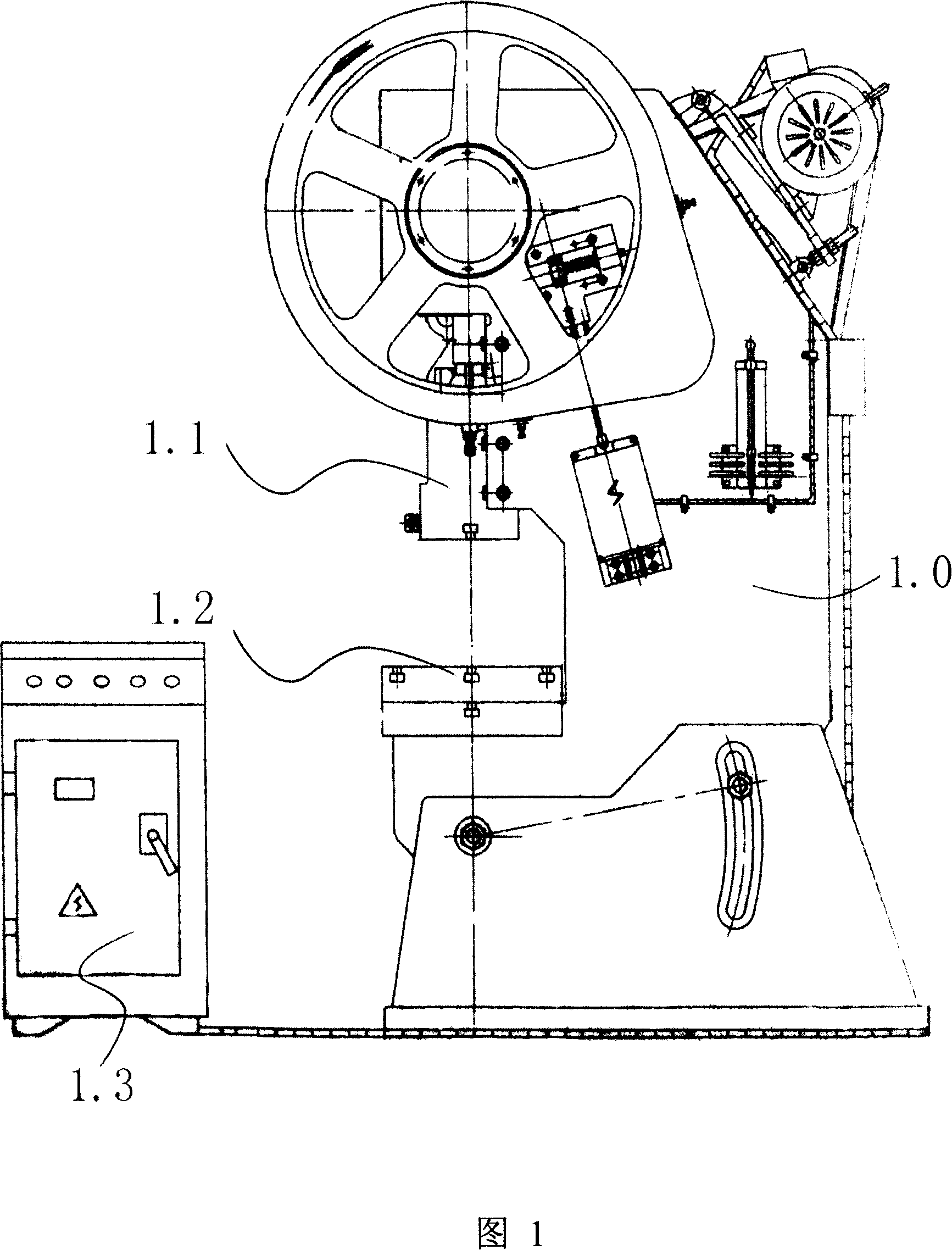

[0022] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5, a pipe blanking device for punching machines provided by the present invention includes a punching mechanism, a pipe clamping mechanism, and a pipe clamping mechanism. The cylinder 205 that the clamping mechanism matches, the cylinder 205 communicates with an air compressor that provides an air source, and the cylinder 205 is a two-way cylinder with two chambers. Between the pipelines that the cylinder 205 communicates with the air compressor, Install a solenoid valve 310 additionally, the solenoid valve 310 communicates with the two chambers on the cylinder respectively, the intake joint 311 of the solenoid valve 310 is connected to the gas source, and the other two joints 312, 313 are respectively connected to the intake joints 212, 313 of the cylinder 205. 213 are connected. As shown in Figure 5, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com