Impeller blade for centrifugal blower, blade-supporting rotator, impeller for centrifugal blower, and method for manufacturing impeller for centrifugal blower

a technology of centrifugal blower and impeller, which is applied in the direction of machines/engines, waterborne vessels, metal-working apparatuses, etc., can solve the problems of insufficient welding strength, large gaps between the weld surfaces of the members, and unevenness, so as to reduce the length of laser welded parts, reduce the pressure applied between the blade-supporting rotator and the blades, and achieve high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090]The following is a description, made with reference to the drawings, of an embodiment of an impeller blade for a centrifugal blower, a blade-supporting rotator, an impeller for a centrifugal blower, and a method for manufacturing an impeller for a centrifugal blower according to the present invention.

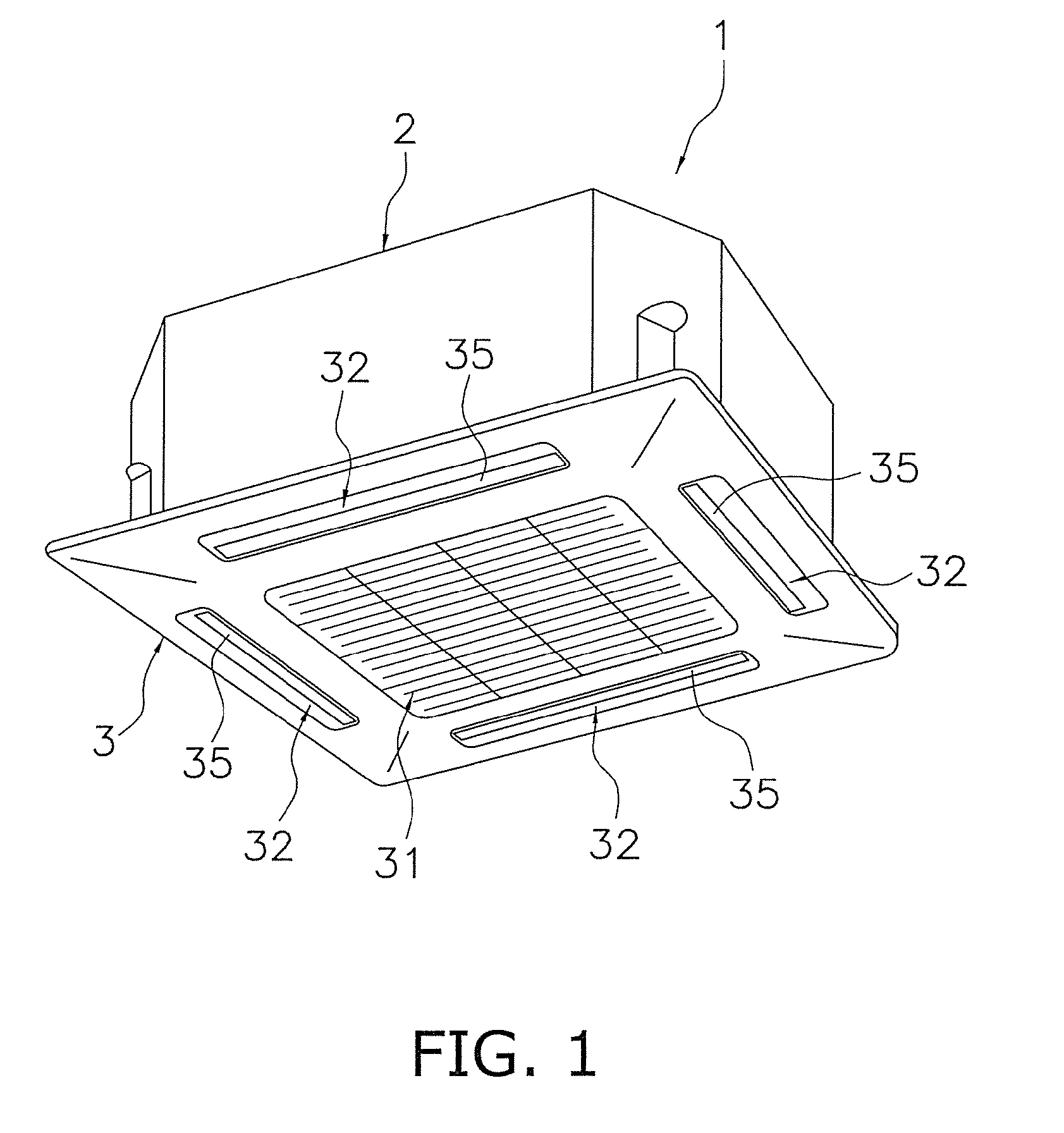

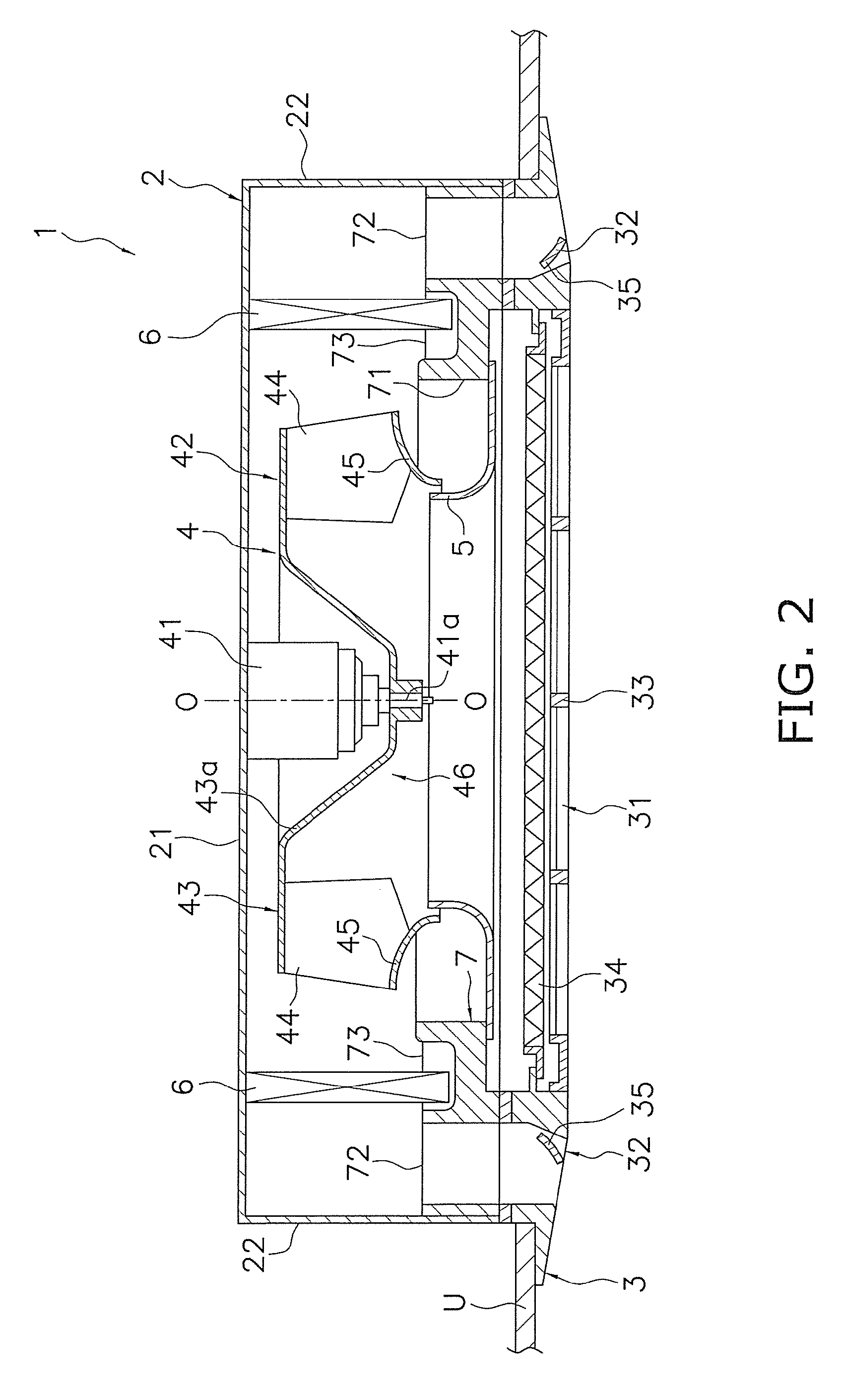

[0091](1) Overall Configuration of Air Conditioning Apparatus

[0092]FIG. 1 shows an external perspective view of an air conditioning apparatus 1 comprising a centrifugal blower that uses a blade, a blade-supporting rotator, and an impeller for a centrifugal blower according to one embodiment of the present invention (the ceiling is omitted). The air conditioning apparatus 1 is a ceiling-embedded air conditioning apparatus, and comprises a casing 2 for accommodating various structural devices in its interior, and a face panel 3 disposed on the underside of the casing 2. Specifically, the casing 2 of the air conditioning apparatus 1 is disposed by being inserted into an opening forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| angles of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com