Core-board with new structure and its production process

A technology of blockboard and production process, which is applied in the direction of wood processing utensils, the joining of wooden veneers, layered products, etc. and other problems, to achieve the effect of improving the strength and quality of use, saving equipment, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

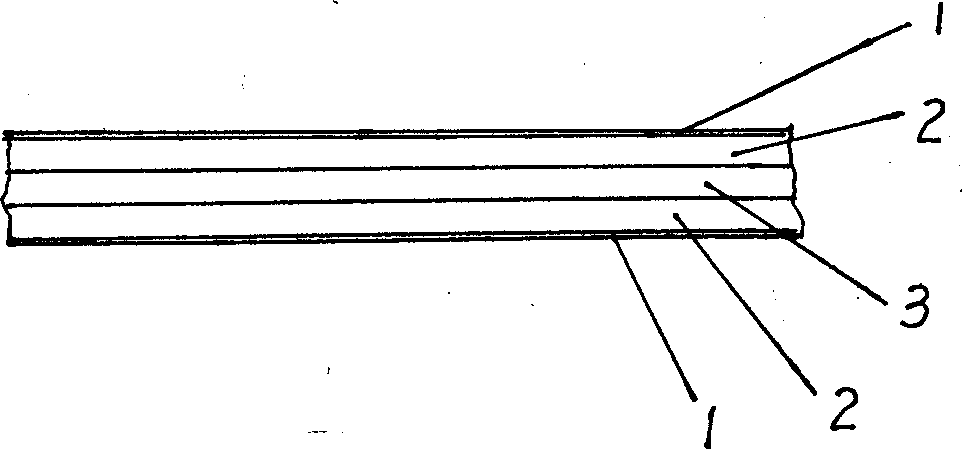

[0007] See figure 1 , first cut poplar logs into veneers with a thickness of 4-10mm with a rotary cutter, with a yield of 80-90%, and then dry them in a drying kiln for 1-4 days. The drying cost per cubic meter is 20-30 yuan , the dried veneer is used as the core board 3 and the upper and lower panels 2, and the middle core board 3 and the upper and lower panels 2 are glued to form a three-layer joinery substrate, and finally the upper and lower surfaces are rough sanded and glued. Stick the veneer skin with a thickness of 0.03mm-0.04mm 1. Perform fine sanding and serve. The specifications of the blockboard are 1.22m wide, 2.44m long, and three thicknesses: 0.012m, 0.015m and 0.018m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com