Multi-component fibre composite asphalt concrete and preparing method thereof

A multi-component fiber and composite asphalt technology is applied in the field of asphalt concrete, which can solve the problems of high price, restrict the application of composite asphalt concrete, and have no obvious improvement in the performance of asphalt mixture, and achieve the effect of reducing project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The synthetic gradation design of ordinary dense gradation (AC) 13 multi-component fiber composite asphalt concrete is shown in Table 1.

[0032] Ordinary dense gradation (AC) 13 multi-component fiber composite asphalt concrete: the optimum asphalt ratio is 5.2%, the amount of multi-component fiber is 0.3%, the void ratio of multi-component fiber asphalt mixture is 4.0%, and the Marshall stability It is 12.8kN, the flow value is 3.5mm, the residual stability is 90.5%, the freeze-thaw splitting strength ratio is 87.6%, and the rutting stability is 5823 times / mm.

Embodiment 2

[0034] The synthetic gradation design of Superpave 12.5 multi-component fiber composite asphalt concrete mixture is shown in Table 2.

[0035] High-performance asphalt pavement (Superpave) 12.5 multi-component fiber composite asphalt mixture: the optimal asphalt ratio is 5.1%, the amount of multi-component fiber is 0.3%, and the void ratio of multi-component fiber asphalt mixture is 4.2%, Marshall The stability is 13.2kN, the flow value is 3.0mm, the residual stability is 91.6%, and the freeze-thaw splitting strength ratio is 88.4%.

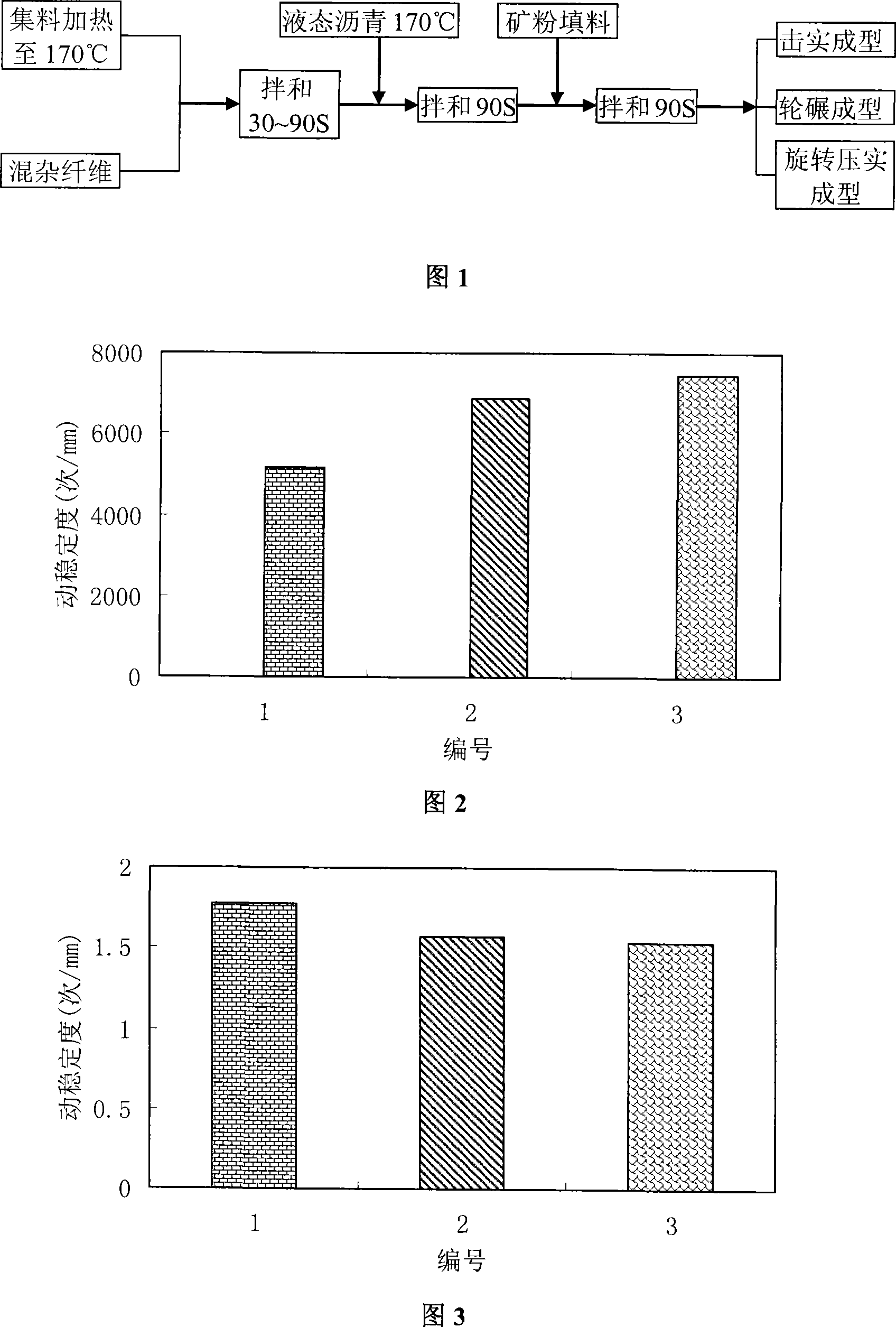

[0036]In this example, the rutting dynamic stability and rutting depth of the asphalt mixture mixed with lignin fiber, polyester fiber and multi-component fiber were compared, see Figure 2 and Figure 3. It can be seen from the results in Fig. 2 that the dynamic stability of rutting of specimen 1 is 5164 times / mm, the dynamic stability of specimen 2 is 6879 times / mm, and the dynamic stability of specimen 3 is 7472 times / mm. The rutting dynamic st...

Embodiment 3

[0038] The synthetic gradation design of asphalt horseshoe macadam (SMA) 16 multi-component fiber composite asphalt concrete mixture is shown in Table 3.

[0039] Asphalt horseshoe grease macadam (SMA) 16 multi-component fiber asphalt mixture: the optimal asphalt ratio is 6.2%, the amount of multi-component fiber is 0.3%, and the void ratio of multi-component fiber asphalt mixture is 4.0%, Marshall The stability is 11.2kN, the flow value is 3.2mm, the residual stability is 89.8%, the freeze-thaw splitting strength ratio is 85.2%, and the rutting dynamic stability is 6824 times / mm.

[0040] schedule

[0041] Table 1 Synthetic gradation design of ordinary dense gradation (AC)13 multi-component fiber composite asphalt mixture

[0042] Aperture mm

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Synthetic gradation%

100

91.8

70.6

38.8

27.1

21.8

17.5

12.7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com