Down and feather garment with effect for locking down, and technique for processing locked down

A treatment process and technology for down jackets, which is applied in the field of anti-drilling down and running down treatment technology, can solve the problems of failure to achieve the best effect for the purpose of use, shortened service life, waste of resources, etc., to protect the living environment, improve product quality, and realize The effect of lock velvet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

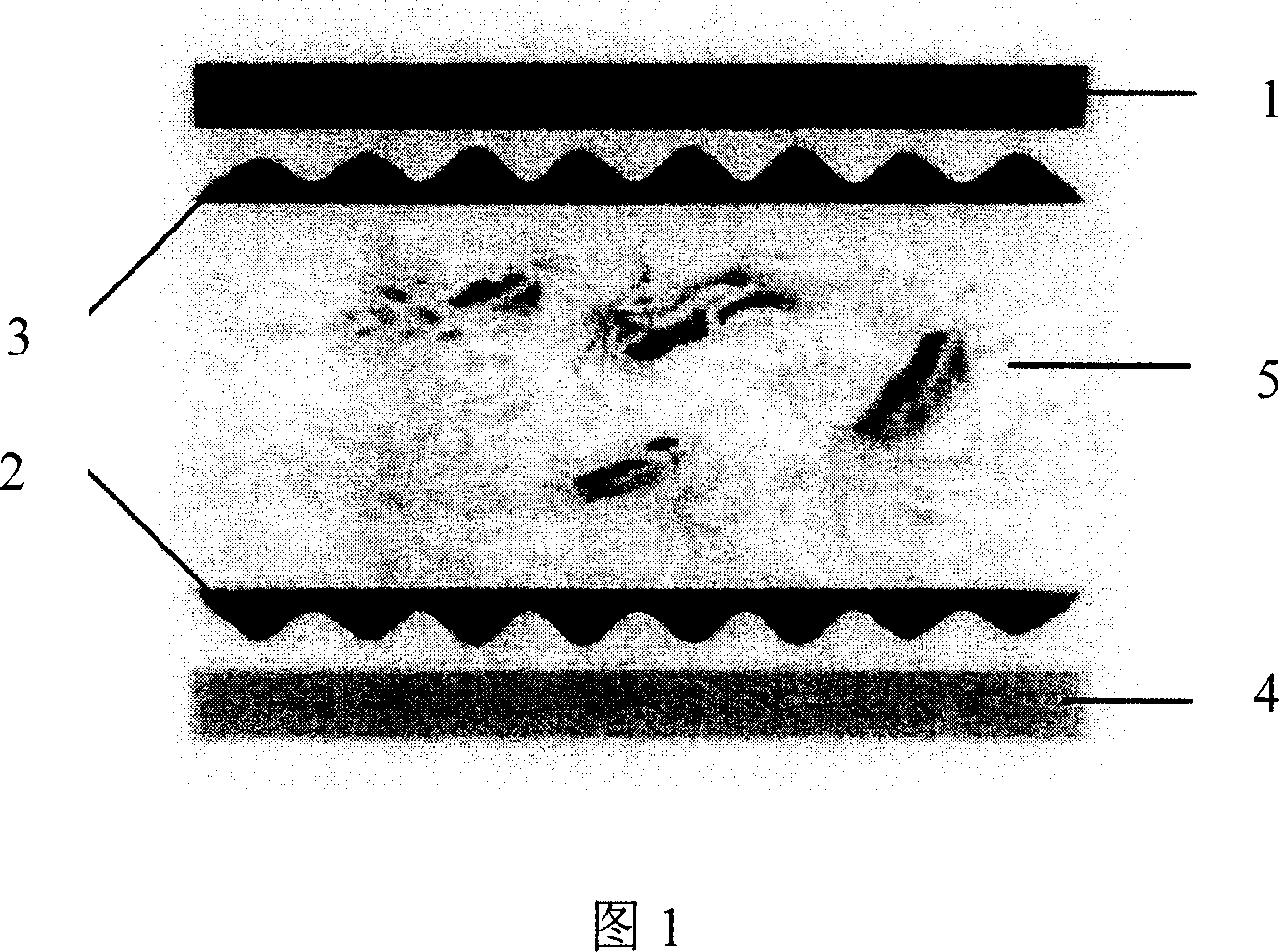

Image

Examples

Embodiment 1

[0027] Example 1: Treatment of fabrics

[0028] On the basis of not destroying the original air permeability, a 100% nylon fiber fabric of 300T 40D×40D / 34F×34F or 332T70D×70D / 48F×48F is used as the fabric, and AC glue coating is performed on the reverse side of the fabric. Acrylic resin is used as the main glue, the main glue is dissolved into a squeegeeable glue with good fluidity, and the glue is evenly coated on the surface of the fabric fiber to form a continuous film. The anti-velvet effect is greatly enhanced. The fabric treated in this way has a certain "self-protection" function after being pierced by the needle hole, that is, the needle hole part of the stitches produced by normal sewing has a certain automatic repair function.

Embodiment 2

[0029] Example 2: Treatment of Gallbladder

[0030] Since the gall material is the first protective layer of the velvet, it must be considered that it has a stable defensive effect. The simple method of using too thick or too dense warp and weft not only increases the cost, wastes resources, but also destroys the feel and texture of the product. At the same time, it will also make it easy to drill down at the pinholes generated during the sewing process. In this example, 260T66D×66D / 72F×72F or 300T 50D×50D / 24F×24F 100% polyester fabric is used as the gall material, and the gall material fabric is subjected to calendering treatment: the fabric is transported to a temperature environment of 170-180 In the calender with 80T degree and pressure conditions, the fabric fibers are flattened, and the softness and gap density of the fabric are improved on the premise that the width of the fabric does not change.

Embodiment 3

[0031] Example 3: Treatment of lining

[0032] After the conventional lining is processed into a finished product, because it is worn in winter, it is easy to generate static electricity during daily activities, which makes it easier to suck out the down in the finished product through the pinhole of the gall material. In this example, 210T 70D×70D / 24F×24F 100% nylon fabric is used as the lining, and the lining is treated with waterproof and antistatic treatment: after drying the dyed lining, add The antistatic agent is dipped and rolled by a rolling car, and then dried at 160 degrees for 30 seconds to set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com