Dust removing device for textile use

A technology of dust removal device and dust removal brush, which is applied in textiles and papermaking, fabric surface trimming, mechanical cleaning, etc. It can solve the problems of not being able to iron the textile cloth, not being able to remove dust and impurities, and the wrinkling of the textile cloth, so as to improve the quality of use , Improve the quality of dust removal, improve the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

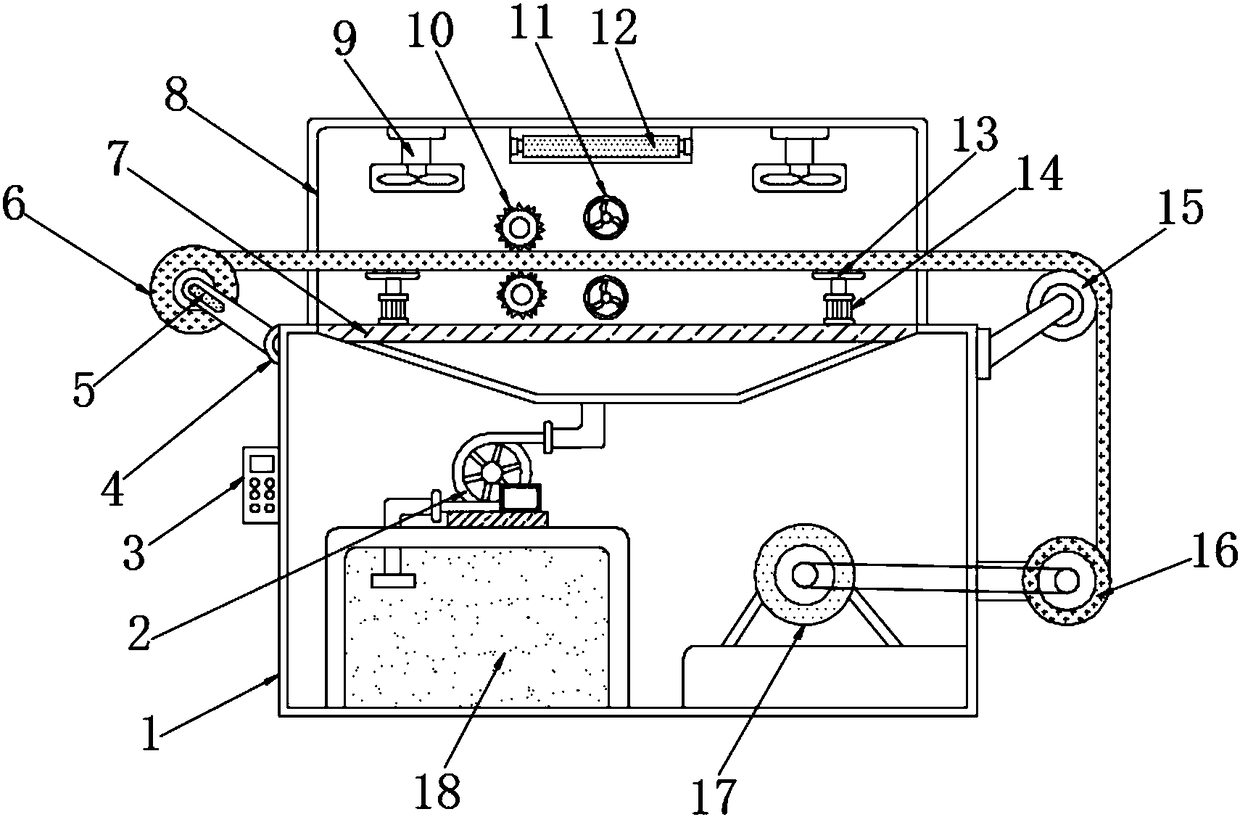

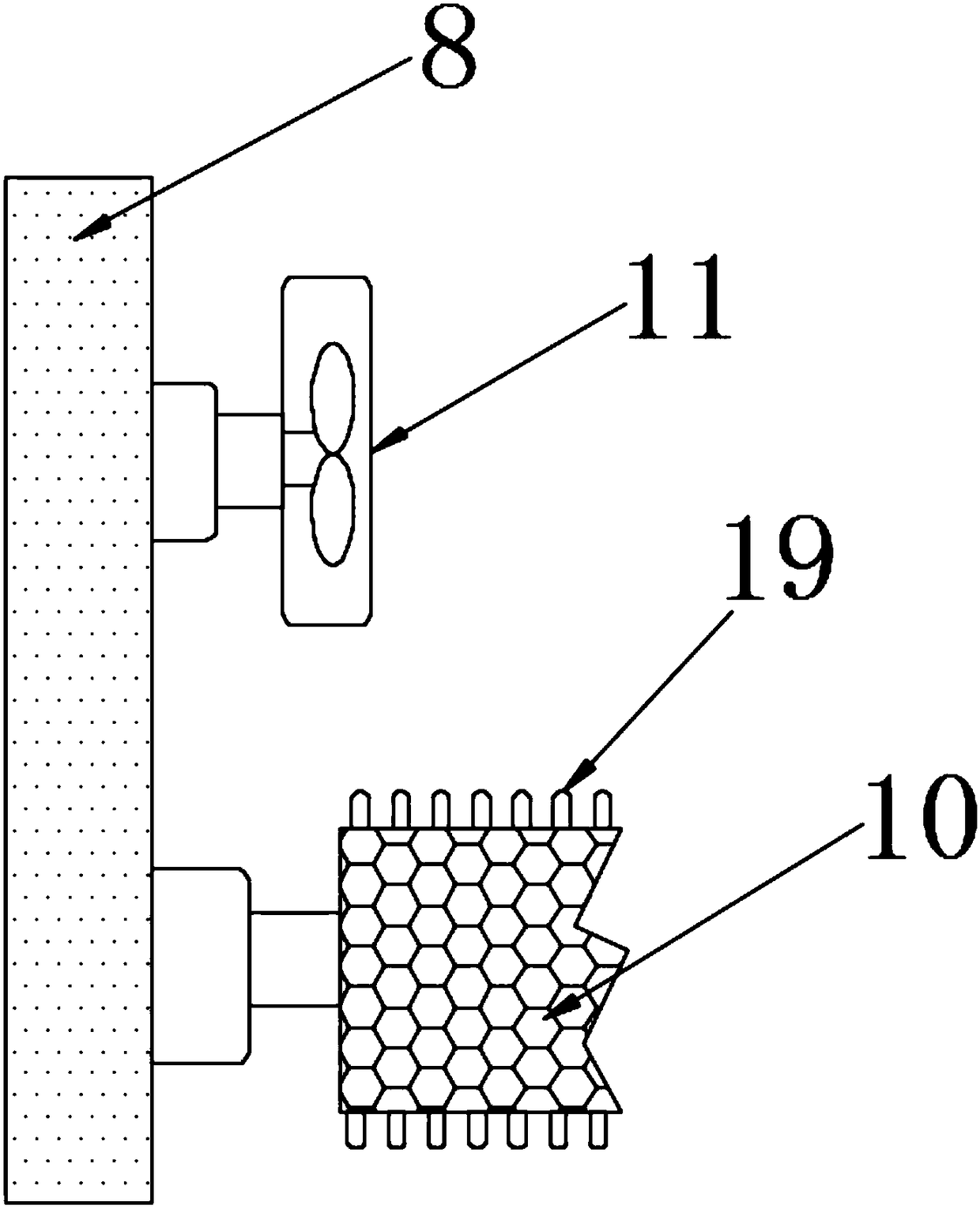

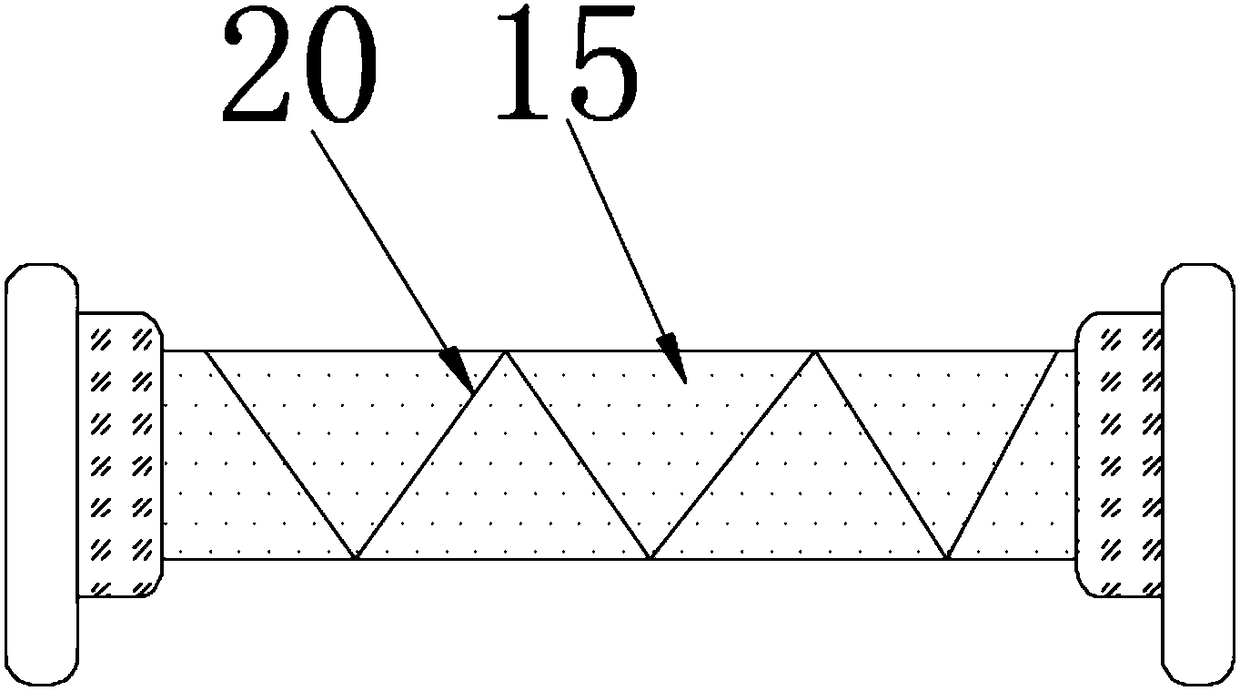

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a dust removal device for textiles, comprising a cabinet 1, the inside of the cabinet 1 is provided with a dust box 18, and the inside of the cabinet 1 is provided with a fan 2 at the upper end of the dust box 18, The inside of the cabinet 1 is provided with a motor 17 at one side of the dust box 18, and the side of the cabinet 1 is provided with a control switch 3, and the side of the cabinet 1 is provided with a rotating shaft 4 at the upper end of the control switch 3, and the side of the cabinet 1 A cloth roller 6 is arranged at one end of the rotating shaft 4 on the side, a handle 5 is arranged at one side of the rotating shaft 4 on the side of the cabinet 1, and a grille 7 is arranged on the upper end of the cabinet 1, and the other side of the cabinet 1 is provided with A cloth rolling roller 16, and the other side of the cabinet 1 is located at the upper end of the cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com