Preparation method of high-strength stainless steel flux-cored wire

A technology of flux-cored welding wire and stainless steel, which is applied to welding equipment, cleaning methods and appliances, chemical instruments and methods, etc. It can solve the problems of long time for changing dry wipes, poor appearance of flux-cored welding wire, and difficulty in removing wire-drawing powder, etc. problems, to achieve the effect of improving dust removal efficiency and quality, and improving drying efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

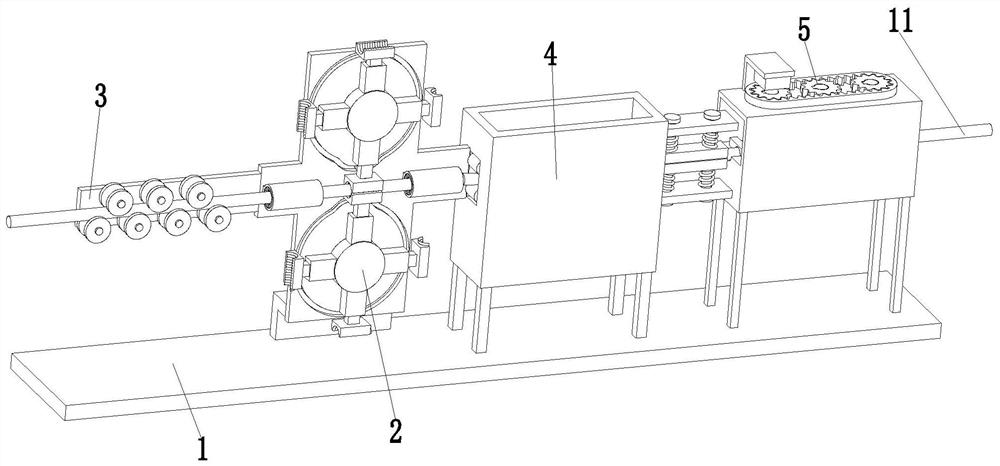

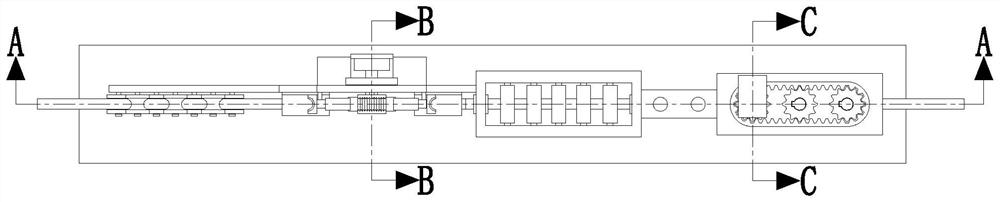

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

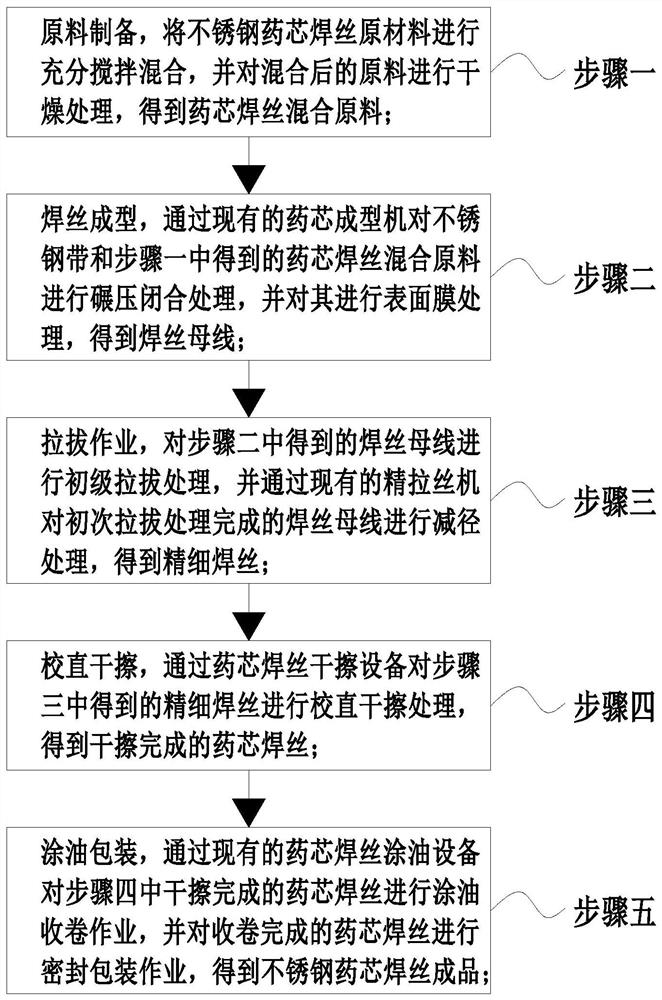

[0037] see figure 1 , figure 2 and image 3 , a method for preparing a high-strength stainless steel flux-cored wire, mainly comprising the following steps:

[0038] Step 1, raw material preparation, fully stirring and mixing the stainless steel flux-cored welding wire raw materials, and drying the mixed raw materials to obtain the flux-cored welding wire mixed raw materials;

[0039] Step 2. Welding wire forming. Using the existing flux core forming machine, the stainless steel strip and the flux cored wire mixed raw material obtained in step 1 are rolled and closed, and the surface film is treated to obtain the welding wire busbar;

[0040] Step 3, drawing operation, the primary drawing treatment is performed on the welding wire busbar obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com