Metal material low-temperature tensile test device and test method

A technology for tensile testing and metal materials, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problem of high production costs, affecting the operability of low-temperature tensile tests, and the inability to guarantee tensile testing. The uniformity of the temperature of the stretched specimens and other issues can be achieved to reduce the cost of the test, reduce the cost of the tensile test, and achieve the effect of good temperature control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

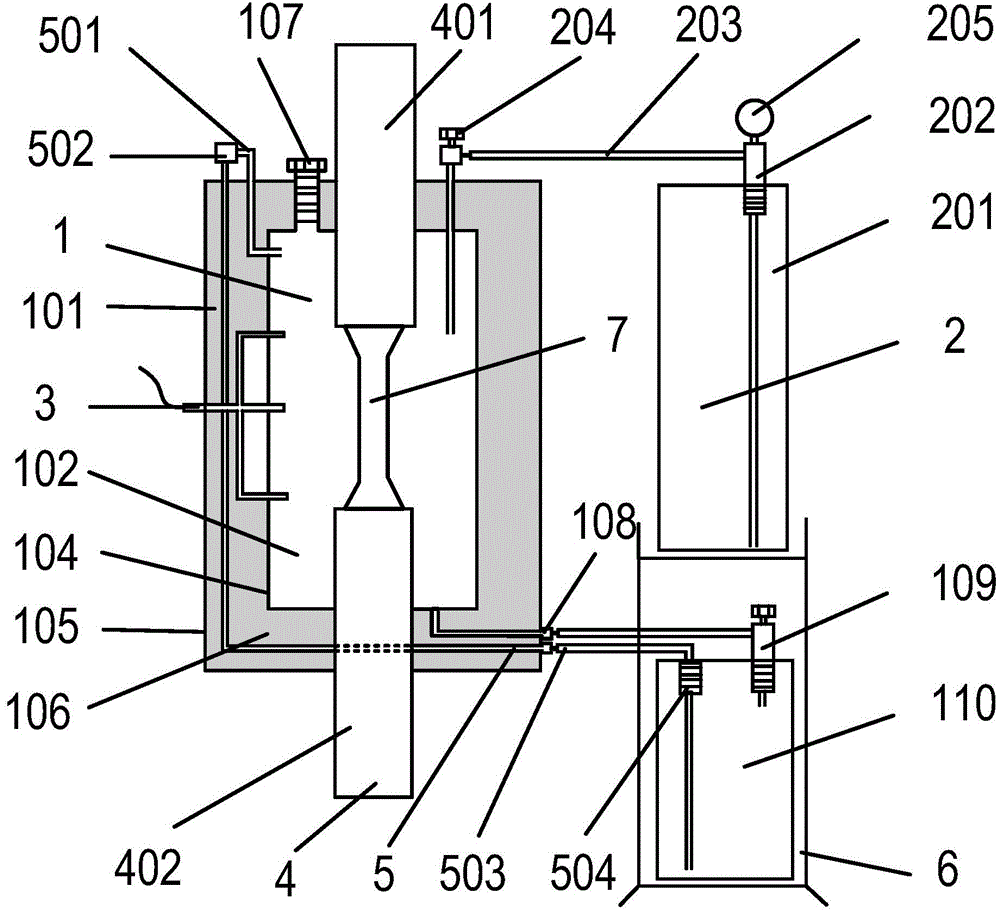

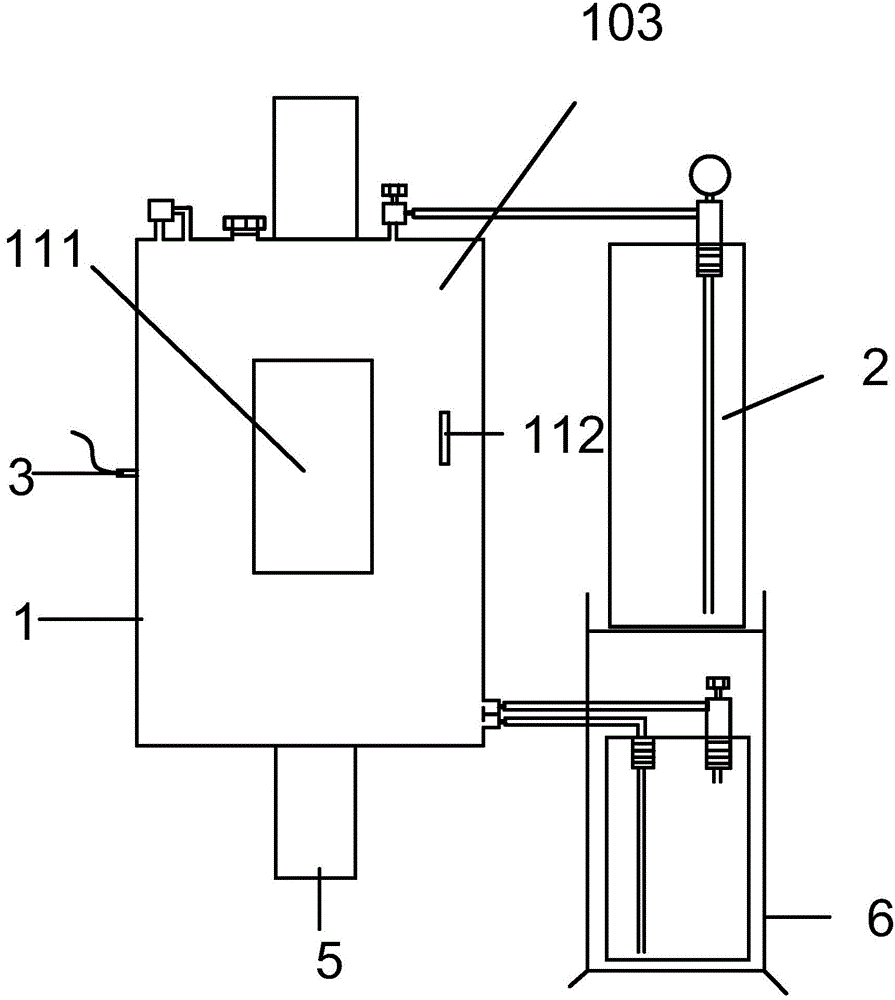

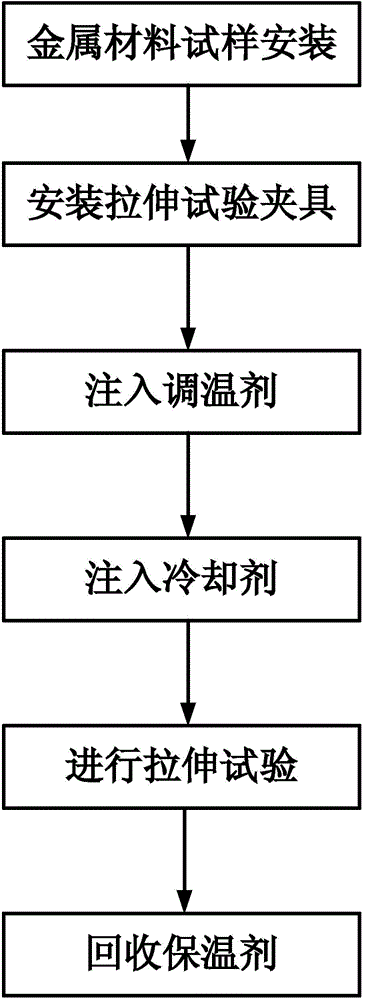

[0041] Such as figure 1 , figure 2 As shown, the metal material low-temperature tensile test device of the present invention includes a temperature measuring device 3, a low-temperature box 1, a low-temperature box refrigeration device 2 communicated with the low-temperature box 1, and a tensile test fixture 4 connected with a tensile testing machine. The low-temperature box 1 comprises a box body 101, a working space 102 in the box and a box door 103 arranged on the box body 101. The box body 101 is composed of an inner shell 104, an outer shell 105, and an insulating layer 106 arranged between the inner shell 104 and the outer shell 105. Composition: Tensile test fixture 4 comprises upper fixture 401 and lower fixture 402, and upper fixture 401 is arranged on the box body 101 top and stretches into the working space 102 in the box, and lower fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com