Aquatic product drying machine and control method

A control method and technology for aquatic products, applied in the direction of progressive dryers, dryers, drying solid materials, etc., can solve the problems of low economic benefits, destruction of nutrients in aquatic products, low level of drying condition control, etc., and achieve drying effect The effect of uniformity, improving work efficiency and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

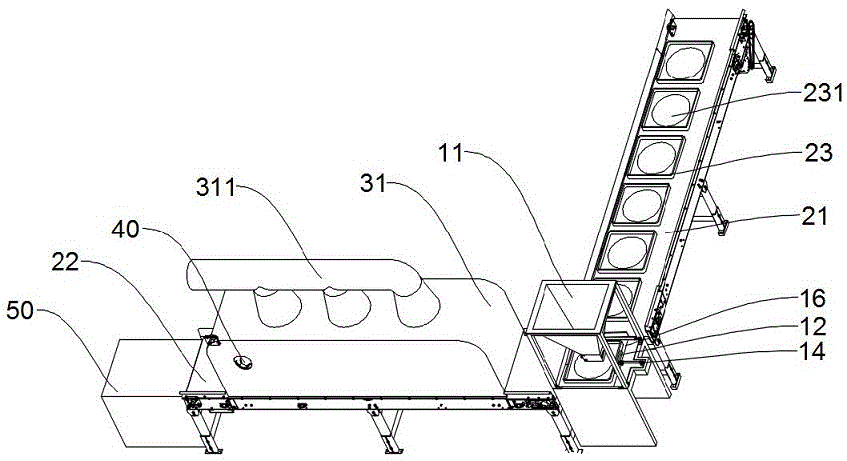

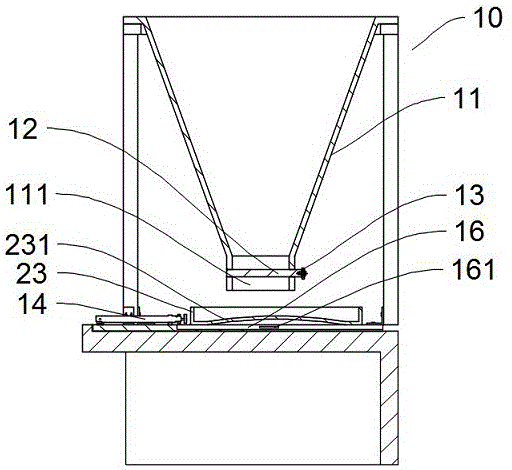

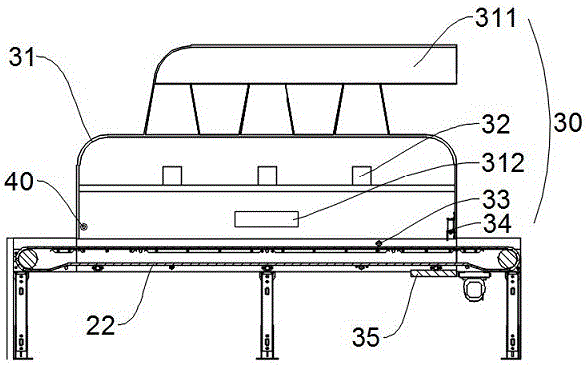

[0040] Examples, please refer to Figure 1 to Figure 4 , a kind of aquatic product drying machine, comprises feeding unit 10, transmission unit 20 and microwave drying unit 30, and described transmission unit 10 comprises first conveyer belt 21 and second conveyer belt 22, and described first conveyer belt 21 is placed with a plurality of Tray 23; the feed unit 10 includes a feed hopper 11, a push plate 12, a feed cylinder 13, a push plate cylinder 14, a first blocking cylinder 15 and a pallet backing plate 16, and the push plate 12 is located on the feed At the lower opening 111 of the material hopper 11, the feed cylinder 13 is connected to the push plate 12 to control the opening and closing of the lower opening 111, and the tray backing plate 16 is arranged below the push plate 12, so that The first blocking cylinder 15 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com