Belt-type dry cooler

A belt-type drying, drying and cooling technology, applied in the direction of dryers, drying solid materials, dry cargo handling, etc., can solve the problems of unsatisfactory effect, no distributor, easy to break, etc., to save heat loss and fully cool Uniform and reduce breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

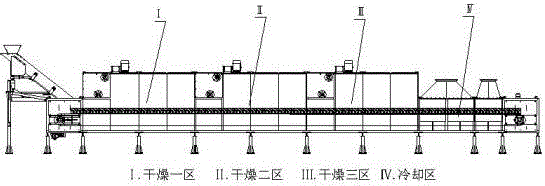

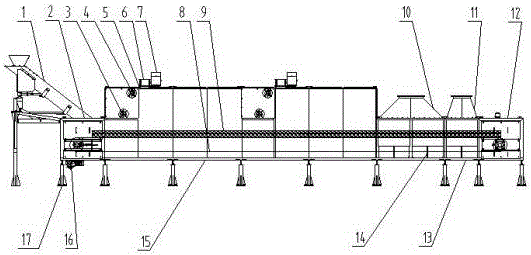

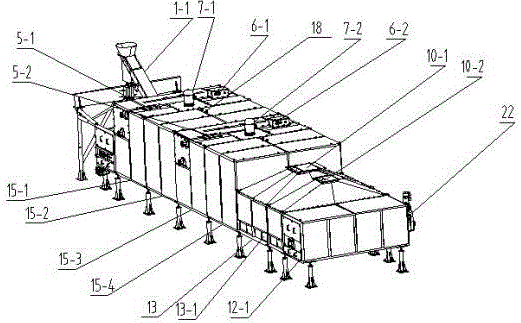

[0032] A belt-type drying and cooling machine, the drying and cooling machine includes a distributor 1, a feed section 2, a drying section 15, a cooling section 13, a discharge section 12 and a foot 17, and the distributor 1 is connected with a cloth The device chute 1-1 is connected to the feed section 2, and the conveyor belt 8 inside the drying cooler passes through the drying section 15, the drying section 15, the cooling section 13 and the discharge section 12 successively, and the described drying section 15 includes at least one In the drying zone, the upper part of each drying zone is independently provided with a make-up air outlet, an air exhaust outlet, a circulation fan, a hot air inlet, a temperature sensor 18 and a heat exchanger 19, and the cooling section 13 includes one or two cooling zones, each cooling There are independent air ducts, exhaust fans and air inlets in each zone, and two windshields 15-5 are arranged between adjacent drying zones, and three winds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com