Drying cooler of fluidized bed

A technology of fluidized bed drying and cooler, which is applied in the direction of drying solid materials, drying gas arrangement, method combination to dry solid materials, etc. It can solve the problems of uneven humidity distribution, high production cost, poor heat transfer effect, etc., and achieve The effect of uniform humidity distribution, long contact time and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

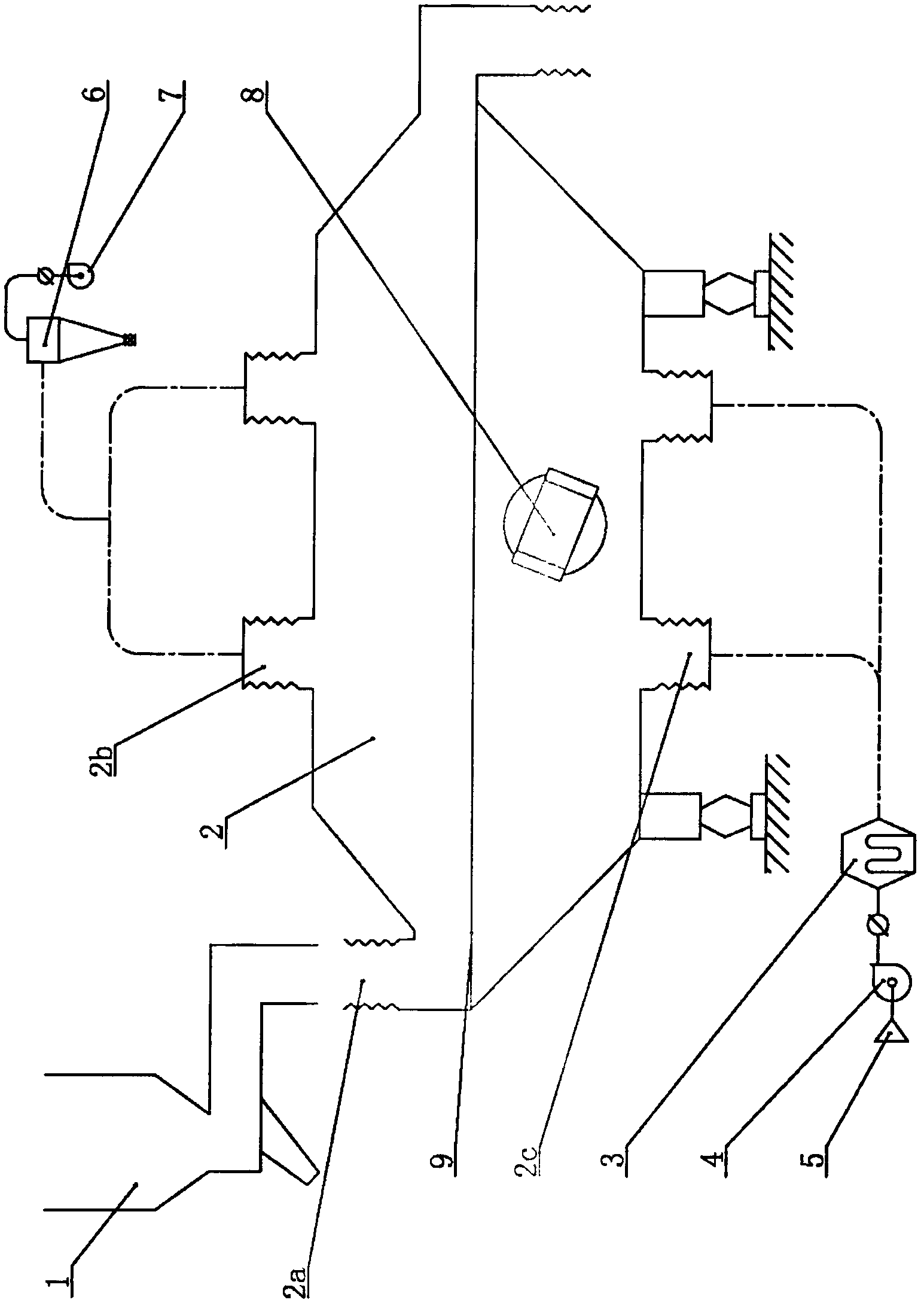

[0010] Such as figure 1 A fluidized bed drying cooler shown includes a feeder 1, the feeder 1 is connected to the feed port 2a of the drying bin 2, and a conveyor belt 9 is arranged in the drying bin 2, and the conveyor belt 9 There are air holes on the top, and a vibrator 8 for controlling the vibration of the conveyor belt 9 is arranged below the conveying belt 9 in the drying chamber 2. Two air inlets 2c are arranged below the drying chamber 2, and two air inlets 2c are arranged above the drying chamber 2. An air outlet 2b, the air outlet 2b is connected to the exhaust fan 7 through the dust collector 6, the air inlet 2c is connected to the outlet of the heat exchanger 3, the inlet of the heat exchanger 3 is connected to the outlet of the fan 4, and the outlet of the fan 4 The inlet is connected to the supply air filter 5 .

[0011] When the present invention works, the material feeder 1 evenly sends the material into the feed port 2a of the drying bin 2, the material fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com