Cement production line fine powder grinding equipment

A production line and cement technology, applied in cement production, grain processing, etc., can solve the problems affecting the quality of ultra-fine powder products, high temperature and high humidity in the mill, and achieve the effect of shortening the grinding cycle, improving the service life and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

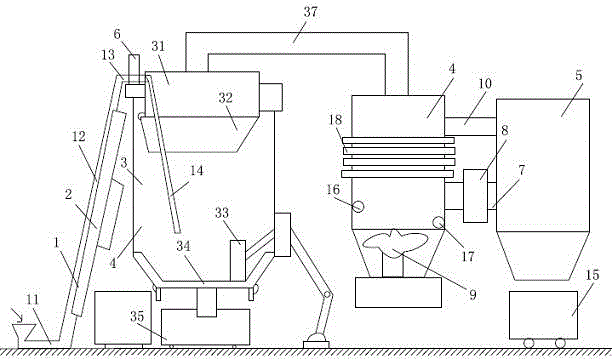

[0016] Such as figure 1 As shown, the fine powder grinding equipment for the cement production line includes an inclined screw feeding device 1, a drying device 2, a hot air device 6, a pulverizer 3, a sieving machine 4 and a fine powder collector 5 connected in sequence, wherein: The powder machine 3 includes a discharge pipe 37, a primary fan 31, a classifier 32, a pendulum roller 33, a millstone 34, a reducer 35 and a motor 36 connected sequentially from top to bottom; the inclined screw feeding device 1 includes horizontal feeders connected in sequence. The feed port 11, the inclined upward spiral conveying section 12, the horizontal conveying section 13 and the inclined f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com