Device and method for drying lignite in a combined mode through microwave and hot air

A technology of combined drying and microwave hot air is applied in the directions of drying gas arrangement, heating to dry solid materials, and preliminary treatment to promote the drying of solid materials. , Dry finished products are prone to moisture and other problems, and achieve the effects of reducing hydrophilicity, increasing gas-solid contact area, and high energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

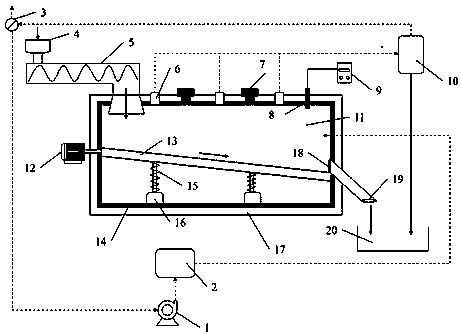

[0042] Such as figure 1 As shown, a device for drying lignite combined with microwave hot air, including: feeding device, vibration transmission mechanism (13), hot air generating device, microwave generating device (7), drying chamber (11), temperature measuring system and tail gas treatment device (10), the feeding device includes a feed hopper (4) and a screw feeder (5), the hot wind generating device includes a blower (1) and a hot blast stove (2), and the drying cavity (11 ) is provided with more than one microwave generating device (7) and more than one exhaust port (6), the cavity is provided with an insulating layer and a metal shell that can shield microwaves, and the vibration transmission mechanism (13) and the cavity The external vibrating motor (12) is connected, and the end is provided with a twitchable baffle (18) and a discharge port (19). Finally, the dried lignite is collected into the finished coal bunker (20). The dotted arrow indicates the movement of the ...

Embodiment 2

[0059] The device structure of microwave hot air combined drying lignite is the same as that in Example 1.

[0060] A method for combining microwave hot air drying lignite, the lignite coal sample used is Yunnan Zhaotong lignite, comprising the following steps:

[0061] 1) The raw coal is pulverized, and the particle size of the coal sample obtained after screening is ≤2mm;

[0062] 2) Add the coal sample obtained in step 1) into the screw feeder through the feed hopper, and continuously supply it to the microwave drying cavity under the stirring of the screw blade;

[0063] 3) Turn on the hot air generating device and the microwave generating device, provide hot air and microwaves to the microwave drying chamber, and adjust the temperature of the hot air device to be 120°C and the power of the microwave generating device to be 1000W and the frequency to be 915MHz;

[0064] 4) Turn on the temperature measuring device to measure the temperature of the microwave drying cavity i...

Embodiment 3

[0070] The device structure of microwave hot air combined drying lignite is the same as that in Example 1.

[0071] A method for combining microwave hot air drying lignite, the lignite coal sample used is Yunnan Zhaotong lignite, comprising the following steps:

[0072] 1) The raw coal is pulverized, and the particle size of the coal sample obtained after screening is ≤3mm;

[0073] 2) Add the coal sample obtained in step 1) into the screw feeder through the feed hopper, and continuously supply it to the microwave drying cavity under the stirring of the screw blade;

[0074] 3) Turn on the hot air generating device and the microwave generating device, provide hot air and microwaves to the microwave drying chamber, and adjust the temperature of the hot air generating device to be 150°C and the power of the microwave generating device to be 4000W and the frequency to be 915MHz;

[0075] 4) Turn on the temperature measuring device to measure the temperature of the microwave dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com