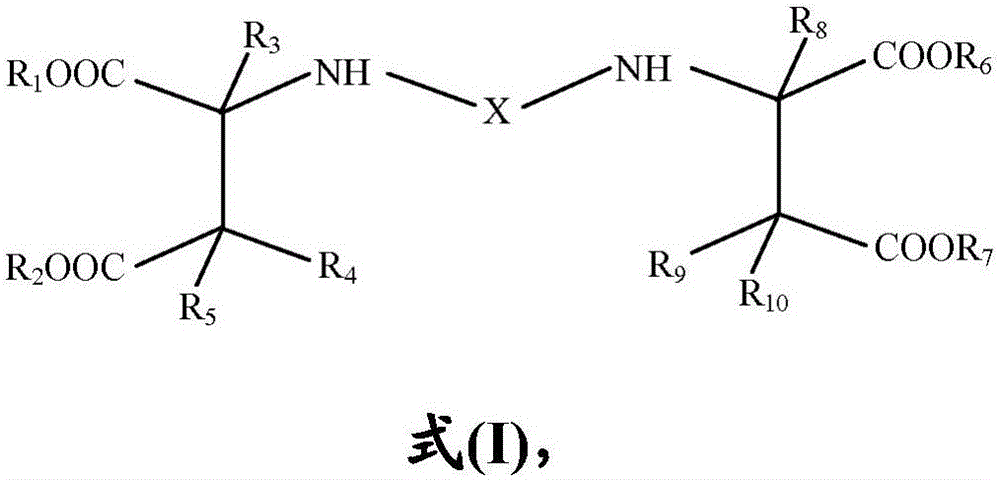

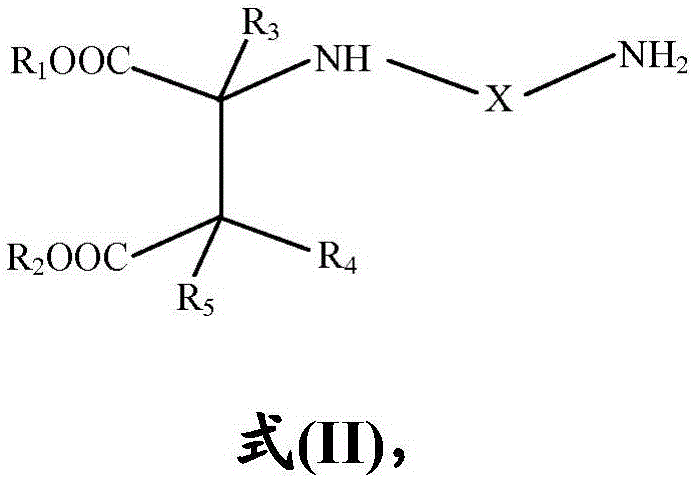

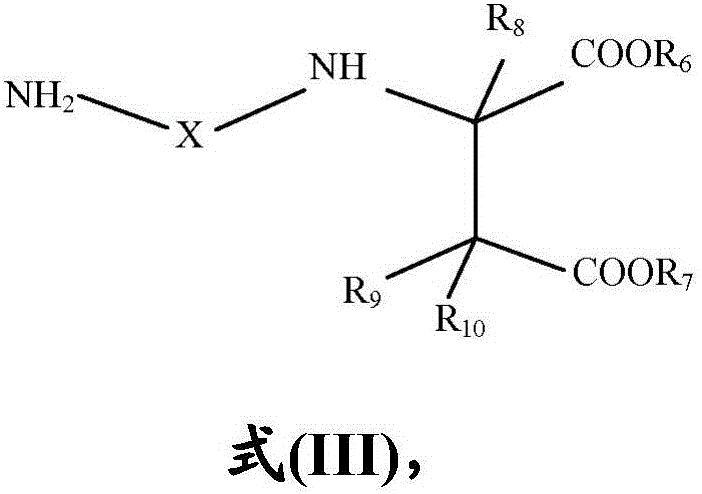

Coating compositions comprising diisocyanate chain extended bisaspartates

A technology of aspartate and monoaspartate, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve problems such as increased viscosity of compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0138] Measurement methods

[0139] The following measurement methods were used to evaluate the parameters given in the examples and claims.

[0140] Hazen color

[0141] Color values are measured on a BYK LCSIII instrument on the Hagstone scale (based on ASTM D1209).

[0142] Gardner-Holdt (bubble) viscosity

[0143] This method allows rapid determination of the kinematic viscosity of liquids such as resins and varnishes. Certified tubes from BykGardner are used to measure viscosity at room temperature.

[0144] valid period

[0145] The pot life of the composition is measured by determining the viscosity (DIN 4 cup) increase as a function of time. Pot life is defined as the time required for the initial viscosity to increase by a factor of 1.5. Pot life defines the period of time during which the clearcoat composition remains readily sprayable.

[0146] viscosity

[0147] The viscosity of the activated clearcoat is determined according to DIN 53211 with a DI...

Embodiment 5

[0184] Embodiment 5: Preparation of the transparent coating based on Comparative Examples 1, 2, 4A and 4B and Invention Example 3

[0185] A clear coat composition was prepared by using a 60.67% based N3390 (aliphatic polyisocyanate HDI trimer, 90% solids, Bayer), 36.93% n-butyl acetate and epoxy functional silane (2.4% from Momentive Performance Materials A187) polyisocyanate activator for activation. The clearcoat formulation and activator were mixed by hand in such a ratio that the NCO to NH ratio was kept constant at 1.21.

[0186] Clearcoats 5A, 5B, 5C, 5D, and 5E were formulated with the compounds shown in Table 1 below.

[0187] Table 1:

[0188]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com