Novel gauze drying and rapid winding equipment

A gauze and fast technology, which is applied in the field of new gauze drying and fast winding equipment, can solve the problems of gauze yarn compactness and flatness interference, loose yarn off-line, residual pimples on the surface of gauze cloth, etc., and achieve improvement The effect of quality assurance, avoiding sticking, and guaranteeing the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

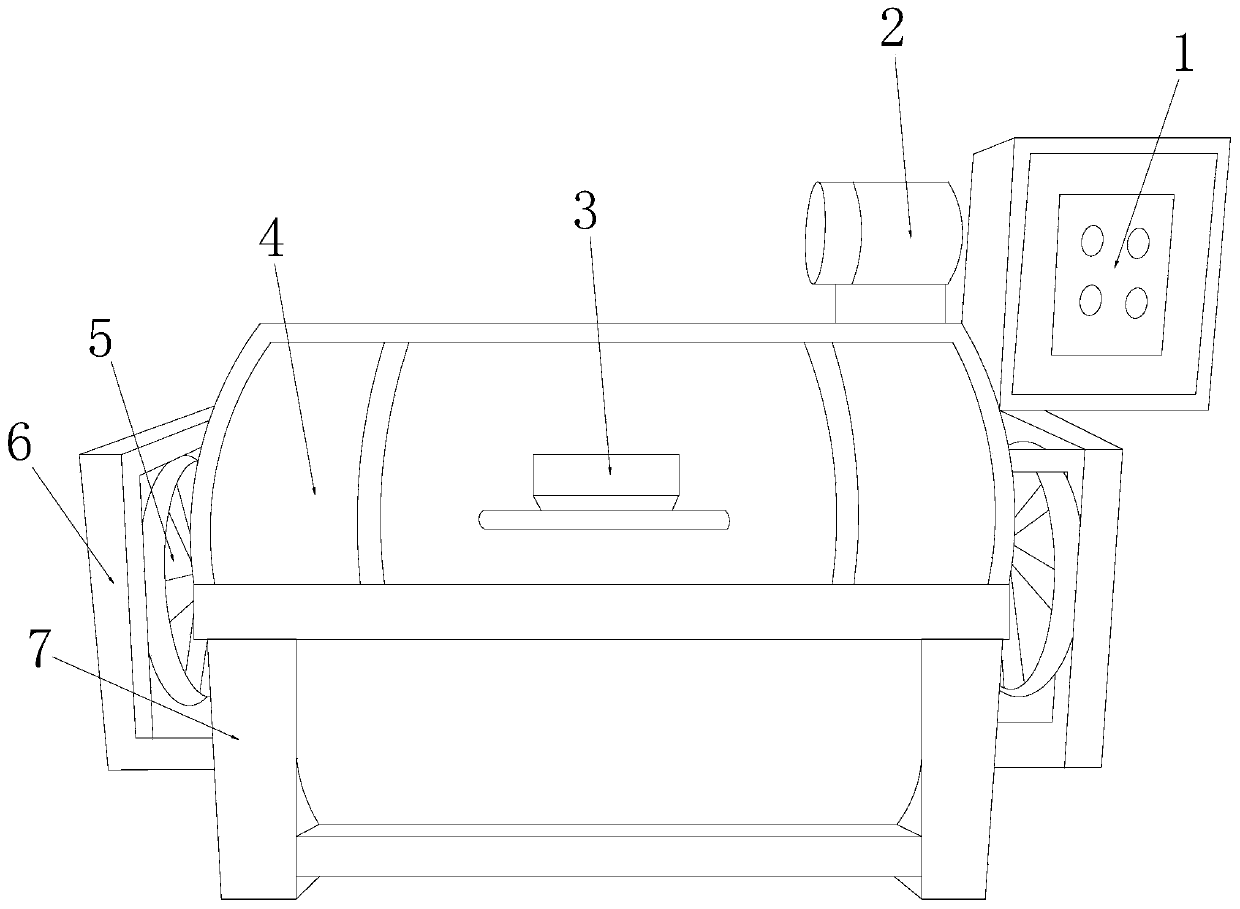

[0032] see Figure 1-Figure 6, the present invention provides a new type of gauze drying and fast winding equipment, the structure of which includes: electric control box 1, shaft motor 2, pull rod handle 3, drying roll sliding lining tube 4, traction wheel frame 5, limit frame Block 6, dash panel frame 7, the roll-drying sliding lining tube 4 is installed inside the dash panel frame 7, and the limit frame block 6 is provided with two and welded on the left and right sides of the dash panel frame 7 respectively On both sides, the traction sheave frame 5 is installed inside the limit frame block 6, the rolling slip bushing tube 4 is mechanically connected with the traction sheave frame 5 and the axes are collinear, and the tie rod handle 3 is welded on The front side of the roll drying sleeve 4, the electric control box 1 is electrically connected with the shaft motor 2, and the shaft motor 2 is installed on the upper right corner of the roll drying sleeve 4, and the roll dryin...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a new type of gauze drying and fast winding equipment, the other aspects are the same as in Embodiment 1, the difference is:

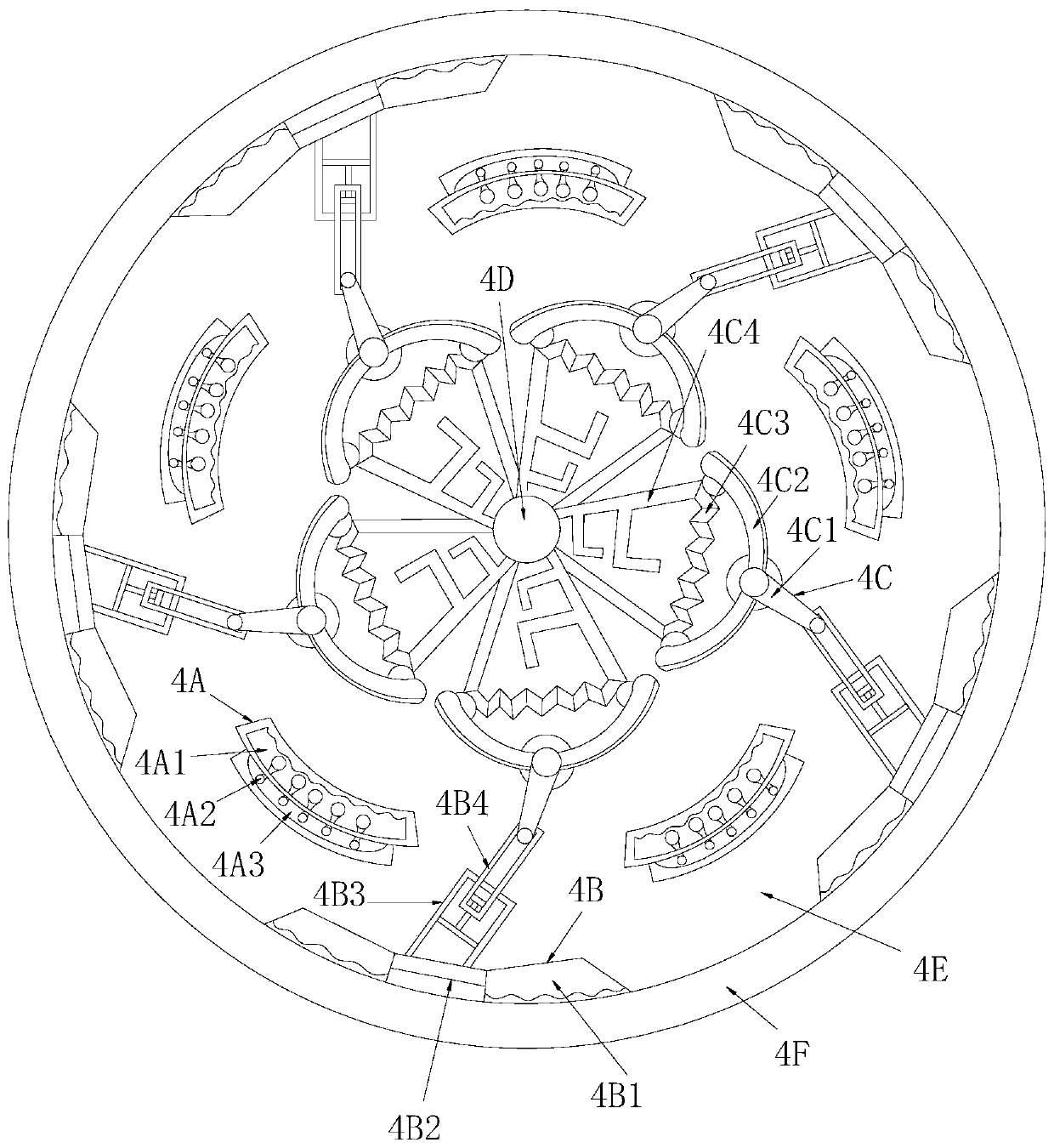

[0040] see figure 2 The arc brush holder plate groove 4A is composed of an inner arc frame track 4A1, a club sliding block 4A2, and a buckle arc groove 4A3, and the press buckle arc groove 4A3 is welded together with the inner arc frame track 4A1 and is on the same arc surface The above-mentioned inner arc frame track 4A1 and the club sliding block 4A2 adopt a gap fit, and the inner arc frame track 4A1 supports the club sliding block 4A2 sliding brush to ensure the overall effect of the middle partition and improve the ventilation linkage around the gap sex.

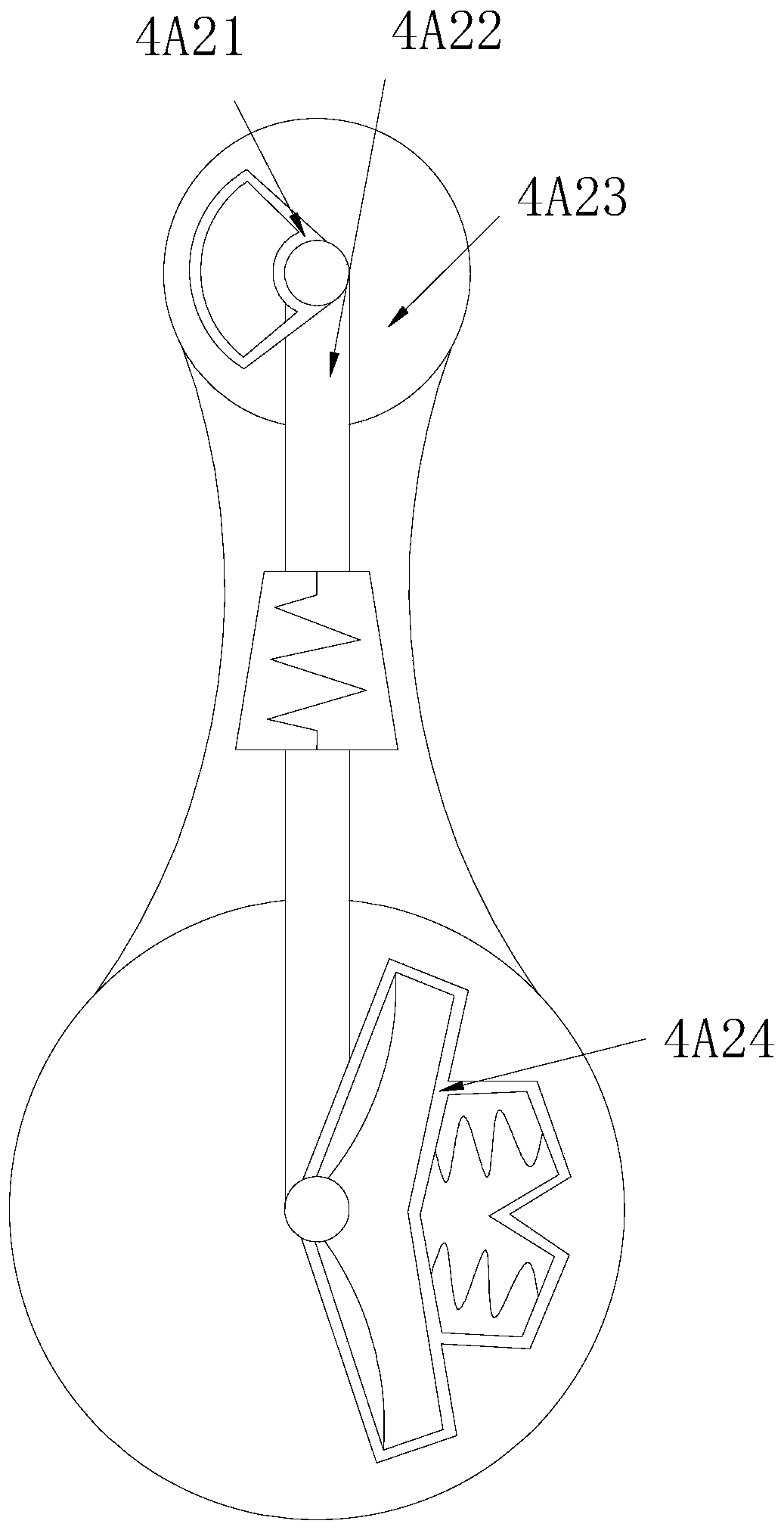

[0041] see image 3 The club sliding block 4A2 is composed of a fan frame 4A21, a slider pole 4A22, a double wheel bar plate 4A23, and a collision bracket 4A24, and the fan frame 4A21 and the collision bracket 4A24 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com