Patents

Literature

153results about How to "Guaranteed maintenance effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

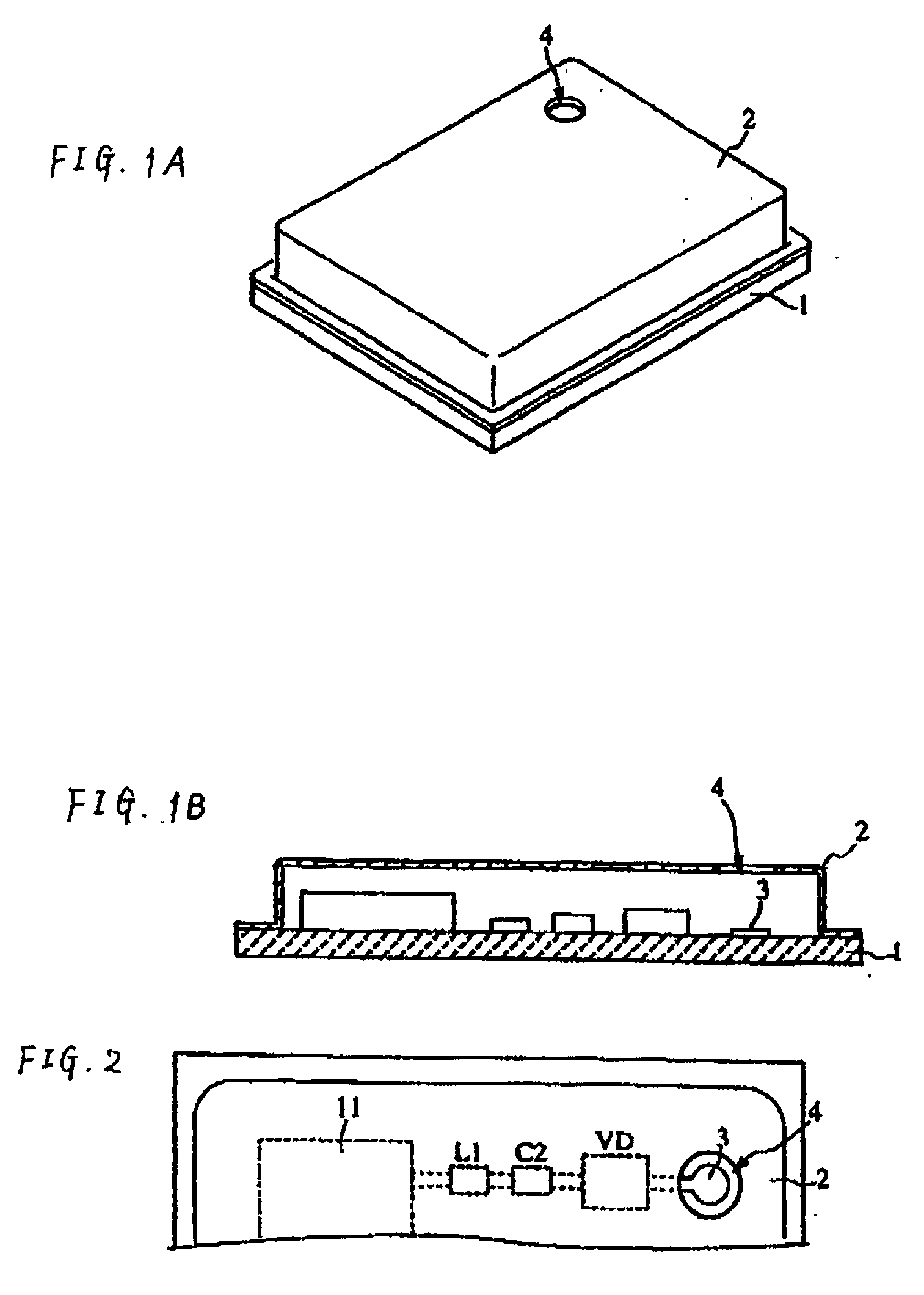

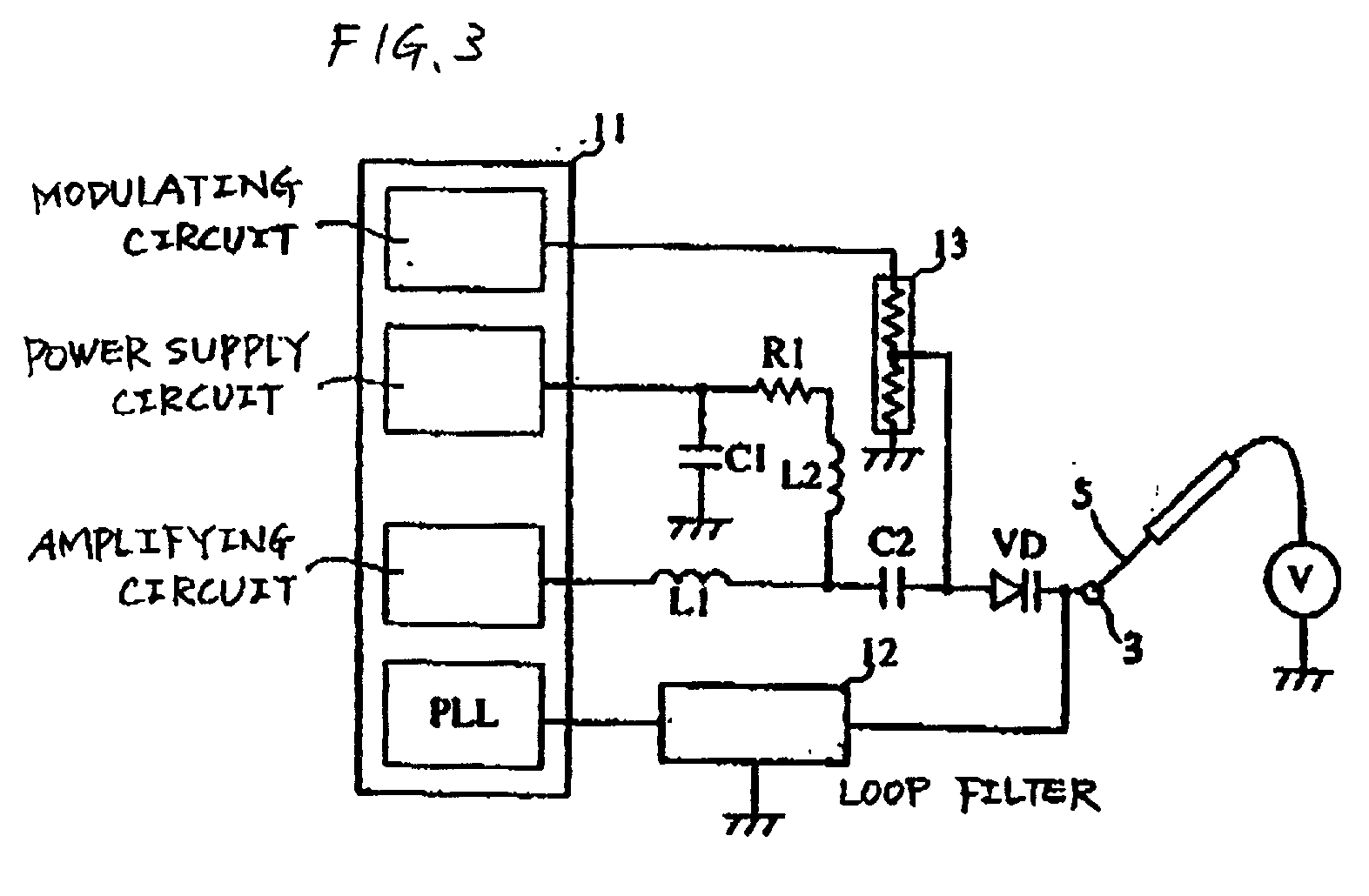

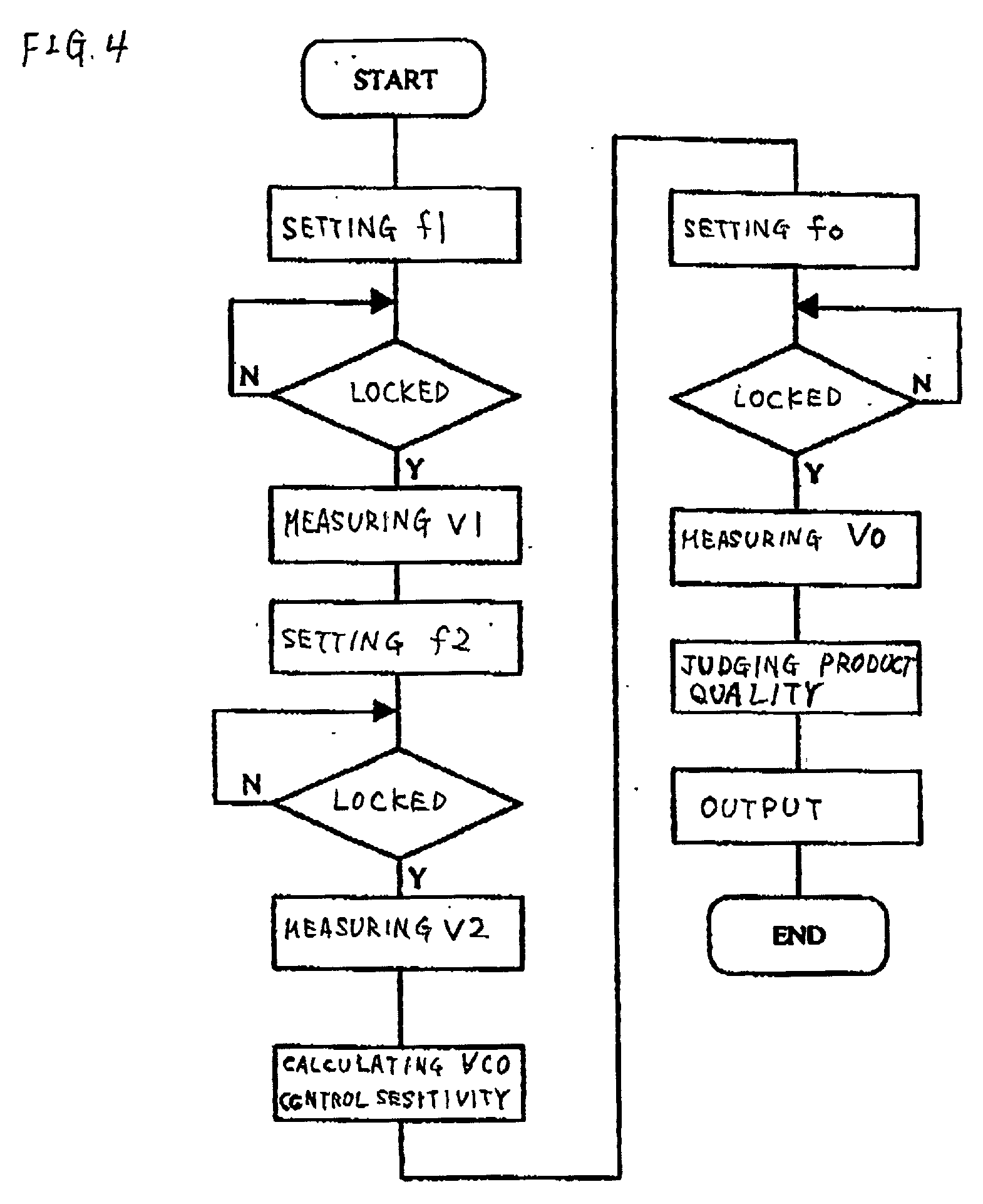

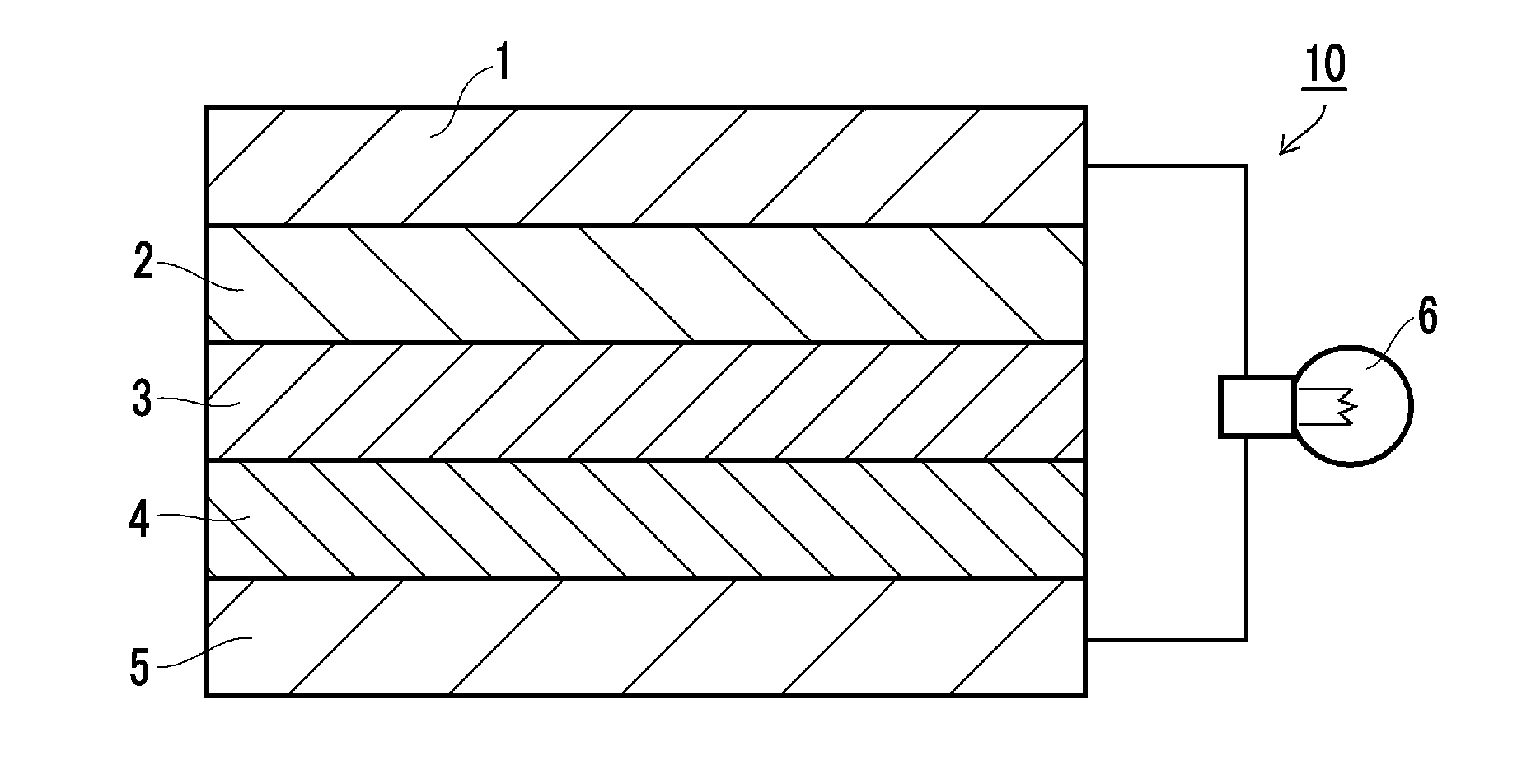

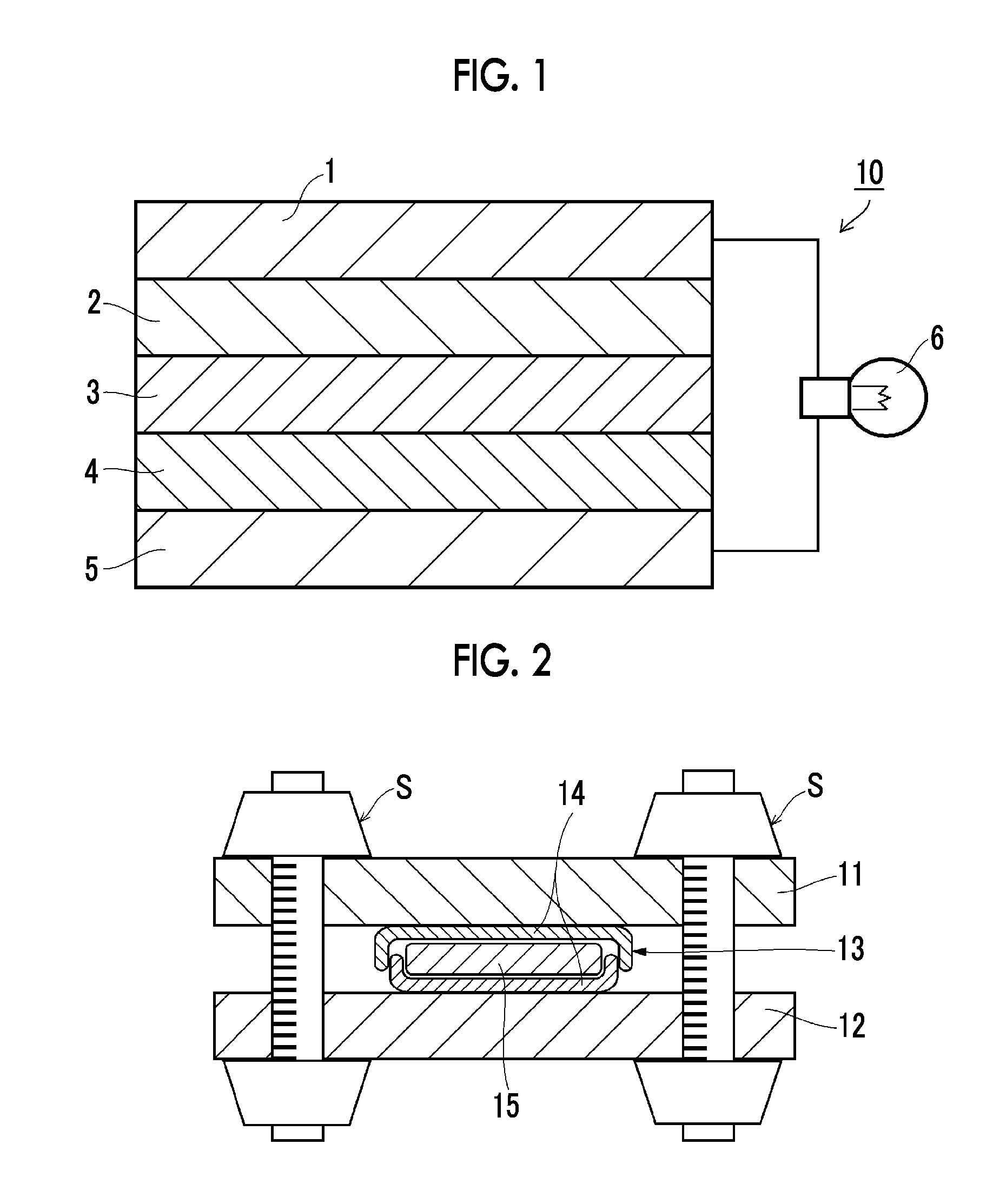

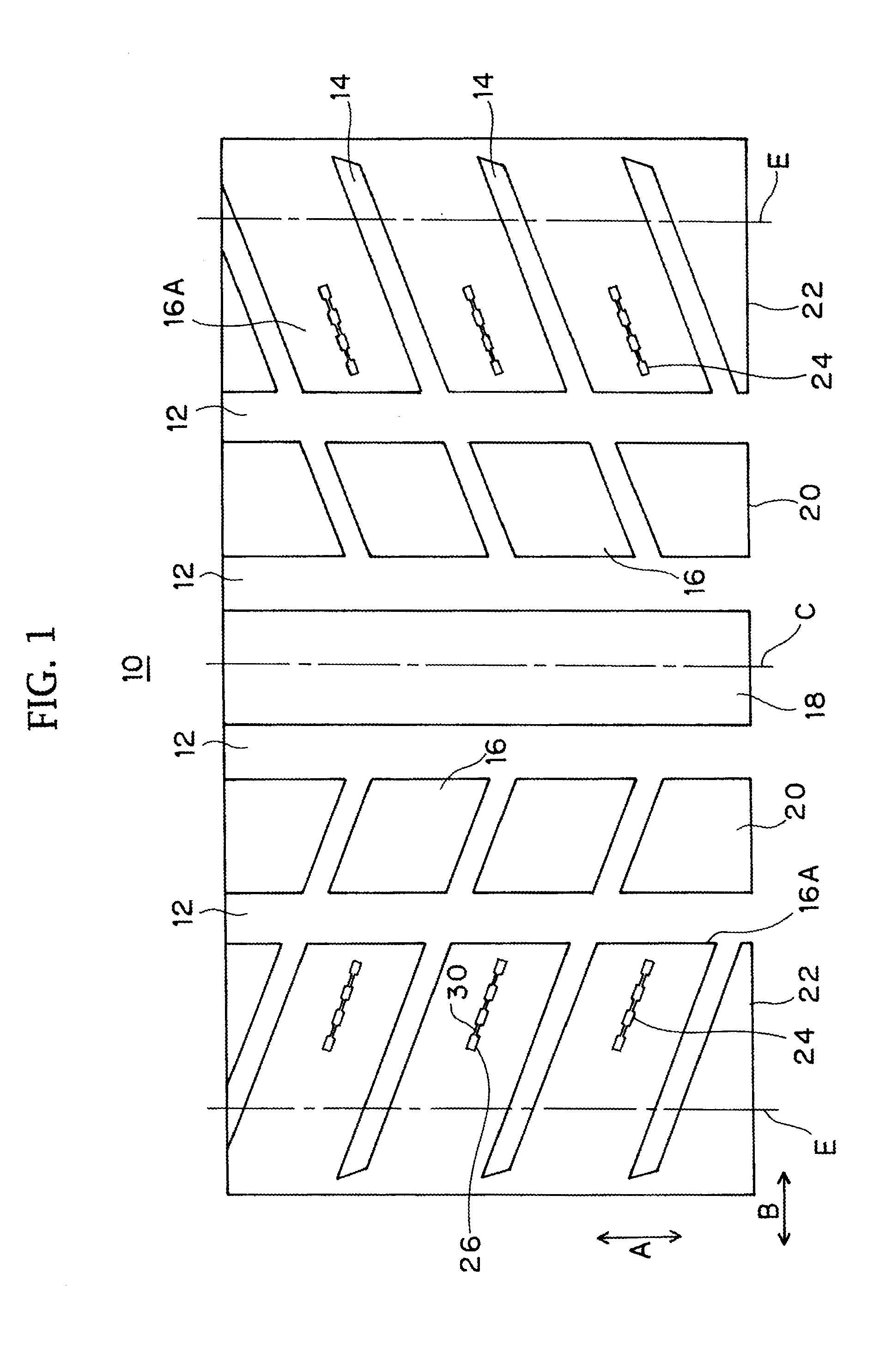

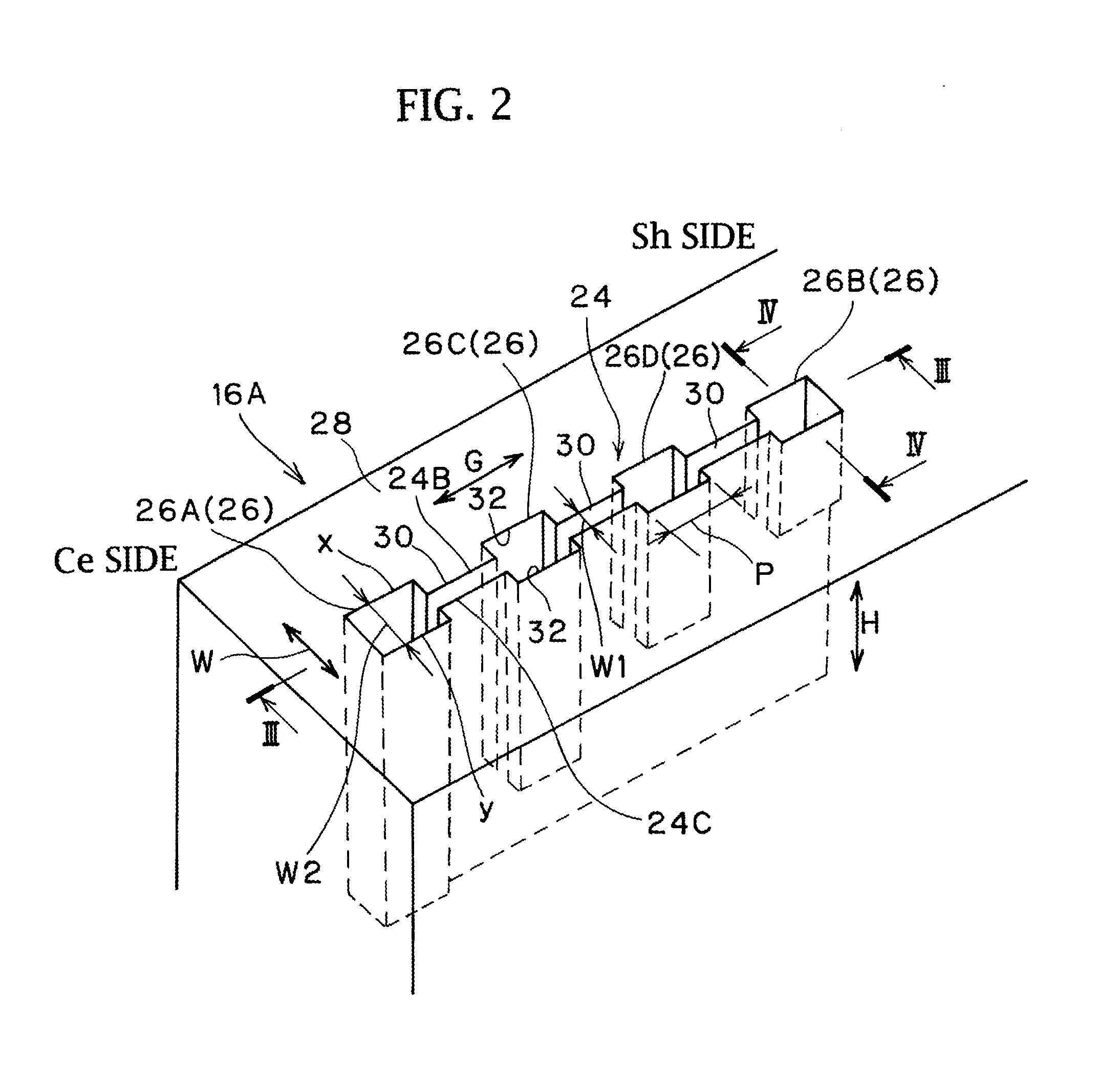

High frequency component, communication apparatus, and method for measuring characteristics of high frequency component

InactiveUS20010050550A1Easy to measureSuppresses radiation and incidenceMagnetic/electric field screeningMeasurement leads/probesCommunication deviceVIT signals

A high frequency component is constructed such that the characteristics of a high frequency circuit that cannot be measured only by an outwardly extending terminal electrode are easily measured at the final-product stage. In the high frequency component, a substrate has an electrode pattern provided including a signal measuring electrode pad. Additionally, chip components are mounted on the substrate. A metal cover has a hole provided near the signal measuring electrode pad. Through the hole, a probe of a measuring apparatus is inserted from the outside to abut with the electrode pad. With the arrangement, a voltage signal obtained at a predetermined point of the high frequency circuit is measured.

Owner:MURATA MFG CO LTD

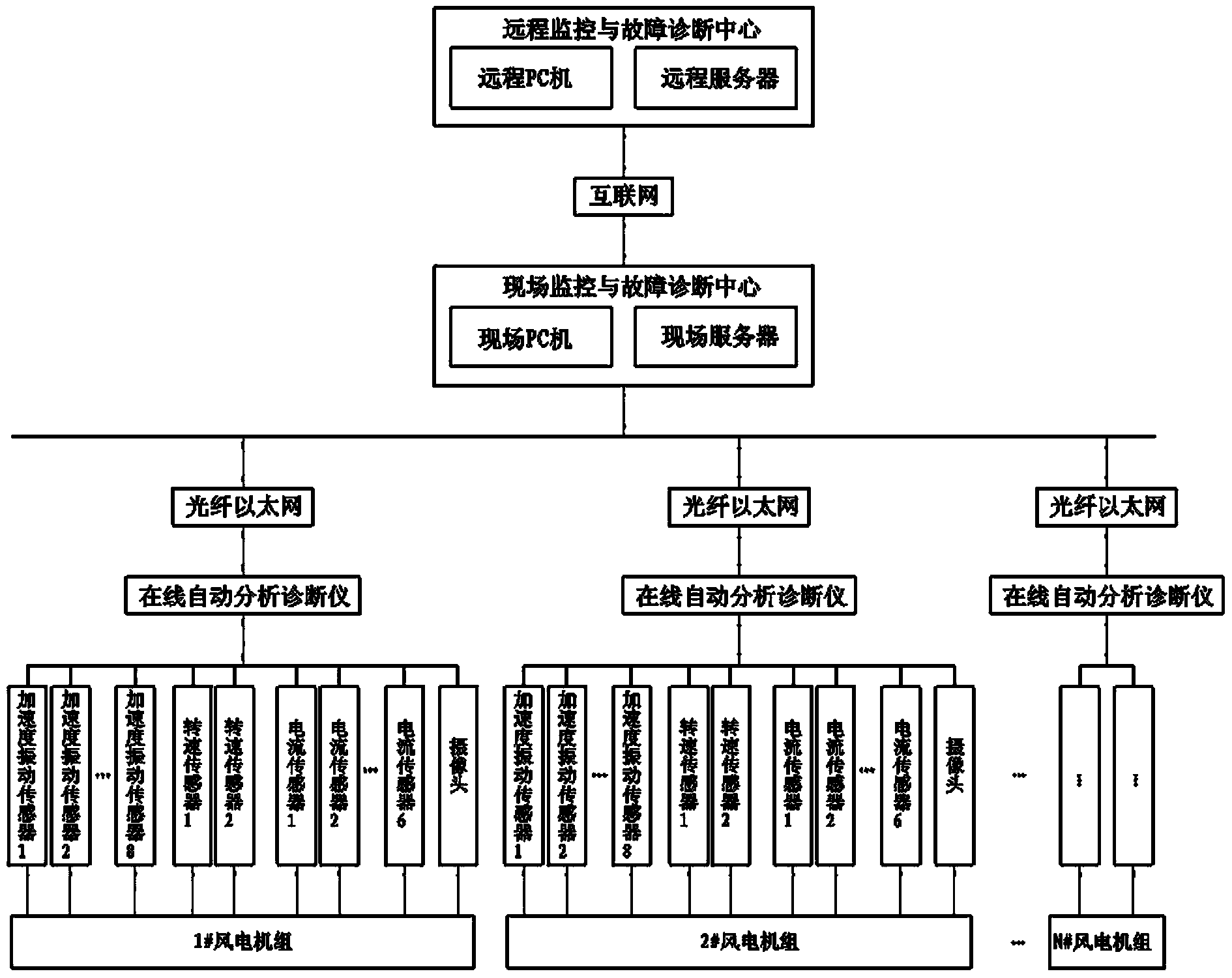

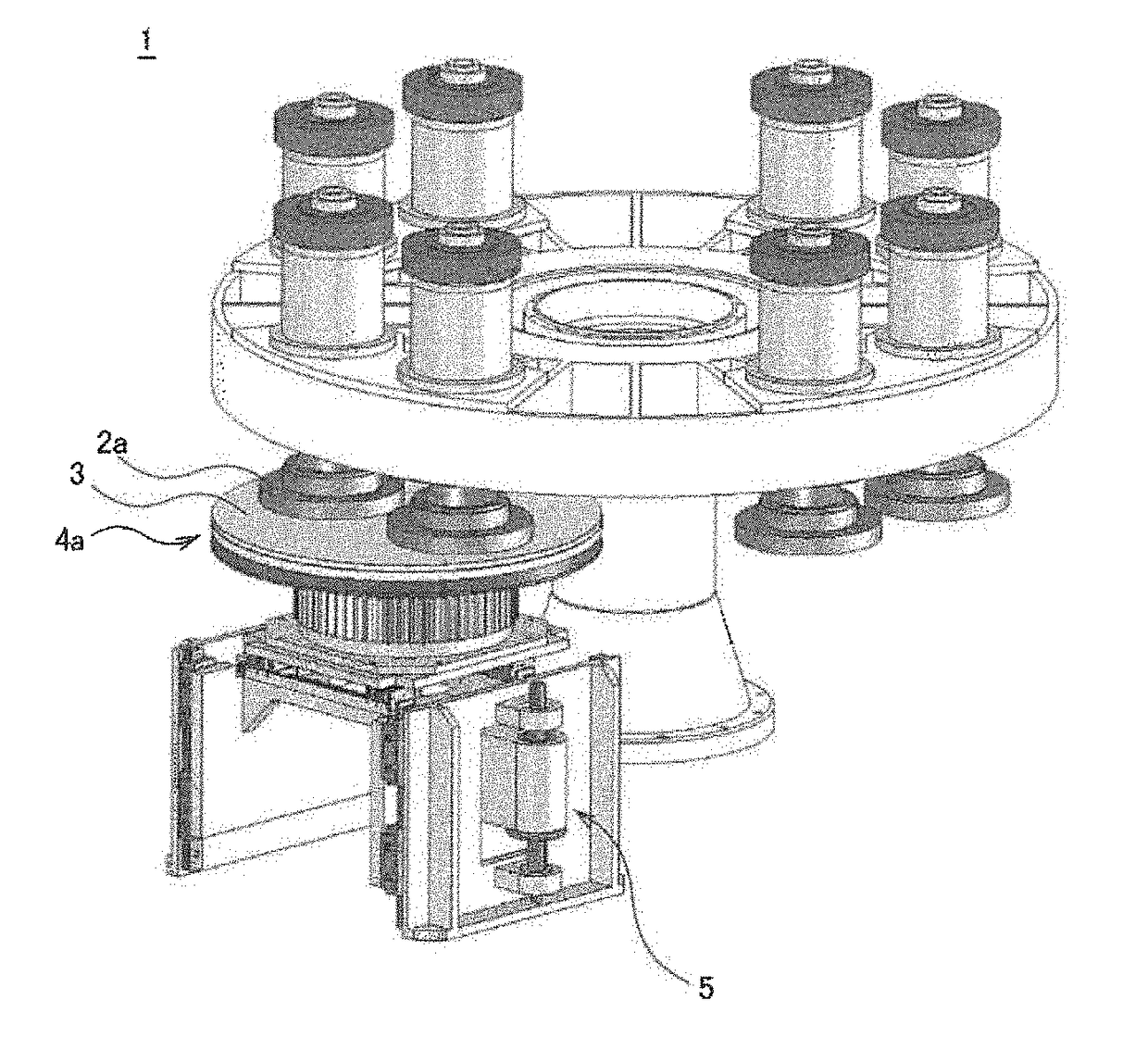

System and method for remote real-time state monitoring and intelligent failure diagnosis of wind turbine generators

ActiveCN103529386AGuaranteed maintenanceGuaranteed maintenance effectNon-electrical signal transmission systemsDynamo-electric machine testingSite monitoringElectricity

The invention relates to a technology for examining and maintaining wind turbine generators, in particular to a system and a method for the remote real-time state monitoring and the intelligent failure diagnosis of the wind turbine generators. The problems that the existing technology for examining and maintaining the wind turbine generators cannot ensure the examining and maintaining effect, cannot timely find the internal failure, the sudden failure and the hidden failure trouble of the wind turbine generators and requires a high examining and maintaining cost are solved. The system for the remote real-time state monitoring and the intelligent failure diagnosis of the wind turbine generators comprises state monitoring equipment, a site monitoring and failure diagnosis center and a remote monitoring and failure diagnosis center, wherein the state monitoring equipment comprises an accelerated vibration sensor, a rotating speed sensor, a current sensor, a camera and an on-line automatic analysis and diagnosis instrument; the site monitoring and failure diagnosis center comprises a site server and a site PC (Personal Computer). The system and the method are suitable for all types of wind turbine generators.

Owner:山西大学工程学院

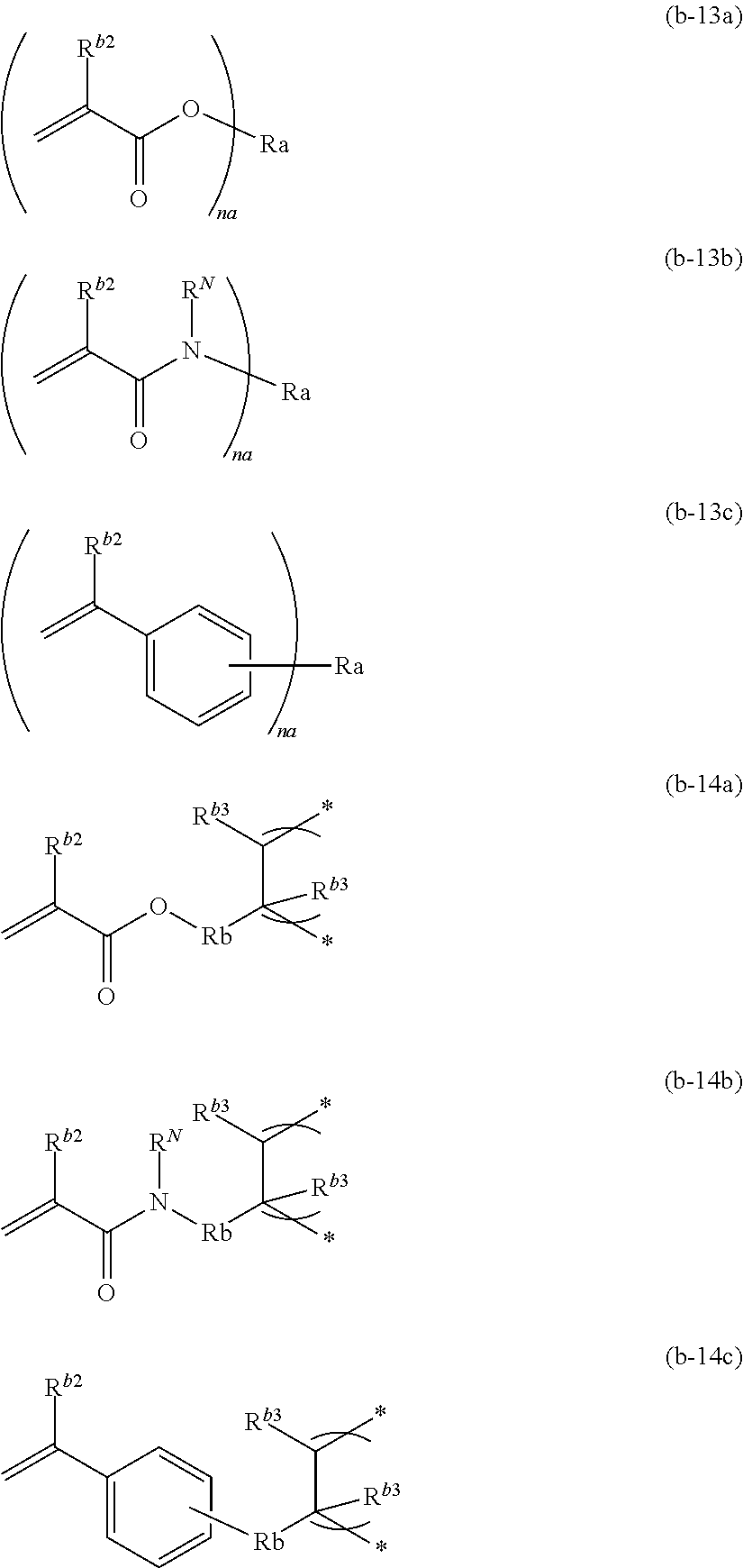

Solid electrolyte composition, electrode sheet for batteries using same and all-solid-state secondary battery

InactiveUS20160204465A1Interface resistance increaseGood effectNon-metal conductorsSolid electrolytesIonSide chain

Provided is a solid electrolyte composition including: an inorganic solid electrolyte (A) having conductivity of an ion of metal belong to Group 1 or 2 in the periodic table; binder particles (B) which is formed of a polymer combined with a macromonomer (X) including a side chain component having a number average molecular weight of 1,000 or greater, and which has an average diameter of 10 nm to 1,000 nm, and a dispersion medium (C).

Owner:FUJIFILM CORP

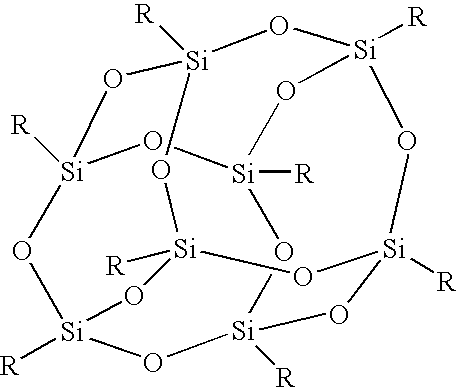

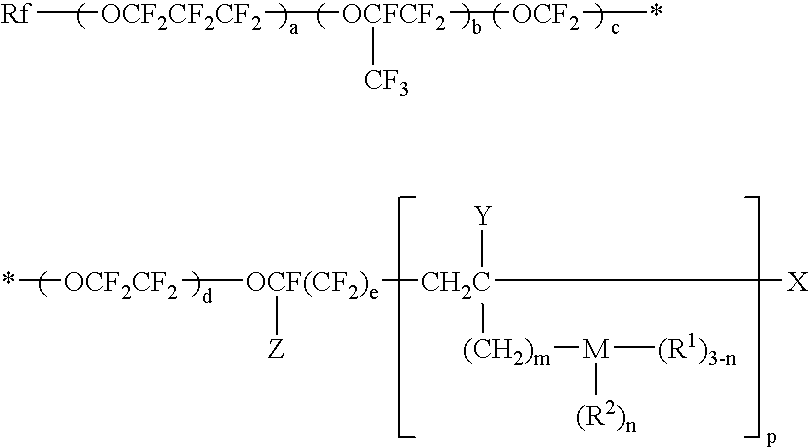

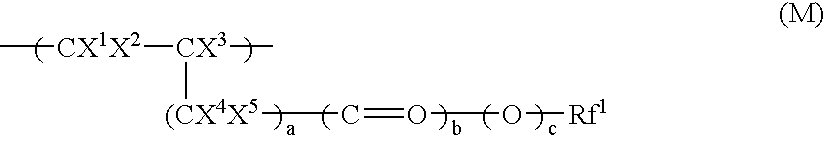

Surface-treating agent comprising inorganic/organic composite material

InactiveUS20040186216A1Excellent releasabilityHigh transparencySynthetic resin layered productsOrganic dyesRefractive indexOrganic chemistry

A surface treatment agent, which contains: (A) a hydrolyzable metal alkoxide or a hydrolyzate thereof, (B) a fluorocompound containing a perfluoroalkyl group and a functional group reactive with the hydrolyzable metal alkoxide (A), and (C) an adhesion improvement agent, can provide a film having transparency and durability while maintaining excellent soil releasability and low refractive index.

Owner:DAIKIN IND LTD

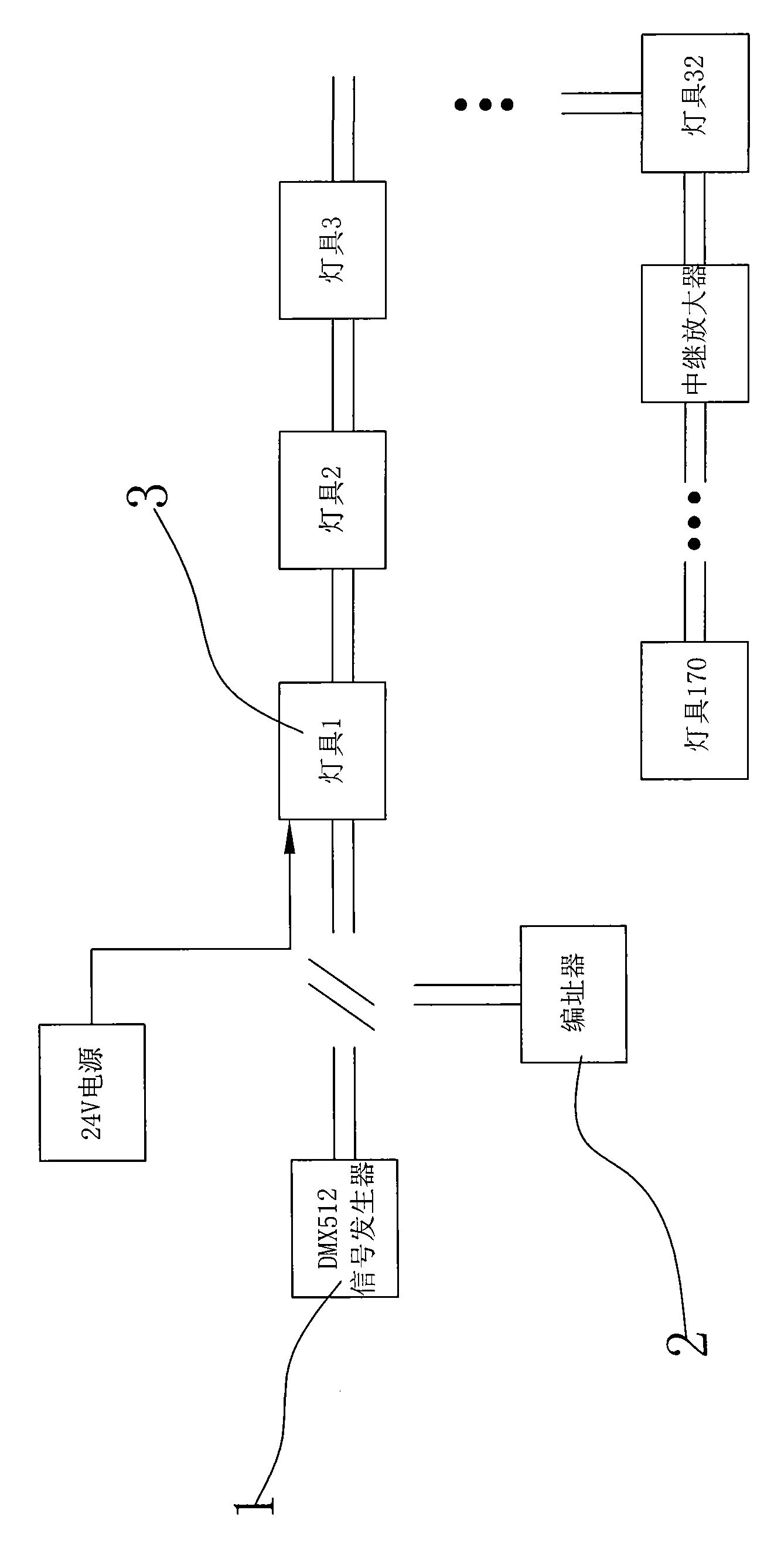

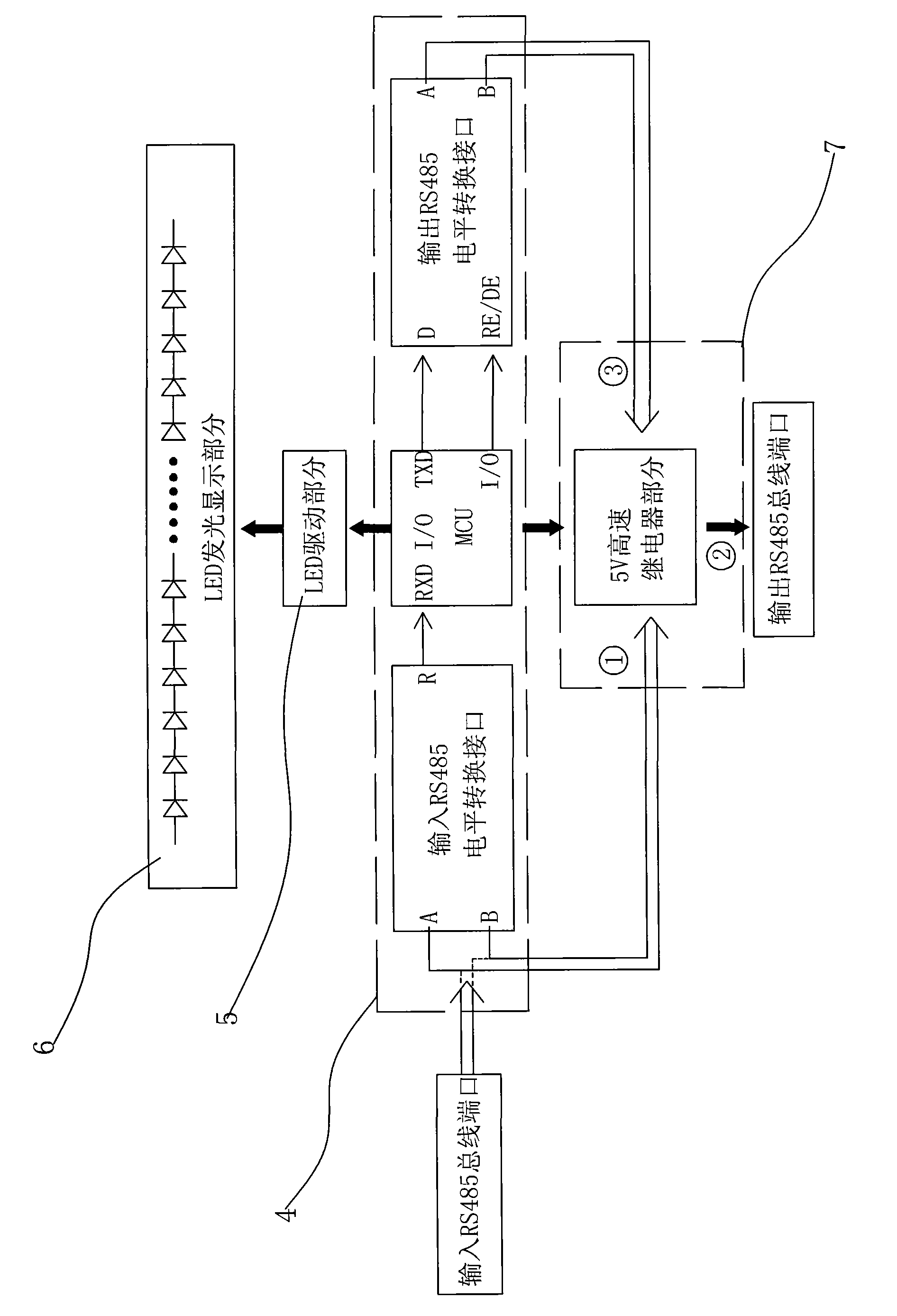

Intelligent LED lamp controller and control method

InactiveCN101945516AImprove efficiencyShorten the construction periodElectric light circuit arrangementEnergy saving control techniquesEmbedded systemDMX512

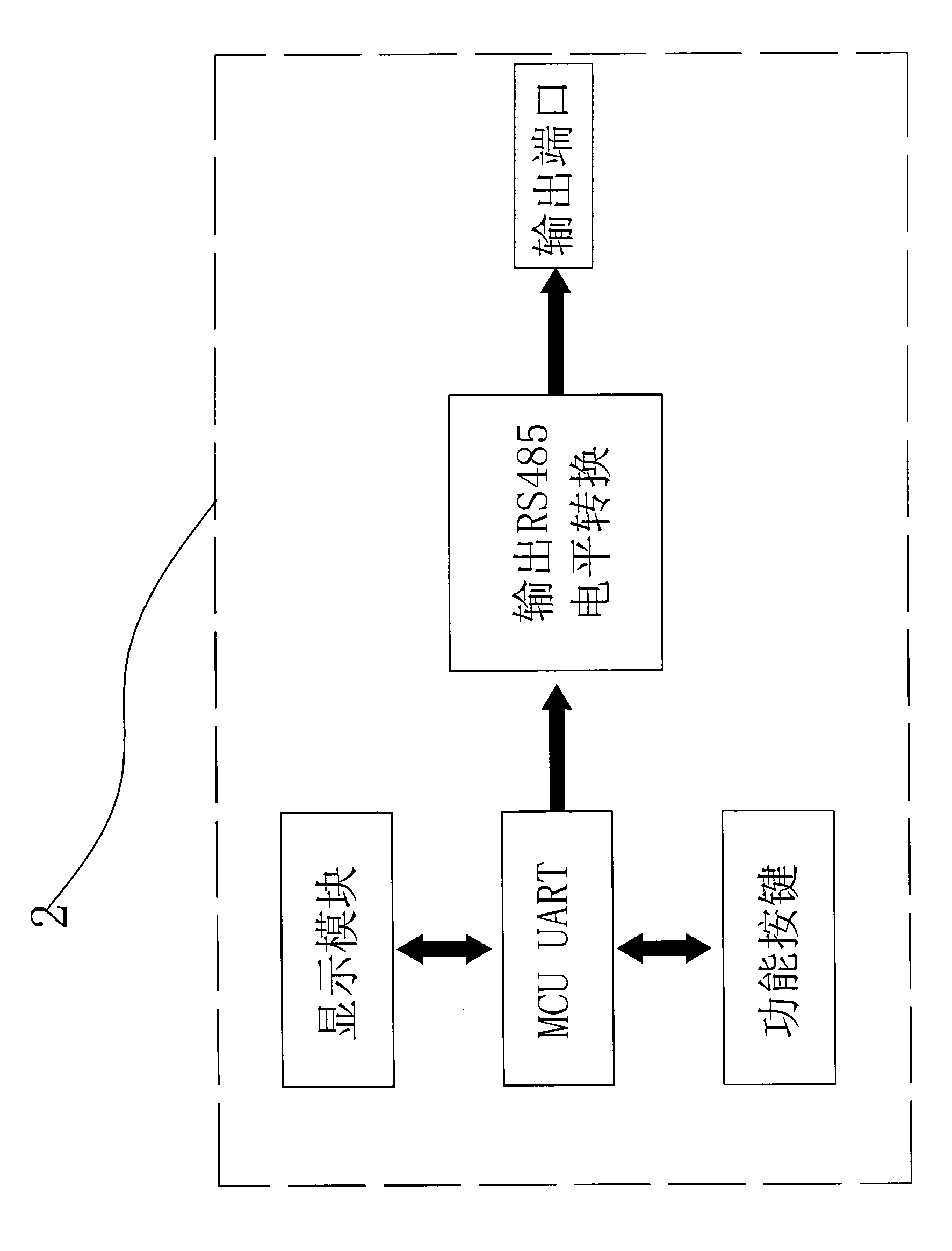

The invention relates to an intelligent LED lamp controller and a control method. The intelligent LED lamp controller is provided with a parallel connection / serial connection conversion unit which is connected with a decoding module. When all LED lamps are not subjected to address code writing and normally receive data transmitted by a DMX512 signal generator, the input RS485 bus and the output RS485 bus of the lamps are in parallel connection, namely the lamps are connected in parallel to a public RS485 bus through the input RS485 bus and the output RS485 bus to perform data communication with the DMX512 signal generator; and when an addressing device codes address codes for the lamps, the decoding module controls the parallel connection / serial connection conversion unit to change the parallel connection of the input and output RS485 buses in the lamps into serial connection. The intelligent LED lamp controller has the advantages that: the failure of one lamp cannot influence other lamps, and the assembly sequence and positions of the lamps can be changed freely, the lamps are serially connected during automatic addressing, and the lamps of the whole system are communicated in parallel through the buses once the address is coded.

Owner:杭州罗莱迪思科技股份有限公司

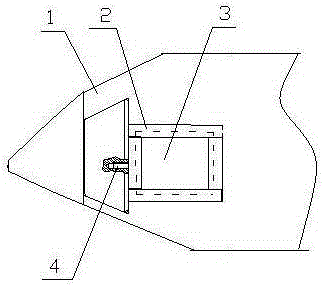

Pneumatic tire and method of manufacturing the same

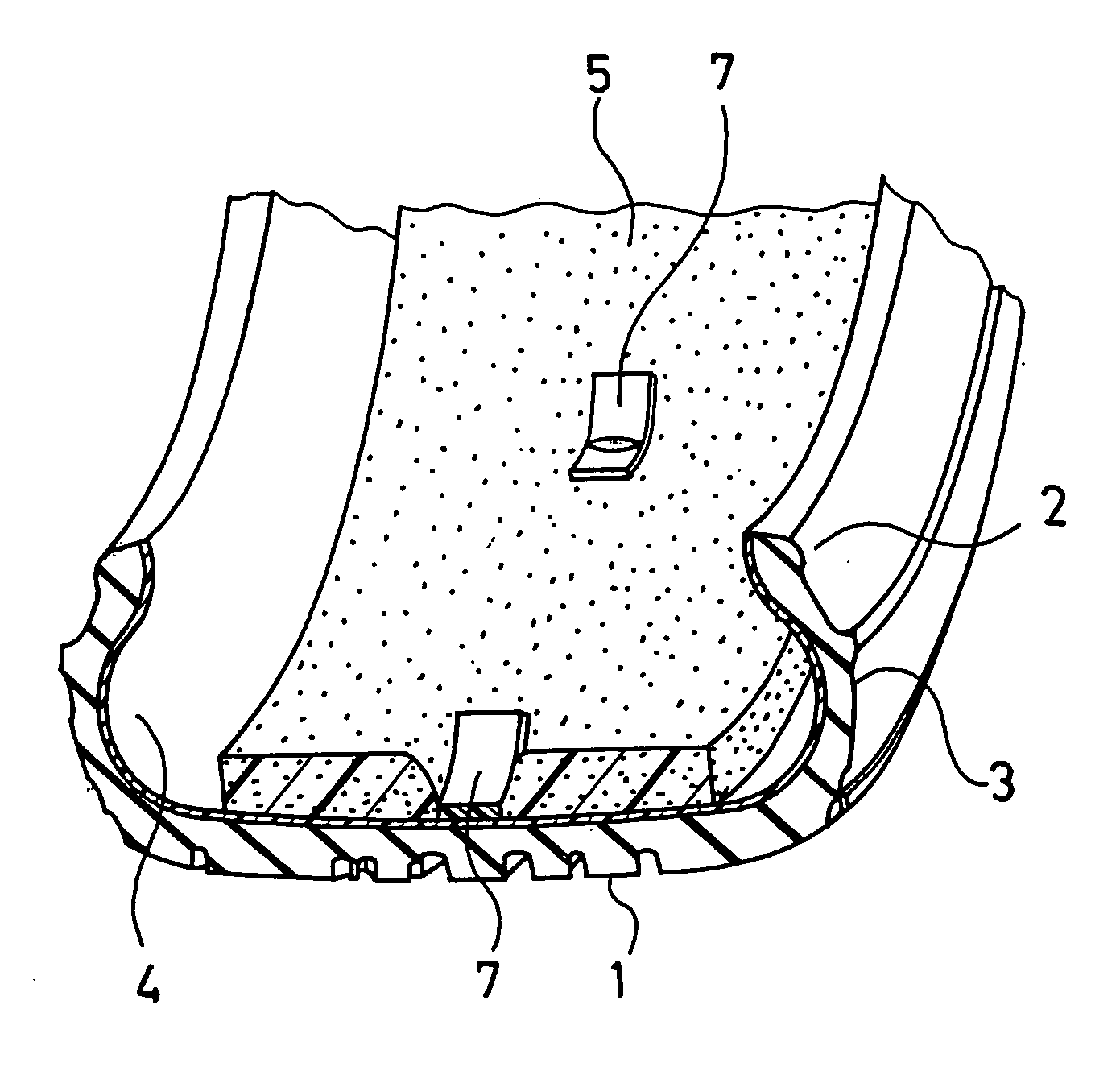

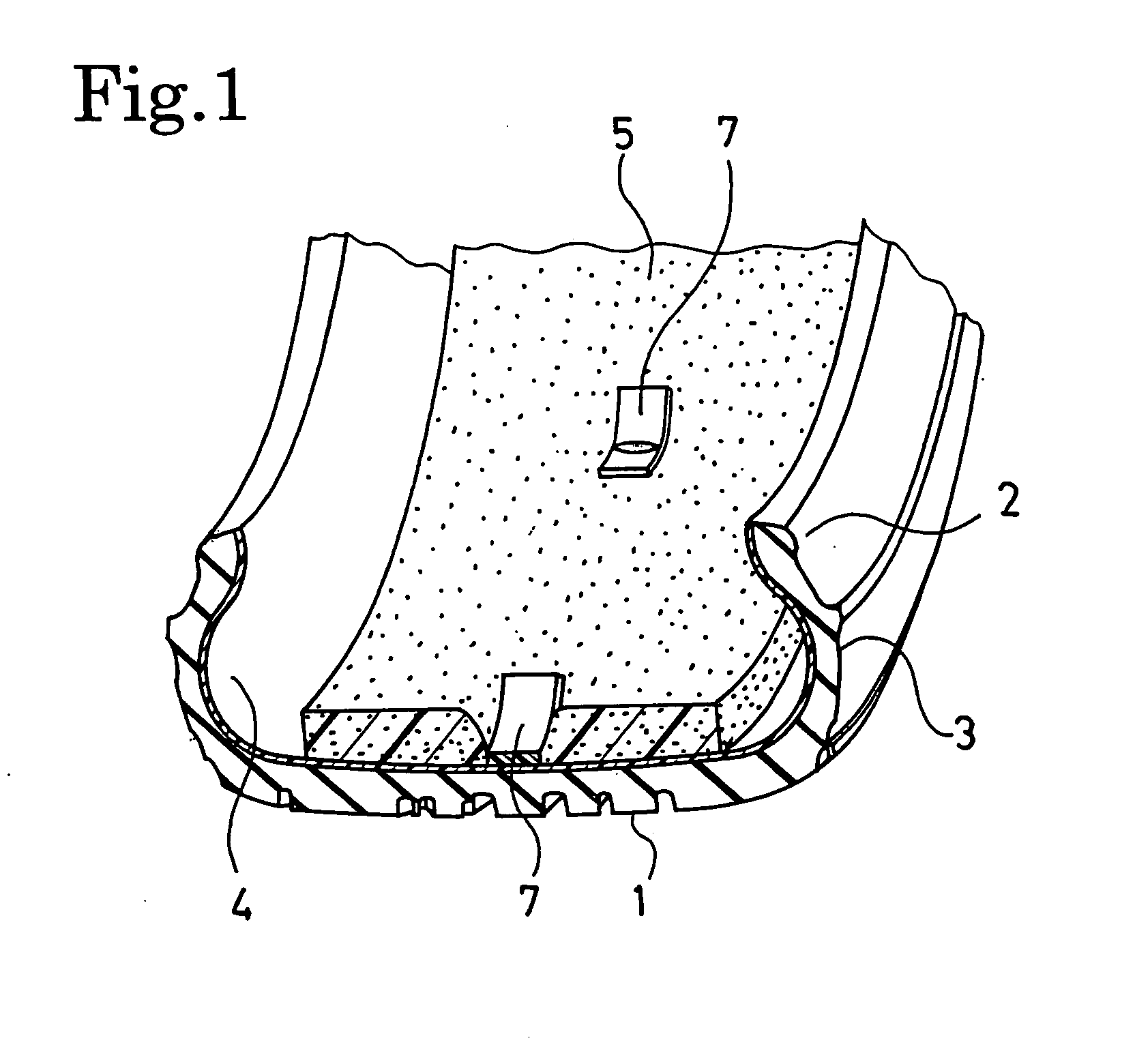

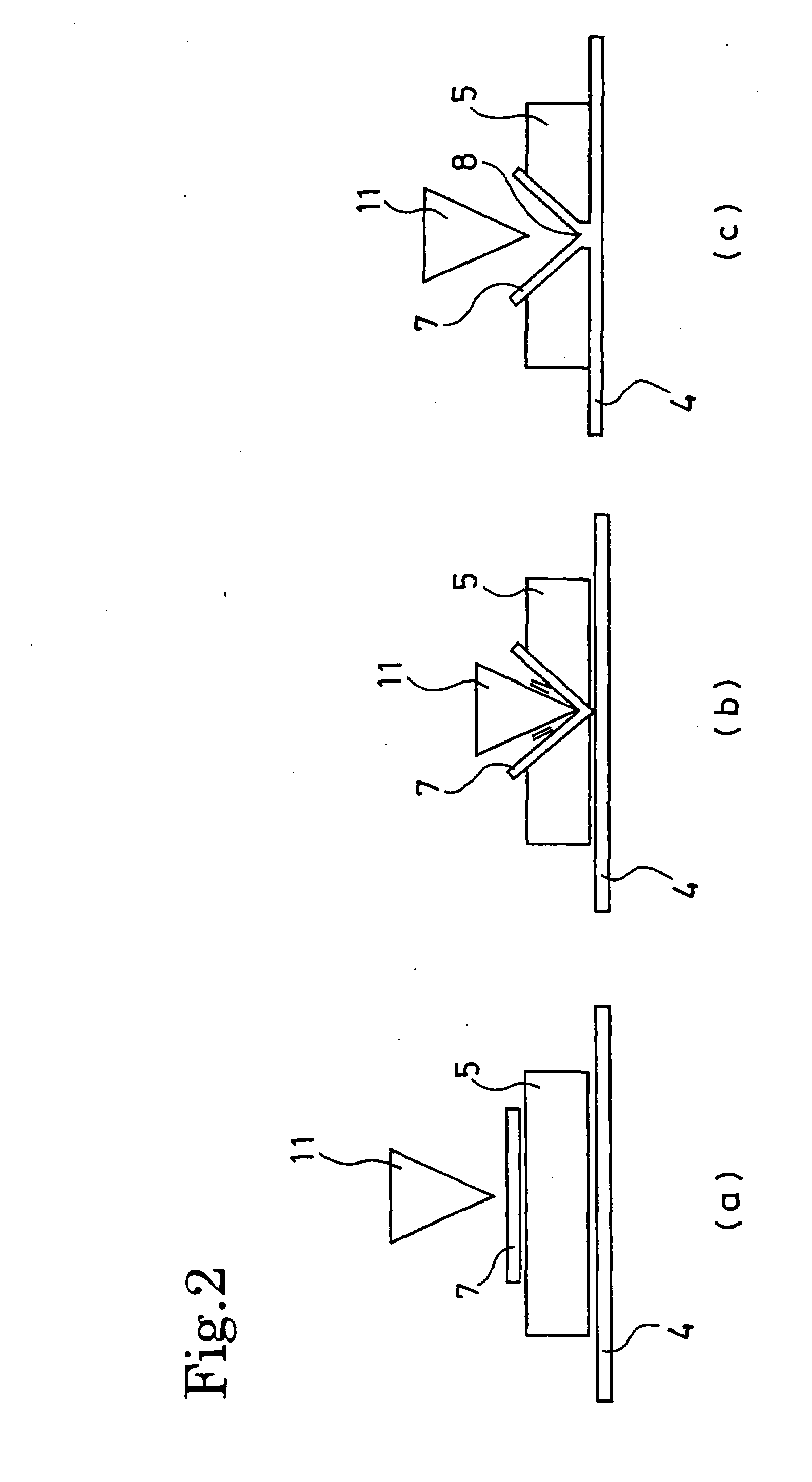

ActiveUS20090199942A1Improve adhesionGuaranteed maintenance effectWithout separate inflatable insertsTyresElastomerThermoplastic elastomer

Provided is a pneumatic tire in which the adhesion of a noise absorbing member formed of a porous material is improved. A pneumatic tire according to the present invention includes a resin layer, a noise absorbing member and a locking member. The resin layer is formed of any one of a thermoplastic resin and a thermoplastic elastomeric composition obtained by dispersing an elastomer in a thermoplastic resin, and is formed on at least a part of the inner surface of the tire. The noise absorbing member is formed of a porous material, and is disposed on the resin layer. The locking member is formed of a thermoplastic resin, and is bonded to the resin layer through the noise absorbing member by thermal fusion.

Owner:THE YOKOHAMA RUBBER CO LTD

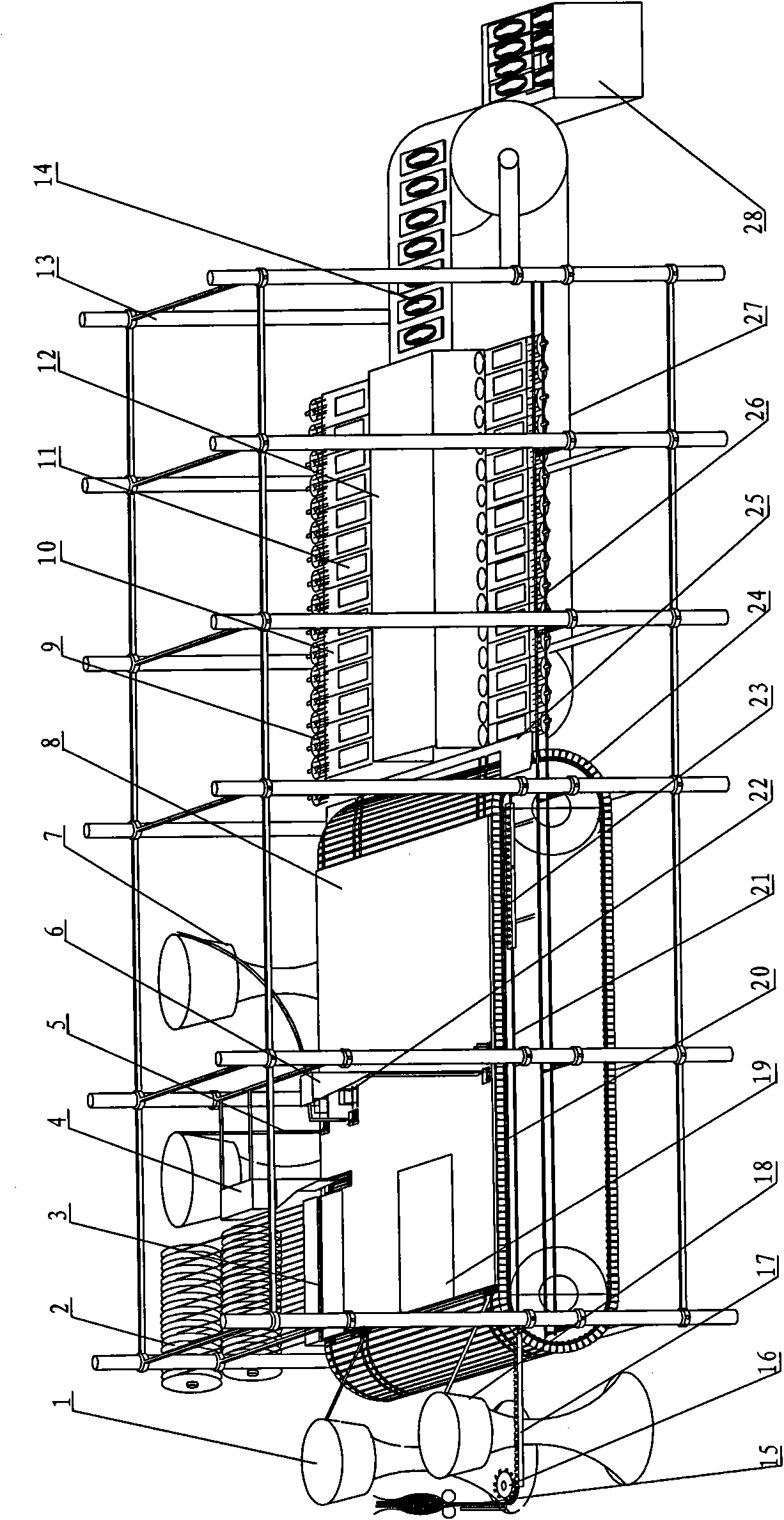

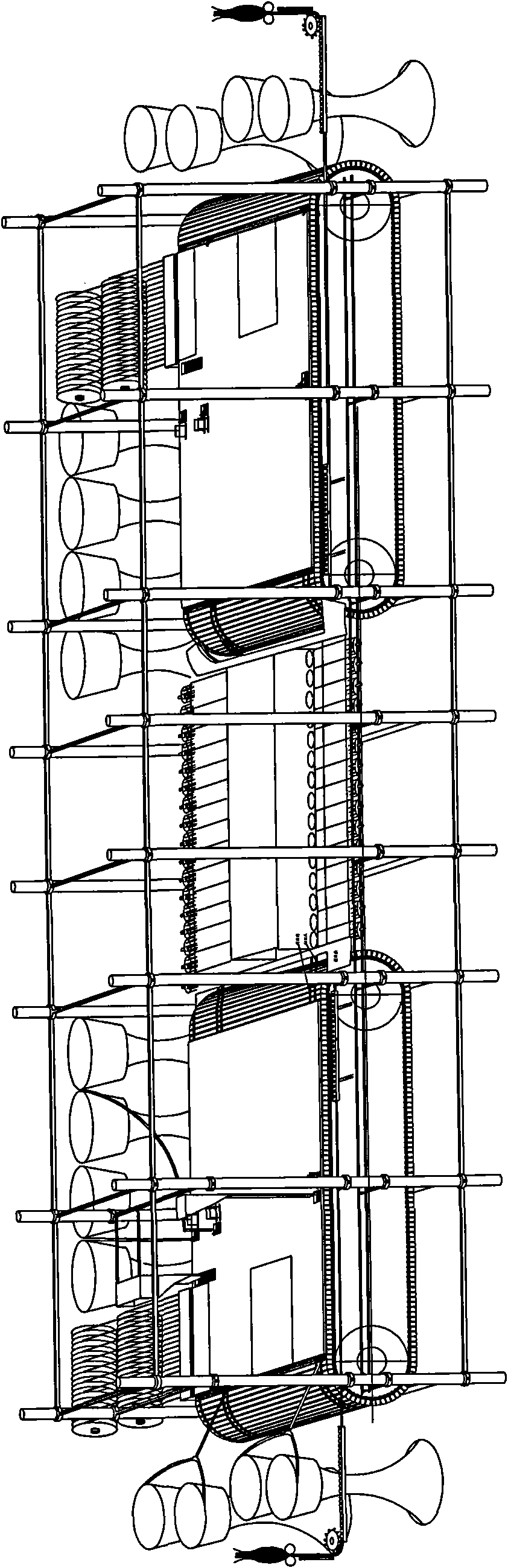

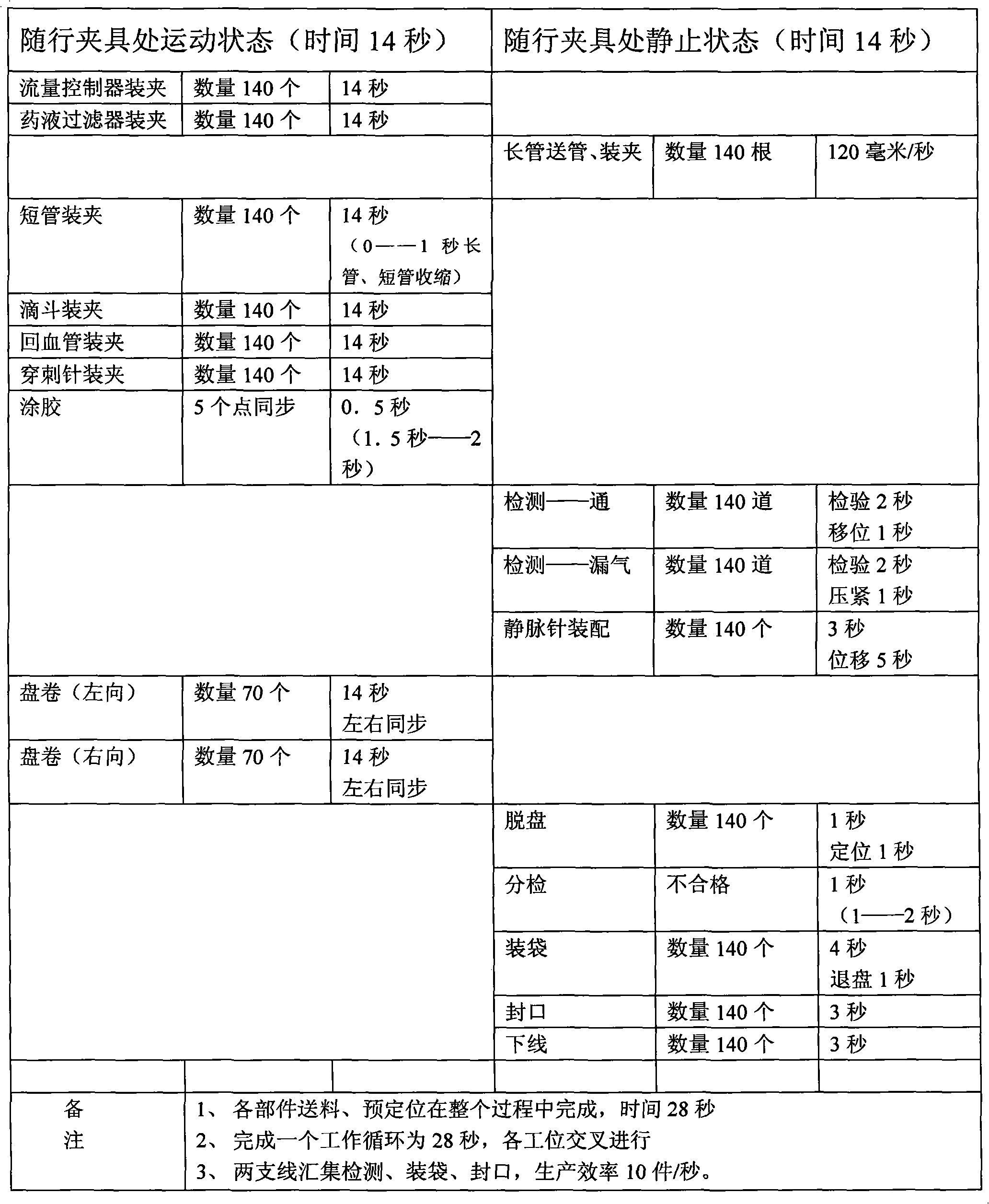

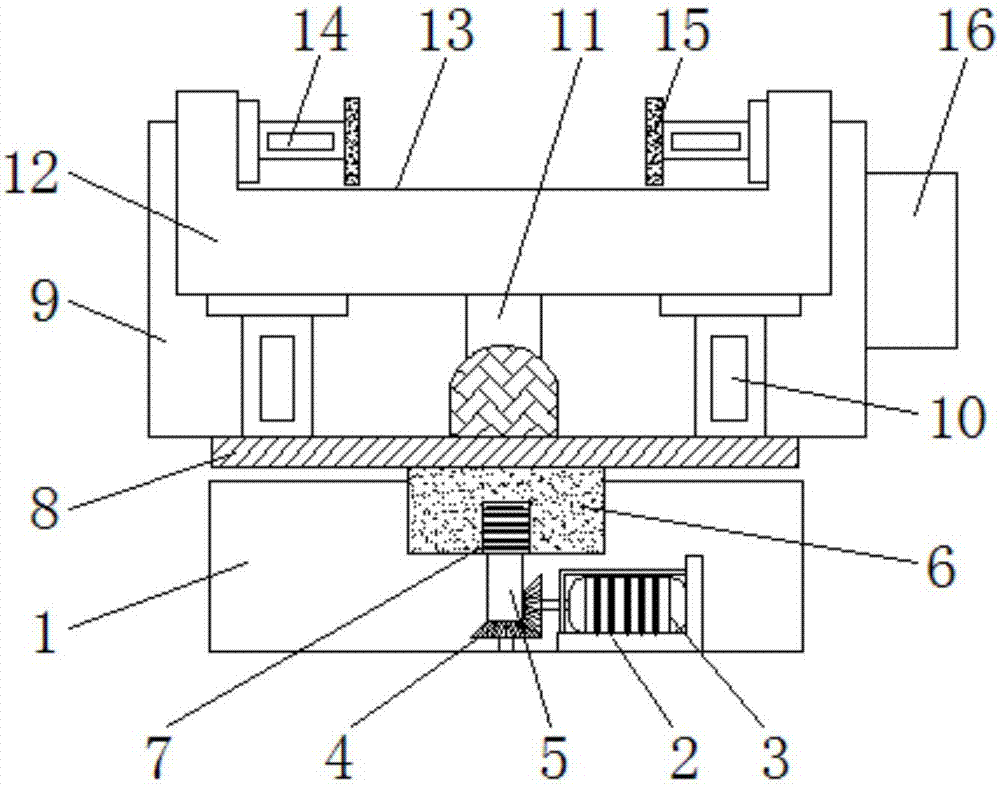

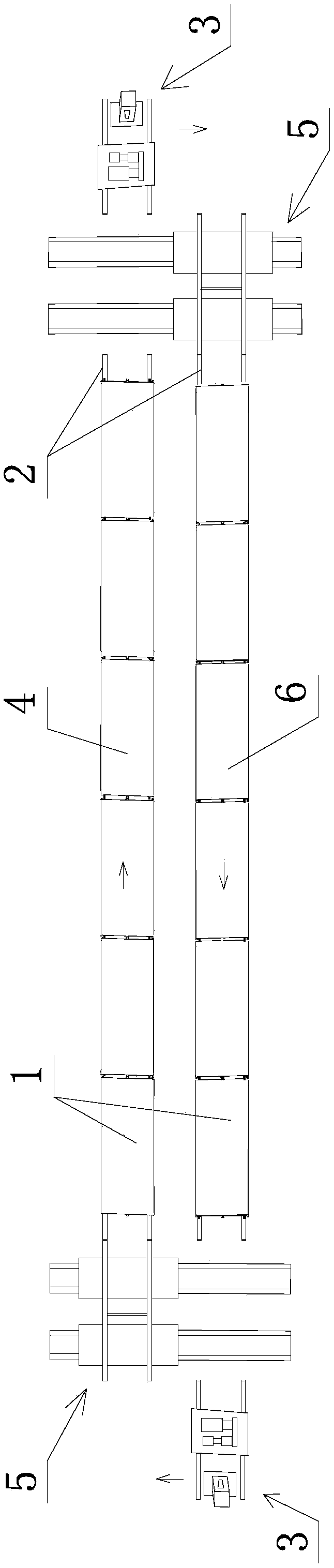

Automatic assembly production line device of disposable sterile infusion sets

InactiveCN101897999AReasonable designCompact structureInfusion devicesConveyor partsDropping funnelTransmission belt

The invention discloses an automatic assembly production line device of disposable sterile infusion sets, which belongs to the technical field of assembly of medical devices and comprises a feeding mechanism, an assembly detection mechanism and a sorting and bagging mechanism, wherein the feeding mechanism comprises a follower fixture group, a feeder of a flow controller, the feeder of a filter, the feeder of a long pipe, the feeder of a short pipe, the feeder of a puncture set, the feeder of a blood returning pipe and the feeder of a dropping funnel are matched and connected on a part feeding area of the follower fixture group, the feeder of an intravenous infusion needle is matched and connected on the front side of a part assembly area of the follower fixture group, the assembly detection mechanism is arranged on the outer side of the feeder of the intravenous infusion needle, the sorting and bagging mechanism is matched and arranged at the right end of the follower fixture group, the sorting and bagging mechanism comprises a stripping plate, plate releasing claws are symmetrically arranged on two sides at the right end of the stripping plate through a plate releasing slideway which is arranged, a guide slot is matched and arranged on the inner side of the stripping plate, the guide slot is connected with a bag sealing mechanism, and a transmission belt is matched and arranged in the bag sealing mechanism. The device has simple structure, high working efficiency, high safety and low production cost.

Owner:杭州临江汽车工程研究院有限公司

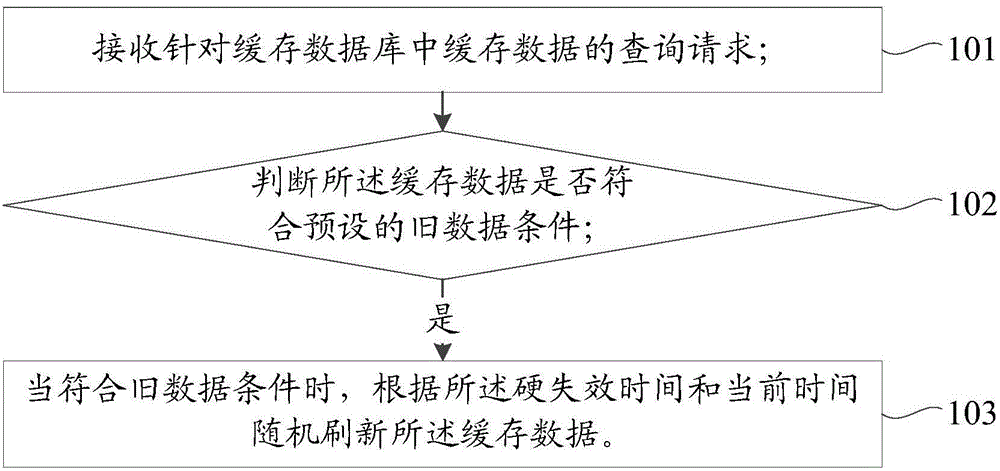

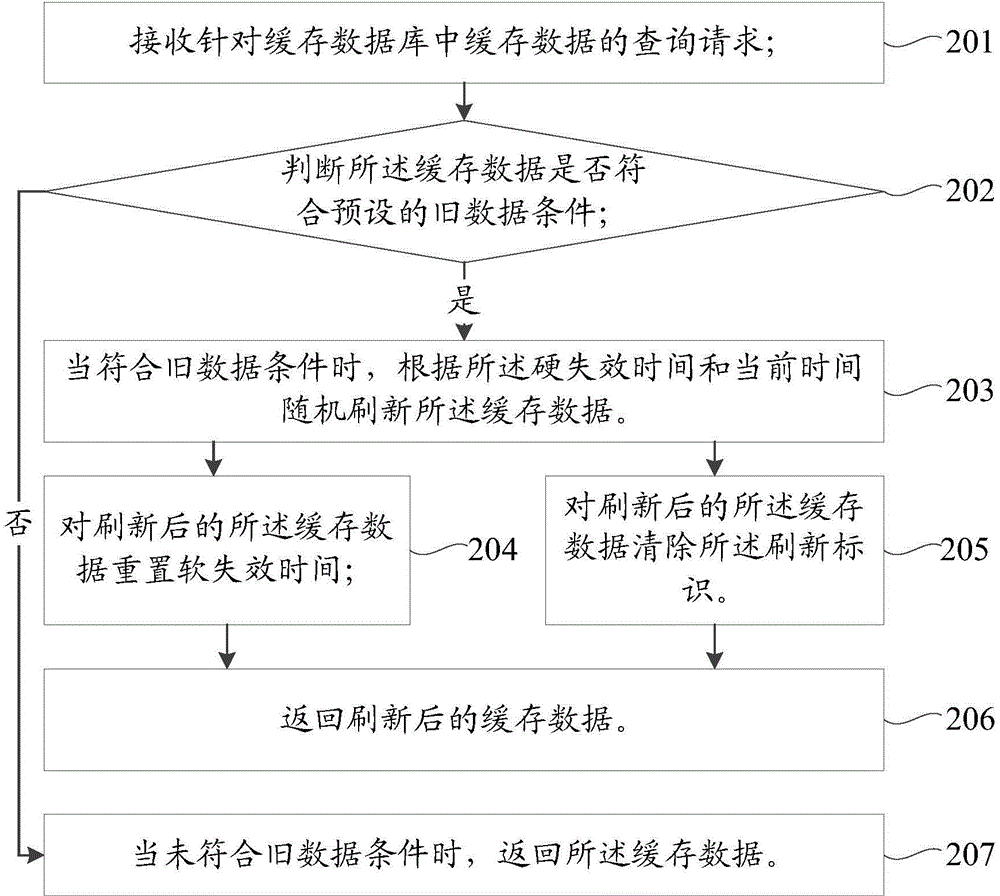

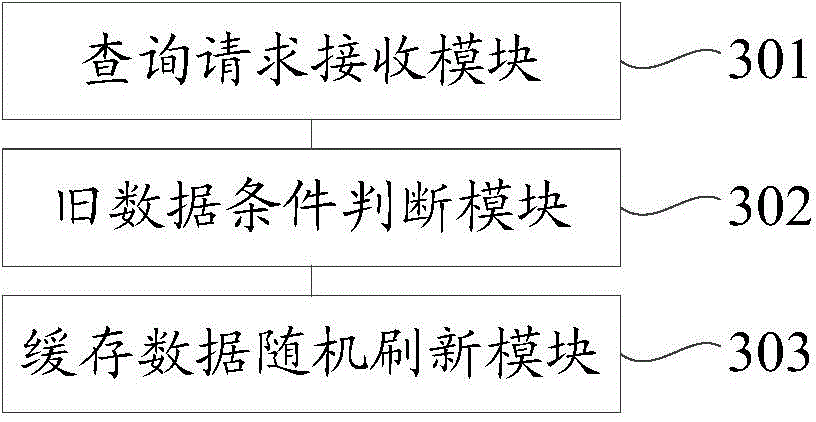

Cached data refreshing method and apparatus

ActiveCN105630819AAvoid shockReduce overheadSpecial data processing applicationsEnd systemComputer science

Embodiments of the invention provide a cached data refreshing method and apparatus. The method comprises the steps of receiving a query request for cached data in a cached database, wherein the cached data has hard failure time; judging whether the cached data meets a preset old data condition or not; and when the old data condition is met, randomly refreshing the cached data according to the hard failure time and current time. According to the embodiments of the invention, one or a few requests are randomly screened out from query requests of numerous cached data to perform refreshing operation, so that excessively great impact on a back-end system is avoided while the cached data is refreshed.

Owner:ADVANCED NEW TECH CO LTD

Long-acting insulin or insulin analogue conjugate

ActiveUS20180161448A1Increase compliance of administrationEliminate side effectsVectorsPeptide/protein ingredientsHalf-lifeIn vivo

The present invention relates to insulin and / or an insulin analogue conjugate, and a use thereof, wherein the insulin and / or insulin analogue have improved in vivo durability and stability by linking the same with an Fe region of immunoglobulin. The insulin and / or an insulin analogue conjugate of the present invention show an in vivo activity similar to that of insulin. In addition, the insulin and / or insulin analogue conjugate of the present invention are long-acting formulations of insulin and / or the analogue thereof, in which serum half-life is remarkably increased, and therefore, the present invention provides remarkable insulin and / or an insulin analogue conjugate, which do not induce hypoglycemia, a drawback of insulin treatment.

Owner:HANMI PHARMA

Maintaining worktable and method for capacitor

Owner:长兴恒业达电子股份有限公司

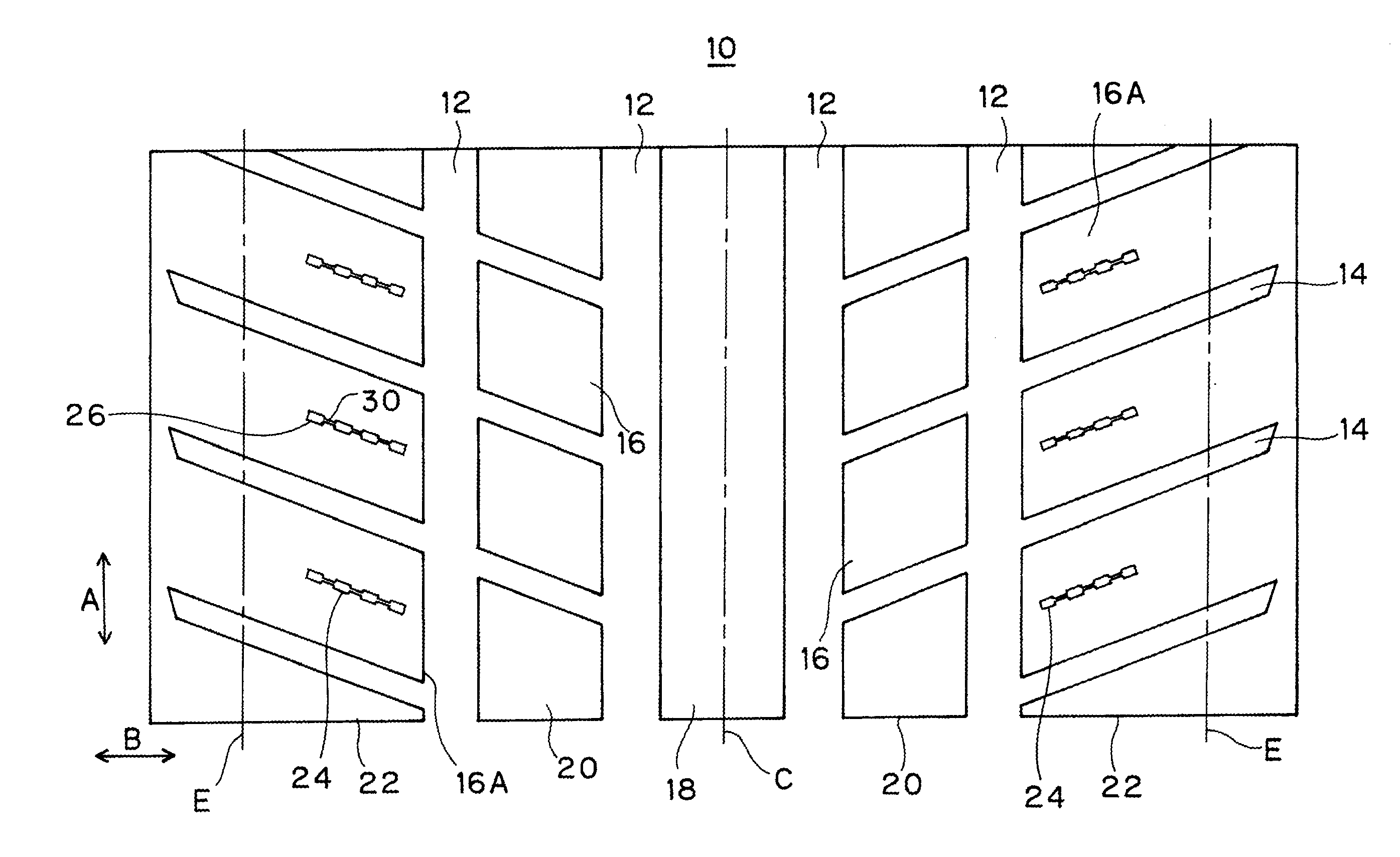

Pneumatic tire

ActiveUS20120090749A1Suppress toeSuppress heel wearTyre tread bands/patternsNon-skid devicesGroove widthEngineering

In a pneumatic tire in which the sipe extending in a direction crossing a tire circumferential direction is provided on a land portion (block) of a tread portion, a wide part having a wide groove width is provided at three or more places in a length direction of the sipe, and the wide part and a narrow part are formed alternately on a tread surface along the sipe length direction. A plurality of the wide parts are extended in a sipe depth direction from the tread surface, and are provided by changing extended lengths in the sipe depth direction.

Owner:TOYO TIRE & RUBBER CO LTD

Long-acting insulin or insulin analogue conjugate

ActiveUS10894089B2Increase compliance of administrationEliminate side effectsVectorsPeptide/protein ingredientsIntravenous gammaglobulinHypoglycemia

The present invention relates to insulin and / or an insulin analogue conjugate, and a use thereof, wherein the insulin and / or insulin analogue have improved in vivo durability and stability by linking the same with an Fc region of immunoglobulin. The insulin and / or an insulin analogue conjugate of the present invention show an in vivo activity similar to that of insulin. In addition, the insulin and / or insulin analogue conjugate of the present invention are long-acting formulations of insulin and / or the analogue thereof, in which serum half-life is remarkably increased, and therefore, the present invention provides remarkable insulin and / or an insulin analogue conjugate, which do not induce hypoglycemia, a drawback of insulin treatment.

Owner:HANMI PHARMA

Method for maintaining blade of wind generating set

The invention discloses a method for maintaining a blade of a wind generating set. A cutting area is formed around a damaged area, beyond a twin-beam structure and a web plate structure, of a blade shell, drying and surface cleaning are conducted on the cutting area, circumferential beveling is conducted to cut off a square area containing the damaged area, so that a trapezoid area which is wide outside and narrow inside is formed, wedge-shaped polishing, shape repairing and interior damage treatment are conducted on the upper corners of the trapezoid area, a fiberglass bar is bonded to the blade shell and the square area through a binder, hand lay-up resin is smeared on the trapezoid area, the square area is installed at the original position and then roughening is conducted on the periphery, at least two layers of glass fiber cloth is pasted with hands and compacted with a brush roll, and polishing is conducted with an angle grinder till the glass fiber cloth is in smooth transition with an original molded surface. According to the method, by cutting off the interior damaged area of the blade shell, maintenance is facilitated; due to precise polishing of a maintained portion and filling and precise bonding after maintenance, interior maintenance and overall follow-up operation are better achieved. The method is especially suitable for out-of-factory maintenance of blades which have been sent to a wind field.

Owner:GUODIAN UNITED POWER TECH LIANYUNGANG CO LTD

Skin care composition

ActiveUS20100047295A1Mitigate and ameliorate undesirable adverse effectSoft and smooth appearanceCosmetic preparationsBiocidePhosphateTG - Triglyceride

Skin care emulsion compositions are disclosed comprising an oil-in-water emulsion comprising phospholipid-stabilized, submicron triglyceride particles, botanical material selected from the group consisting of a vegetal material, a marine material and combinations thereof; a polycarboxylate polymer and a phosphate ester-type emulsifier. The skin care compositions can be topically applied to the skin before, and surprisingly, together with, and / or after applying a skin colorant (i.e., pigmented) cosmetic composition to moisturize the skin and achieve, augment, and / or maintain a visibly desirable cosmetic appearance.

Owner:JG SKIN INC

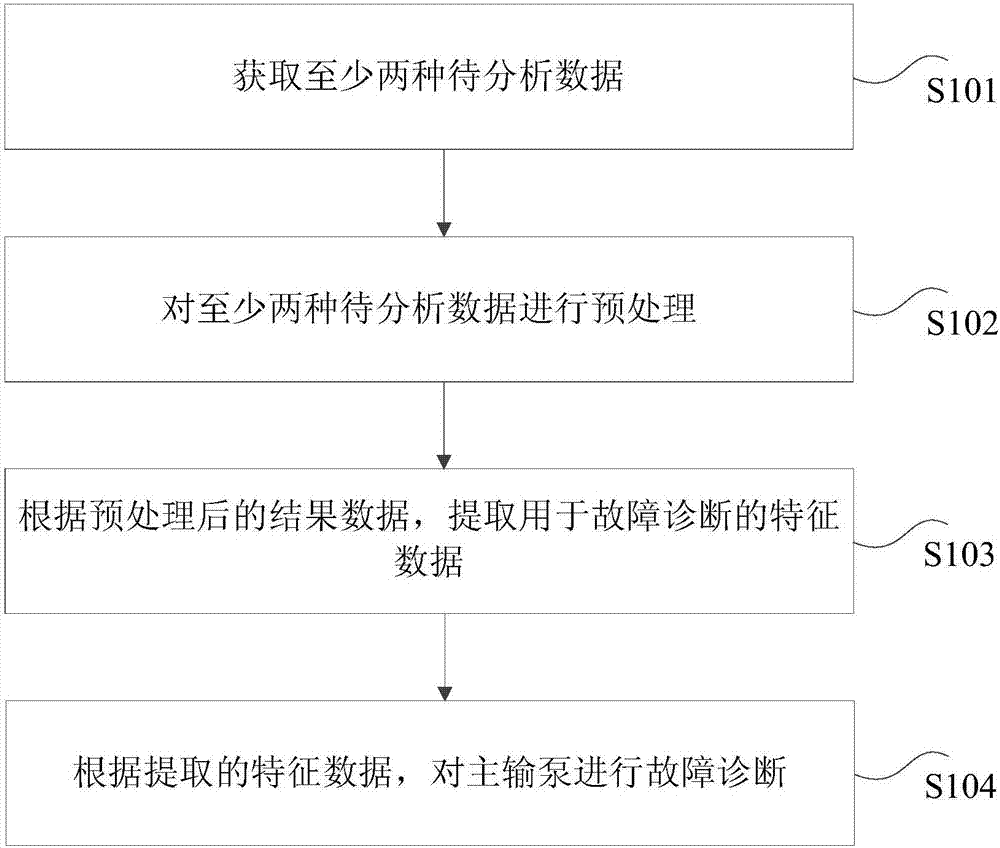

Fault diagnosis method and system for main transport pump

InactiveCN106930934AAvoid information lossTimely and accurate diagnosis of the root cause of the faultPump testingPositive-displacement liquid enginesDiagnosis methodsEngineering

The invention provides a fault diagnosis method and system for a main transport pump. The method can comprise the following steps of: obtaining at least two to-be-analyzed data; pre-processing the at least two to-be-analyzed data; extracting characteristic data used for fault diagnosis according to the preprocessed result data; and performing fault diagnosis on the main transport pump according to the extracted characteristic data. According to the embodiment of the invention, at least two to-be-analyzed data is obtained, information loss during analysis of a single vibration signal is effectively avoided, overall monitoring for a state of the main transport pump is realized, and problems that potential weak faults and the like of the main transport pump cannot be effectively recognized as a single signal is easily submersed by noises in the prior art are solved; and furthermore, the to-be-analyzed data is preprocessed, and noise data in the to-be-analyzed data is removed, so that more precise to-be-analyzed data can be obtained, a fault source is timely and accurately judged, and repair and maintenance effects of the main transport pump are effectively guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

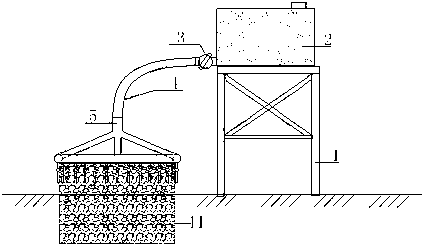

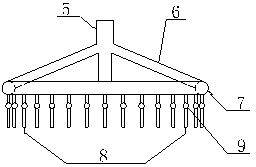

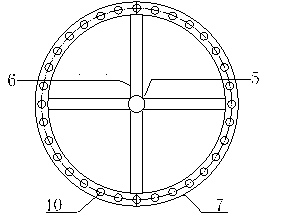

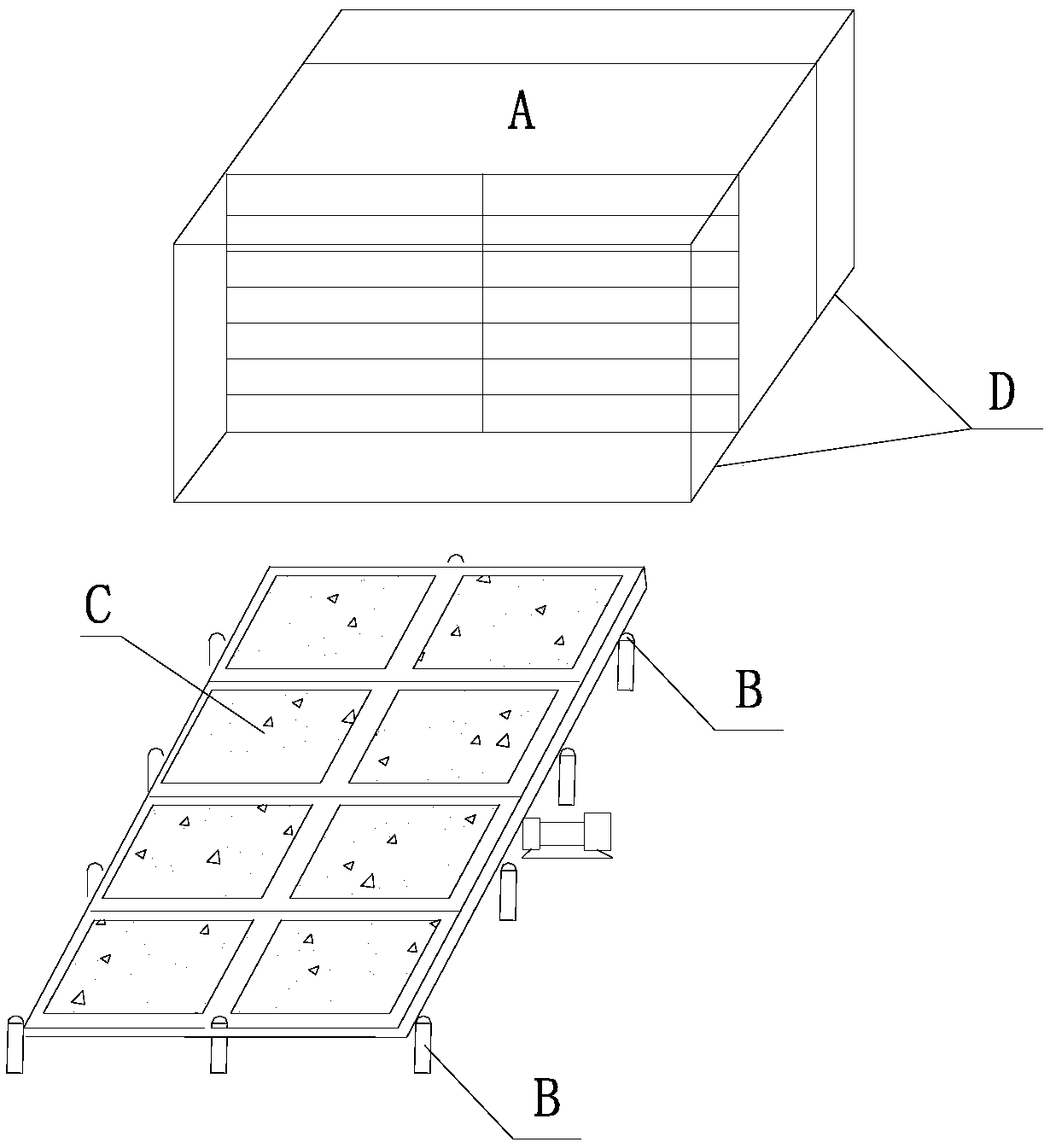

Conservation method of basic on-site concrete of transmission tower in desert areas

InactiveCN103290857ASave maintenance waterImprove water resource utilizationFoundation engineeringWater diversionWater pipe

The invention discloses a conservation method of basic on-site concrete of a transmission tower in desert areas. The conservation method is characterized in that a concrete conservation film is coated on the surface of basic concrete, a drip conservation device is utilized, and water-drenching conservation is performed on the surface of concrete continuously in a drip manner during the conservation period to save water consumption for conservation on the premise of guaranteeing conservation effect. The drip conservation device can be machined in to a rectangular, square or circular shape according to different basic shapes of the conserved towers. The drip conservation device comprises a water container, a water injecting pipe, a water injecting port, pressure equalizing water diversion pipes, a drip main pipe, drip branch pipes, and adjusting valves. The water container is arranged on a support, and the bottom of a side of the water container is connected to the water injecting pipe and the drip branch pipes through the adjusting valves. Water-drenching conservation is performed on the surface of concrete continuously in a drip manner during the conservation period, concrete conservation effect is guaranteed, water amount for conservation is reduced, and labor intensity of construction staff is reduced.

Owner:STATE GRID CORP OF CHINA +2

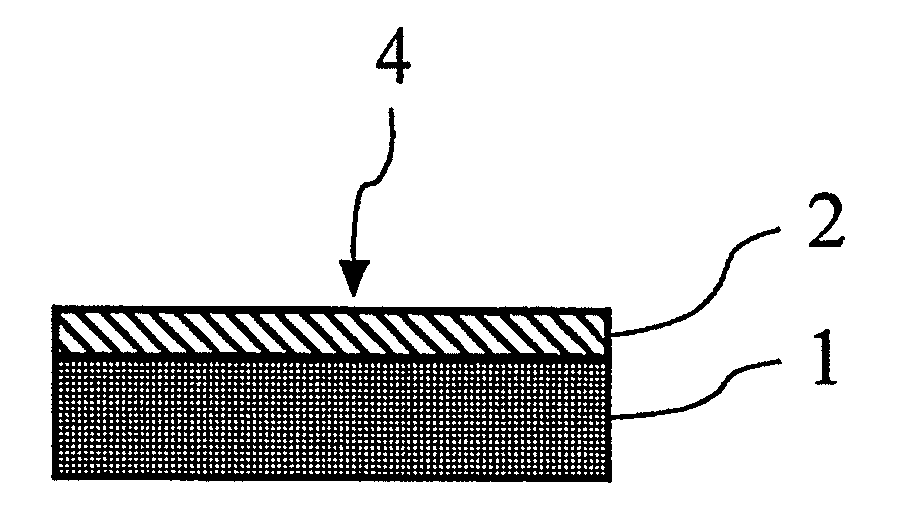

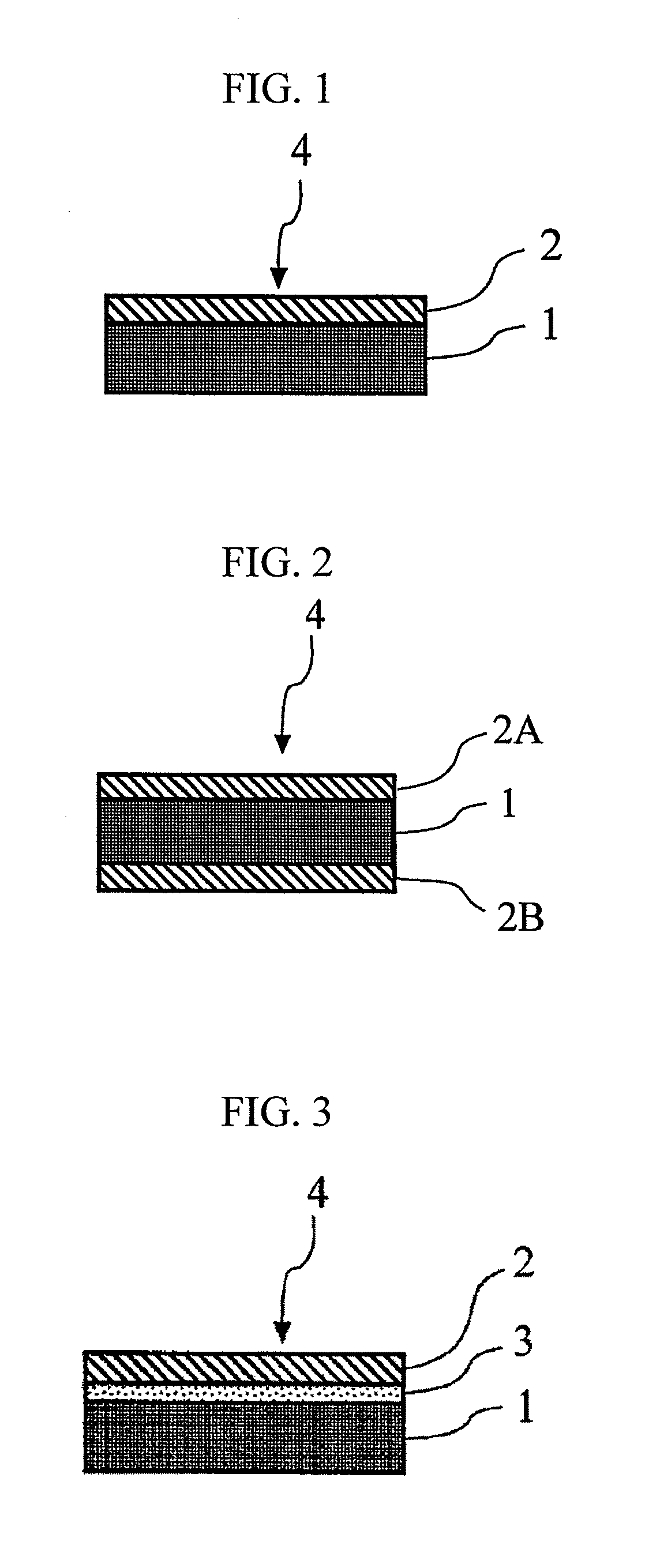

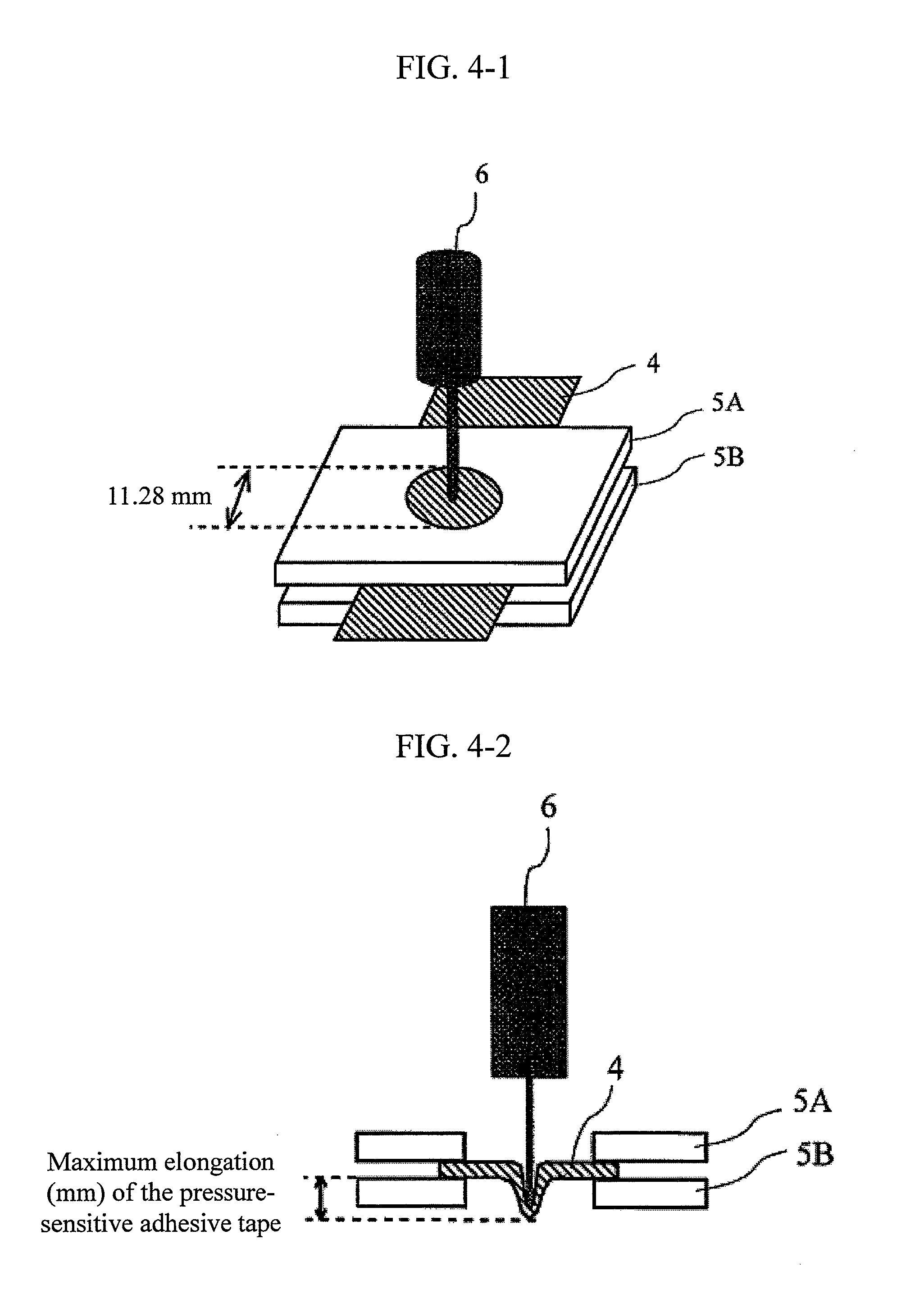

Pressure-sensitive adhesive tape for protecting electrode plate

InactiveUS20120052295A1Avoid it happening againImprove reliabilityCell component detailsThin material handlingCalculation methodsRADIUS

The present invention relates to a pressure-sensitive adhesive tape for protecting an electrode plate, containing: a substrate, and a pressure-sensitive adhesive layer provided on at least one side of a the substrate, in which the pressure-sensitive adhesive tape has a piercing resistance, obtained by the following calculation method, of 300 gf·mm or more; and has a heat shrinkage ratio, when heating is performed at 260° C. for 1 hour, of 1.0% or less in both of TD (width) direction and MD (length) direction, and in which the calculation method contains fixing the pressure-sensitive adhesive tape to a fixing plate in which a circular hole having a diameter of 11.28 mm is formed, piercing a needle of which the end of has a curvature radius of 0.5 mm to the pressure-sensitive adhesive tape at a speed of 2 mm / s under condition of 23±2° C., and measuring a maximum load (gf) and a maximum elongation (mm) of the pressure-sensitive adhesive tape when the needle penetrates the pressure-sensitive adhesive tape; and the piercing resistance is calculated by the following equation (1):Piercing resistance=[Maximum load (gf)]×[Maximum elongation (mm) of the pressure-sensitive adhesive tape]×½ (1).

Owner:NITTO DENKO CORP

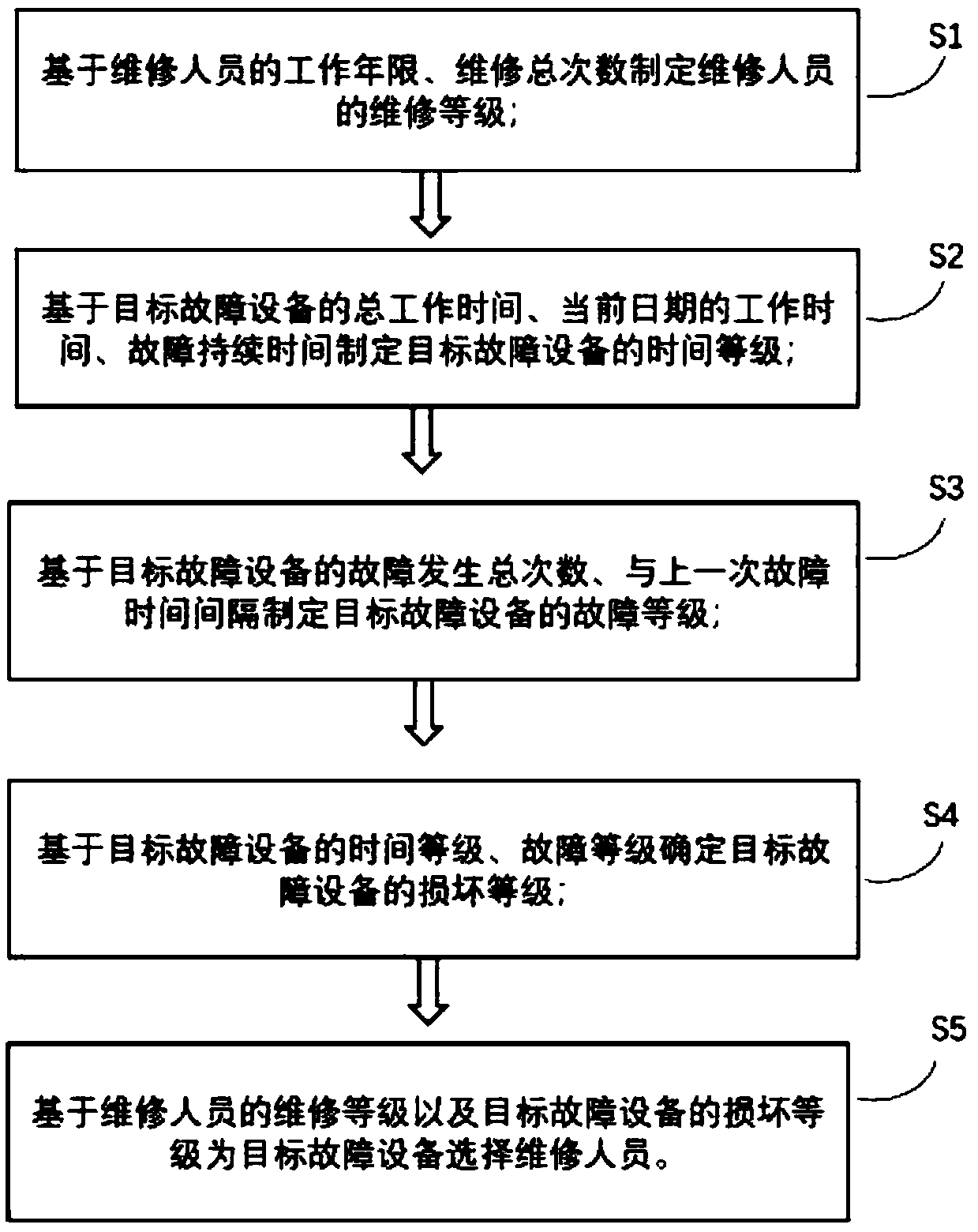

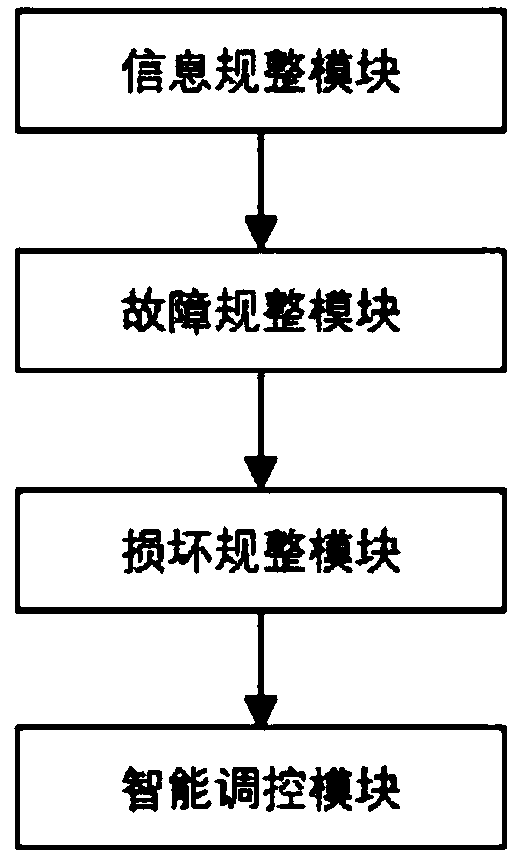

An intelligent control method of maintenance work order management

InactiveCN109272200AImprove maintainabilityImprove work efficiencyOffice automationResourcesFault occurrenceDevice failure

The invention discloses an intelligent control method for maintenance work order management. The method includes: S1, determining the maintenance level of the maintenance personnel based on the service life and the total maintenance times; 2, based on the total working time, the work time of the current date and the failure duration time, determining the time grade of the target failure equipment;3, based on the total number of fault occurrence and the time interval between the last fault and the target fault equipment, determining the fault level of the target fault equipment; S4, determining the damage level of the target faulty equipment based on the time level and the fault level; S5, selecting a serviceman for the target faulty equipment based on the maintenance level of the serviceman and the damage level of the target faulty equipment. The invention combines the damage grade of the faulty equipment and the maintenance grade of the maintenance personnel to select the maintenancepersonnel, which is conducive to improving the matching degree between the maintenance personnel and the equipment faults, improving the maintenance effect of the faulty equipment, enabling the maintenance personnel to carry out effective maintenance on the faulty equipment quickly and accurately, and improving the work efficiency of the maintenance personnel.

Owner:HEFEI HDB INFORMATION TECH CO LTD

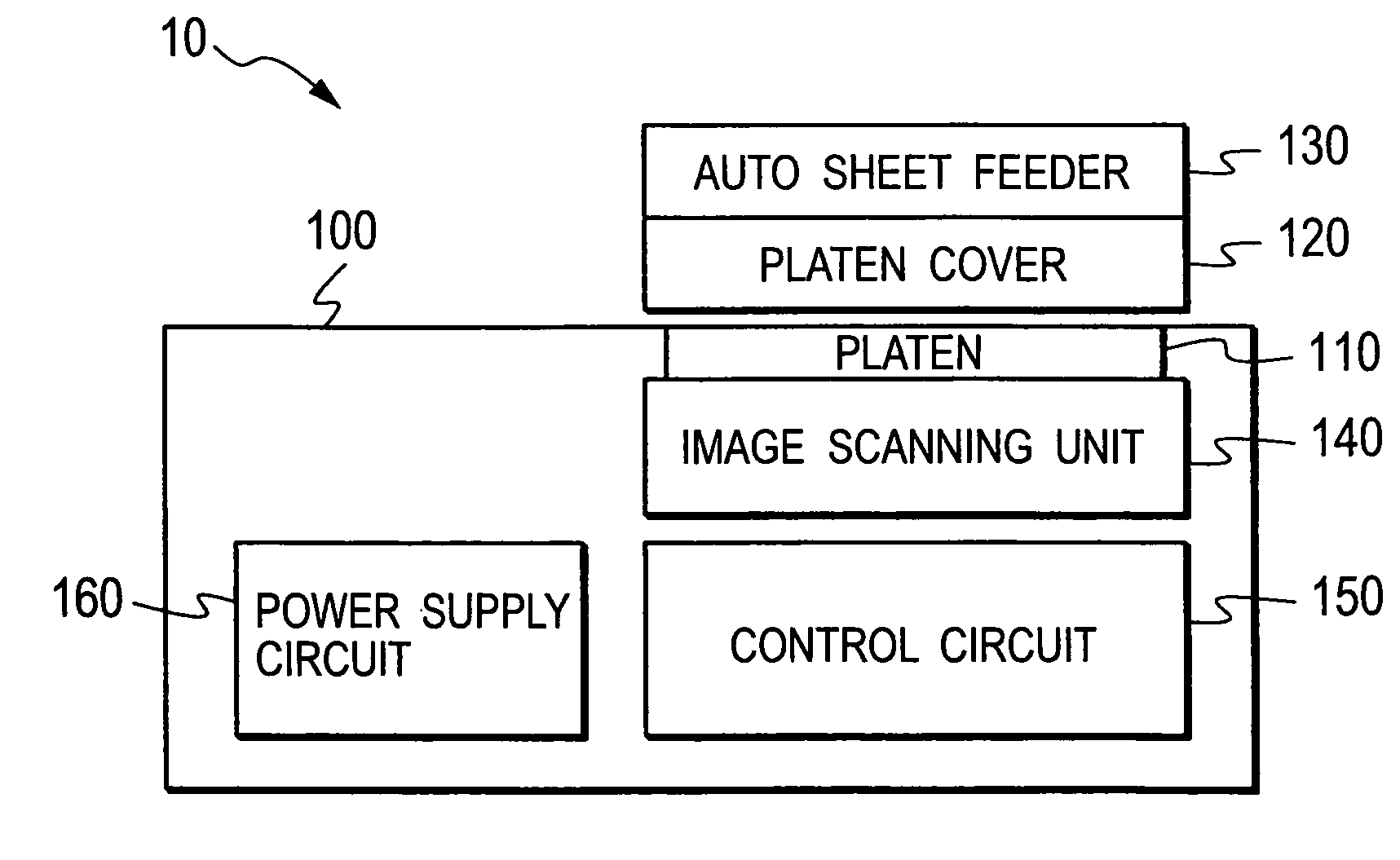

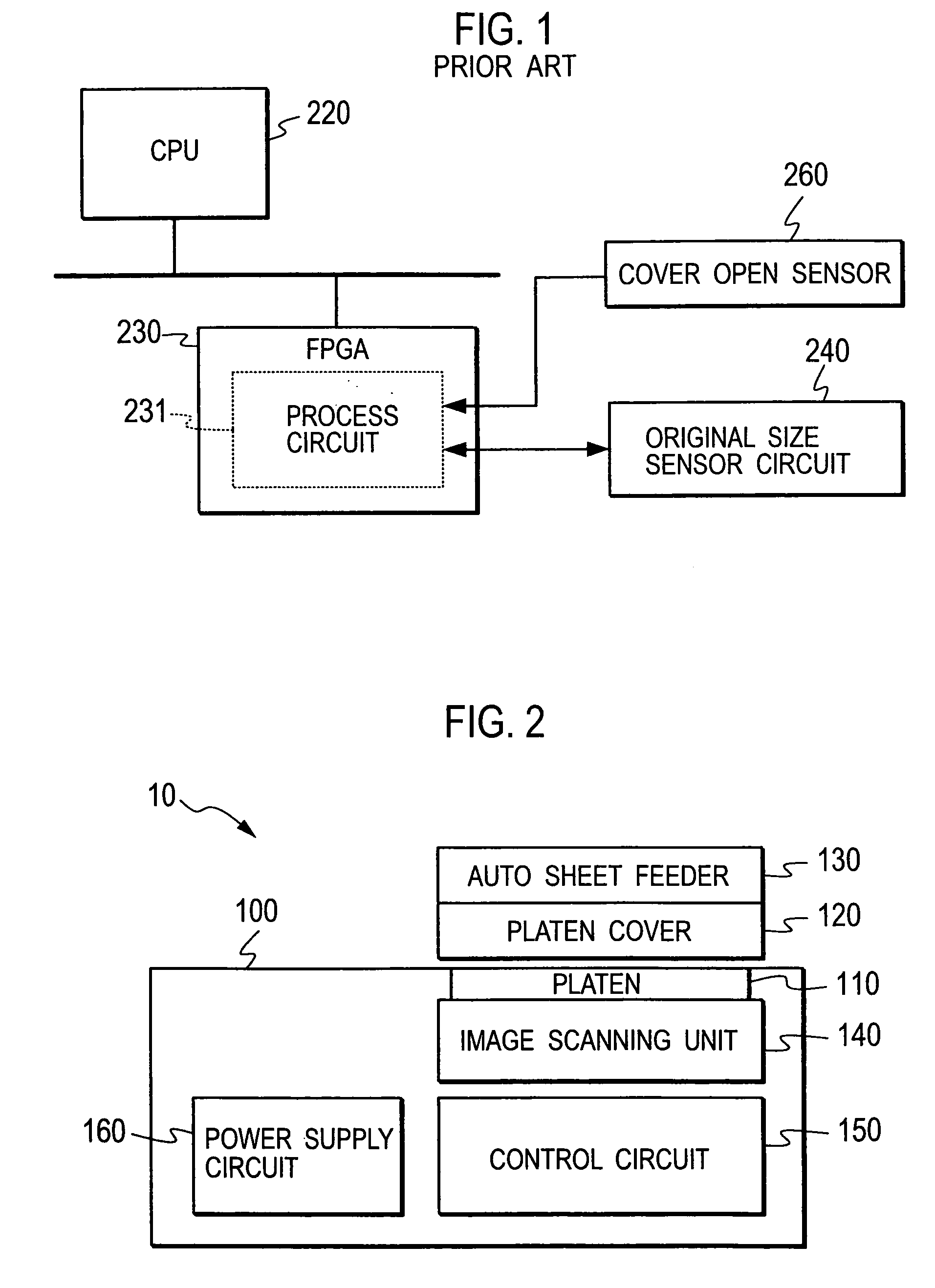

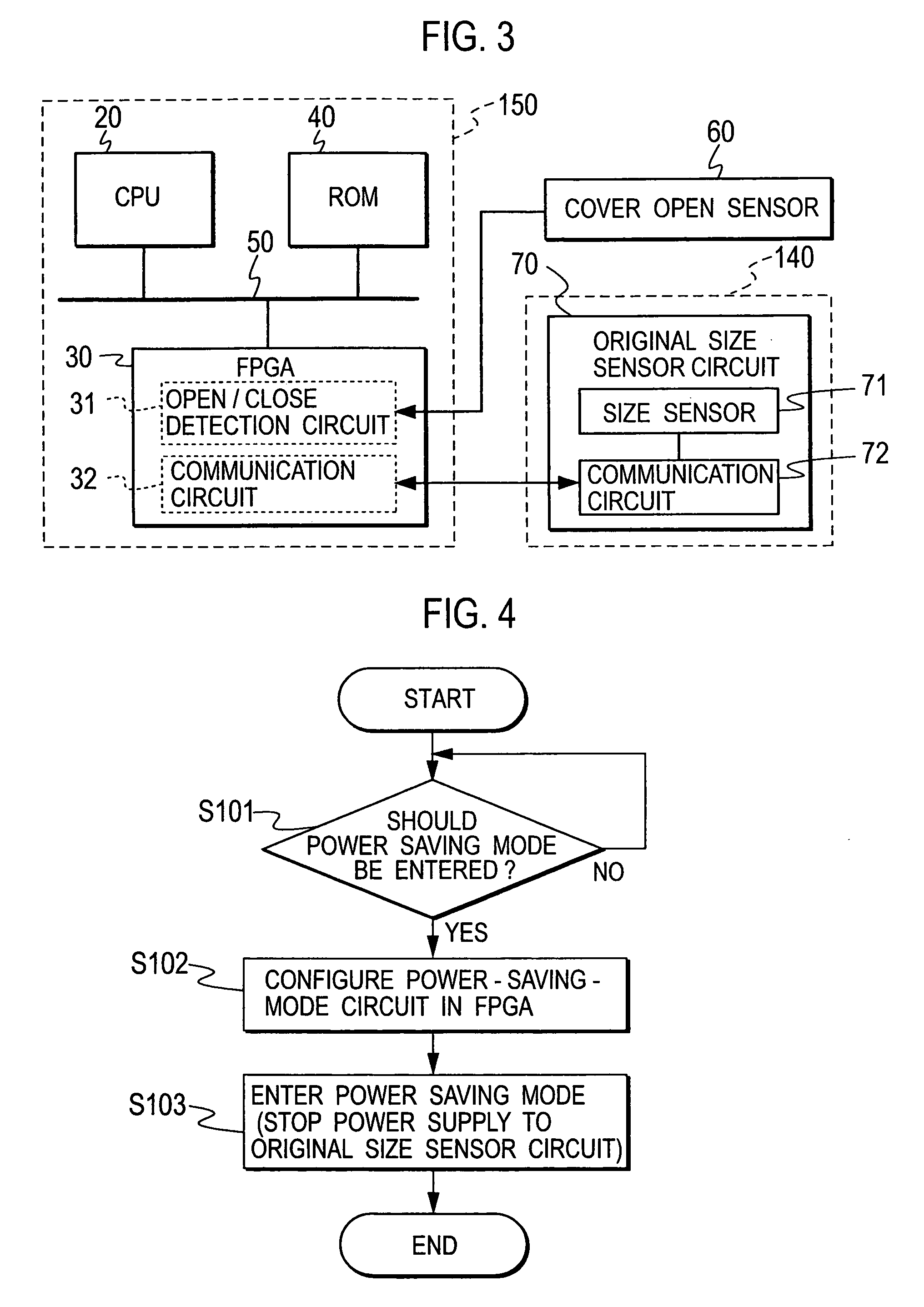

Image scanner and control method thereof

ActiveUS20090122362A1Shorten the timeMaintenance savingVisual presentationPrintingPower savingNormal mode

An image scanner operates in a normal mode in which an image scanning process is executable; and a power saving mode in which less electric power is consumed than in the normal mode. The image scanner includes: a CPU for switching the image scanner between the normal mode and the power saving mode; an original size sensor circuit; and an FPGA connected to the CPU and the original size sensor circuit. In the normal mode, the CPU configures, in the FPGA, a normal-mode circuit needed for the image scanning process. When the image scanner transfers from the normal mode to the power saving mode, the CPU configures, in the FPGA, a power-saving-mode circuit for communicating with the original size sensor circuit, and stops the original size sensor circuit from operating. The power-saving-mode circuit is smaller in circuit size than the normal-mode circuit.

Owner:RISO KAGAKU CORP

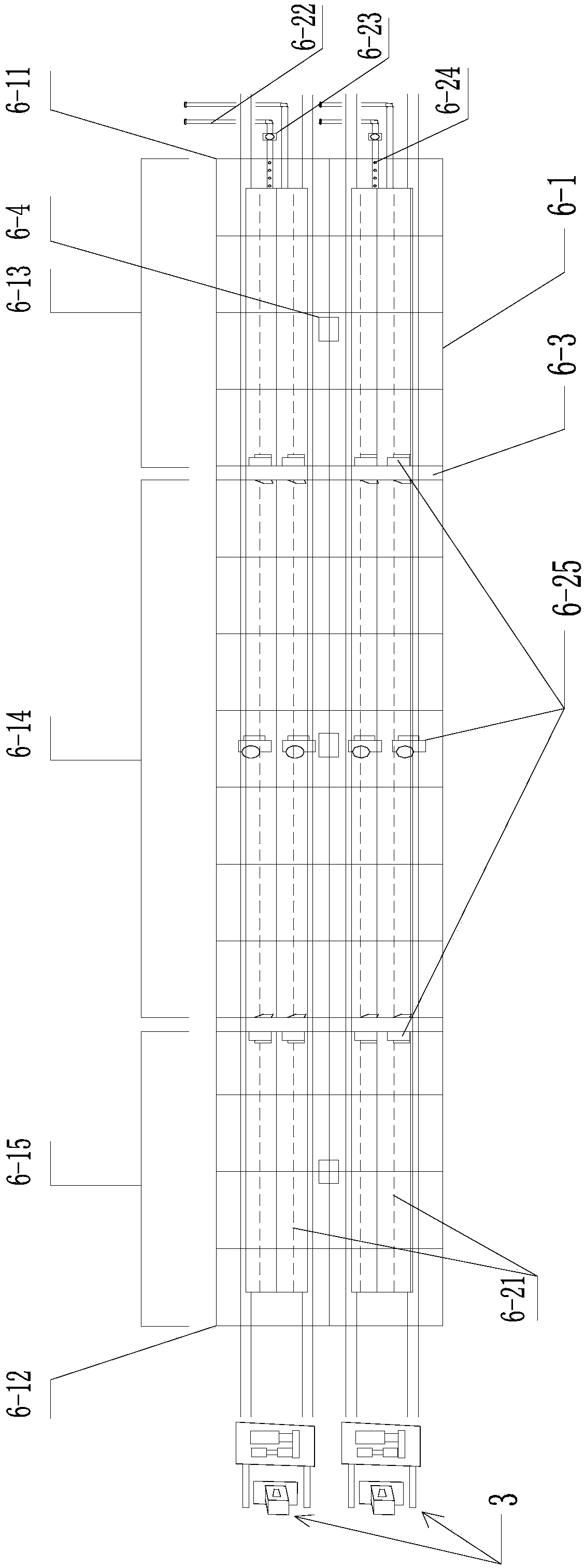

Curing kiln for building concrete wallboard prefabricated part production line

PendingCN108705666AEliminate handlingIncrease productivityCeramic shaping apparatusProduction lineMoisture sensor

The invention discloses a curing kiln for a building concrete wallboard prefabricated part production line. The curing kiln comprises a curing kiln body which horizontally extends and is provided withan airtight side wall, and openings are formed in the two ends of the curing kiln body and refer to an inlet and an outlet correspondingly. A curing kiln body inner cavity located between the inlet and the outlet is a channel for allowing to-be-curved prefabricated parts to pass through. The curing kiln body is sequentially provided with a temperature increasing section, a constant temperature section and a temperature decreasing section from the inlet to the outlet. A temperature and humidity adjusting device and a temperature and humidity sensor are arranged in the curing kiln body. The temperature and humidity adjusting device comprises a heat supply heating device, a steam conveying pipeline with nozzles, and a fan. Due to the fact that the curing kiln horizontally extends, organic connection between the curing kiln and a prefabricated part conveying system is achieved, the prefabricated parts are cured in the conveying process, a vertical material carrying link in a traditional production method is omitted, the whole production period is shortened, and the production efficiency of the production line is improved.

Owner:正方利民(天镇)建筑工业化有限公司 +2

Intelligent fault reporting and repairing control system

InactiveCN109190958AImprove monitoringImprove repair effectTesting/monitoring control systemsStructural/machines measurementWork periodControl system

The invention discloses an intelligent fault reporting and repairing control system. An information regulating module is used for establishing the time grade of the target fault equipment based on thetotal working time, the working time of the current date and the fault duration. A fault regulating module is used for determining the fault level of the target fault equipment based on the fault type. The damage regularization module is used for determining the damage level of the target fault equipment based on the total number of times of fault occurrence and the time interval between the lastfault and the fault. An intelligent control module is used to make fault reporting strategy for the target fault equipment. The invention collects the actual parameter information such as number of fault times, the fault time and the fault type of the fault equipment in real time to analyze and classify the fault of the equipment; according to the analysis results, different repair methods are selected to improve the overall and effective monitoring of the fault situation of the fault equipment in the working process, and the repair effect of the fault equipment, which is conducive to ensurethe maintenance efficiency of the fault equipment.

Owner:HEFEI HDB INFORMATION TECH CO LTD

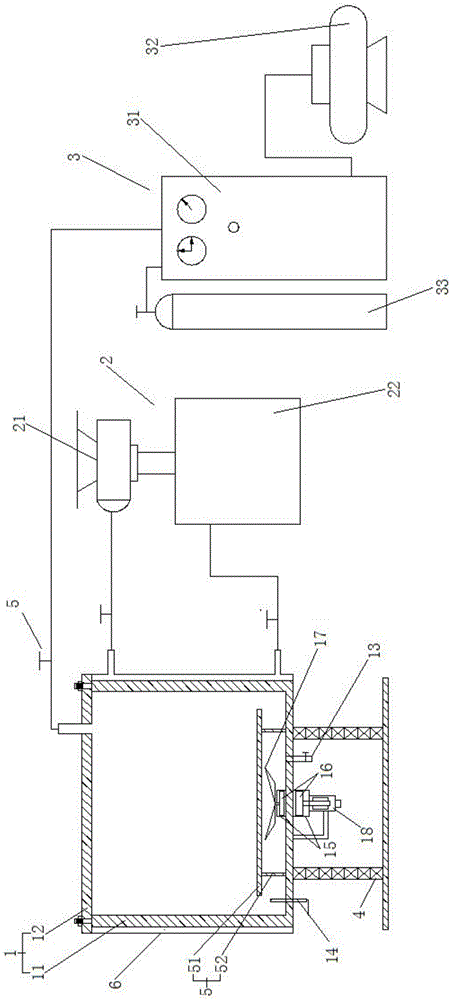

Variable-temperature variable-pressure curing device for well cementing slurry test mold

InactiveCN106042160ASimple structureEasy to operatePreparing sample for investigationCeramic shaping apparatusTemperature controlNitrogen

The invention relates to a variable-temperature variable-pressure curing device for a well cementing slurry test mold. The variable-temperature variable-pressure curing device comprises a curing box, a temperature-control circulating system and a pressurizing system. The curing box is mounted on the ground through a supporting seat, and a test mold support is arranged at the inner bottom of the curing box. A temperature-control circulating bath cover is arranged outside the side walls of the curing box in a wrapping mode. A sealed cavity is formed between the temperature-control circulating bath cover and the side walls of the curing box. The temperature-control circulating bath cover is provided with a water inlet and a water outlet, and the water inlet and the water outlet communicate with the cavity and are connected with the temperature-control circulating system through pipelines correspondingly. An air inlet is formed in the top of the curing box and connected with the pressurizing system through a pipeline. The variable-temperature variable-pressure curing device has the advantages of being simple in structure, convenient to use and operate, low in production cost, capable of fully simulating the actual underground temperature, and capable of fully simulating the actual underground pressure condition by pressurizing the interior of the curing box through nitrogen, and enabling the cement slurry curing environment to approximate to the actual environment so that test mold performance measuring results can be more accurate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

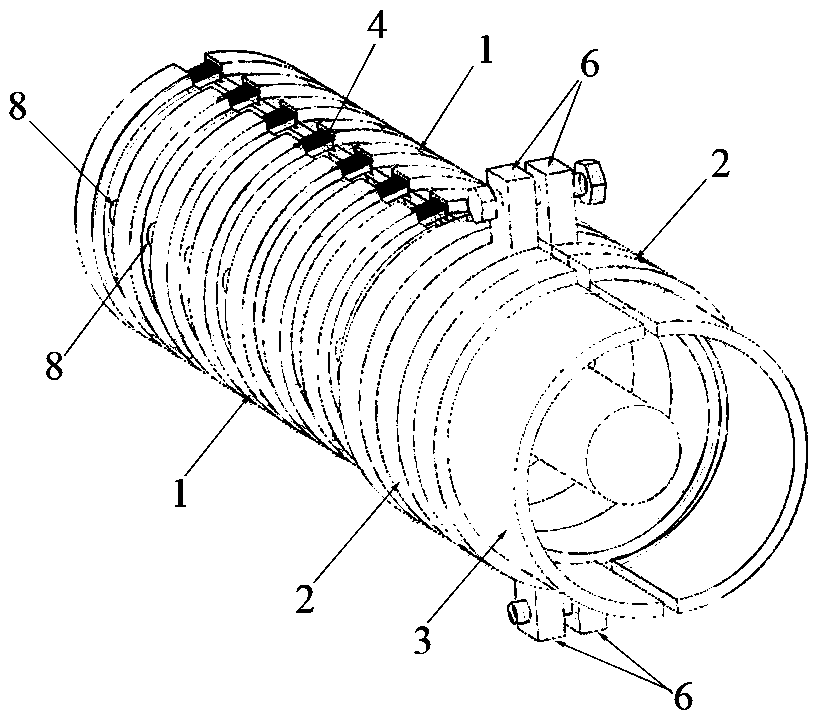

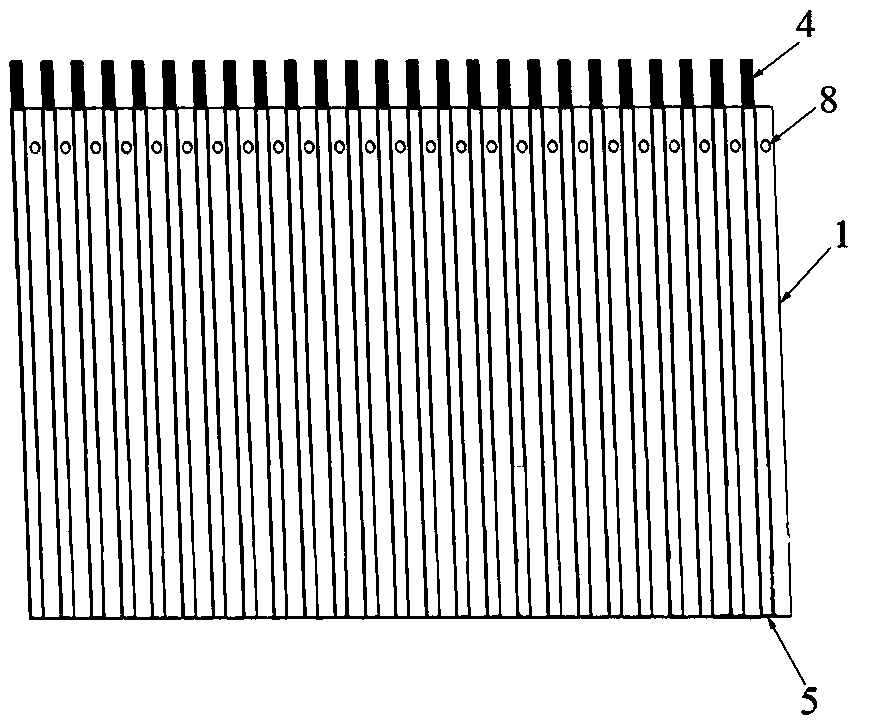

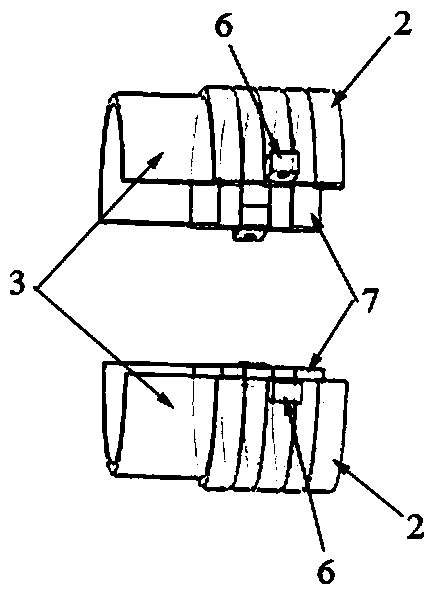

Fast assembly and disassemble type cable protecting jacket

The invention relates to a consumable item special for overhauling, and in particular relates to a fast assembly and disassembly type cable protecting jacket comprising a protecting jacket formed by two half pipes which are detachably buckled together, wherein the protecting jacket is made of OVC material, and an anticorrosive paint layer is arranged on the outer surface of the protecting jacket.According to the fast assembly and disassemble type cable protecting jacket provided by the invention, the problem that a flexible conduit of a damaged cable is difficult to change on the overhaulingscene is solved; the protecting jacket provided by the invention is simple in structure, convenient to install and unnecessary to disassemble the cable for change, so that required time of such work can be greatly reduced, a cable maintenance effect can be ensured while work efficiency is improved, and safe operation of outdoor power transformation equipment is ensured.

Owner:国网山西省电力公司超高压变电分公司 +1

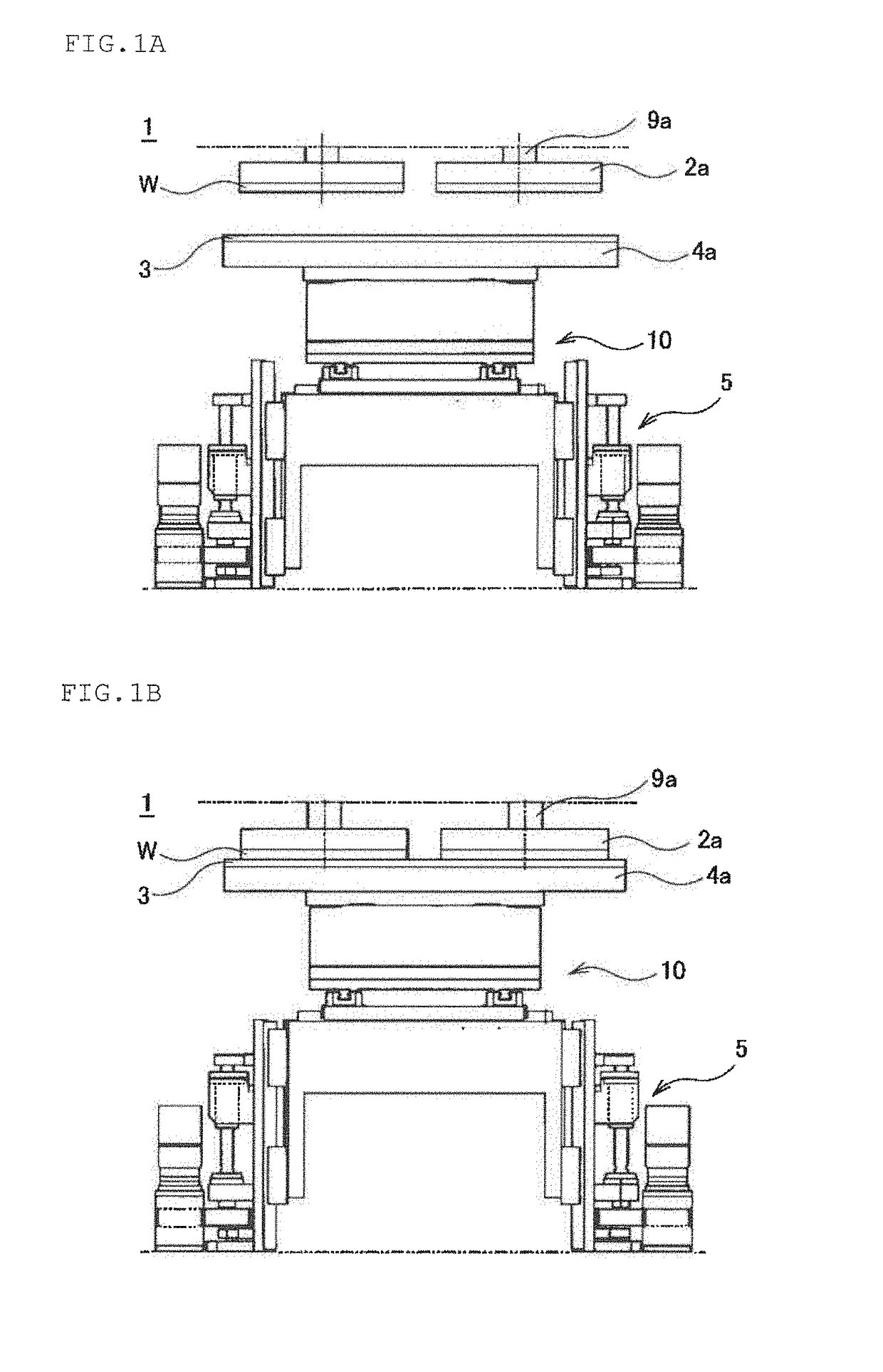

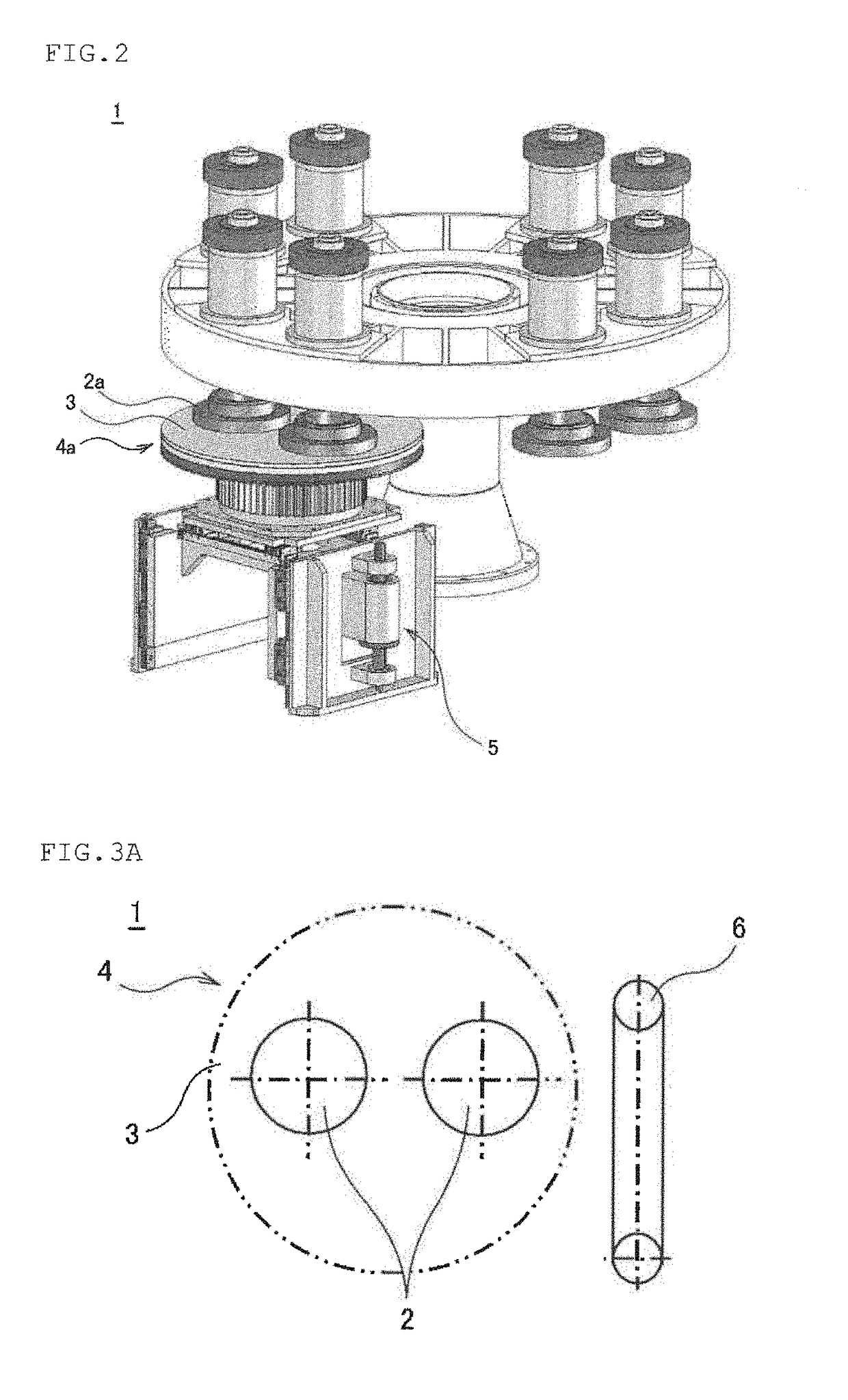

Polishing apparatus and wafer polishing method

ActiveUS20170304992A1Shorten the lengthReduce displacementSemiconductor/solid-state device manufacturingLapping machinesEngineeringIndex system

A polishing apparatus which is an index system polishing apparatus which includes a polishing head for holding a wafer, a plurality of turn tables to which polishing pads for polishing the wafer are attached, and a loading / unloading stage for loading the wafer to the polishing head or unloading the wafer from the polishing head, and which polishes the wafer while switching the turn tables to be used for polishing the wafer held at the polishing head by causing the polishing head to perform rotation movement, the polishing apparatus including a turn table upward and downward movement mechanism which allows the turn table to move upward and downward. With this polishing apparatus, it is possible to reduce an amount of displacement caused when moment load is applied on the polishing head during polishing.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

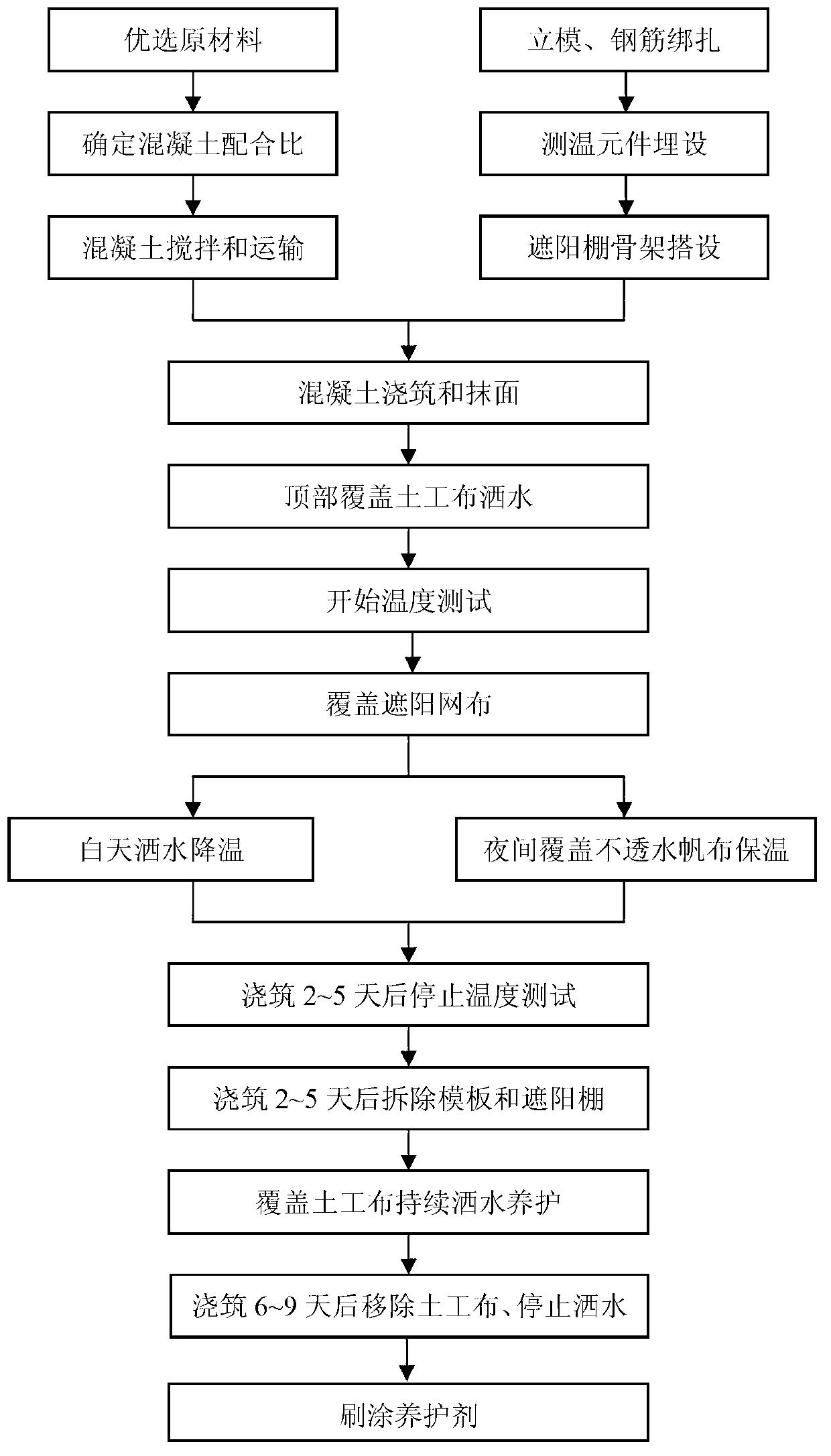

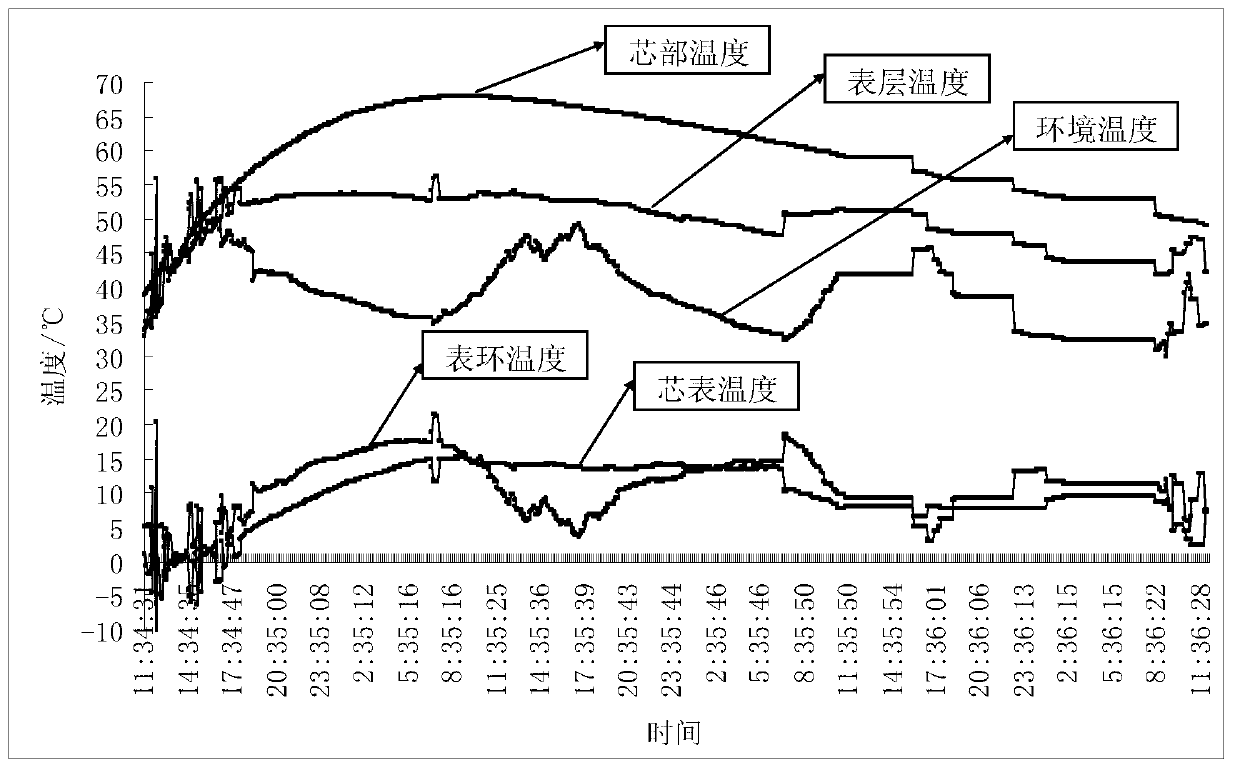

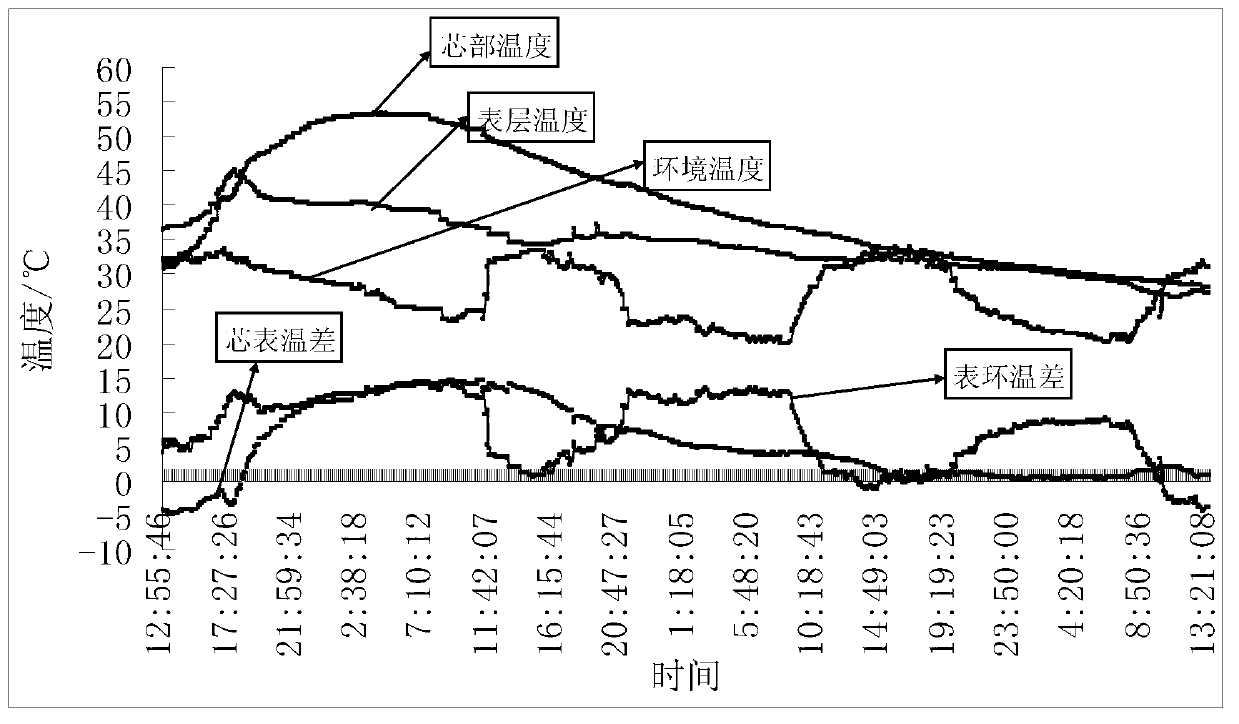

High-performance concrete temperature control and maintenance method under strong wind gobi environment

ActiveCN103273564AImprove applicabilityAvoid temperature riseCeramic shaping apparatusSurface finishShrinkage cracking

The invention discloses a high-performance concrete temperature control and maintenance method under a strong wind gobi environment. The method includes the steps of immediately covering a concrete pouring surface with moisturizing materials and spraying water to conduct moisturizing maintenance after concrete pouring surface finishing construction is completed, conducting temperature reduction through a net awning and by spraying water in the day, conducting heat preservation by covering the concrete pouring surface with the moisturizing materials at night, conducting form removal when intensity of poured concrete meets form removal requirements and the central temperature of the concrete starts to be reduced, removing the net awning, meanwhile, covering the concrete pouring surface with the moisturizing materials and spraying water to conduct the maintenance until a suitable age, removing the covered moisturizing materials after water spraying maintenance is completed, and conducting middle and later period maintenance by coating with a curing agent with brushes. The high-performance concrete temperature control and maintenance method under the strong wind gobi environment solves the difficult technical problems of temperature cracking, shrinkage cracking, delayed crazing and performance degradation of concrete under the strong wind gobi environment with the high-temperature characteristic, the dry characteristic, the strong wind characteristic and the large temperature difference characteristic.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +1

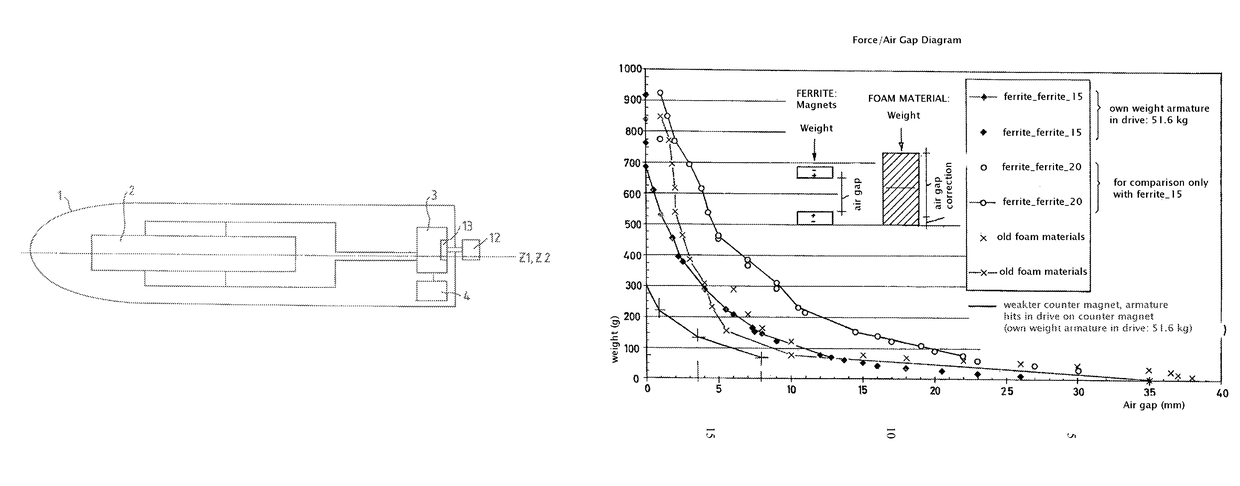

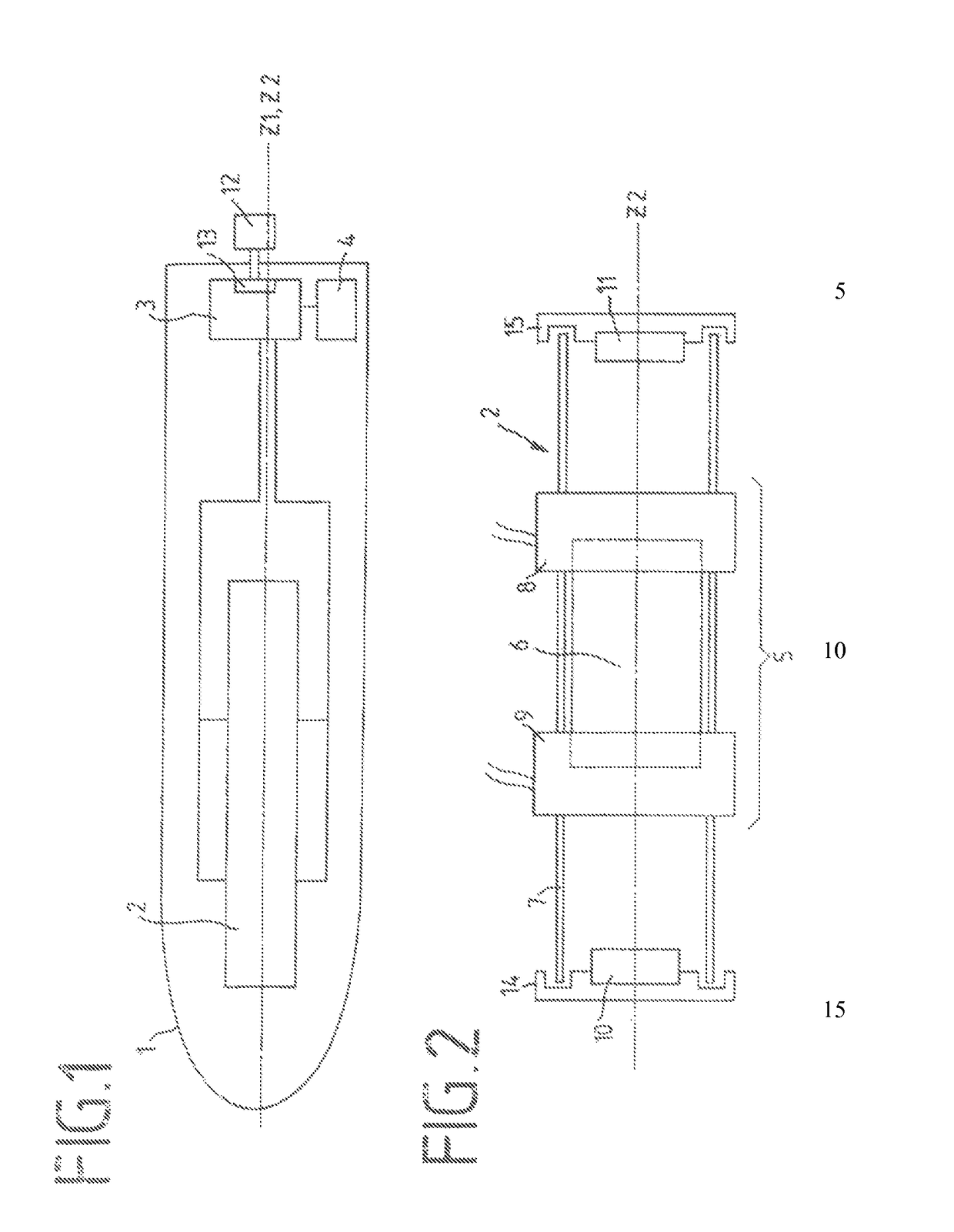

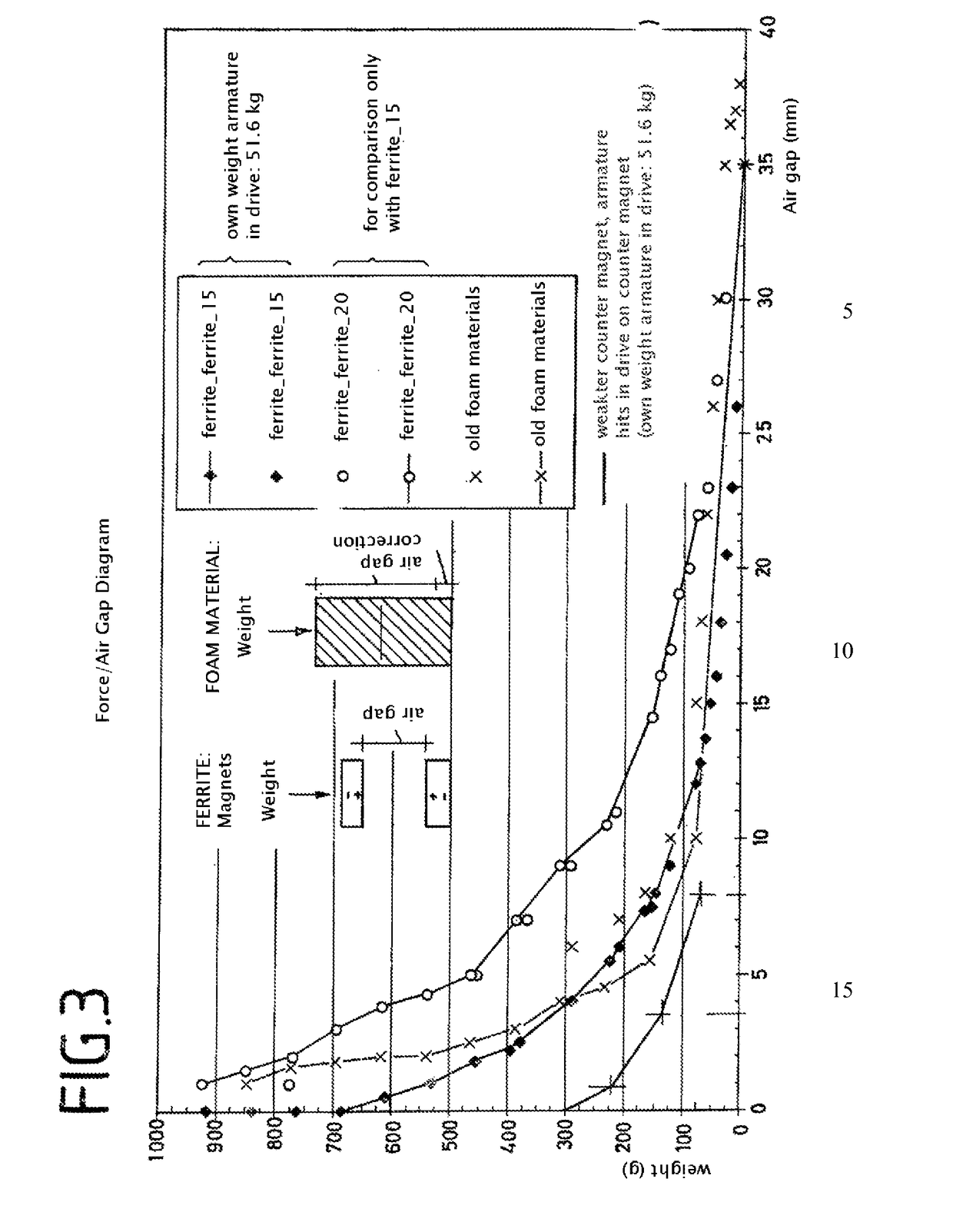

Massage device

ActiveUS10085913B2Shorten the lengthSoftlyPneumatic massageGymnastic exercisingMassageElectrical polarity

The massaging device includes electromechanical means, for generating mechanical vibrations, in a housing, electronic means for controlling the electromechanical means, and a power source connected to the electromechanical and electronic means. The electromechanical means includes a cylinder element, in which a core is guided in parallel to a cylinder element axis (Z2), in particular, coaxial with respect to the cylinder element axis (Z2), at least one coil element, the coil axis (Z3) of which is arranged coaxially with respect to the cylinder element, and which encloses the cylinder element, and one impact element arranged at each end of the cylinder element and in the interior thereof, characterized in that the impact elements are formed as end magnets, wherein the ends of the end magnets respectively facing the ends of the core have a magnetic polarity which is identical to the polarity of the respectively facing ends of the core.

Owner:BLENK UDO +1

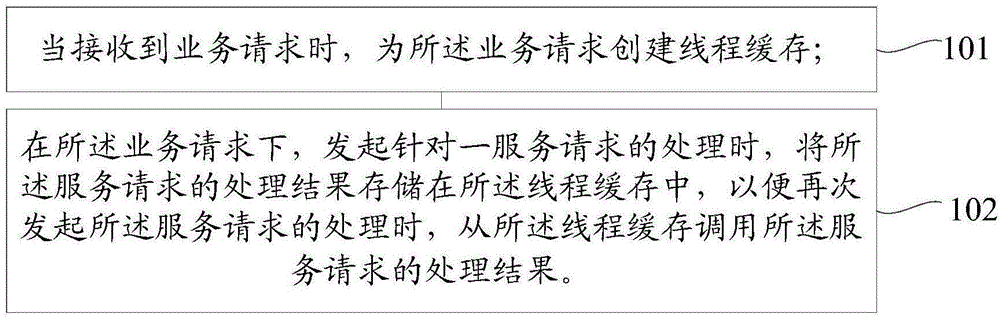

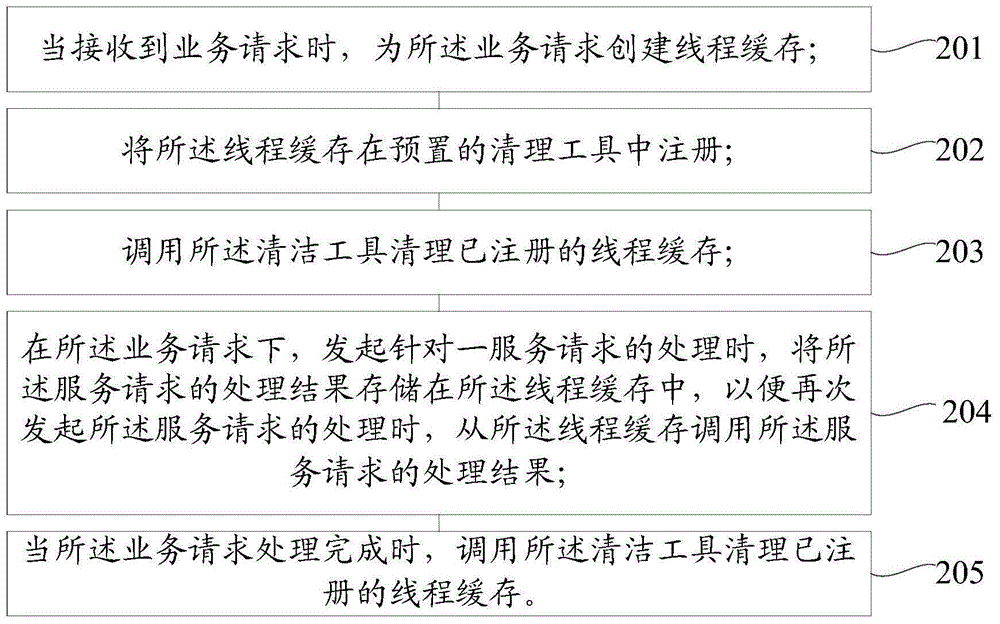

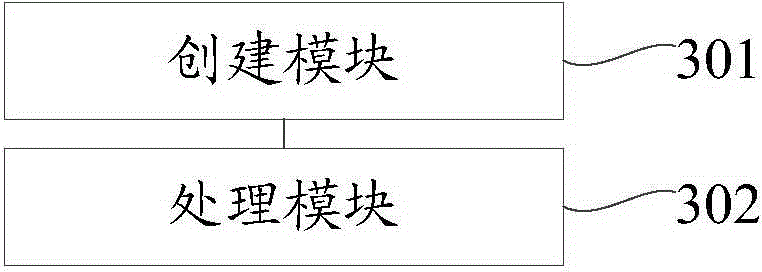

Business processing method and device

InactiveCN105635208AReduce the number of callsAvoid mergingTransmissionMaintainabilityOperating system

Embodiments of the invention provide a business processing method and device. The method comprises the following steps: when a business request is received, creating thread cache for the business request; and, under the business request, when processing aiming at a service request is initiated, storing a processing result of the service request in the thread cache so that the processing result of the service request is called from the thread cache when the processing for the service request is initiated again. The processing result is extracted from the thread cache, an external service system does not need to be called again, the call frequency of the external service system is greatly reduced, and the system resource overhead is lowered; and the processing result does not rely on any other storage and neither occupies a memory space of an application, the method is a lightweight thread cache implementation scheme, business interfaces are prevented from being merged, a single responsibility of each interface is kept, and system expansibility and maintainability are guaranteed.

Owner:ALIBABA GRP HLDG LTD

Polymeric Thickeners

The present invention is concerned with an emulsion copolymer latex comprising an acrylic / methacrylic copolymer obtainable by the emulsion copolymerisation of the following monomer components: A: from 75% weight to 97.5% by weight, based on the total weight of monomer components A+B+C+D, of methyl acrylate; B: from 0.1% to 15% by weight, based on the total weight of monomer components A+B+C+D, of at least one ethylenically unsaturated carboxylic acid monomer containing one C≡C double bond capable of free radical copolymerisation with component A and at least one carboxylic acid (CO2H) group; C: from 1% to 20% by weight based on the total weight of monomer components A+B+C+D of at least one associative monomer being a (meth)acrylate ester of an alkoxylated alcohol; and D: from 0% to 15% by weight of one or more non-ionic ethylenically unsaturated monomers other than those defined above as A, B or C; wherein the total monomer components A+B+C+D together add up to 100%. The present invention also provides a composition suitable for use as a pH responsive thickener comprising the hydrolysis product of the emulsion copolymer latex.

Owner:SCOTT BADER CO LTD

Neutron radiation resisting barite low hydration heat concrete construction technology

ActiveCN104712144AGuarantee the construction qualityImprove workabilityBuilding material handlingSlagNeutron radiation

The invention relates to the technical field of building construction, in particular to a neutron radiation resisting barite low hydration heat concrete construction technology. According to the neutron radiation resisting barite low hydration heat concrete construction technology, raw materials of concrete are iron sand, glass dust, heavy crystal sand, iron ore, barite, cement, mineral powder, water and a water reducing agent; the construction technology comprises the following steps of A, calculating working mix proportion; B, feeding; C, stirring; D, transporting; E, pouring; F, maintaining. The technical scheme can effectively guarantee the construction quality of the concrete, good workability, no bleeding and good mobility in concrete pouring are guaranteed, and the requirements for radiation resistance, low shrink, high density, high uniformity and the like are satisfied. When a mass concrete structure with the minimum geometric dimensioning larger than 1.2m is subjected to construction by the adoption of the technical scheme provided by the neutron radiation resisting barite low hydration heat concrete construction technology, low hydration heat of the concrete construction can be guaranteed, the temperature difference between inside and outside is lower than or equal to 20 DEG C, the adiabatic temperature rise is lower than or equal to 55 DEG C, the phenomena of honeycombs, holes, slag inclusion and cracks do not occur on the surface of the concrete, and therefore higher pouring and vibrating quality can be guaranteed.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR +1

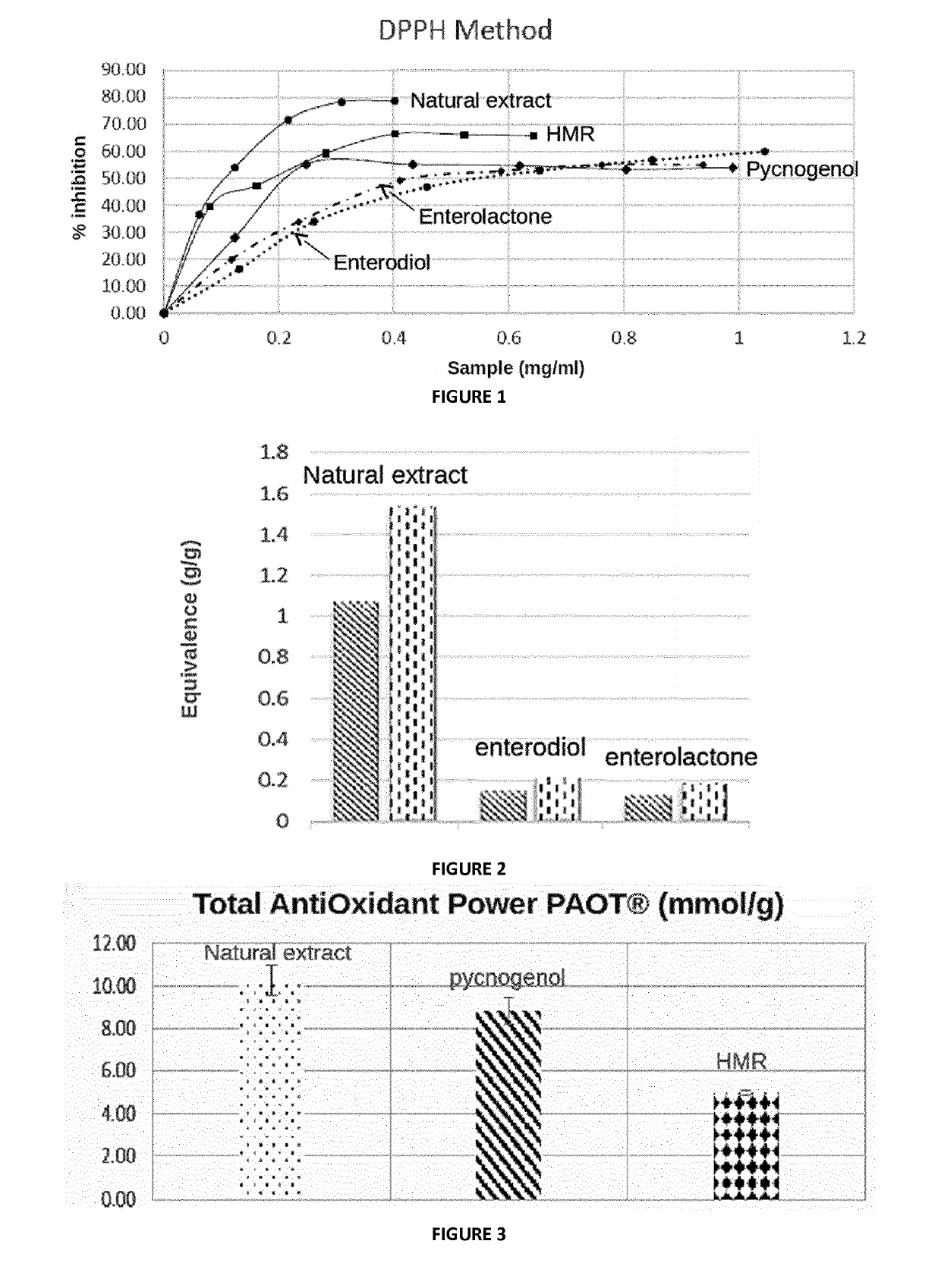

Sublingual compositions comprising natural extracts and uses thereof

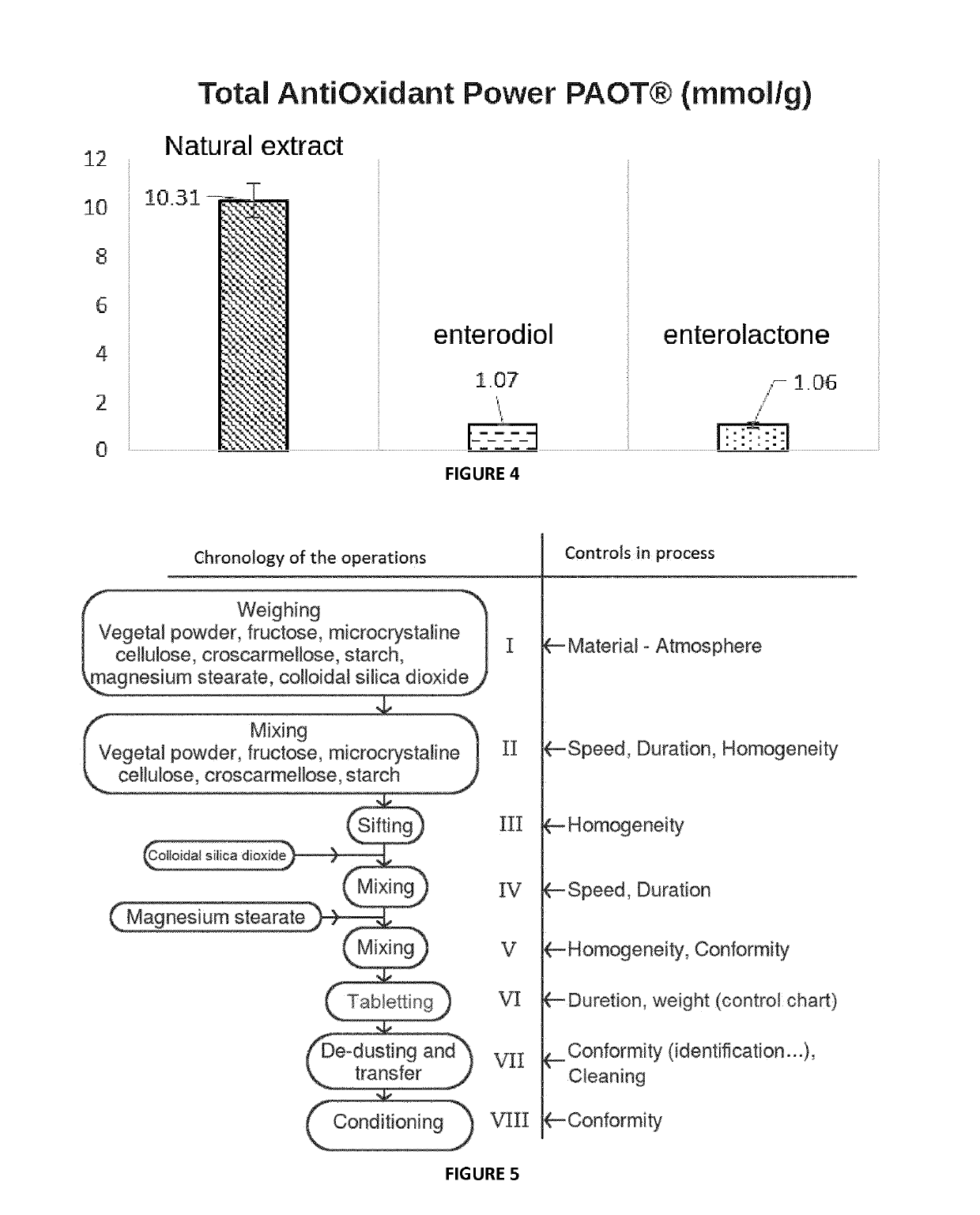

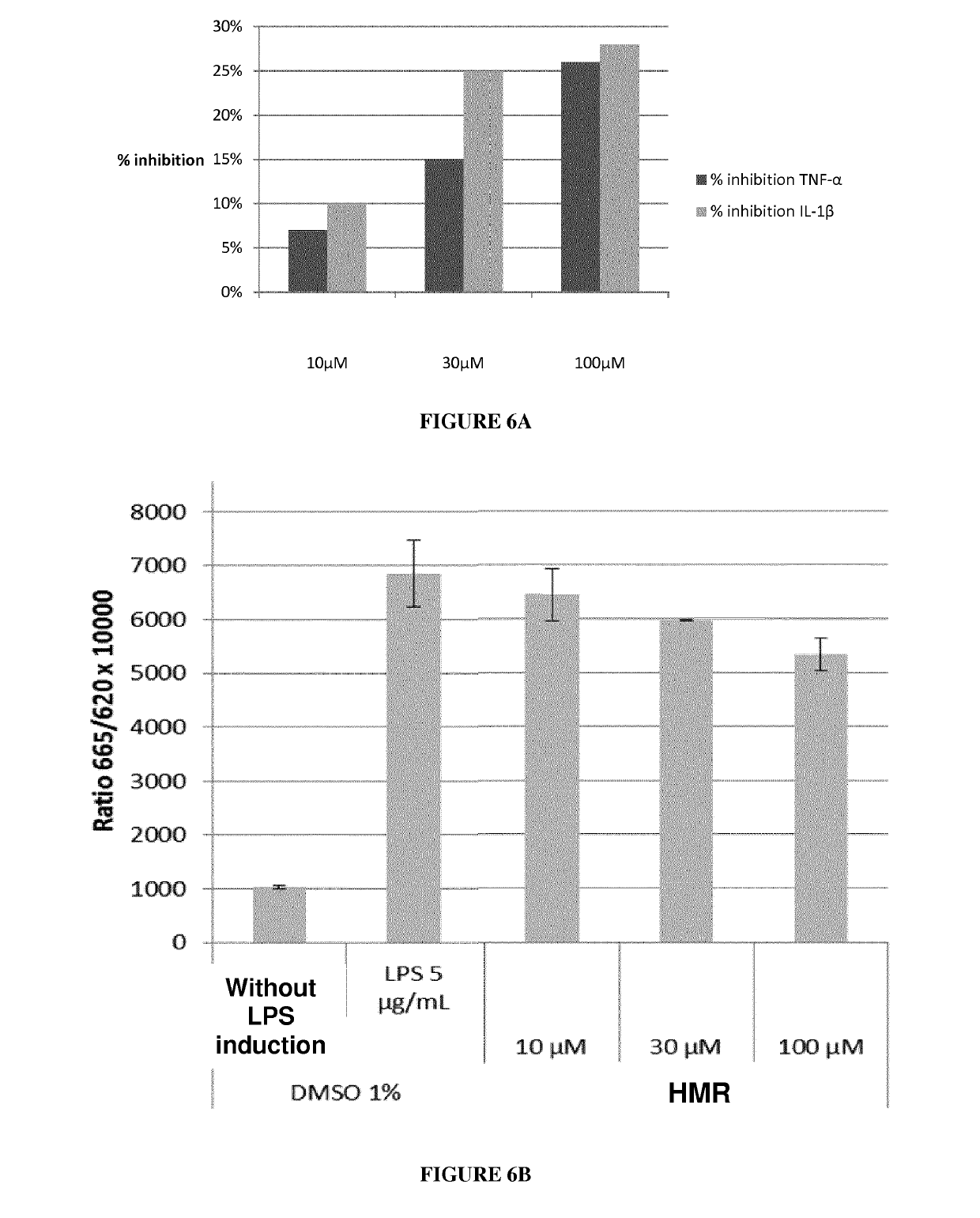

InactiveUS20190117555A1Improve antioxidant capacityMaintaining anti-inflammatory effectAntipyreticAnalgesicsJoint painTraditional medicine

The present invention relates to a sublingual composition comprising a part of branch extract, preferably from at least one resinous tree comprising at least about 50% by weight of polyphenols and less than about 10% by weight of terpenes, relative to the total weight of the extract. The present invention further relates to the non-therapeutic uses of such sublingual composition for improving the respiratory wellness, relieving joint pain and / or muscular pain and cramps and / or improving endurance, and improving libido and / or fertility.

Owner:HARMONIC PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com