High-performance concrete temperature control and maintenance method under strong wind gobi environment

A high-performance concrete and concrete technology, applied in the field of concrete, can solve problems such as failure to meet concrete maintenance requirements, maintenance effect cannot be guaranteed, and cracks cannot be prevented, so as to save water resources and labor resources, ensure maintenance effect, and prevent temperature rise. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

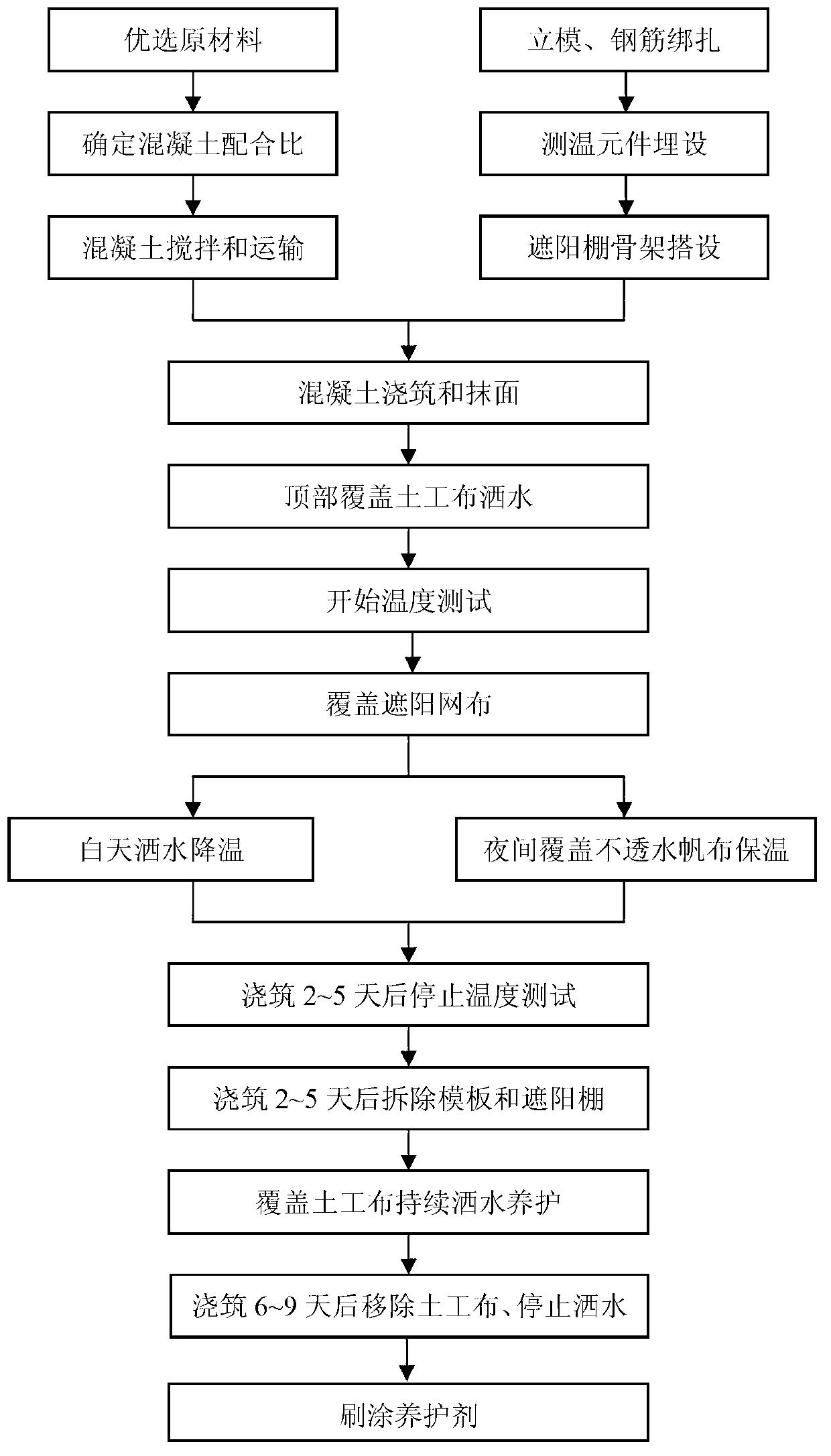

[0040] Concrete components: large-volume piers in the Yandun wind zone of the second bid section of the Hongliuhe-Hami section of the new railway Lanzhou-Urumqi second double-track project. The mix ratio and main mix ratio parameters of this concrete are shown in Table 1.

[0041] Table 1 Pier body concrete mix ratio and main mix ratio parameters

[0042]

[0043] The specific temperature control and maintenance plan is: after the concrete is poured, cover it with a sunshade net shed during the day and sprinkle water to cool down, and cover it with impermeable canvas at night for heat preservation. After 3 days of concrete pouring, remove the formwork and remove the sunshade net shed, and at the same time cover the geotextile and Plastic film, sprinkle water for curing, remove the geotextile and plastic film after 7 days of concrete pouring, and brush the curing agent.

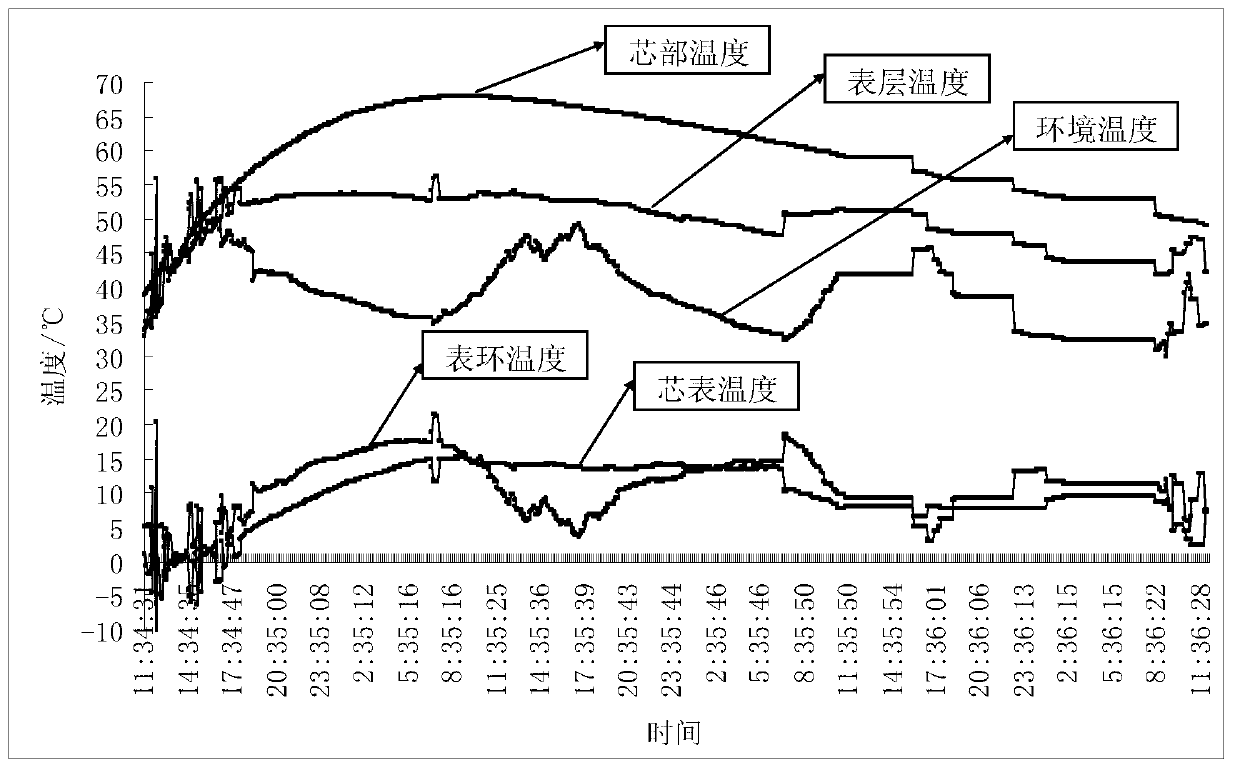

[0044] The concrete construction time is September 2010. Concrete pouring started at 11:00 in the eveni...

Embodiment 2

[0058] The construction object selected in this embodiment is the prefabricated T-beam of the second bid Hami prefabrication field of the station front project of the second double-line Hongliuhe to Hami section of the new railway from Lanzhou to Urumqi. Through the temperature control and maintenance scheme of the present invention and the current domestic commonly used temperature Control and maintenance schemes are compared to illustrate the implementation effect of the temperature control and maintenance schemes of the present invention.

[0059] Table 2 Prefabricated T-beam concrete mix ratio and main mix ratio parameters

[0060]

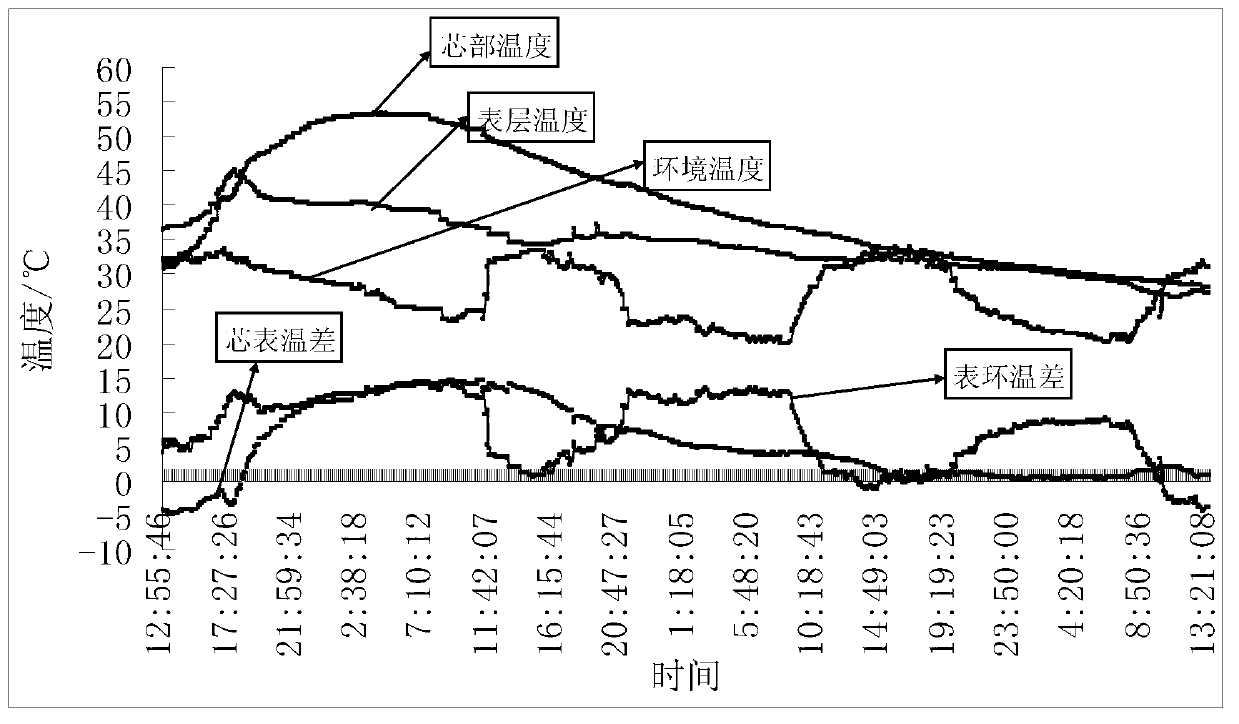

[0061] The span of the prefabricated T-beam is 16m, and the concrete mix ratio is shown in Table 2. The concrete construction time is September 2010. The concrete pouring starts at 8:00 in the morning. The temperature was 41°C, and within one month after the concrete was poured, there were strong winds above level 10.

[0062] (1) Tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freeze resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com