Patents

Literature

143results about How to "Guaranteed economic interests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

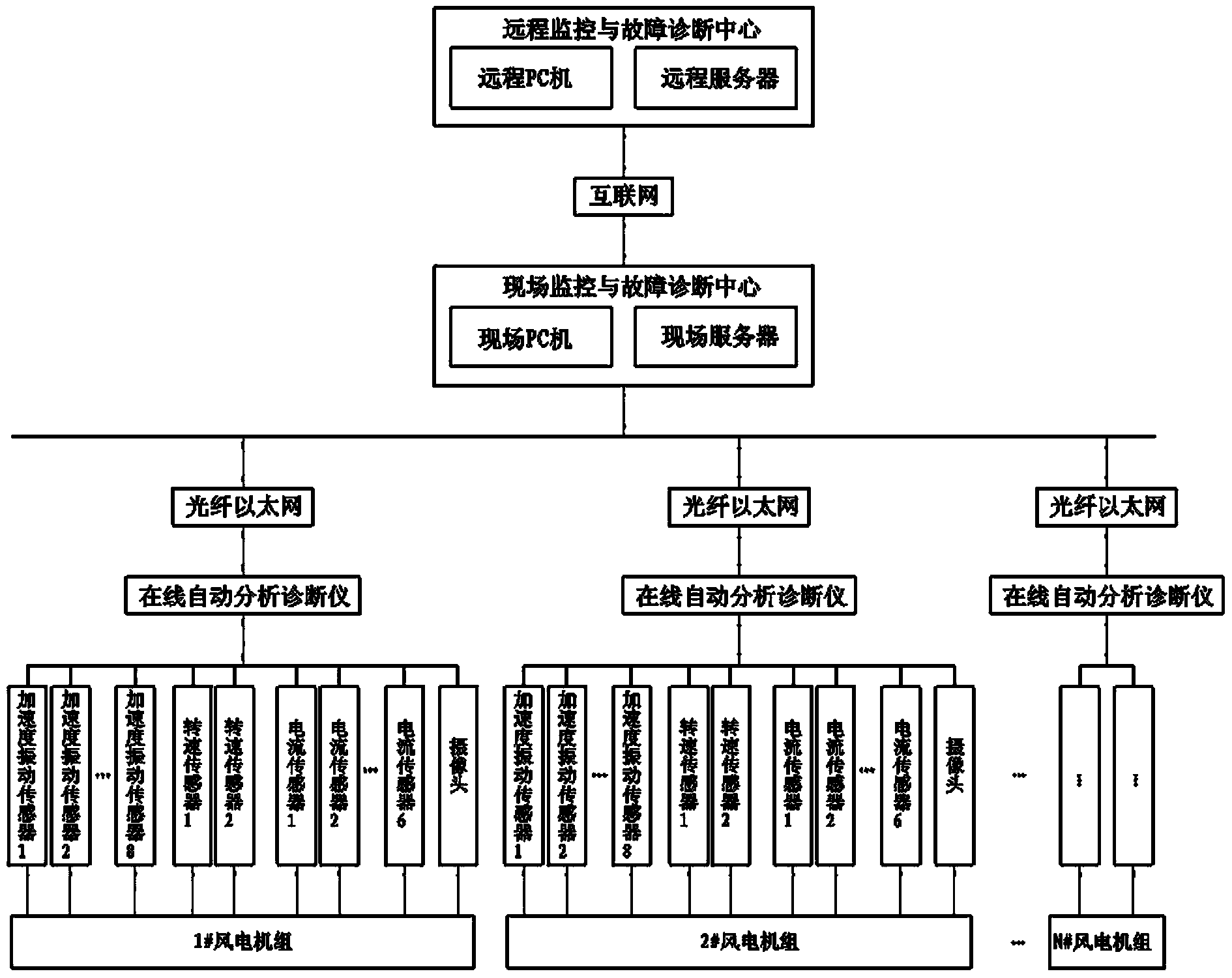

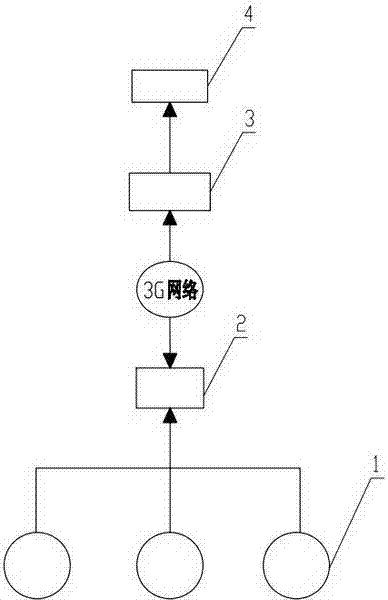

System and method for remote real-time state monitoring and intelligent failure diagnosis of wind turbine generators

ActiveCN103529386AGuaranteed maintenanceGuaranteed maintenance effectNon-electrical signal transmission systemsDynamo-electric machine testingSite monitoringElectricity

The invention relates to a technology for examining and maintaining wind turbine generators, in particular to a system and a method for the remote real-time state monitoring and the intelligent failure diagnosis of the wind turbine generators. The problems that the existing technology for examining and maintaining the wind turbine generators cannot ensure the examining and maintaining effect, cannot timely find the internal failure, the sudden failure and the hidden failure trouble of the wind turbine generators and requires a high examining and maintaining cost are solved. The system for the remote real-time state monitoring and the intelligent failure diagnosis of the wind turbine generators comprises state monitoring equipment, a site monitoring and failure diagnosis center and a remote monitoring and failure diagnosis center, wherein the state monitoring equipment comprises an accelerated vibration sensor, a rotating speed sensor, a current sensor, a camera and an on-line automatic analysis and diagnosis instrument; the site monitoring and failure diagnosis center comprises a site server and a site PC (Personal Computer). The system and the method are suitable for all types of wind turbine generators.

Owner:山西大学工程学院

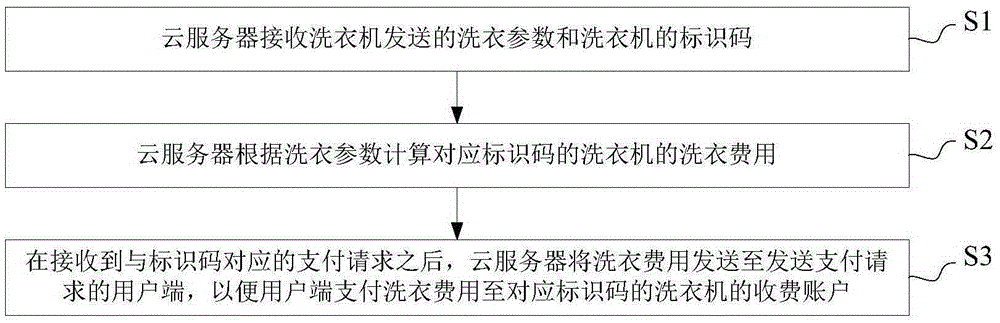

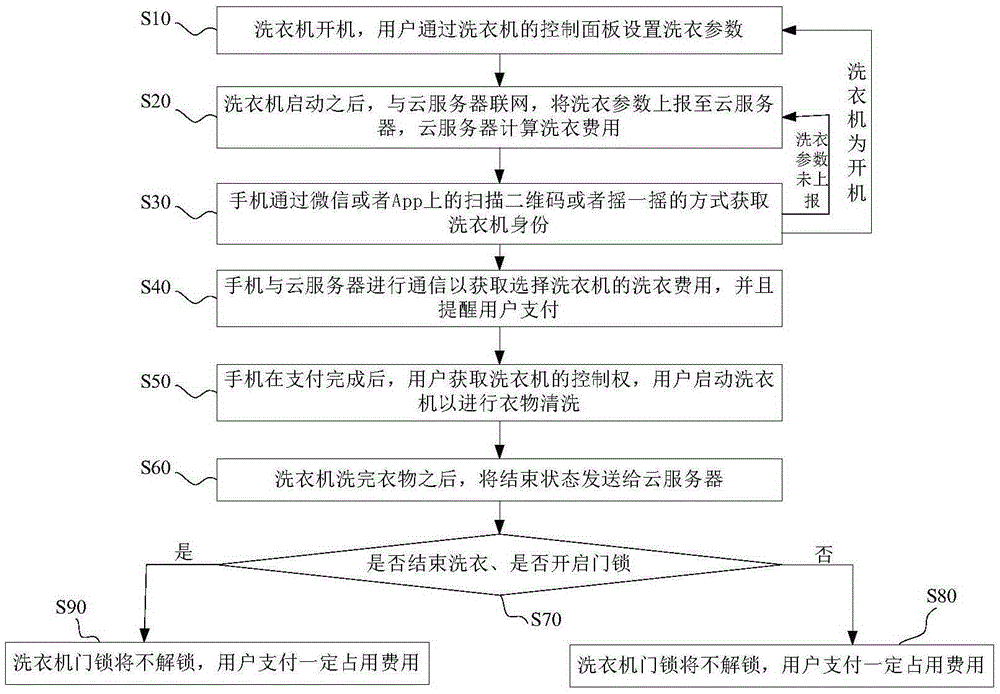

Laundry expense paying method, washing machine, cloud server, user side and system

InactiveCN105336052AImprove experienceKeep abreast of the running statusOther washing machinesPayment architecturePaymentLaundry

The invention discloses a laundry expense paying method of a public washing machine. The paying method comprises the following steps that a cloud server receives washing parameters sent by the washing machine and an identification code of the washing machine; the cloud server calculates the laundry expense of the washing machine corresponding to the identification code according to the washing parameters; after receiving the payment request corresponding to the identification code, the cloud server sends the laundry expense to the user side sending the payment request, so that the user side pays the laundry expense to a charging account of the washing machine corresponding to the identification code conveniently. According to the paying method, the laundry expense can be paid conveniently, so that the user experience is improved. The invention also discloses a washing machine, a cloud server, a user side and a laundry expense paying system of the public washing machine.

Owner:无锡小净共享网络科技有限公司

Method and system for realizing network advertisement release

InactiveCN102122380AGuaranteed economic interestsPrevent situations that reduce ad effectivenessCommerceStable stateRelease time

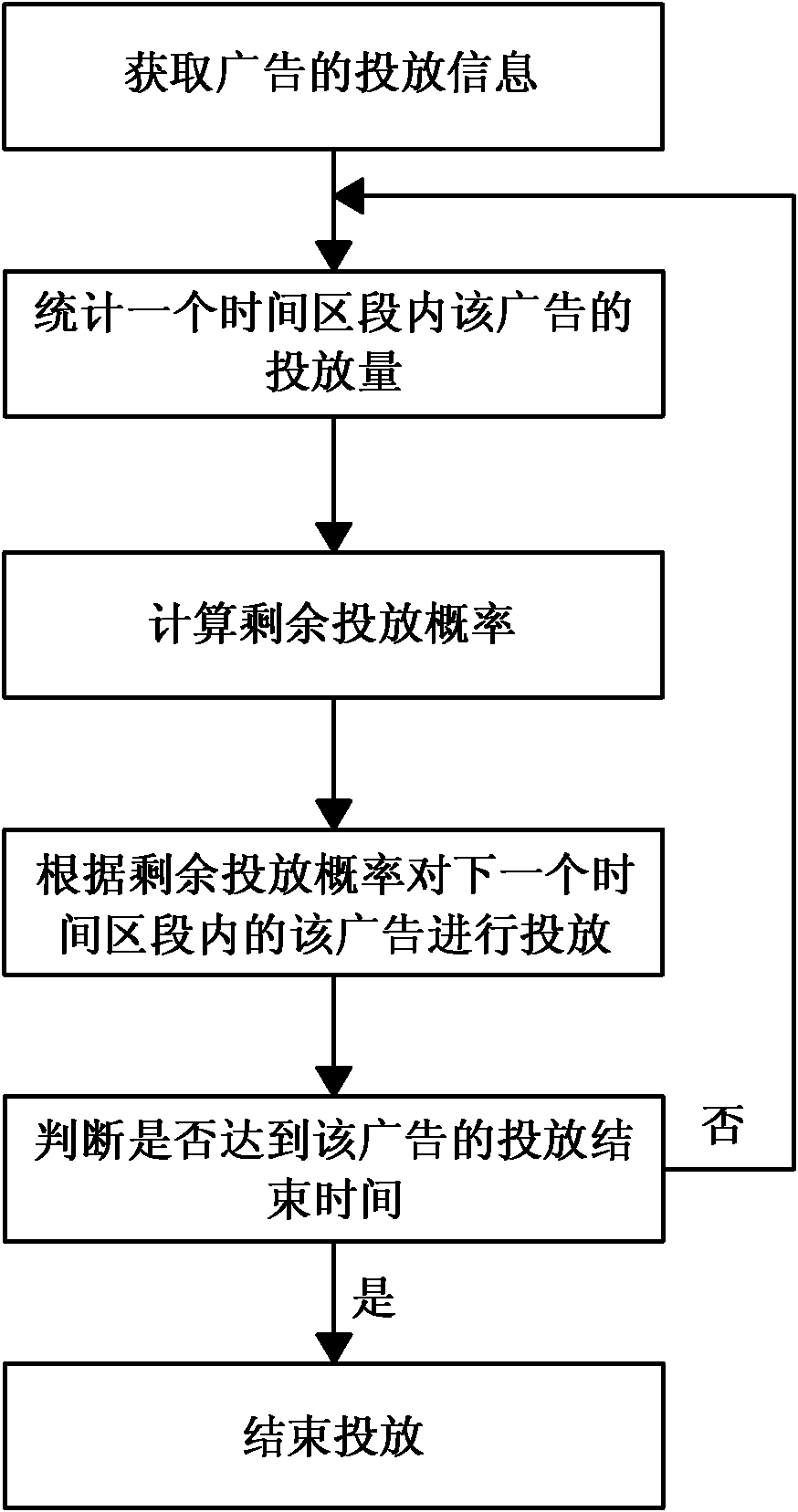

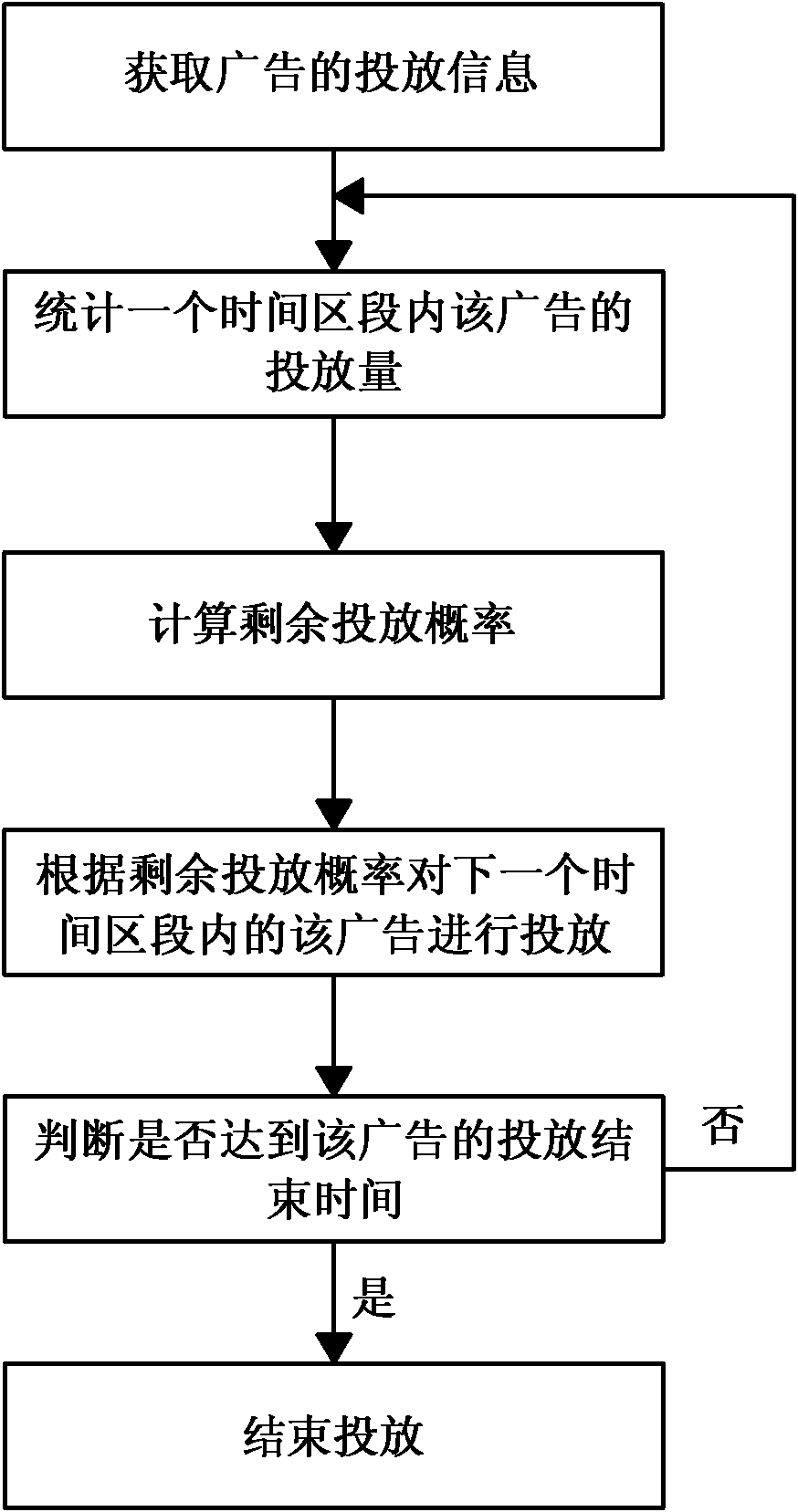

The invention discloses a method and system for realizing network advertisement release. The method comprises the following steps of: (S1) acquiring the release information of an advertisement; (S2) counting the release quantity of the advertisements in a time interval; (S3) calculating the residual release probability; (S4) releasing the advertisement in the next time interval according to the residual release probability; and (S5) judging whether the release finishing time of the advertisement is reached, if the finishing time is not up, turning to the step (S2), and if the finishing time is up, finishing the release. By using the method and the system, the release ratio of the advertisement in the release time is maintained in a stable state, the situation of excessively intensive advertisement release is prevented, and the economic benefit of an advertiser is protected.

Owner:BEIJING PEOPLE HAPPY INFORMATION TECH

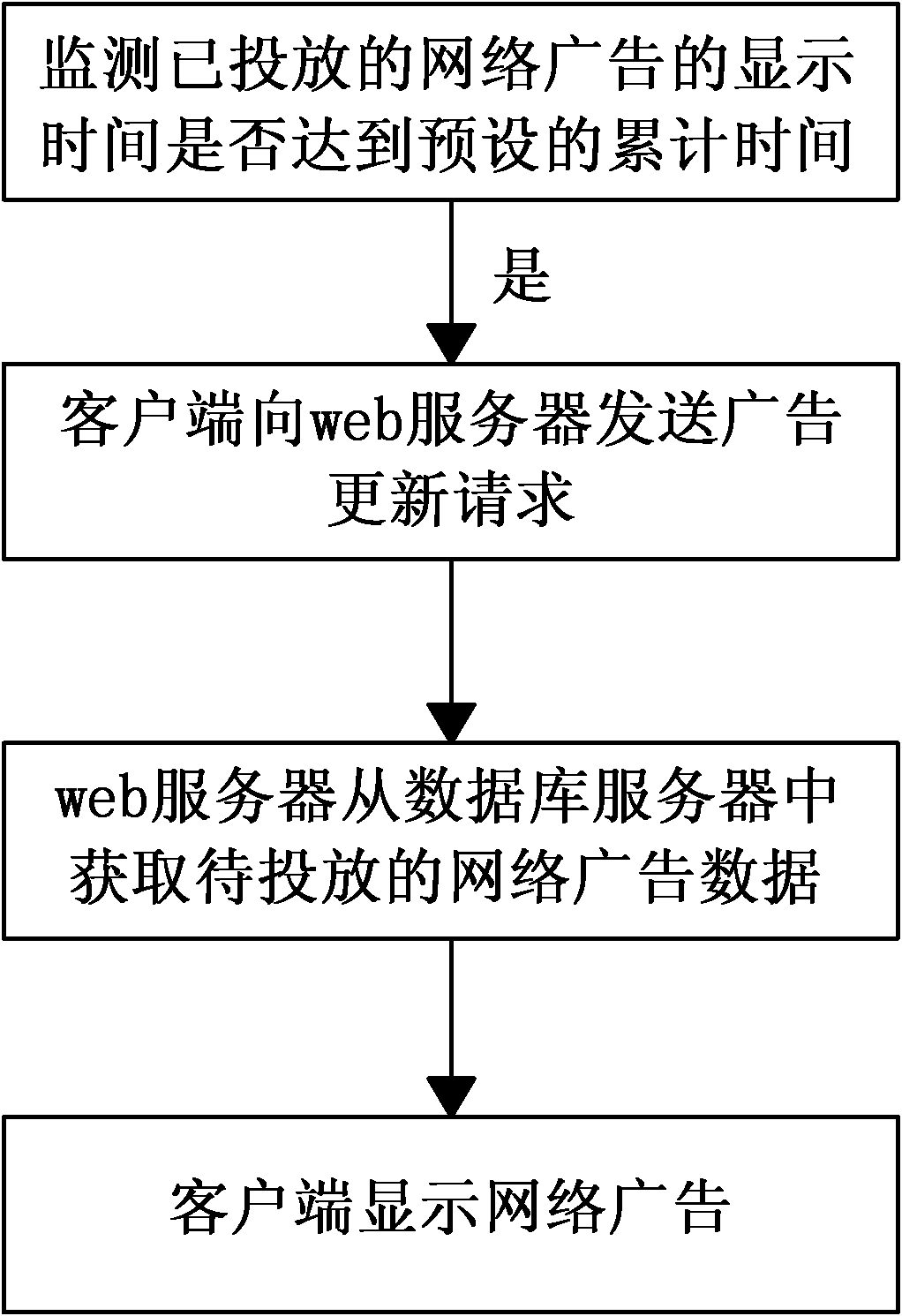

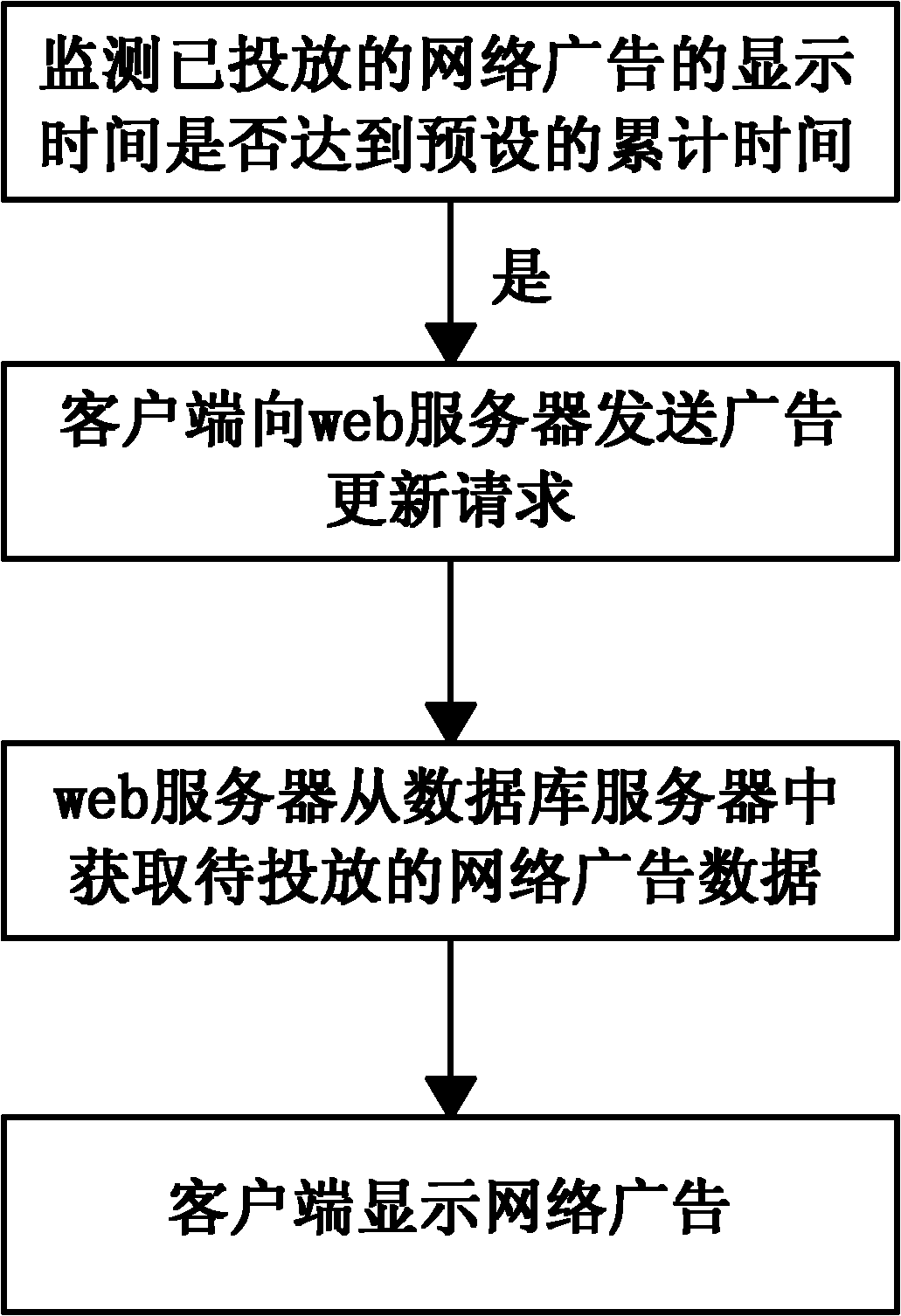

Updating method for network advertisement and system thereof

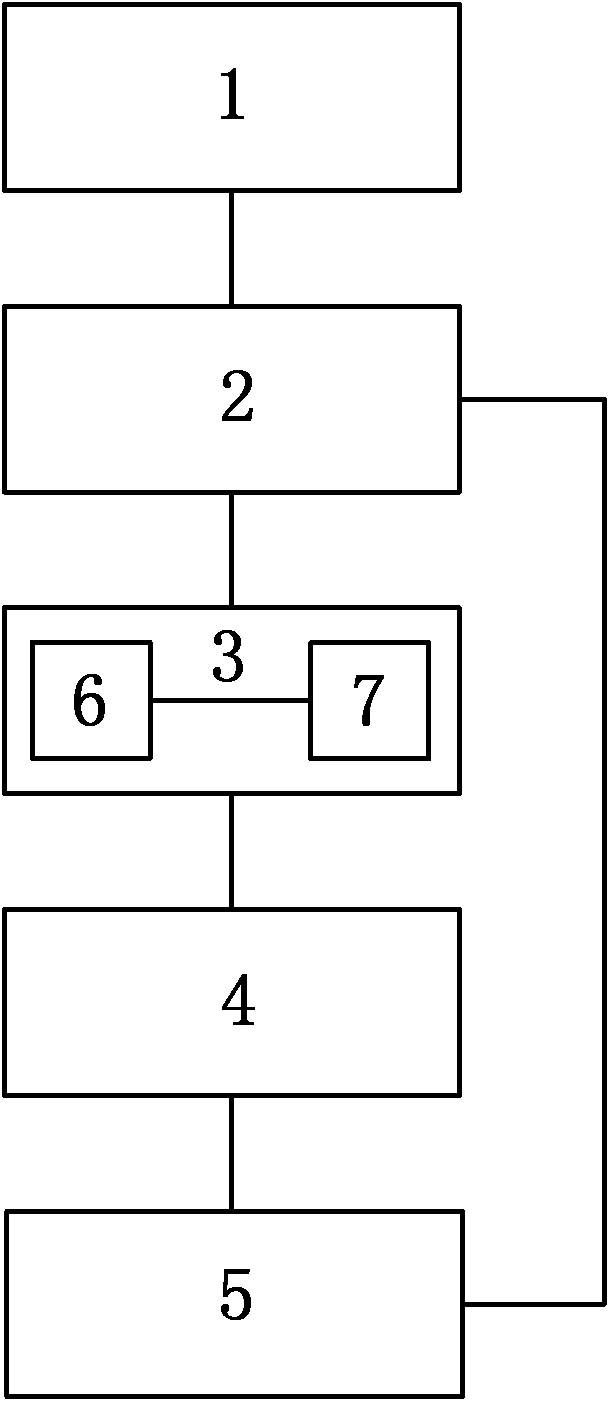

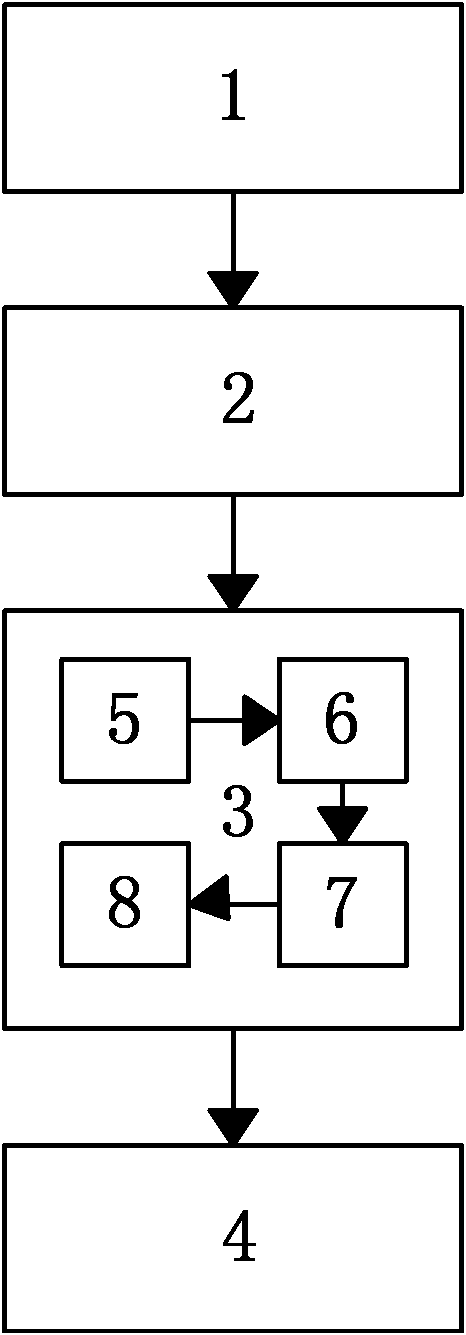

InactiveCN102158478AImplement automatic updatesGuaranteed economic interestsTransmissionWeb serviceDatabase server

The invention discloses an updating method for a network advertisement and a system thereof; the method comprises the following steps of: S1, a client monitors whether the display time of a delivered network advertisement reaches preset cumulative time; S2, if the display time of the network advertisement reaches the preset cumulative time, the client sends an advertisement updating request to a web server; S3, the web server obtains network advertisement data to be delivered from a database server; S4, the client displays the network advertisement. The method and the system can increase the display possibility of advertisements delivered by an advertiser and protect the benefit of the advertiser so that a user enjoys rich and suitable advertisement; therefore, the user experience of social network is improved.

Owner:BEIJING PEOPLE HAPPY INFORMATION TECH

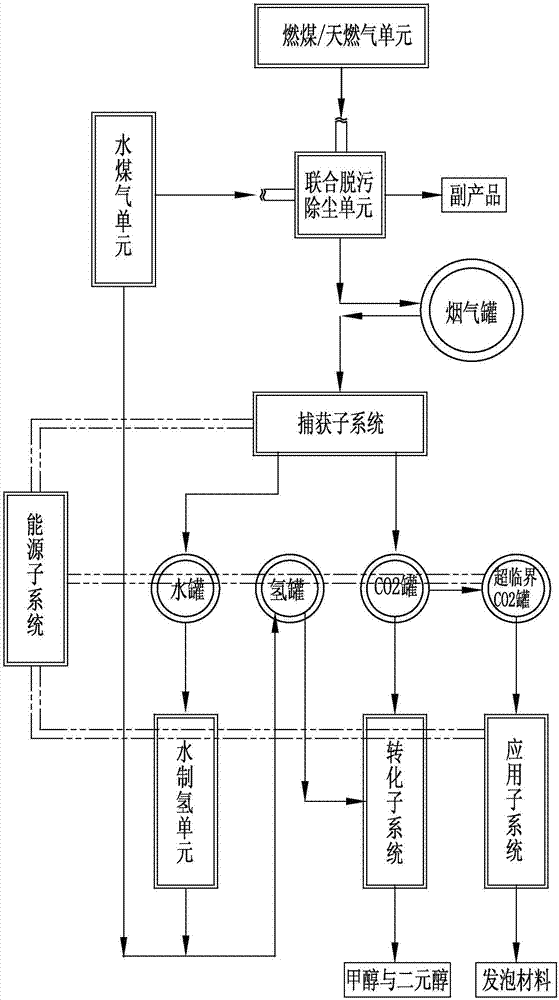

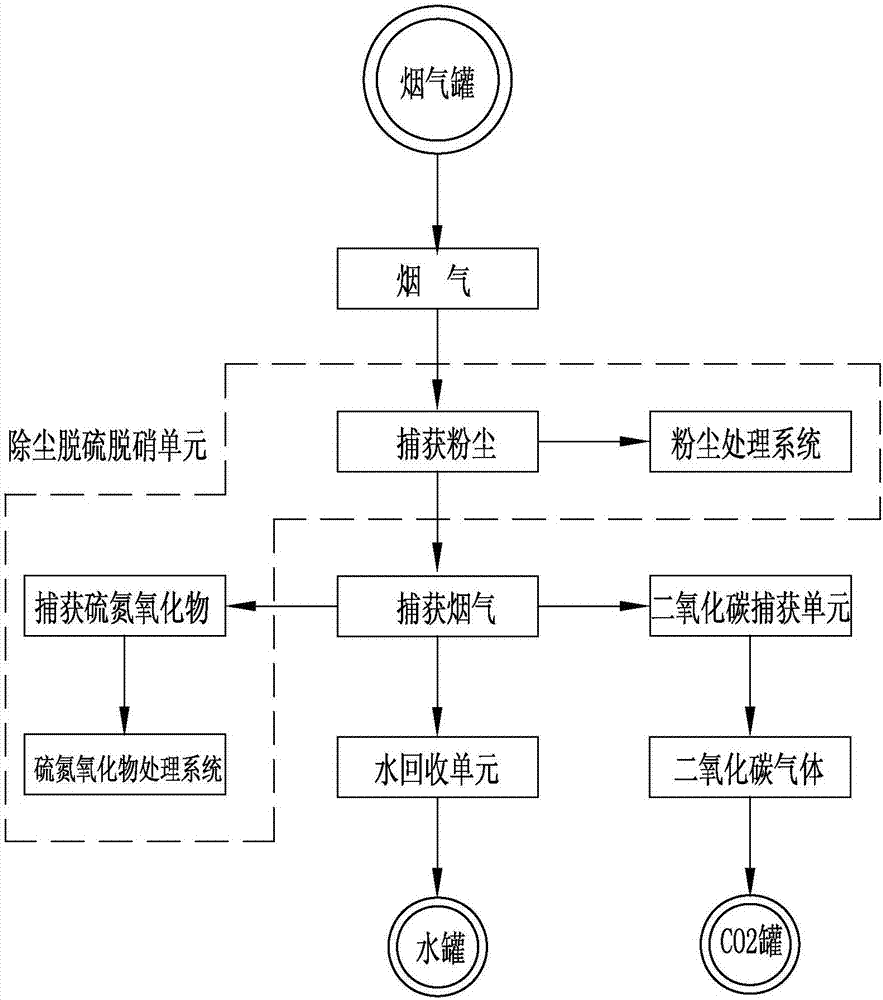

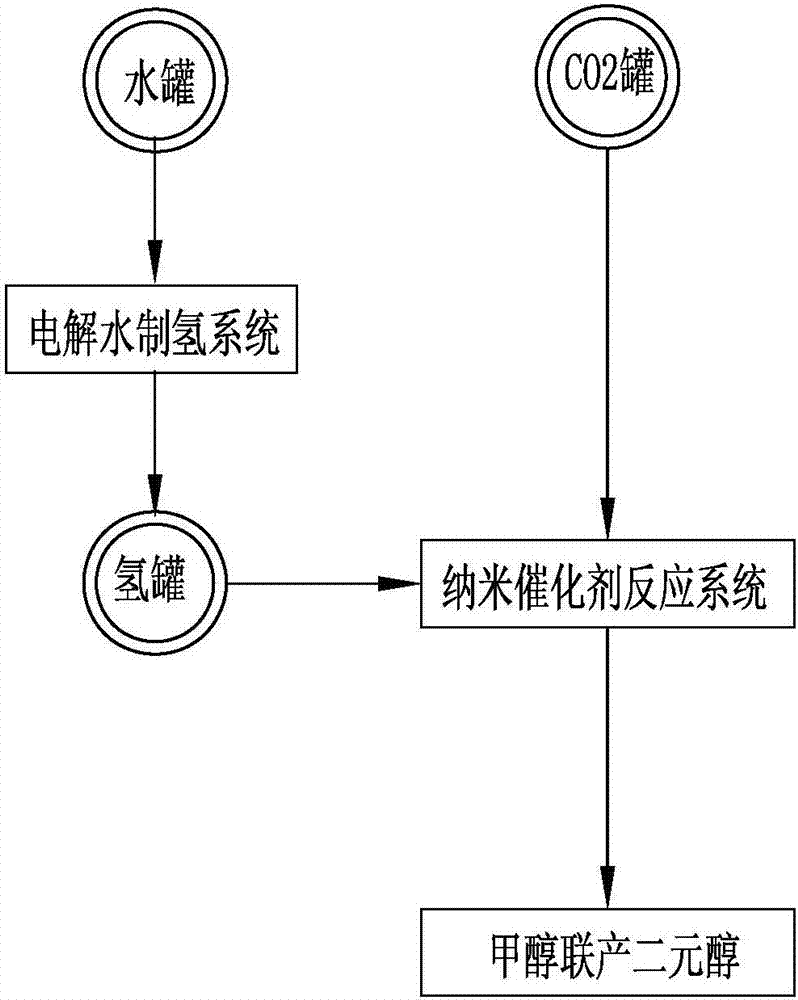

Flue gas capture, transformation and application total recycling system in factories, power plants and refinery plants

ActiveCN107983089AImprove performanceLow densityGas treatmentInternal combustion piston enginesDust controlAtmospheric pollution

The invention discloses a flue gas capture, transformation and application total recycling system in factories, power plants and refinery plants. The operating method comprises the following steps: removing dust and oxides by virtue of a combined decontamination and dust removal unit; capturing CO2 by a capture subsystem, and recovering water by a water recovery unit; decomposing water into hydrogen and oxygen by a hydrogen production unit, and combustion-supporting by an oxygen feed water gas unit toobtain the hydrogen; carrying out a catalytic reaction on the CO2 and hydrogen to be transformed into methanol and dihydric alcohol by a transformation subsystem; preparing supercritical CO2 nano-cellulose paste by an application subsystem, blending and extruding material particles to become asupercritical CO2 nano-cellulose foam material; and connecting an energy subsystem to solar wind power, and supplementing energy by virtue of waste heat and hydrogen power generation. According to the system disclosed by the invention, a combined technology for total-component, total-dose integrated recycling and high value-added production of the flue gas is designed for the first time; the fluegas is transformed into the methanol, dihydric alcohol and the ultra-light super-strong nano-cellulose foam material, and absolute reduction, transformation and application of the CO2 can be realized; and the problems of atmospheric pollution and greenhouse effects are completely improved.

Owner:山西清洁碳经济产业研究院有限公司 +1

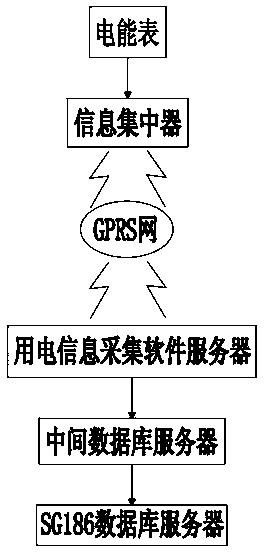

Line loss analysis management system and line loss analysis management method

InactiveCN103020754AQuick analysisAccurate analysisResourcesTransmissionGeneral Packet Radio ServiceStatistical analysis

The invention discloses a line loss analysis management system and a line loss analysis management method and is applicable to the technical field of electric measurement. The line loss analysis management system comprises an information concentrator, a power consumption information acquisition software server, a middle database server and an SG186 database server, wherein the information concentrator is connected with a data interface of an electric energy meter through a data line; the power consumption information acquisition software server and the information concentrator transmit the data through a general packet radio service (GPRS) network; the input end of the middle database server is connected with the output end of the power consumption information acquisition software server; and the input end of the SG186 database server is connected with the output end of the middle database server. The system has the beneficial effects that statistic analysis of the middle data is utilized, so that the line loss abnormity reasons are conveniently and rapidly found; and moreover, the line loss abnormity reasons can be analyzed, so that the workers can conveniently check the line, the line loss abnormity reasons are processed, the line loss abnormity check efficiency is improved, and the economic benefits of the power grid company are maintained.

Owner:STATE GRID CORP OF CHINA +2

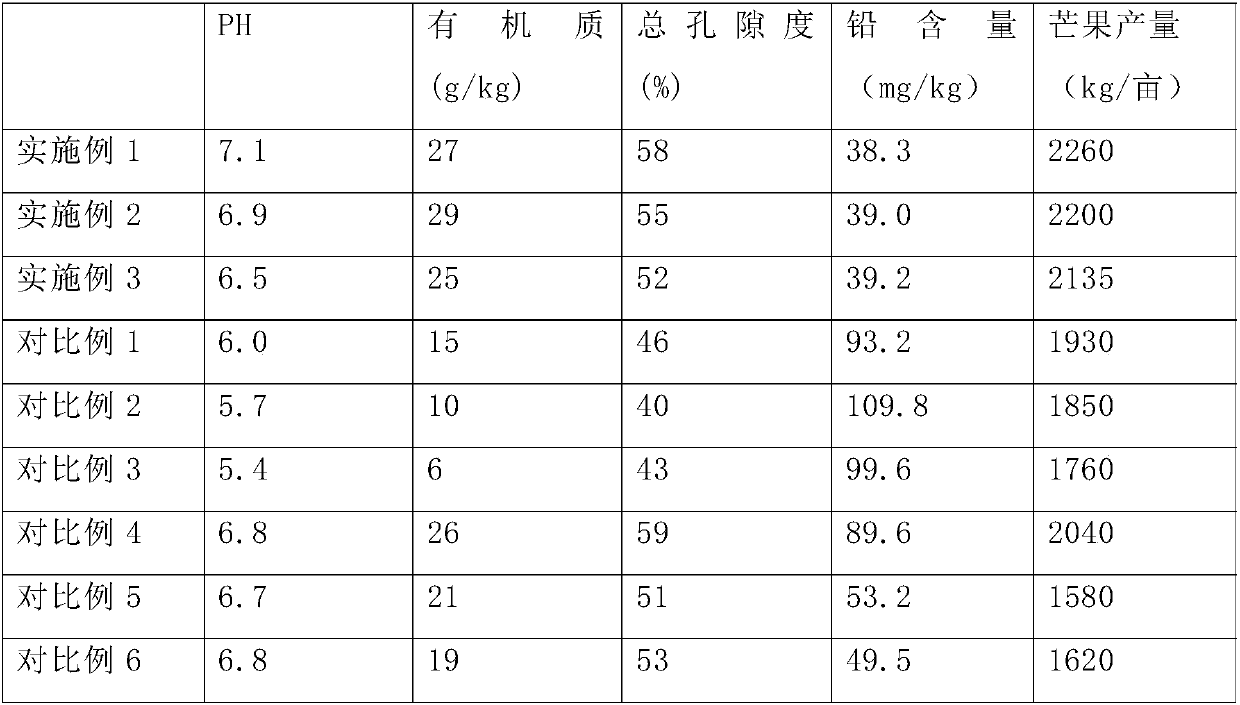

Comprehensive method for soil conditioning and restoration

ActiveCN107580818AExtended release timeIncrease profitFertilising methodsSoil-working methodsOysterPotassium

The invention provides a comprehensive method for soil conditioning and restoration. The method comprises the following steps: before crops are planted or after fruit trees are harvested, oyster shellpowder, silicon-calcium-potassium-magnesium fertilizer, biological organic fertilizer, a biological control agent and ternary compound fertilizer are applied to soil; before the fruit trees are sprouted and bloomed, a macroelement water-soluble fertilizer and humic acid water-soluble fertilizer are applied to the soil; during a swelling period of young fruits of the fruit trees, silicon-calcium-potassium-magnesium fertilizer and a composite microbial bacterial liquid are applied to the soil; and during a fruit strengthening period of the fruit trees, high-potassium fertilizer and seaweed fertilizer are applied to the soil. The method is used for conditioning and restoring the soil, so that the pH of the soil tends to be neutral, and the acidification degree is obviously reduced; the organic matter content of the soil is obviously increased, the soil becomes loose and breathable, and the soil layer is deep and thick; and the heavy metal content in the soil is reduced, so that securityof the planted crops is improved, and the yield is improved. The method provided by the invention does not interrupt growth of the crops in the soil, enables the crops to grow healthily while conditioning and restoring the soil, and improves quality of the crops, so that economic benefits of growers are guaranteed.

Owner:四川微施地健土壤修复技术有限公司

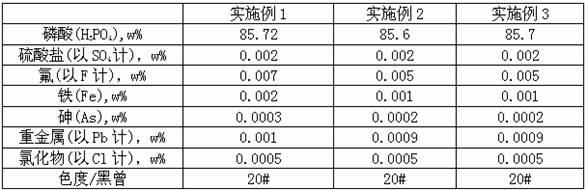

Washing technology for refinement of wet-process phosphoric acid by solvent extraction method

ActiveCN102442657AReduce contentWill not cause misunderstandingPhosphorus compoundsSulfate radicalsPhosphate

The invention relates to a washing technology for refinement of wet-process phosphoric acid by a solvent extraction method. The technology comprises: subjecting crude phosphoric acid obtained from a wet process to pretreatment and extraction in order so as to obtain a saturated phase, and taking 400-600g / L of phosphoric acid as mixing acid, with the phase ratio of the mixing acid and the saturated phase maintained at 1:16-25, then adding NH4<+> ions which are of 100-120% of the stoichiometric amount of sulfate radicals in the saturated phase into the mixing acid for dissolving, conducting filtration after dissolving, and washing the saturated phase with washing water obtained from filtration so as to obtain a washed phase and scourage, carrying out subsequent treatment to the washed phase so as to obtain industrial grade 85% phosphoric acid, and subjecting the scourage to heavy metal ion removal and desulphurization treatment in order, thus obtaining colorless or white industrial grade monoammonium phosphate. The technology design of the invention not only can effectively remove corroded nickel, chromium, manganese, molybdenum and other metal ions in a phosphoric acid feed liquid and improve sulfate radical removing effect, but also has high recovery and utilization rate to the scourage, thus boasting powerful economic benefits.

Owner:吴杰

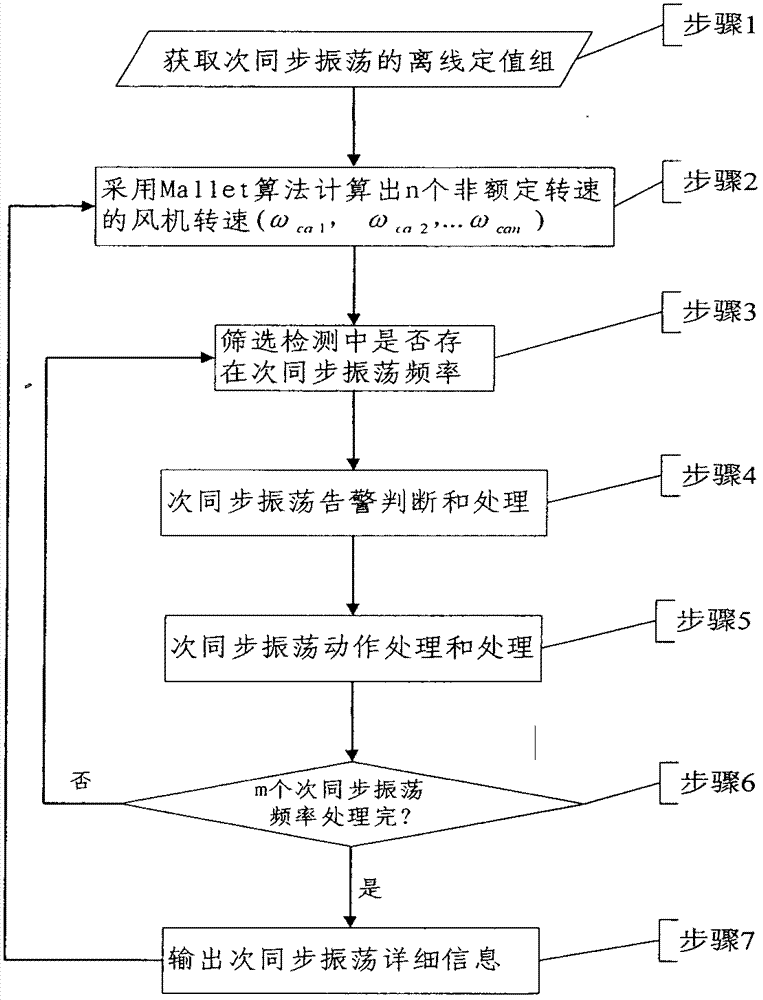

Method for rapidly identifying sub-synchronous oscillation in wind power integrated system

InactiveCN102820665AMaintain dynamic stabilityUndamagedPower oscillations reduction/preventionMalletElectric power system

The invention relates to a method for rapidly identifying sub-synchronous oscillation in a wind power integrated system, and is applicable to detection and control on sub-synchronous oscillation of a wind power system, belonging to the control technical field of electrical power system. On the basis of the rotate speed of a wind turbine generator and a Mallet arithmetic, the rotate speeds of multiple sub-synchronous oscillation frequencies in real time are calculated, the condition that the wind turbine generator has the sub-synchronous oscillation phenomena or does not have is judged according to a fixed off-line value of sub-synchronous oscillation, and depending on the sub-synchronous oscillation degree, the wind turbine generator is given an alarm or the operation parameter of the wind turbine generator is adjusted and even the control measures of cutting-off the wind turbine generator is adopted. The Mallet arithmetic on the basis of the wavelet overcomes the deficiencies that the traditional Fourier transform lacks the spatial locality and is difficult to endure the location and distribution of a singular point. The Mallet arithmetic makes use of the good localization feature in time domain and frequency domain, resolves the rotate speed signals of the wind turbine generator through different scale observing signals with and different resolution ratios, and further realizes the precise detection and control on multiple sub-synchronous oscillation frequencies of the wind power system.

Owner:JIANGSU CHUANGHANG ELECTRIC CO LTD

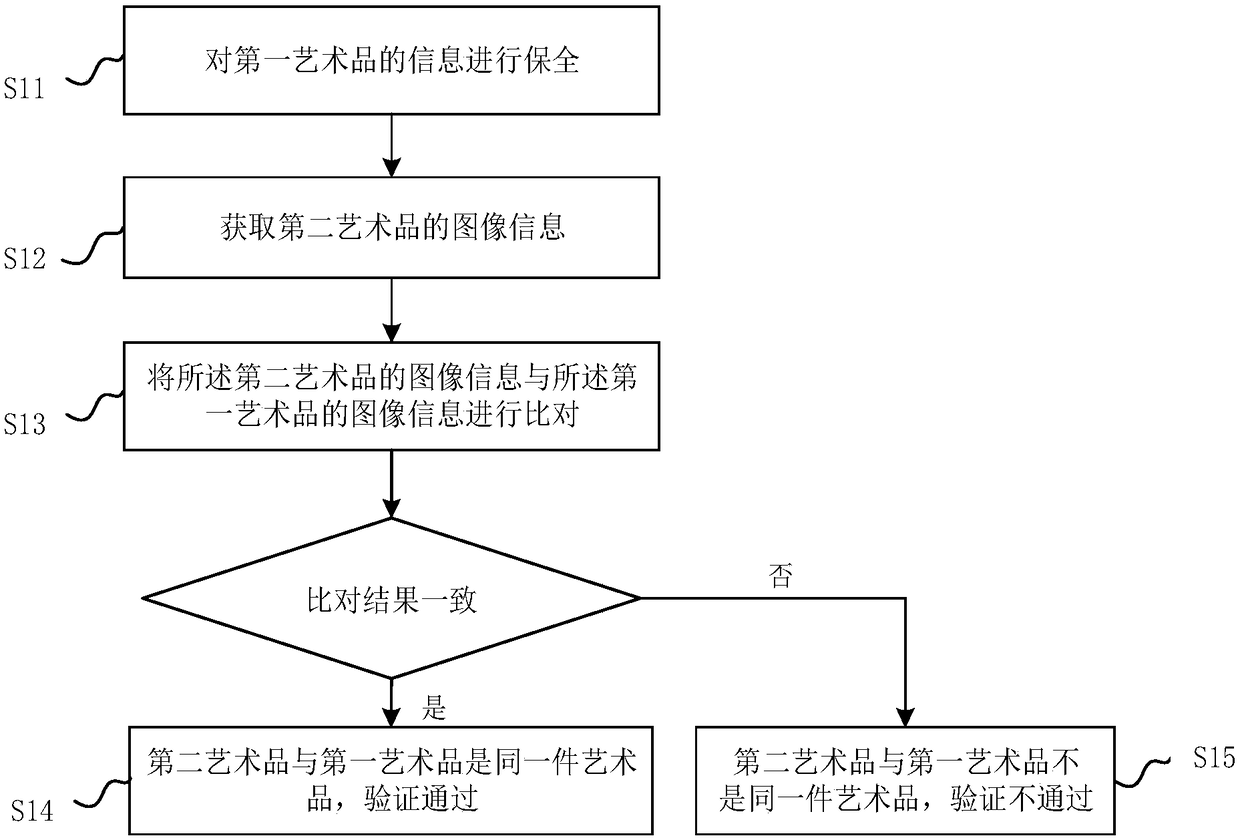

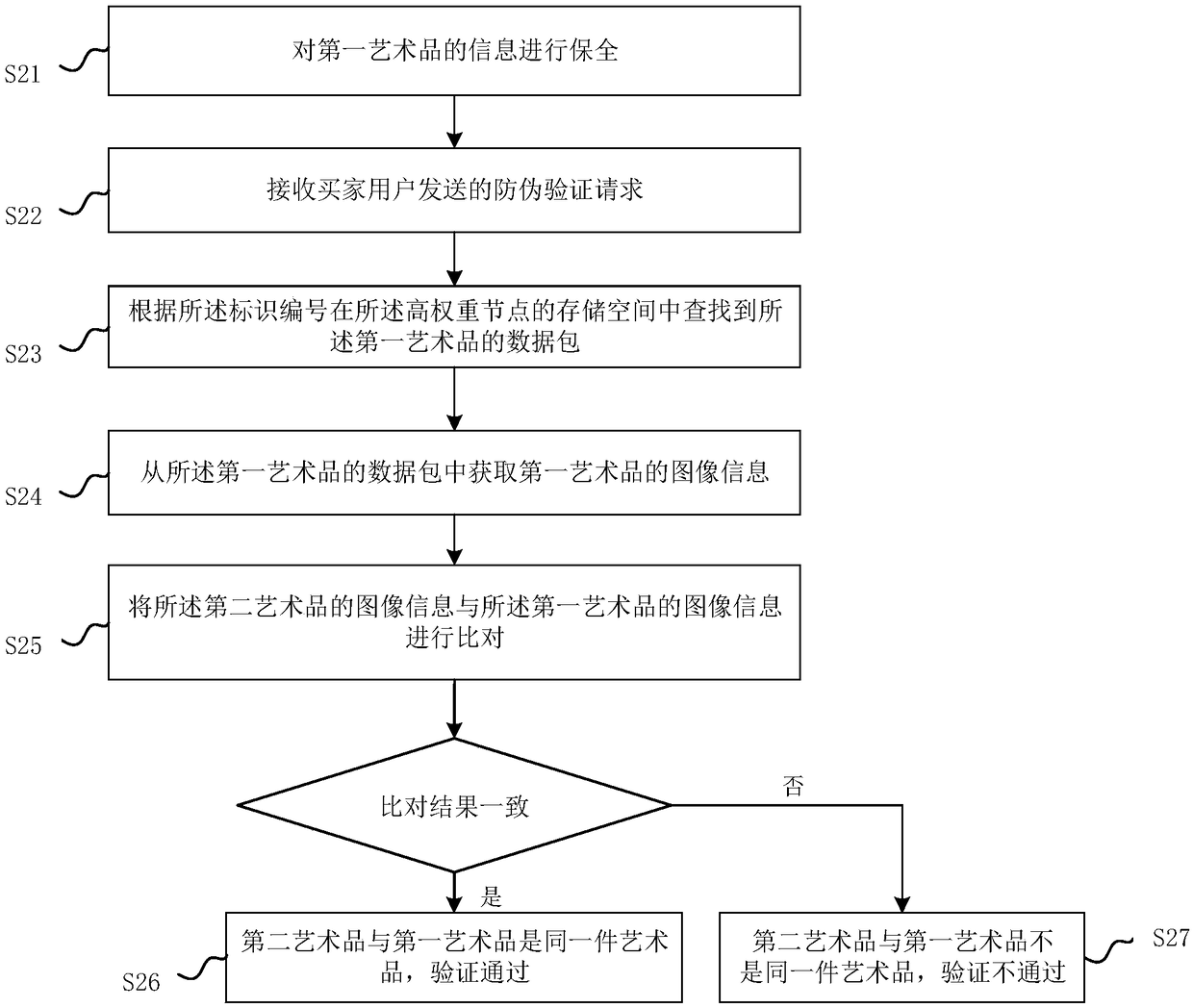

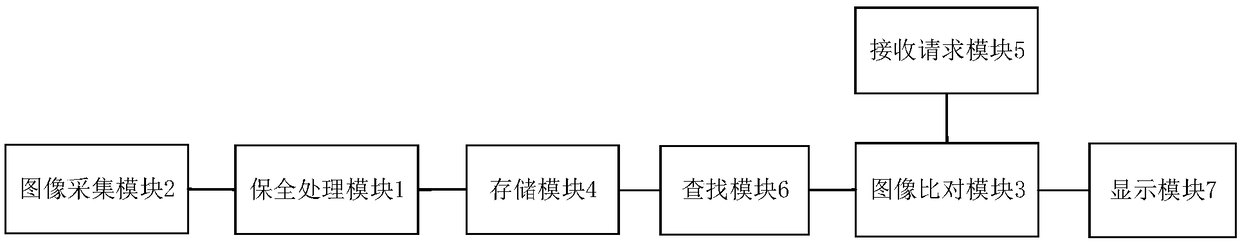

Method and device for anti-counterfeiting of artwork based on block chain

InactiveCN109034135AAnti-counterfeiting realizationImprove anti-counterfeiting performanceCharacter and pattern recognitionDigital data protectionSoftware engineeringBlockchain

The invention relates to a block chain-based artwork anti-counterfeiting method and device. The method comprises: preserving the information of a first artwork; acquiring image information of the second artwork; comparing the image information of the second artwork with the image information of the first artwork, and if the comparison result is consistent, verifying that the second artwork and thefirst artwork are the same artwork; otherwise, the second artwork and the first artwork are not the same artwork, and the verification fails. The invention completes the comparison and verification of the traded artwork and the seller's pre-sold traded artwork by uploading the image information of the traded artwork by the buyer user during the trading. The method can ensure that the artwork actually bought by the buyer is the artwork seen at the beginning in the process of the art transaction, and avoid the problem of being imitated and replaced in the process of the transaction, which is conducive to ensuring the economic interests of the buyer and the user. The method adopts the image attribute of the artwork itself to realize the anti-counterfeit of the artwork, and the anti-counterfeit is higher.

Owner:深圳市航成机械设备有限公司

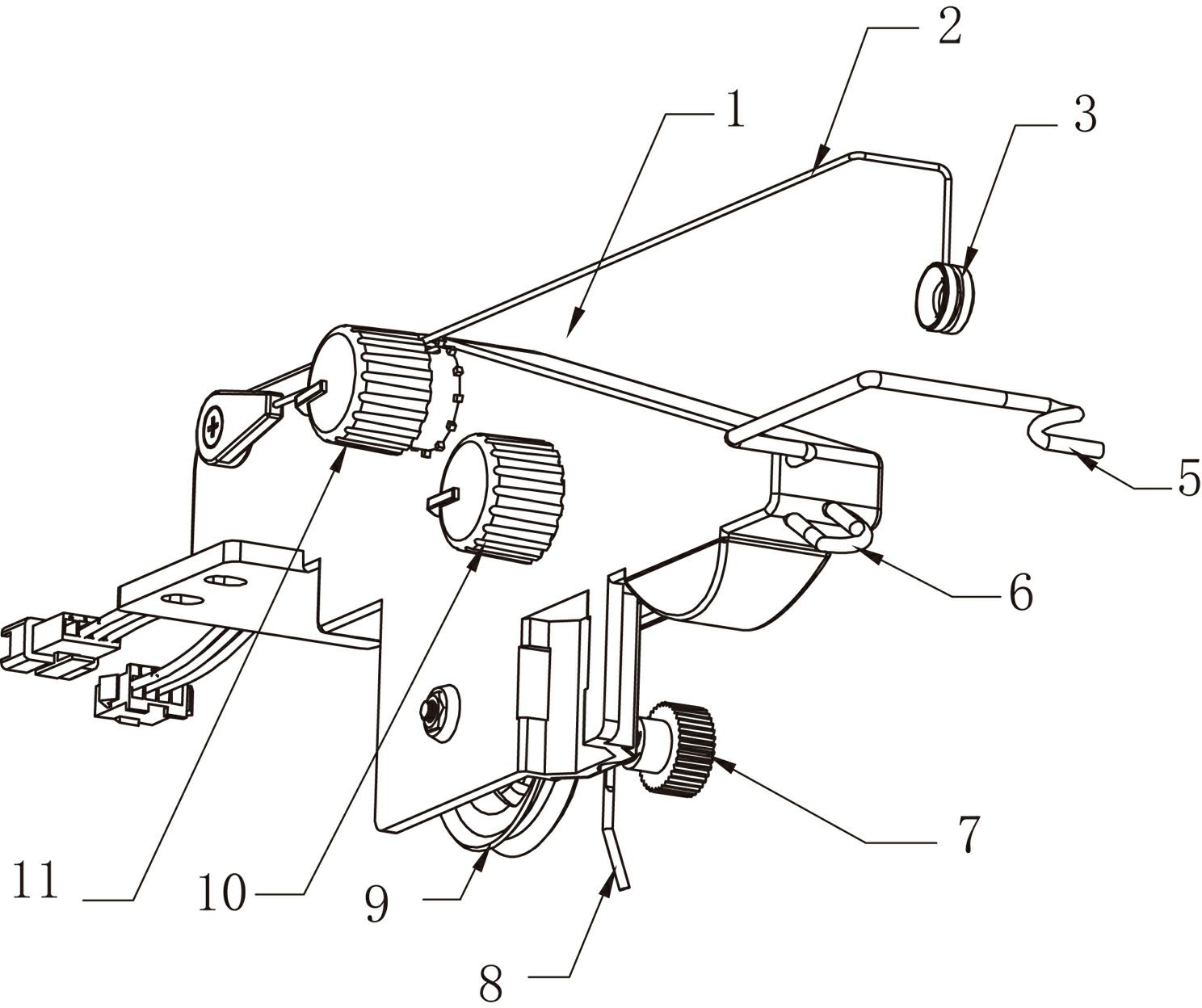

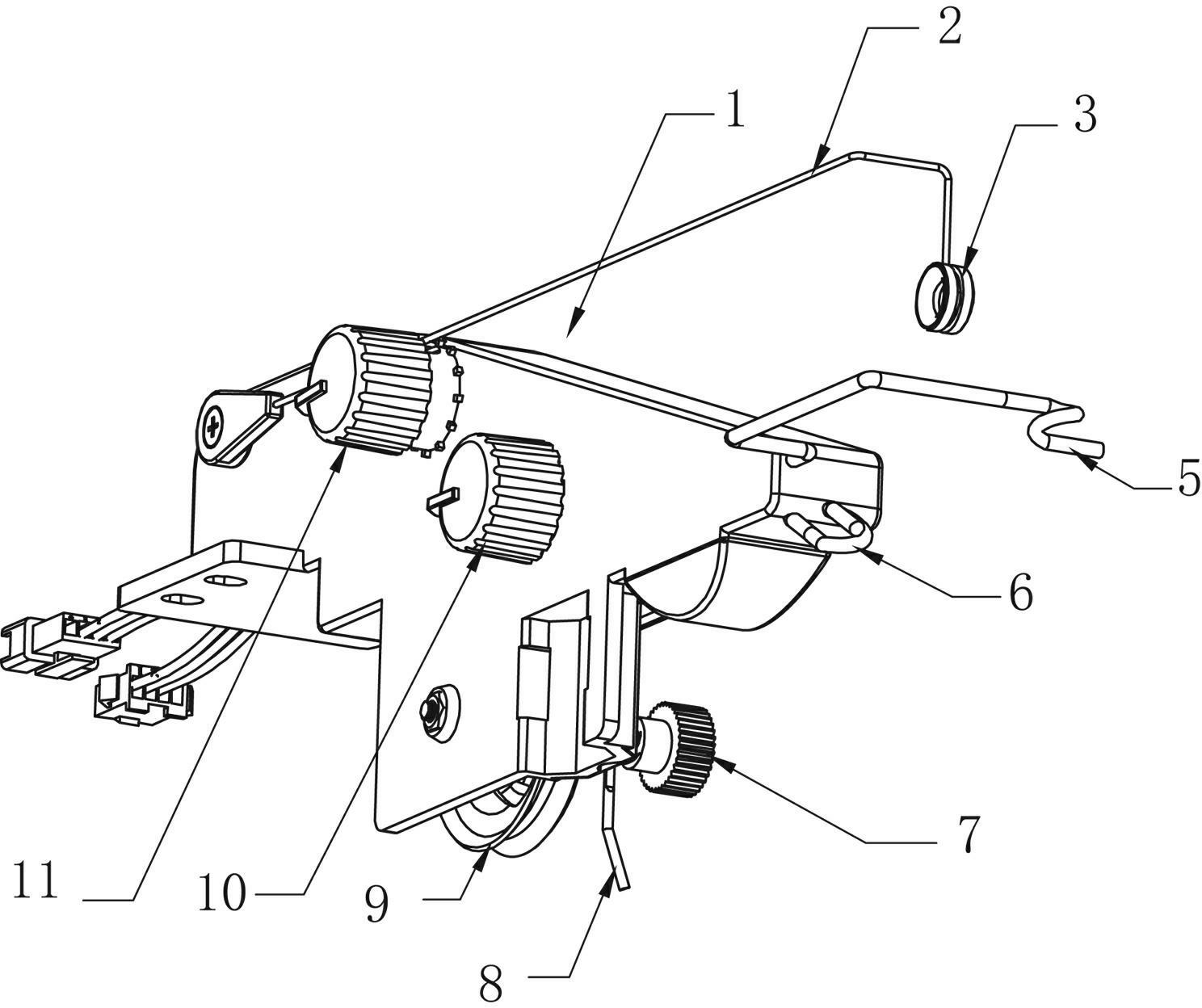

Antenna platform device

The invention discloses an antenna platform device which comprises an antenna platform body, a plurality of threading holes connected to the body, a thread clamping sheet with two sheets connected each other, a thread clamping sheet adjusting knob for adjusting a gap between the two sheets, and a ram used for connecting the threading holes, wherein a spring is arranged between the ram and the body, a trigger mechanism is arranged at the tail end of the ram, a knot tying claw is arranged on the routing track of a yarn, a certain gap is left between the knot tying claw and the body, and the knot tying claw is connected with the trigger mechanism. The antenna platform device has the beneficial effects that the yarn tension and slub size can be controlled, and when the yarn is broken, the device alarms and quits working, thereby preventing inferior cloth from occurring, reducing the yarn waste and protecting the economic benefit of customers.

Owner:NINGBO CIXING

Rapid detecting method for hydroxymethyl furfural in honey

InactiveCN104359901AShorten the timeGuaranteed food safetyMaterial analysis by observing effect on chemical indicatorBiotechnologyBiochemical engineering

The invention discloses a rapid detecting method for hydroxymethyl furfural (HMF) in honey. The rapid detecting method comprises the following steps: (1) preparing a sample, namely accurately weighing and adding 7.5g of honey sample into a small beaker, adding 10mL of distilled water, uniformly mixing the distilled water and the honey sample by a glass rod to obtain a mixture, transferring the mixture to a 25mL volumetric flask, adding distilled water to make up to volume, and uniformly shaking; (2) developing color, namely taking and adding 1.00ml of a to-be-detected sample into a graduated test tube with a stopper, then, adding 3mL of mixed solution into the test tube, and developing color for 5 minutes after uniformly mixing; (3) detecting, namely comparing the color of a developed solution with a color chart to determine the content of HMF. The rapid detecting method for hydroxymethyl furfural in honey disclosed by the invention has characteristics of a simple used reagent, no complex condition and apparatus equipment, simplicity and convenience in operation and rapidness.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for rapidly detecting amylase value in honey

InactiveCN104132939AQuick checkSimple and fast operationMaterial analysis by observing effect on chemical indicatorAmylaseEnzymatic hydrolysis

The invention discloses a method for rapidly detecting the amylase value in honey. The method comprises the following steps: 1, sample preparation: accurately weighing 5.0g of a honey sample, putting the honey sample in a beaker, adding 7.5mL of an enzymatic hydrolysis buffer solution and 10mL of distilled water, stirring until the sample is completely dissolved, transferring the above obtained solution to a 25mL volumetric flask, adding distilled water to a constant volume, and shaking up; 2, enzymatic hydrolysis: accurately sucking 2.5mL of the prepared sample solution to a test tube with 12.5mL of a starch solution, uniformly mixing, and carrying out enzymatic hydrolysis at normal temperature for 10min or 20min; 3, coloration: sucking the obtained enzymatic hydrolysis liquid to a colorimetric pipe with a coloration solution and distilled water, and coloring at normal temperature for 5min; and 4, detection: comparing the color of the coloration solution with a multicolor colourimetric card, and determining the amylase value in the honey. The method is characterized in that amylase reacts with starch at normal temperature, and a colourimetric card technique is cooperated to detect. The method has the advantages of simple operation, simple conditions, rapidness and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

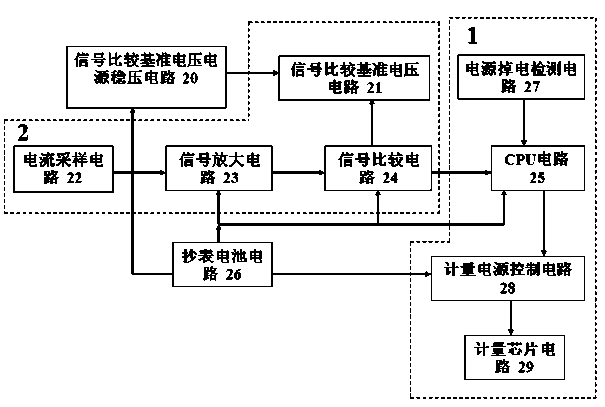

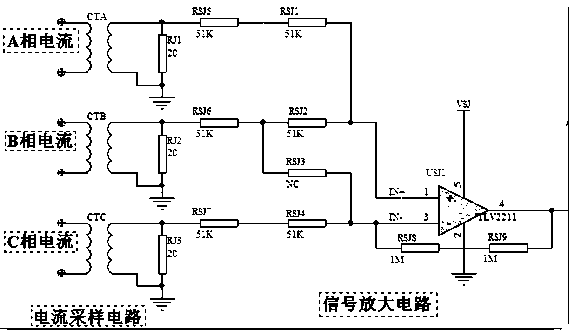

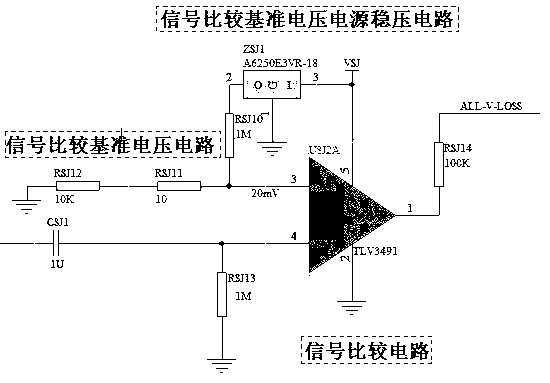

Three-phase electronic type multi-functional total voltage loss detection system

InactiveCN103884903AGuaranteed economic interestsSolve the problem of inaccurate detection and false positivesMeasurement using digital techniquesElectrical batteryControl cell

The invention provides a three-phase electronic type multi-functional total voltage loss detection system. The three-phase electronic type multi-functional total voltage loss detection system comprises a control unit used for judging and recording total voltage loss conditions, a meter reading battery circuit used for providing power for the system, a total voltage loss detection circuit and a signal comparison reference voltage power supply voltage stabilizing circuit. The total voltage loss detection circuit transmits collected and processed voltage signals to the control unit, and the signal comparison reference voltage power supply voltage stabilizing circuit provides stable voltage for the total voltage loss detection circuit. By adding the signal comparison reference voltage power supply voltage stabilizing circuit, power of a signal comparison reference voltage circuit is made to be stable, even if voltage of the meter reading battery circuit decreases, the power of the signal comparison reference voltage circuit cannot be changed, reference voltage output by the signal comparison reference voltage circuit can not be changed either, therefore, the problems of total voltage loss detection is inaccurate and false alarm occurs are solved, electricity quantity compensation can be performed normally after the total voltage loss situation occurs, accurate total voltage loss detection is guaranteed, and economic benefits of power enterprises are guaranteed.

Owner:HUIZHOU ZHONGCHENG ELECTRONICS TECH

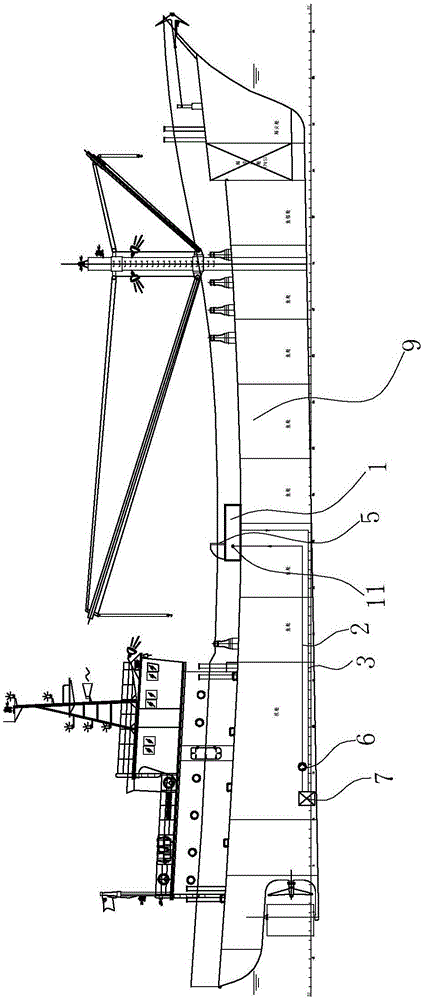

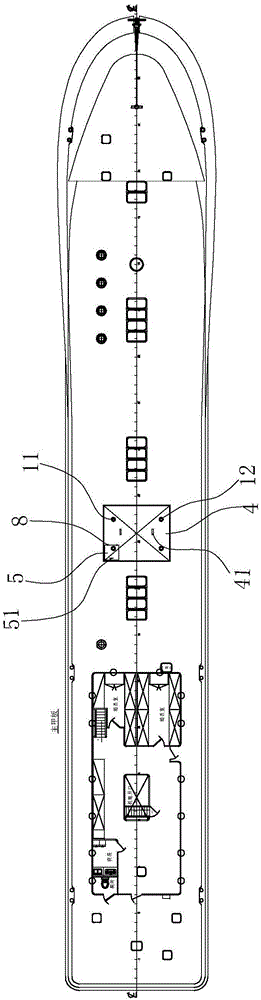

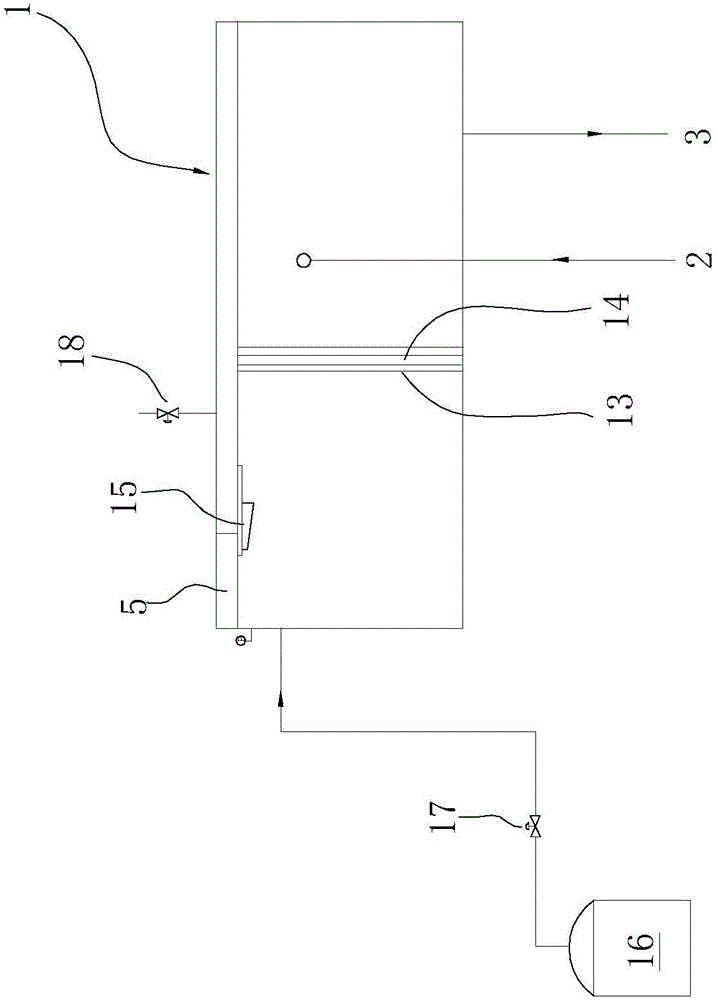

Closed live box on fishing boat

InactiveCN106828805AEliminate the effects ofEliminate security concernsFishing vesselsEconomic benefitsEngineering

A closed live box on a fishing boat comprises a box body and is characterized in that the box body is arranged at the middle part of a deck of a boat body; a cabin cover is arranged at an opening in the upper end of the box body in an oppositely closed manner; a water inlet is formed in the side surface of the box body; a water drainage opening is formed in the bottom of the box body; the water inlet is connected with a water supply pipeline; a seawater pump is arranged on the water supply pipeline; the water drainage opening is connected with a water drainage pipeline; a sea bottom door is arranged at the bottom of the boat body; and the sea bottom door is in communication with the water supply pipeline and the water drainage pipeline. The closed live box on the fishing boat has the advantages that the structure is reasonably designed, the influence of the live box on stability is changed from an uncontrolled state into a controlled state because stability calculation is taken into consideration in the design stage, the influence of a free liquid surface and hidden dangers in the safety aspect are eliminated, and the economic benefits of the fisherman is also guaranteed.

Owner:ZHEJIANG OCEAN UNIV

Prebiotics polysaccharide feed and production method thereof

ActiveCN102524586APromote digestionPromote absorptionFood processingAnimal feeding stuffAspergillus nigerAstragalus mongholicus

The invention relates to a prebiotics polysaccharide feed for livestock. Feed material is fermented under the effect of mixed bacteria at least comprising two of bacillus, saccharomycete, lactobacillus, Geotrichum candidum Link and aspergillus niger. The weight part of the mixed bacteria is 0.2-0.4. The proportion by weight of each component in the feed material is as follows: 750 to 800 parts of corn flour, 130 to 160 partsof soybean meal, 30 to 60 parts of cottonseed meal, 2 to 5 parts of edible salt, 8 to 12 parts of calcium hydrophosphate, 2 to 4 parts of brown sugar, 3 to 5 parts of sirup, 800 to 1000 parts of water and 0.2-0.4 part of Chinese herbal medicine additive which is a powder stirred after crushing and mixing 30 parts of Astragalus mongholicus, 30 parts of Rhizoma Atractylodis Macrocephalae, 20 parts of Codonopsis pilosula, 30 parts of Poria cocos, 30 parts of Rhizoma alismatis, 30 parts of root of red-rooted salvia, 30 parts of fructus forsythia, 20 parts of cassia twig, 20 parts of radix bupleuri and 30 parts of liquorice by weight part. The invention also provides a method for producing the prebiotics polysaccharide feed.

Owner:天津津门赛普科技有限公司

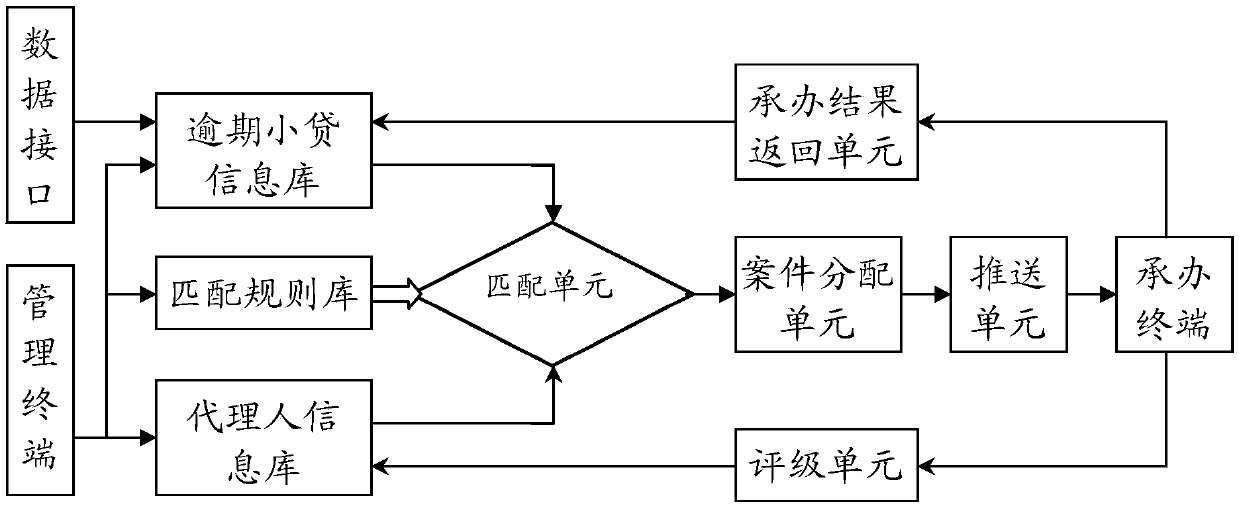

Small credit loan overdue disposal method and system

PendingCN109584035AEasy to handleGuaranteed economic interestsFinanceInformation agentsOperations research

The invention discloses a small credit loan overdue disposal method and system, and the method comprises the steps: enabling the case attribute of a small credit loan overdue case to be matched with the agent attribute of an agent; And according to a matching result, respectively generating corresponding legal files according to the batch small loan overdue case information and the agent information, and respectively pushing the matched case information and legal files to corresponding agent dependency methods for processing. The system comprises a matching unit, a case distribution unit, a pushing unit and a acceptance terminal.

Owner:成都律军风险管理股份有限公司

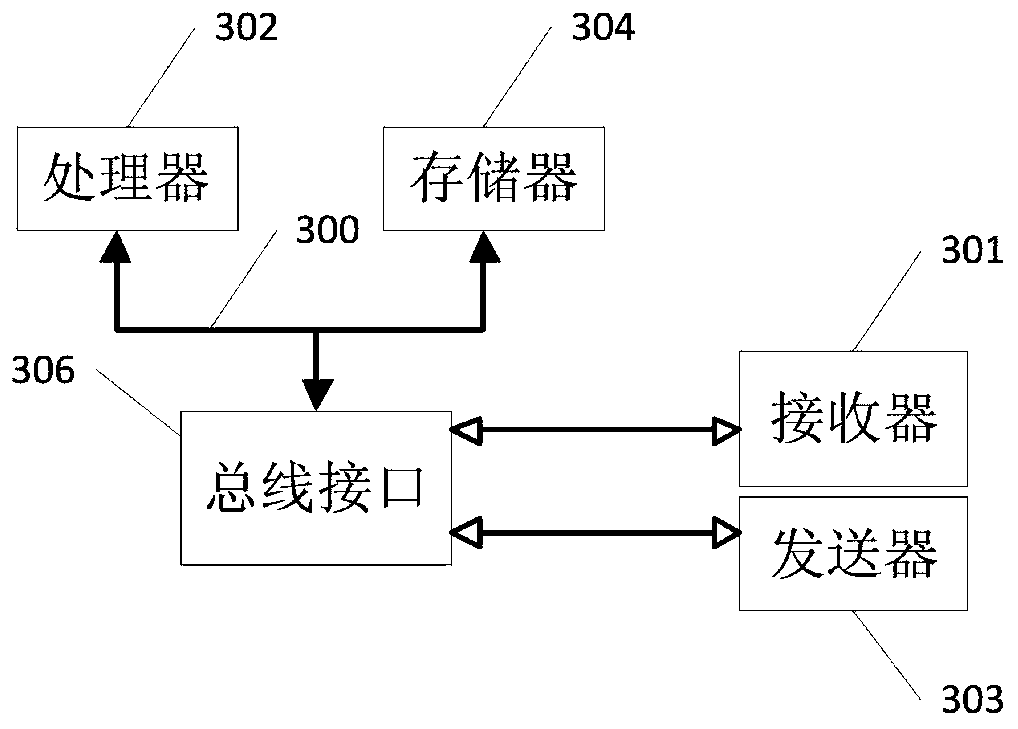

Control system for intelligent prepayment teletransmission water meter

InactiveCN103035071AConvenient fee managementEasy to manageApparatus for hiring articlesControl systemEconomic benefits

The invention discloses a control system for an intelligent prepayment teletransmission water meter, which relates to the technical field of water supply systems. The control system comprises a prepayment water meter, a collector, a concentrator and a server, wherein the output end of the prepayment water meter is in one-way connection with the input end of the collector; the collector and the concentrator are in double-way connection by a wireless network; and the concentrator and the server are in double-way connection. The control system provided by the invention has the benefits that intelligent control over the water meter is truly realized by a water supply company through the system, various worries of the water supply company about the intelligent water meter are solved, and the purposes of truely intelligent water supply and water resource saving are achieved. A teletranmission function is increased on the basis of the existing intelligent prepayment water meter so that the difficult charging and messy water management problems of the water supply company are thoroughly solved. On the basis of the realization of the intelligent prepayment control, the system can also avoid stealing and leakage, timely discover failed water meters and ensure the economic benefit of the water supply company.

Owner:泊头市普惠仪表有限公司

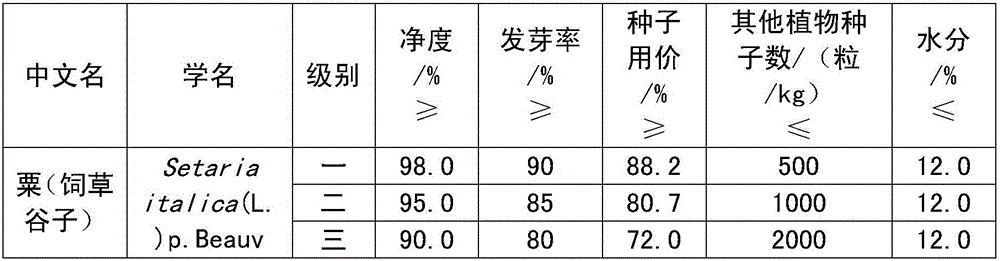

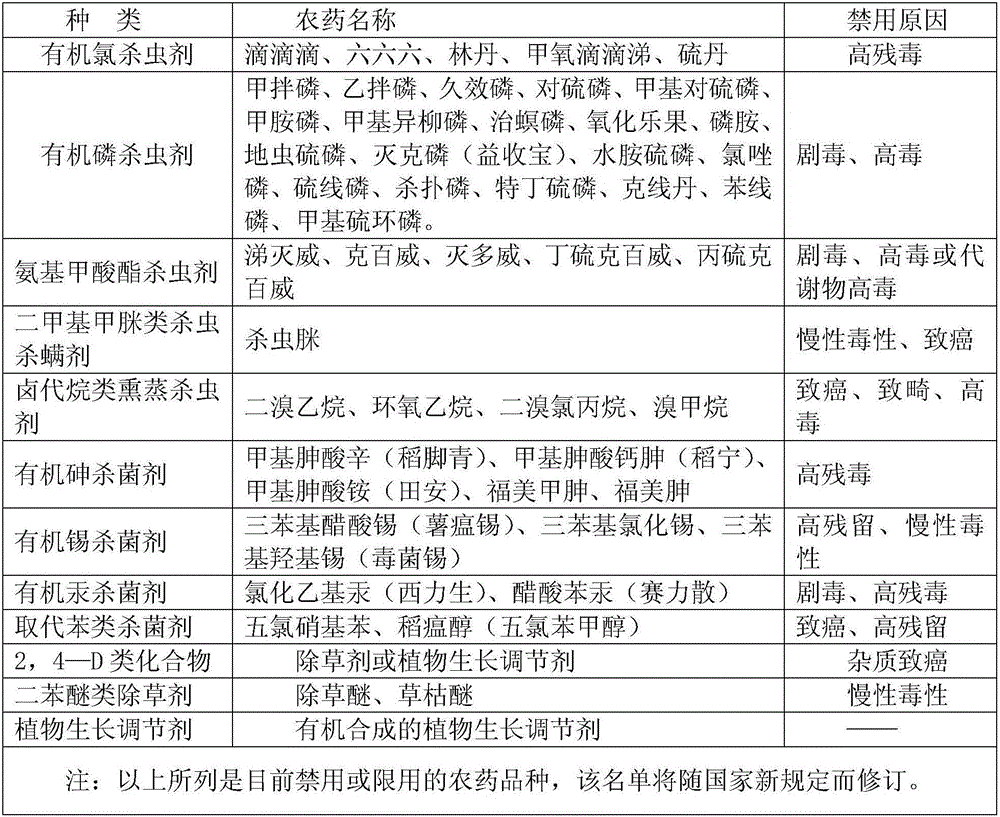

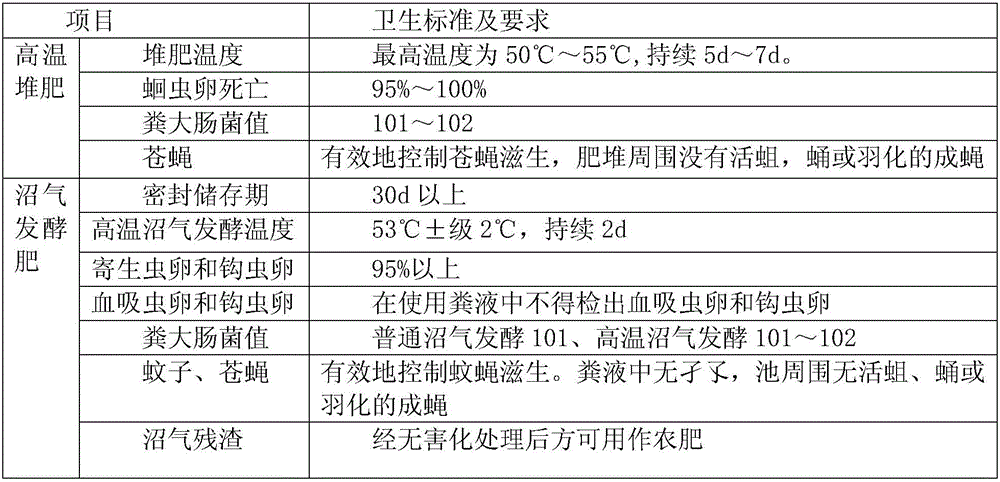

Planting method of soiling setaria italica forage grass

ActiveCN105724037AIncrease profitIncrease productionFertilising methodsCultivating equipmentsAdditive ingredientEconomic benefits

The invention discloses a planting method of soiling setaria italica forage grass, and belongs to the technical field of planting of the setaria italica forage grass. The planting method comprises the steps of site selection, preparation before sowing, sowing requirement meeting, field management, harvesting, inspection and storage. The planting technology of the soiling setaria italica forage grass has the advantages that the utilization rate of idle soil is increased, a seasonal idle field or autumn idle field can be developed on the condition that the planting season of food crops passes away, the forage grass can be planted through the method, and the economic benefit is guaranteed; the setaria italica forage grass which is high in protein and high in relative feed value can be planted through the method, and the serious problem that the forage grass is insufficient in winter and in spring can be relieved; selenium-rich forage grass can be planted through the method, and the milk quality and nutritional ingredients of livestock meat can be guaranteed after the forage grass is eaten by livestock.

Owner:GRAIN RES INST HEBEI ACAD OF AGRI & FORESTRY SCI

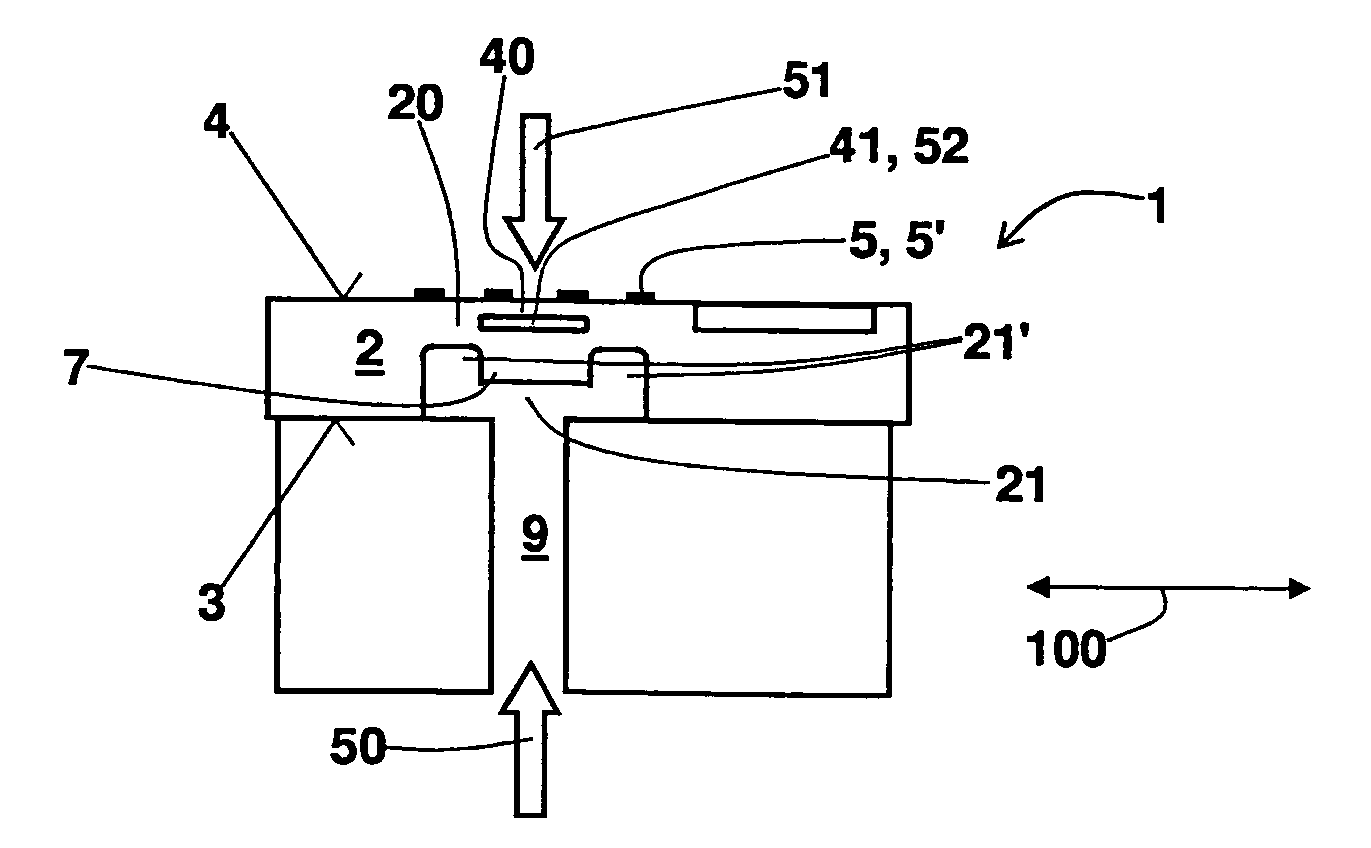

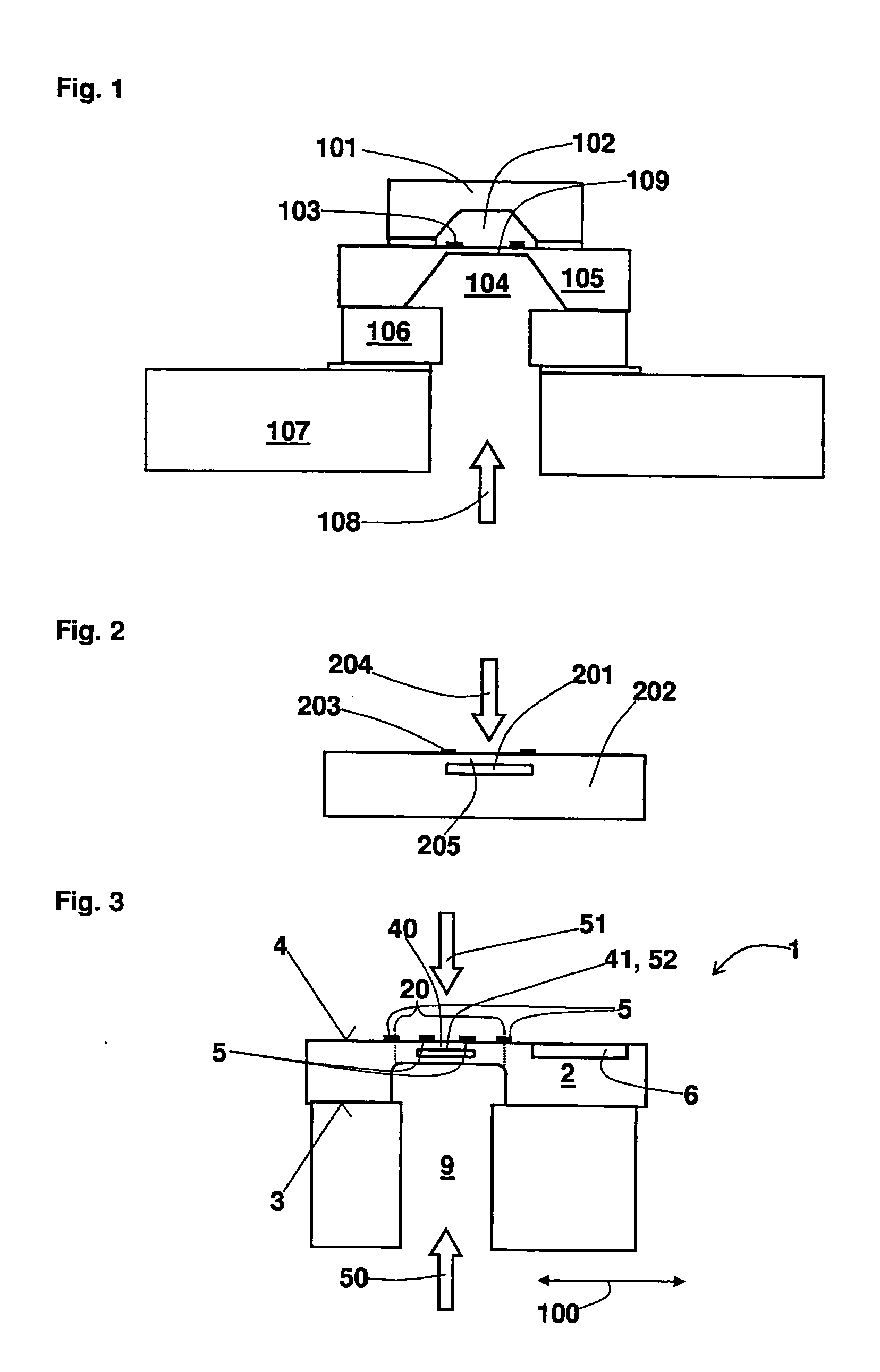

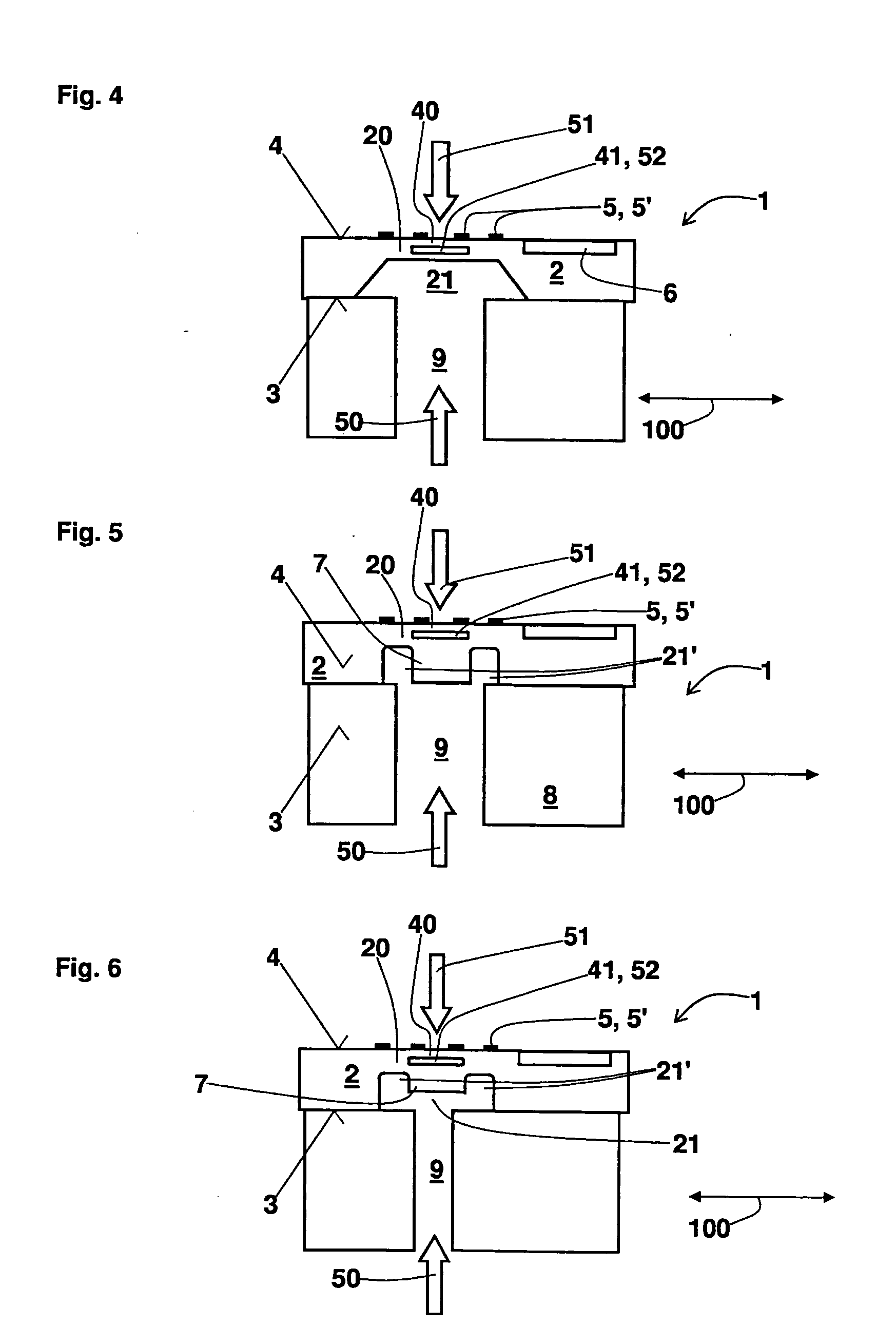

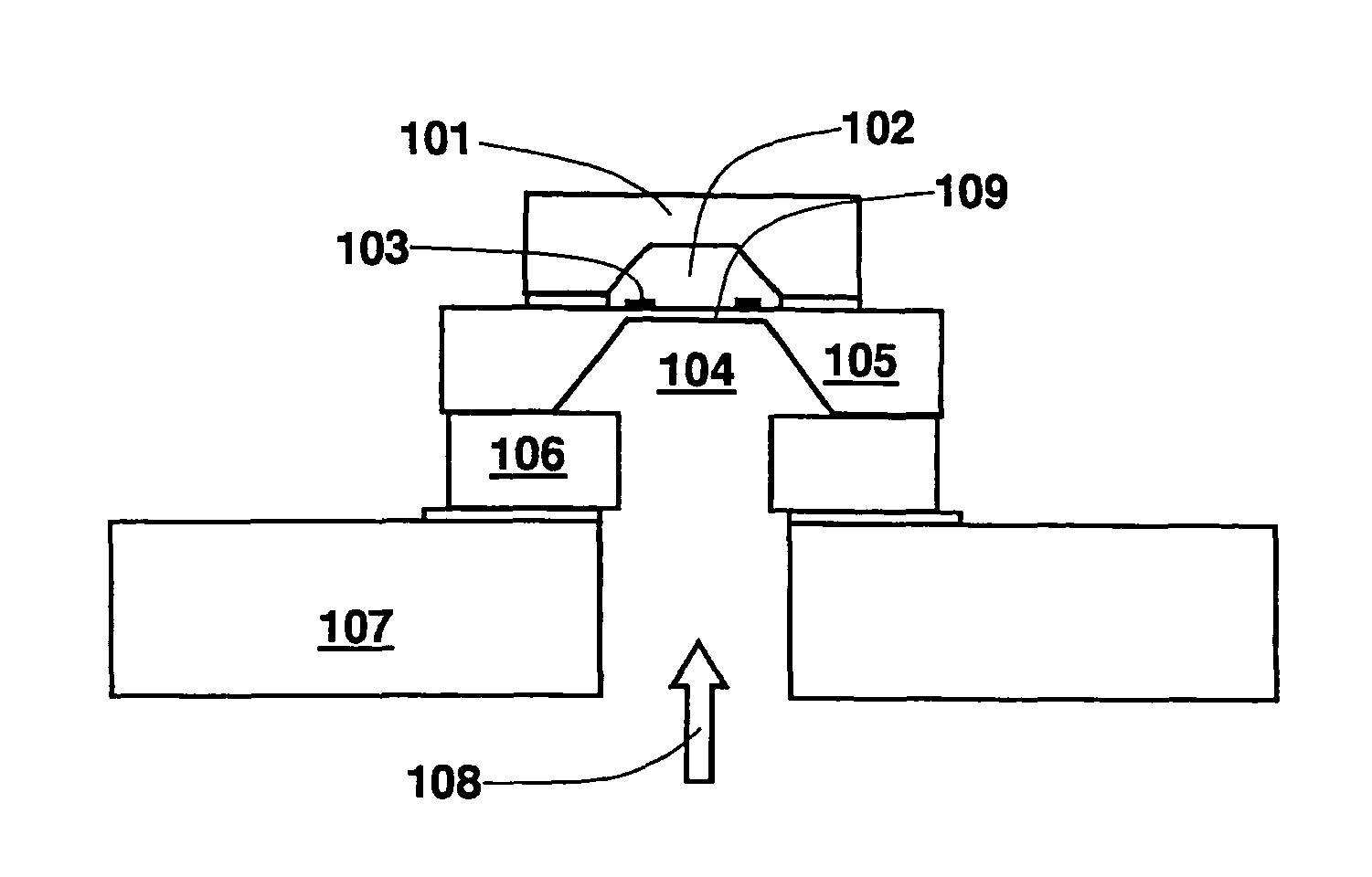

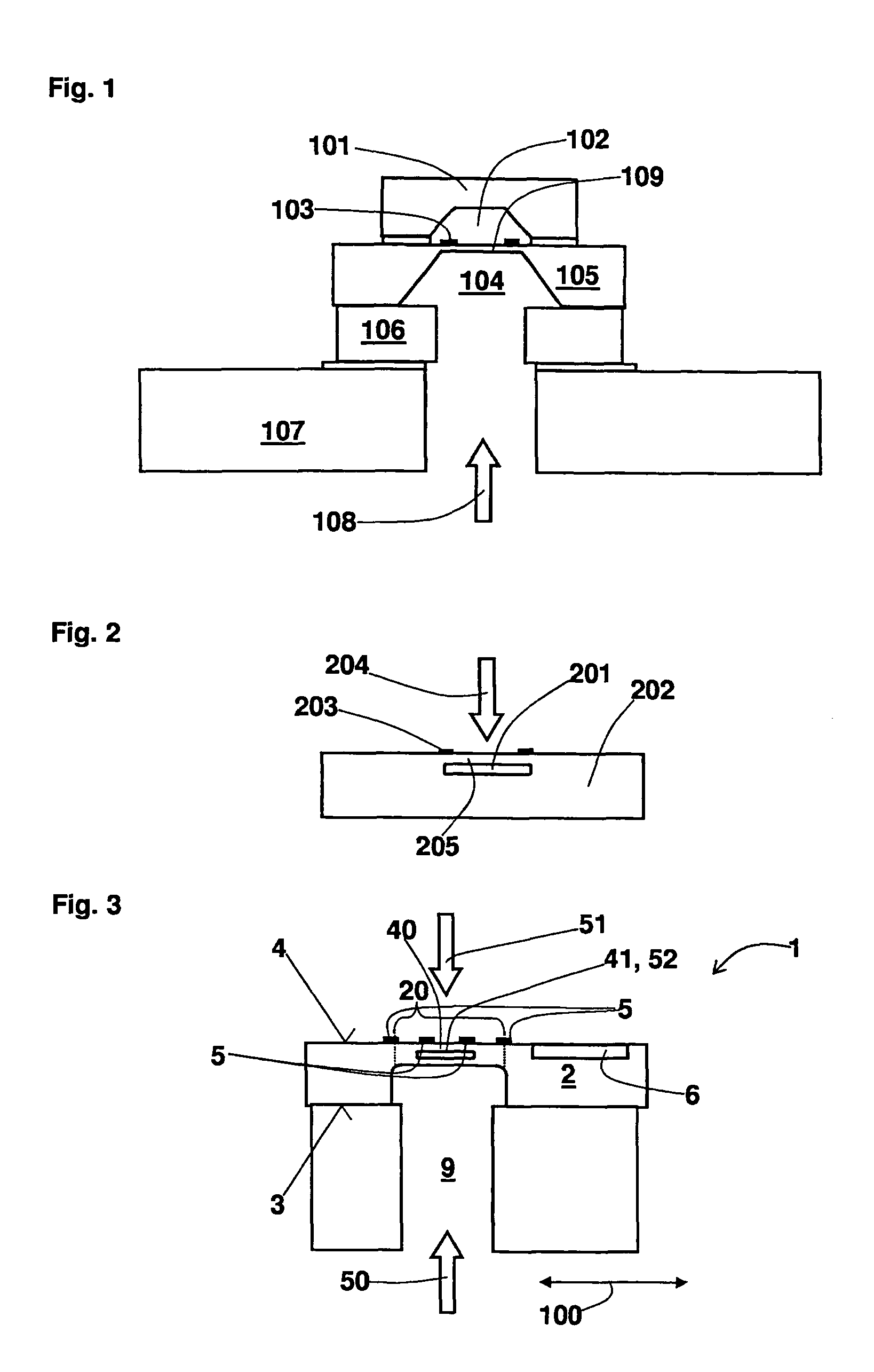

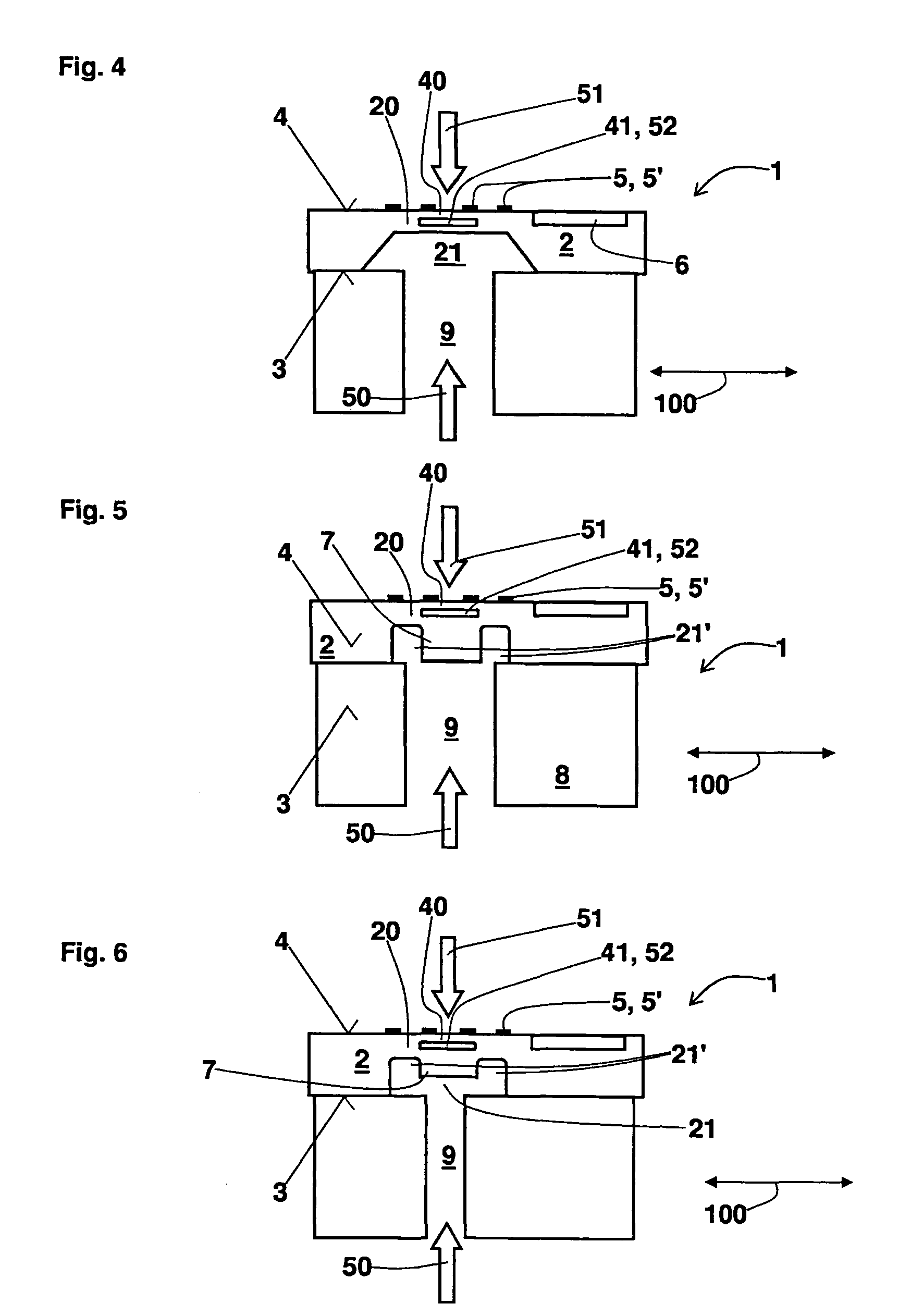

Sensor system, method for operating a sensor system, and method for manufacturing a sensor system

InactiveUS20110259109A1High aspect ratioAdvantageously producedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringSensor system

A sensor system, e.g., a pressure sensor system, includes a substrate having at least one trench on a first side. The trench is provided for forming a first diaphragm region on a second side opposite from the first side. In addition, a second diaphragm region and a cavern are integrated into the material of the first diaphragm region.

Owner:ROBERT BOSCH GMBH

Preparation method of juicy peach wine

InactiveCN104004624ASolve technical problems that are not easy to storeFruityAlcoholic beverage preparationFiltrationFermentation

Owner:ZHANGJIAGANG TAOYUAN FOOD

Sensor system, method for operating a sensor system, and method for manufacturing a sensor system

InactiveUS8485041B2Simple and cost-effectiveIncrease pressureFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm zone

A sensor system, e.g., a pressure sensor system, includes a substrate having at least one trench on a first side. The trench is provided for forming a first diaphragm region on a second side opposite from the first side. In addition, a second diaphragm region and a cavern are integrated into the material of the first diaphragm region.

Owner:ROBERT BOSCH GMBH

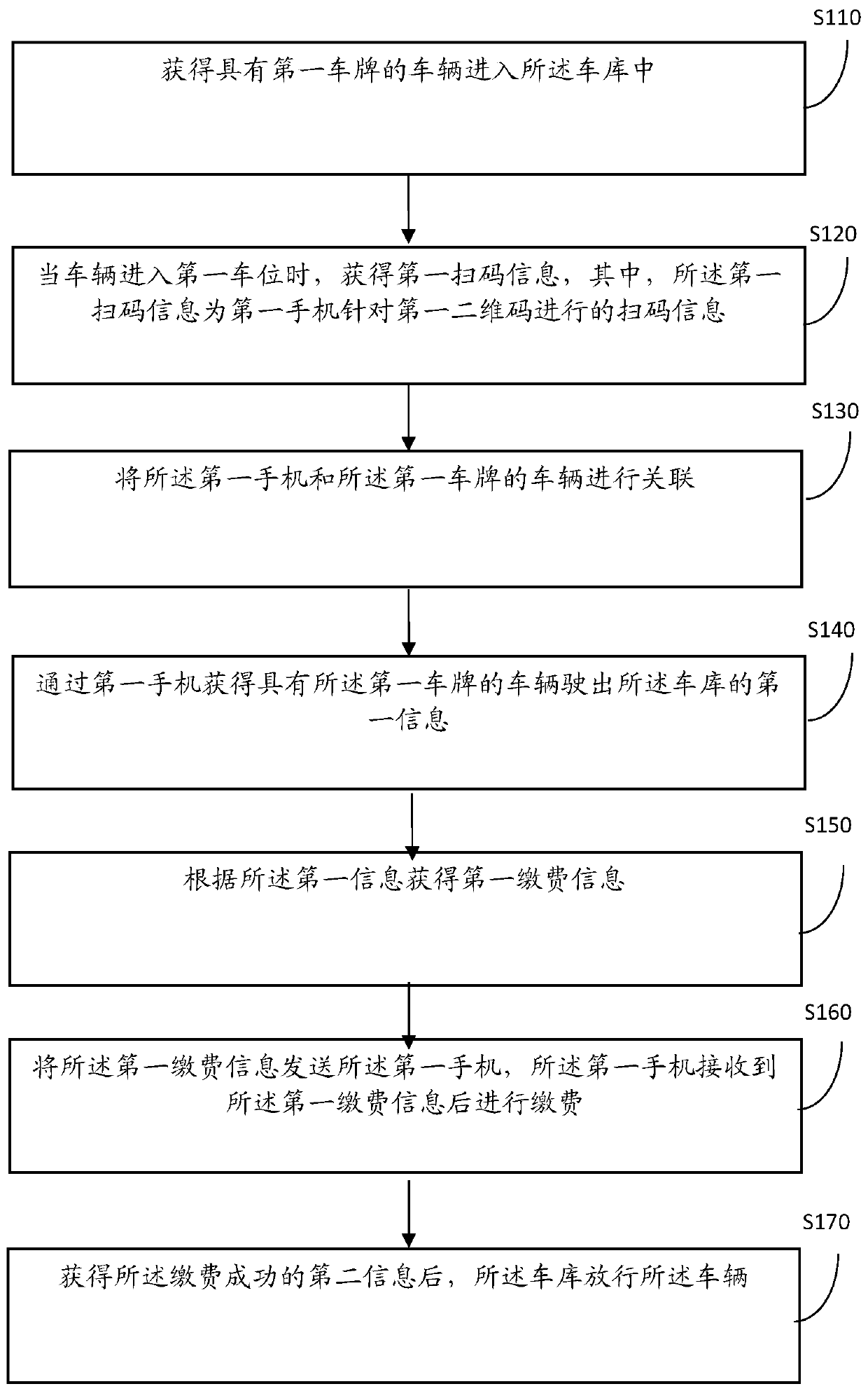

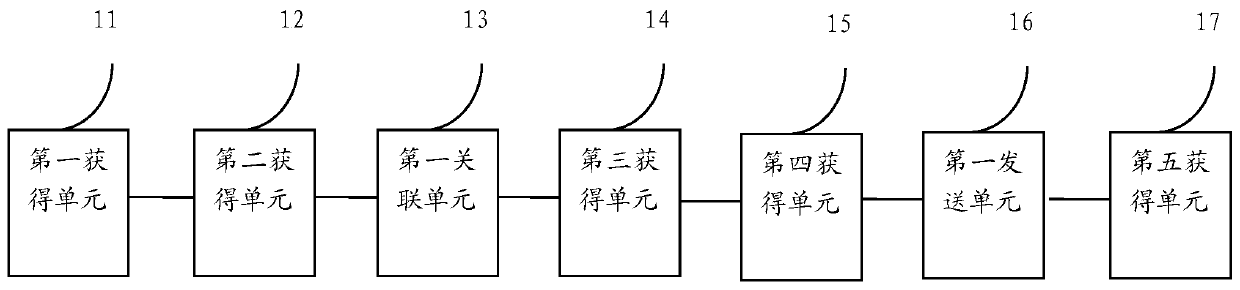

Garage information processing method and device based on cloud platform

ActiveCN109989609AImprove delivery efficiencyGuaranteed economic interestsTicket-issuing apparatusParkingsInformation processingPayment

The invention provides a garage information processing method and device based on a cloud platform. The method comprises the steps that information about a vehicle with a first license plate enteringa garage is obtained; when the vehicle enters a first parking space, first code scanning information is obtained, and a first mobile phone is associated with the vehicle with the first license plate;first information of the vehicle with the first license plate running out of the garage is obtained through the first mobile phone; first payment information is obtained according to the first information; the first payment information is sent to the first mobile phone, and the first mobile phone carries out payment; and after second information of successful payment is obtained, the vehicle is released from the garage. The technical problems that the charging duration is inconsistent with the actual parking time, the parking cost of a vehicle owner is increased and the payment process is time-consuming as the parking cost is based on running into or running out of a garage are solved. The technical effects that the information of actually parking on the parking space is taken as the charging information, the real parking duration is taken as the charging basis, the economic benefit of the vehicle owner is ensured, and the charging operation process through the cloud platform is convenient and fast are achieved.

Owner:苏州平步网络科技有限公司

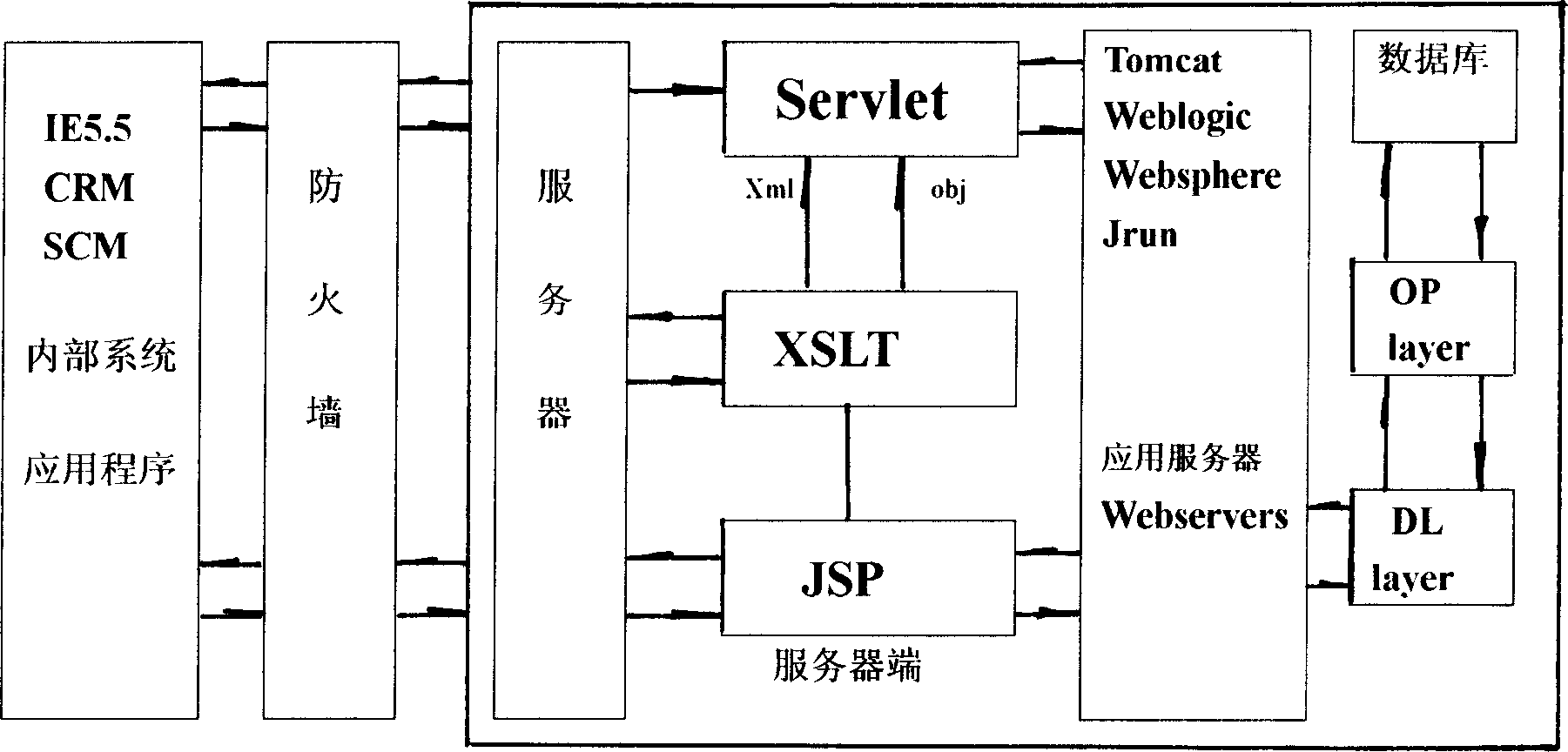

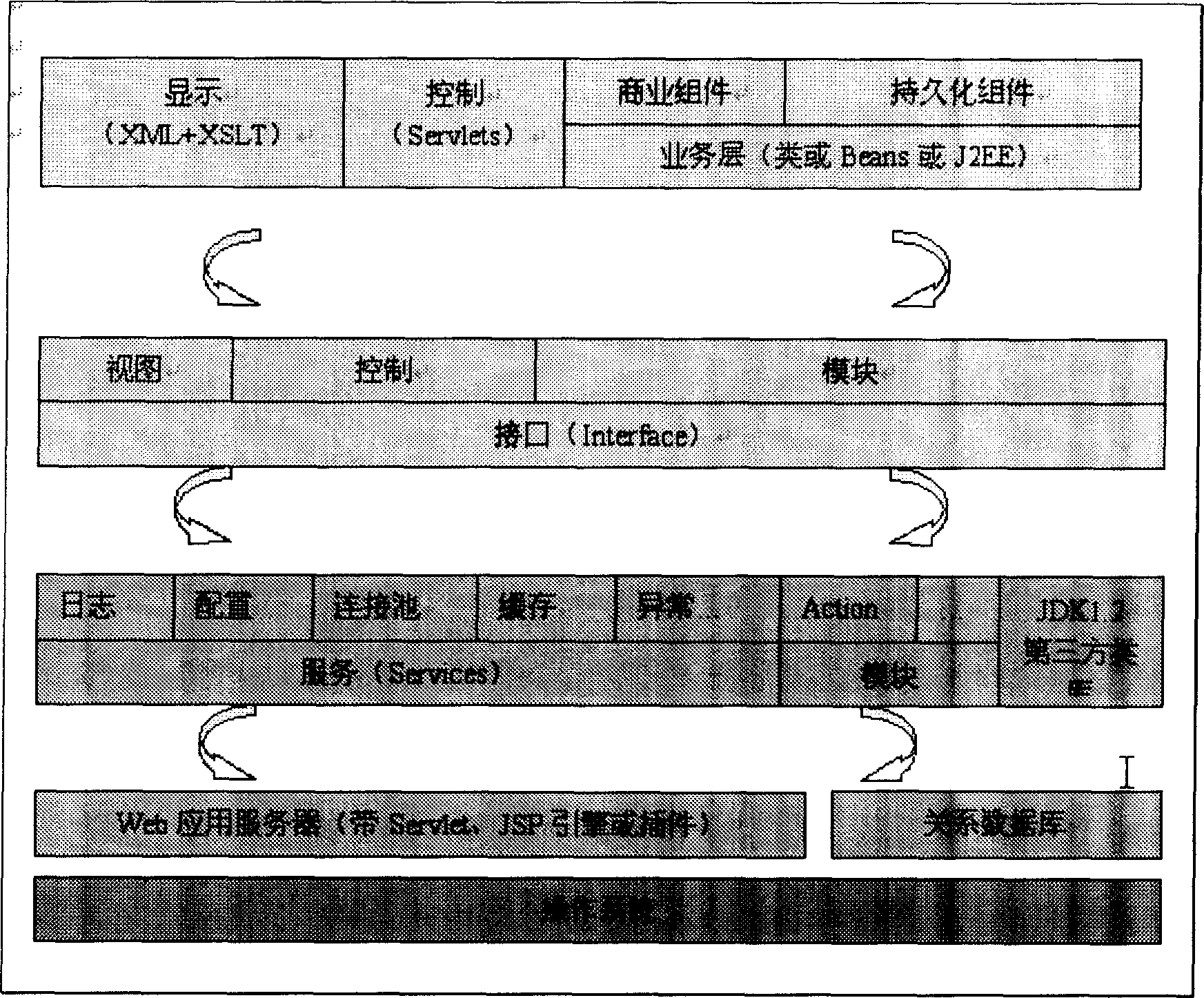

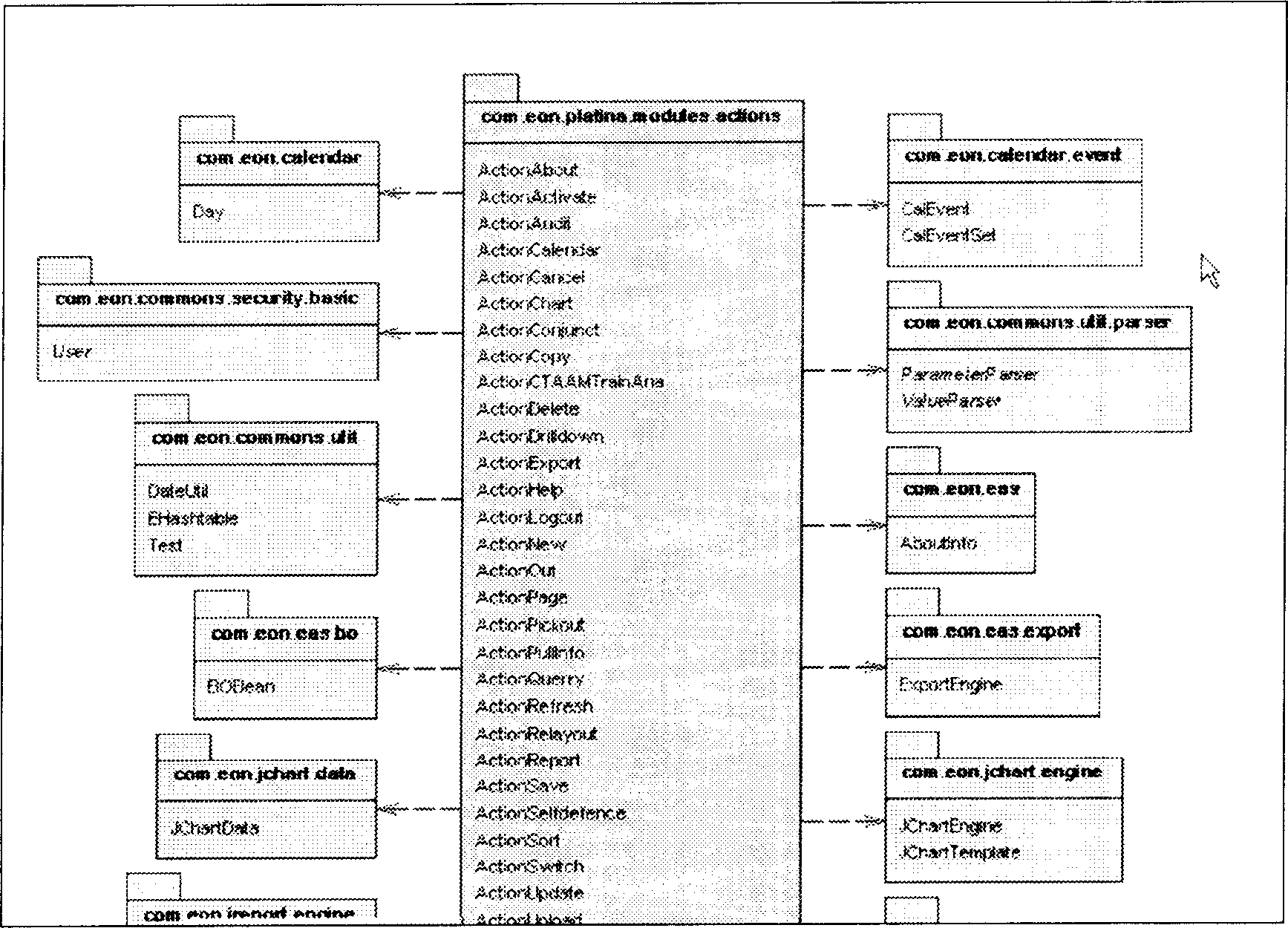

Trans-enterprise supply chain system WEB application platform for automobile industry

InactiveCN1881242AReduce duplication of development effortShorten development timeResourcesLogisticsControl layerWeb application

The invention relates to a WEB application platform of company-span supply chain system of vehicle industry, belonging to the network information technique, wherein it is characterized in that: it uses main flow database, persistent layer, service logic layer, control layer and UI layer web; the control layer, based on the event sent from user terminal, distributes the event to the service logic layer to be treated, and feeds back the data generated by the service logic layer to the user terminal, and processes the load balance, priority check, and log treatment; the data sent from the control layer can be transformed into content displayed by the user terminal; the service object layer is distributed by the service logic layer to treat the event; the persistent layer transforms the database operation command of service logic layer into the database language, to operate the database to obtain the result group to be transformed into xml object to be feedback to the service logic layer.

Owner:张晓东 +1

Intelligent platform applied to agriculture

InactiveCN104778556AAvoid wastingGuaranteed economic interestsResourcesData acquisitionData acquisition module

The invention discloses an intelligent platform applied to agriculture, wherein a data acquisition module is used for collecting data of a remote sensing satellite and a sensor group which is arranged in a farmland, and simultaneously marking the collected data in a longitude and latitude manner and transmitting the collected longitude-latitude-marked data to a central server group; the central server group stores the received data in a database, and meanwhile, the database saves historical agricultural yield and current crop market average price of each region of the whole country; a weather collecting module is used for collecting weather information; a data analyzing module is used for invoking data in the database, outputting the yield and price curve chart of agricultural products according to the data saved in the database, predicting the current crop yield and price according to the yield and price curve chart, and simultaneously drawing a current planting map; an information pushing module is used for pushing the yield and price curve chart predicted by the data analyzing module and the planting map drawn by the data analyzing module into a client. The intelligent platform applied to the agriculture has the advantage of avoiding food wastes.

Owner:LIUZHOU YINONG TECH

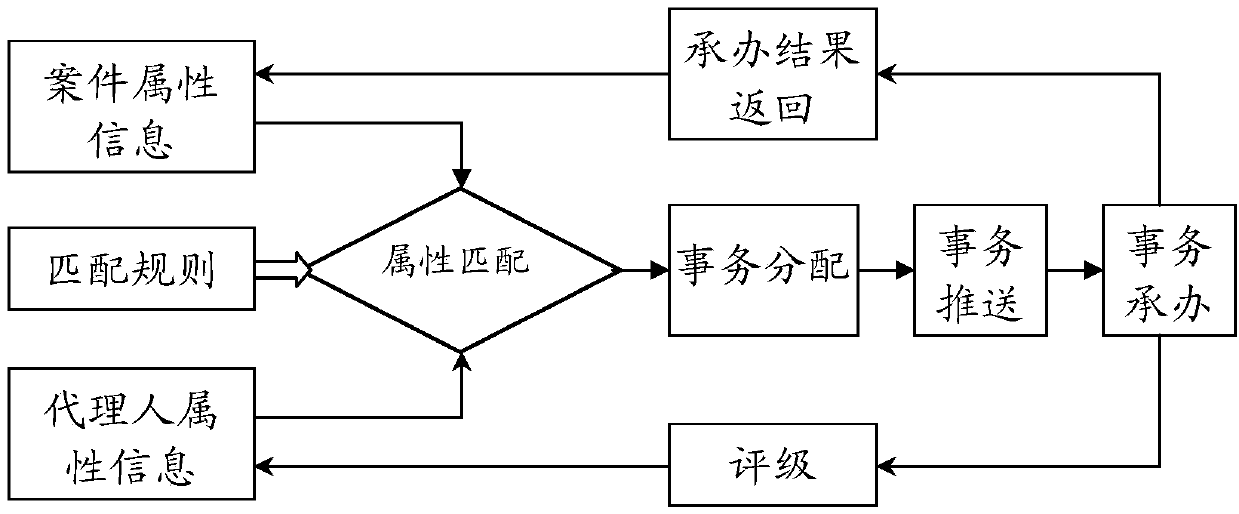

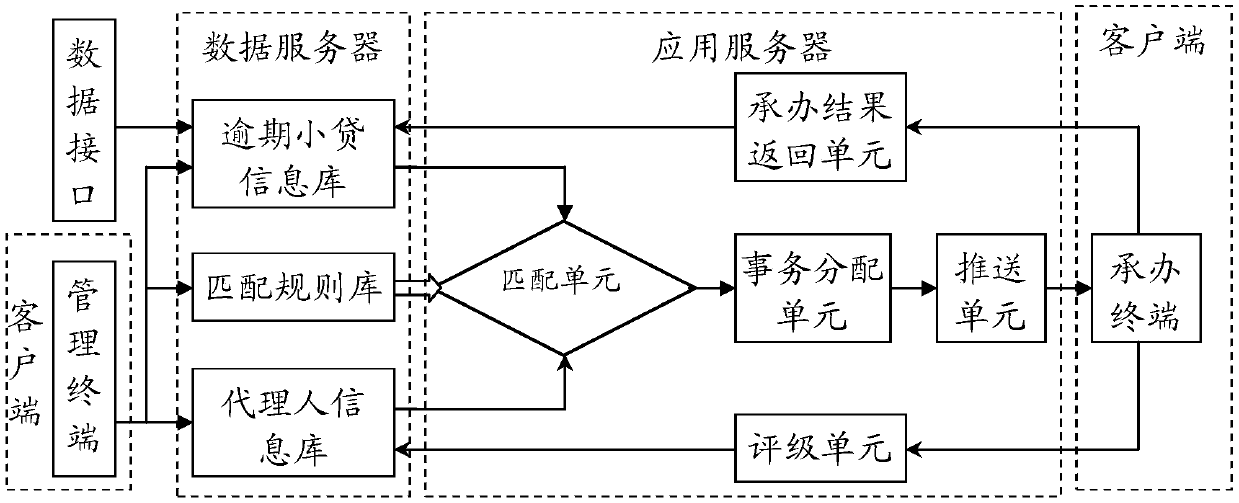

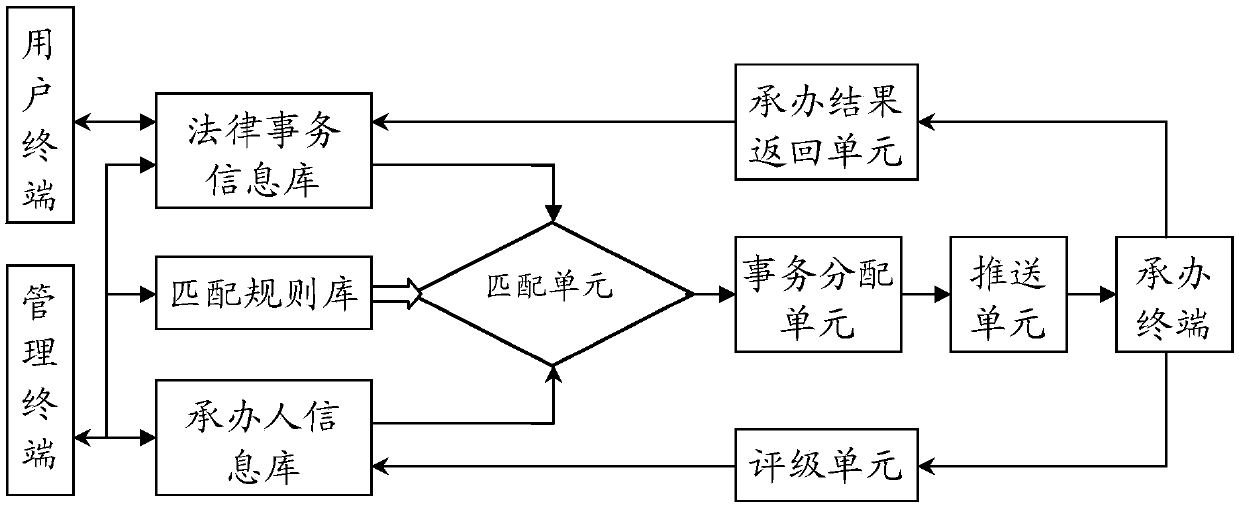

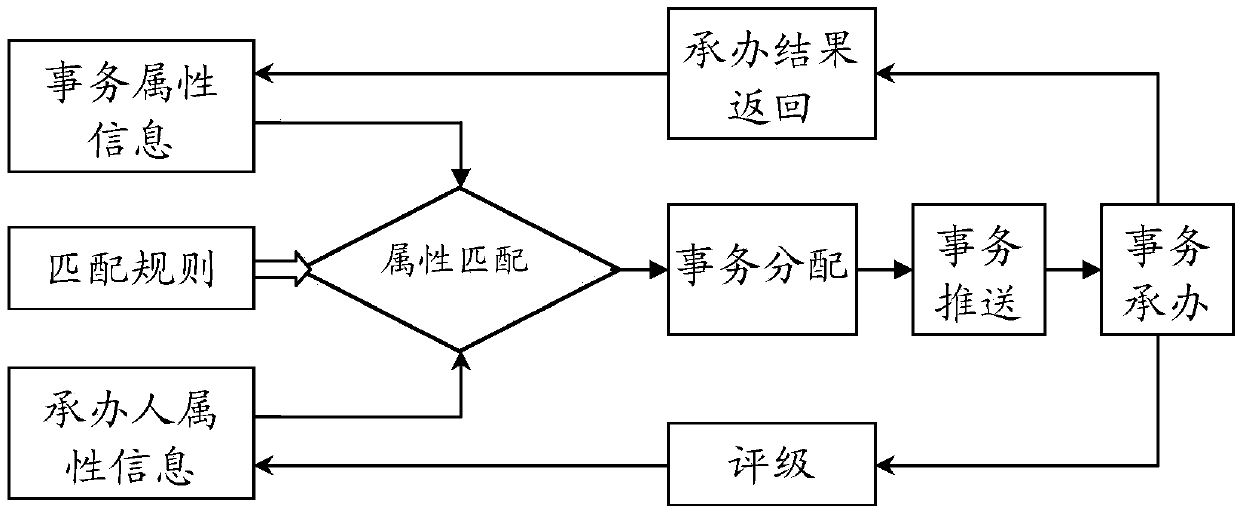

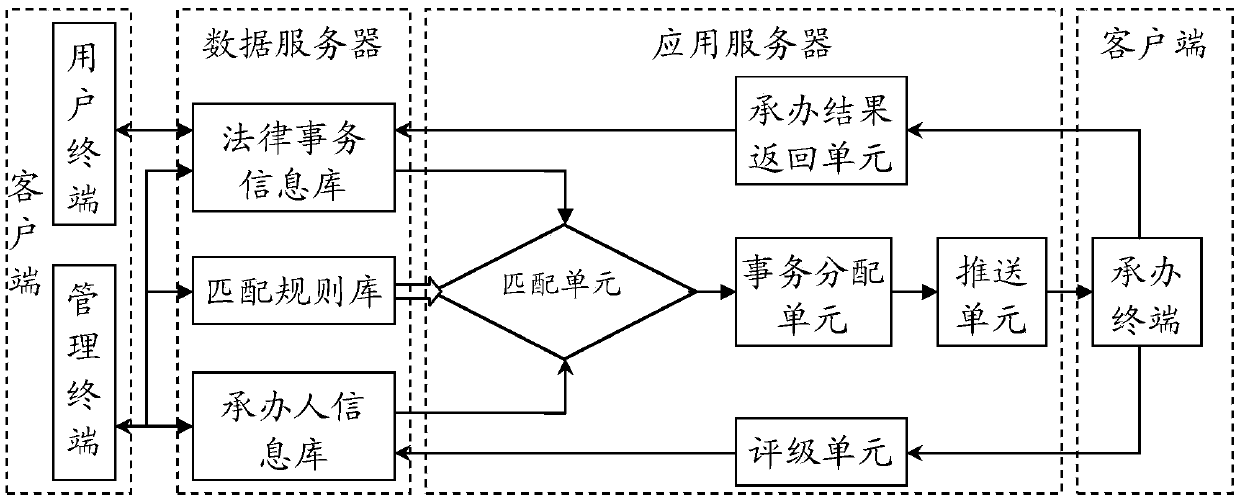

Legal affair processing system and method

PendingCN109584119AQuality improvementGuaranteed economic interestsFinanceData miningTransaction processing

The invention discloses a legal affair processing system and method, and the method comprises the steps: carrying out the matching according to the affair attribute of a legal affair and the attributeof a carrier, and distributing legal affair information and / or a file to different carriers which meet the attribute matching for handling. The legal affair processing system comprises a matching unit which is used for matching the affair attribute of the legal affair with the attribute of the undertaker of the undertaker; The transaction distribution unit is used for distributing legal transactions to corresponding undertakers meeting attribute matching; The pushing unit is used for respectively sending legal affair information and / or files to the undertakers; And the acceptance terminal isused for acceptance processing of the transactions by the undertaker. According to the invention, high-efficiency and high-quality processing can be carried out on a large number of legal affairs, especially on a cross-region large number of legal affairs.

Owner:成都律军风险管理股份有限公司

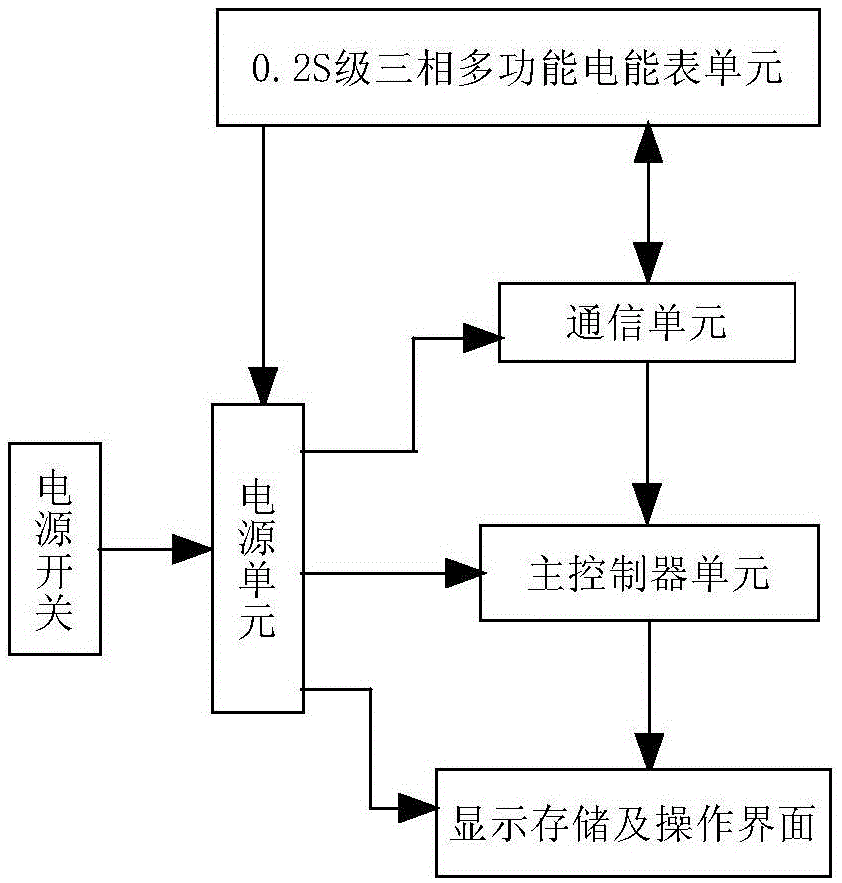

Gateway electric energy meter online replacing mode electric quantity loss compensation metering system

InactiveCN105093161AFriendly man-machine interfaceAccurate and reliable measurementElectrical measurementsCommunication interfaceHuman–machine interface

The invention provides a gateway electric energy meter online replacing mode electric quantity loss compensation metering system comprising a power supply switching unit, a power supply unit, a 0.2S class three-phase multifunctional electric energy meter unit, a master controller unit, a communication interface unit and a display storage and operation interface unit. According to a gateway electric energy meter online replacing mode electric quantity loss compensation metering method, the system is environment-friendly in design, simple and reliable and friendly in human-computer interface so that accurate and reliable metering of important gateway electric energy meter online replacing mode electric quantity loss can be provided for onsite work personnel. Meanwhile, credibility of metering results is realized by adopting the 0.2S class gateway electric energy meter unit, and data storage inquiring can be performed so that the economic benefit of both power purchasing and selling sides can be guaranteed.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

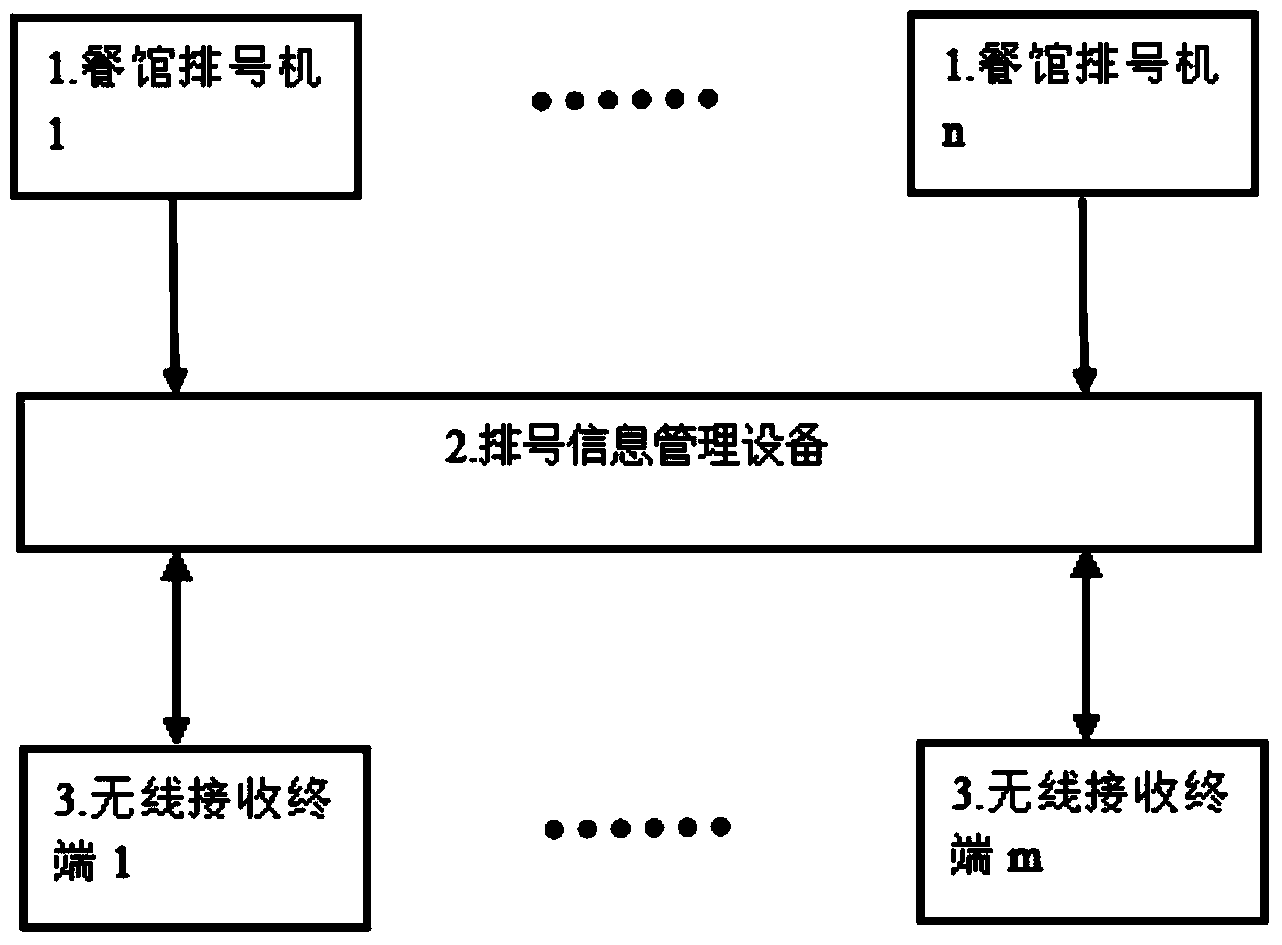

Restaurant queuing information management method

InactiveCN104063821AGuaranteed economic interestsReduce queuing timeData processing applicationsSpecial data processing applicationsComputer scienceWireless connectivity

The invention relates to a restaurant queuing information management method. The method comprises the step that a wireless restaurant queuing information publishing system is provided. The publishing system comprises a plurality of restaurant queuing machines, a queuing information management device and a plurality of wireless receiving terminals. Each restaurant is provided with one restaurant queuing machine used for storing the queuing information of the restaurant at the current time quantum. The queuing information management device is in wireless connection with all the restaurant queuing machines to obtain the queuing information of all the restaurants at the current time quantum, and the wireless receiving terminals are in wireless connection with the queuing information management device and are used for obtaining the queuing information of the restaurant needed by users at the current time quantum based on requests of the users holding the wireless receiving terminals. By means of the restaurant queuing information management method, the dining users can inquire the queuing situation of the favorite restaurant anytime and anywhere, more restaurants with the same cuisines can be provided for the users to be selected when there are many people queuing in the favorite restaurant, using is facilitated for the users, and reasonable allocation of restaurant resources is guaranteed.

Owner:WUXI BEIDOUXINGTONG INFORMATION TECH

Image processing-based agricultural intelligent platform

InactiveCN104778630AAvoid wastingGuaranteed economic interestsData processing applicationsData acquisitionData acquisition module

The invention discloses an image processing-based agricultural intelligent platform. The image processing-based agricultural intelligent platform comprises an FRID tag, an FRID reader-writer, a data acquisition module, a central server group, a weather collecting module, a data analysis module, and an information pushing module, wherein the FRID is used for marking a producing area and a sale price of a crop; the FRID reader-writer is used for reading information of the FRID tag; the data acquisition module is used for acquiring data and transferring the acquired data to the central server group; the central server group stores the received data into a database, and meanwhile the database saves agricultural yield over the years and market average prices of the crops in the current year of each place in the whole country; the weather collecting module is used for collecting weather information; the data analysis module is used for retrieving the data from the database, outputting the yield-price curve chart of the agricultural product according to the data saved in the database, predicting the yield and the price in the current year according to the yield-price curve chart, and meanwhile drawing the planting map in the current year; the information pushing module pushes the yield-price curve chart and the planting map predicted by the data analysis module to a user side. The image processing-based agricultural intelligent platform has the advantage of avoiding the grain waste.

Owner:LIUZHOU YINONG TECH

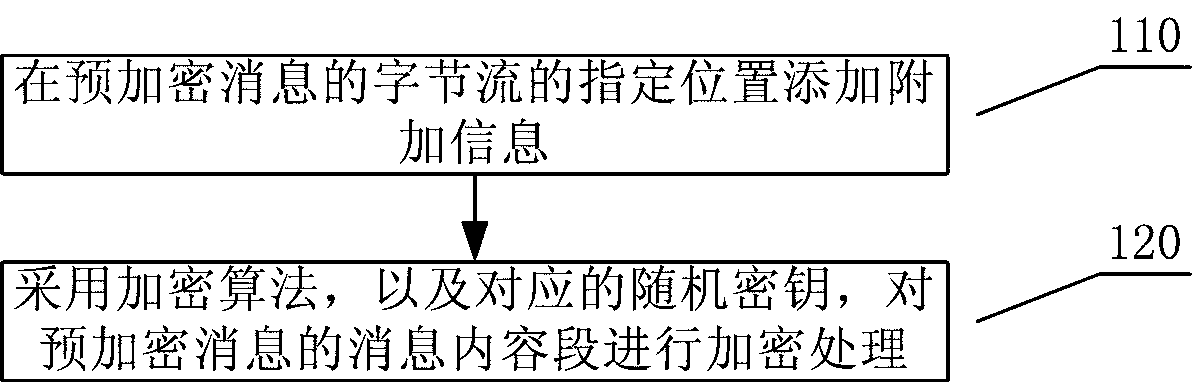

Method for dynamically encrypting network data, and storage medium

InactiveCN108768649AData suppressionMaintain fairnessMultiple keys/algorithms usageEncryption apparatus with shift registers/memoriesPlaintextCiphertext

The invention discloses a method for dynamically encrypting network data, and a storage medium. The method comprises the following steps: adding additional information at a specified location of a byte stream of a pre-encrypted message, wherein the additional information comprises random encryption algorithm representation bit, and a random key corresponding to an encryption algorithm representedby the random encryption algorithm representation bit; and performing encryption processing on the message content section of the pre-encrypted message by adopting the encryption algorithm representedby the random encryption algorithm representation bit in the additional information and the random key corresponding to the encryption algorithm represented by the random encryption algorithm representation bit. Through the method for dynamically encrypting network data and the storage medium disclosed by the invention, the data in the network transmission can be dynamically encrypted, so that the same plaintext data is corresponding to different ciphertext data, thereby directly and effectively a behavior that a WPE type software counterfeiting sender sends the data capable of being processed by a receiver to the receiver.

Owner:SNAIL GAMES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com