Washing technology for refinement of wet-process phosphoric acid by solvent extraction method

A technology of wet-process phosphoric acid and extraction method, which is applied in the fields of phosphorus compounds, chemical instruments and methods, and inorganic chemistry. Economic benefits, the effect of ensuring the selling price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A washing process for refining wet-process phosphoric acid by solvent extraction, comprising the following steps in sequence:

[0050] The first step: full production: first pretreat the crude phosphoric acid obtained by the wet method, the pretreatment includes the steps of concentration, defluorination, desulfurization, decolorization and filtration in sequence, and then extract the filtered filtrate, after extraction The resulting organic phase is saturated;

[0051] The second step: the preparation of washing water: first take phosphoric acid with a concentration of 400g / L as the matching acid, and the ratio of the matching acid to the saturated one is 1:25, and then add NH 4 + The ions are added to the acid for dissolution according to 100% of the stoichiometric amount of sulfuric acid in the saturated medium. After the dissolution is completed, filter, and the filtered filtrate is the washing water;

[0052] The third step: the washing process: first use the abo...

Embodiment 2

[0055] Step is with embodiment 1, and difference is:

[0056] The second step: the preparation of washing water: first take phosphoric acid with a concentration of 500g / L as the matching acid, and the ratio of the matching acid to the saturated one is 1:16, and then add NH 4 + The ions are added to the acid compound according to 120% of the stoichiometric amount of sulfuric acid in the saturated medium for dissolution, and then filtered after the dissolution is completed, and the filtrate obtained from the filtration is the washing water;

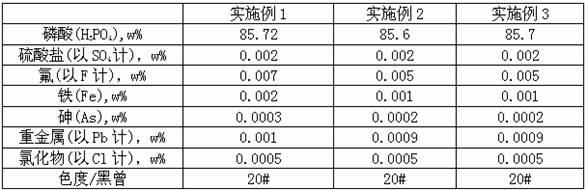

[0057] The third step: washing process: see attached table 1 for product quality; the follow-up treatment of the washing water refers to: first recovering the washing water from the extraction agent, and then sending the treated washing water into an airtight container Then add sulfides to the washing water, add 100mL of sulfides with a mass percentage concentration of 6% per liter of washing water, heat again, and keep stirring at 85-90°C...

Embodiment 3

[0059] Step is with embodiment 1, and difference is:

[0060] The second step: the preparation of washing water: first take phosphoric acid with a concentration of 600g / L as the matching acid, and the ratio of the matching acid to the saturated one is 1:22, and then add NH 4 + The ions are added to the acid compound according to 110% of the stoichiometric amount of sulfuric acid in the saturated medium for dissolution, and then filtered after the dissolution is completed, and the filtrate obtained from the filtration is the washing water;

[0061] The third step: washing process: see attached table 1 for product quality; the follow-up treatment of the washing water refers to: first recovering the washing water from the extraction agent, and then sending the treated washing water into an airtight container Then add sulfides into the washing water, add 200mL of sulfides with a mass percentage concentration of 1% per liter of washing water, heat again, and keep stirring at 85-90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com