Method for maintaining blade of wind generating set

A technology for wind turbines and blades is applied in the field of maintenance of blades of wind turbines, which can solve the problems of unhelpful internal structure and poor effect, and achieve the effects of good internal maintenance, good maintenance effect and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

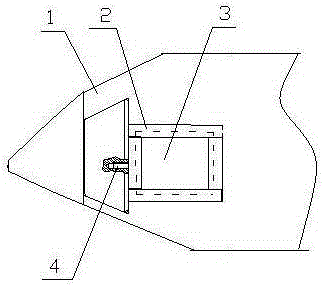

[0021] Embodiment 1, with reference to figure 1 and figure 2 , a maintenance method for wind turbine blades, the steps of which are,

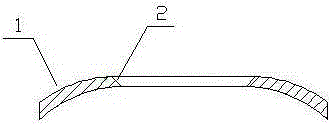

[0022] (1) Form a cutting area around the damaged area of the blade shell 1 except for the double-beam structure and the web structure, dry the cutting area and clean the surface, and perform circumferential cutting along the periphery of the damaged area after cleaning. The next square area 3 containing the damaged area leaves a cut on the blade shell 1, and the cutting surface at the cut forms a gradient area 2 that is wide on the outside and narrow on the inside;

[0023] (2) Perform wedge grinding and type repair on the corners of the gradient area 2 first, and then perform internal damage treatment on the damaged area in the cut square area 3;

[0024] (3) After the internal damage treatment is completed, use the FRP strip 4 to draw a bonding line in the middle of the FRP strip 4, and the FRP strip 4 on one side of the bonding line is...

Embodiment 2

[0028] Embodiment 2, in the maintenance method described in Embodiment 1: the width of the glass fiber reinforced plastic bar 4 used is 40mm.

Embodiment 3

[0029] Embodiment 3, in the maintenance method described in Embodiment 1: the width of the glass fiber reinforced plastic bar 4 used is 60mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com