Curing kiln for building concrete wallboard prefabricated part production line

A prefabricated component and curing kiln technology, applied in the construction field, can solve problems affecting the curing effect of prefabricated components, reduce the production efficiency of the production line, and reduce the production efficiency of the curing kiln, so as to eliminate the vertical material handling link, reduce energy consumption, and reduce equipment maintenance Effects on costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the design concept of the present invention, the present invention will be described below in conjunction with examples.

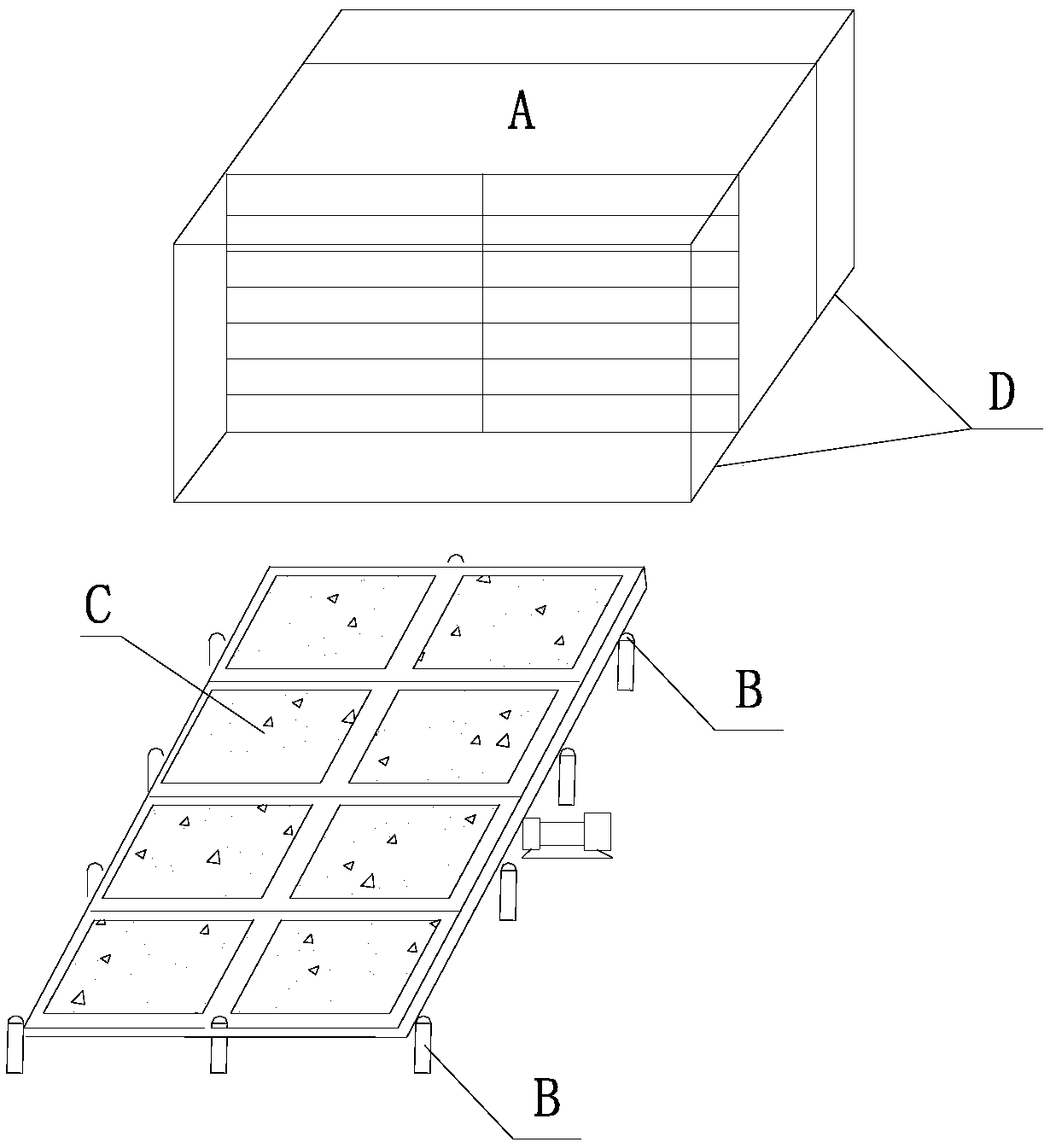

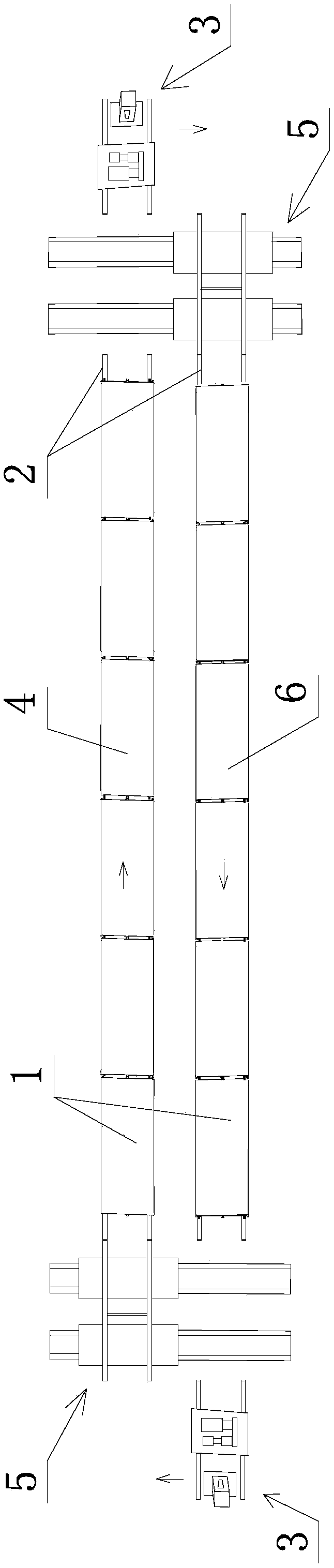

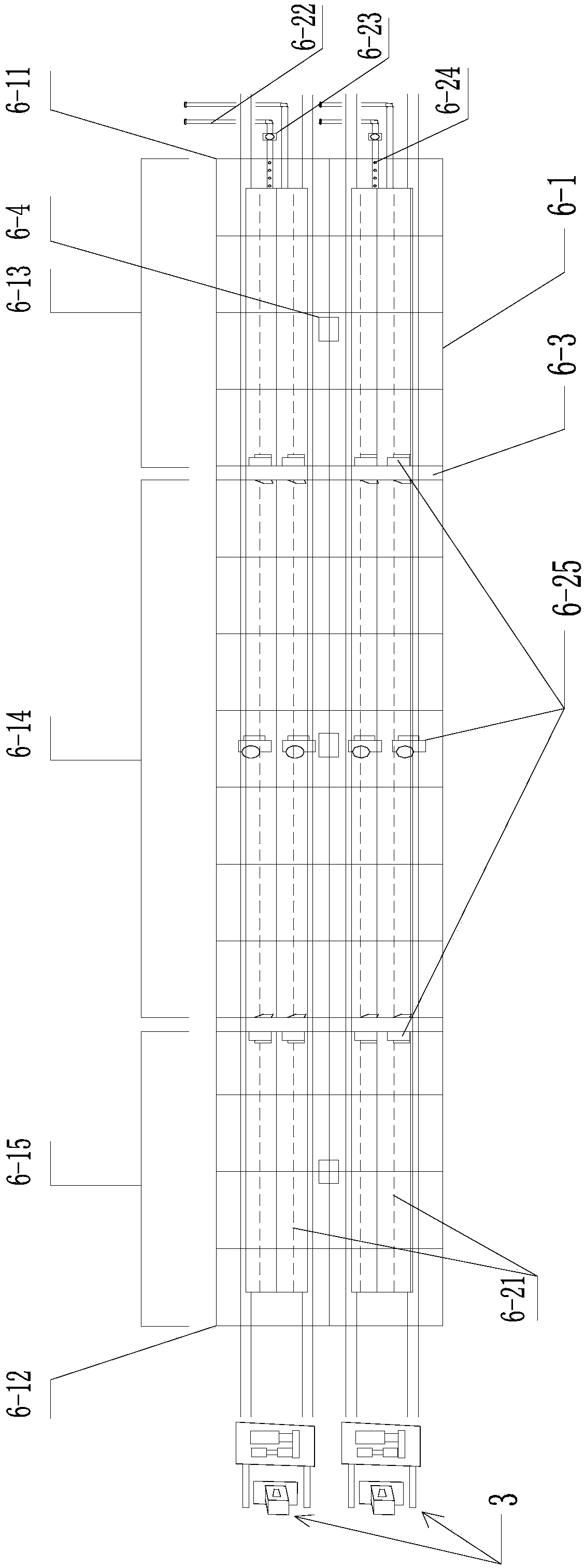

[0028] Such as Figure 3-4 In the example shown, the curing kiln for the production line of prefabricated building concrete wall panels according to the present invention includes a curing kiln body 6-1 with openings at both ends, extending horizontally and having a closed side wall, and the openings at both ends are the inlets 6 of the curing kiln respectively. -11 and outlet 6-12, the inner cavity of the curing kiln body 6-1 between the inlet 6-11 and the outlet 6-12 is a passage for the prefabricated components to be cured to pass through, and the curing kiln body 6-1 passes through its inlet 6- From 11 to its outlet 6-12, a heating section 6-13, a constant temperature section 6-14, and a cooling section 6-15 are sequentially arranged, and a temperature and humidity adjustment device 6-2 and a temperature and humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com