Automatic warehousing method for automobile parts

A technology for auto parts and storage locations, which is applied in the direction of computer parts, induction recording carriers, resources, etc., can solve the problems of high job requirements, low storage efficiency, and high labor intensity of employees, so as to reduce investment and improve storage Efficiency, the effect of eliminating the handling link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. It should be understood that the following examples are only illustrative and explain the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

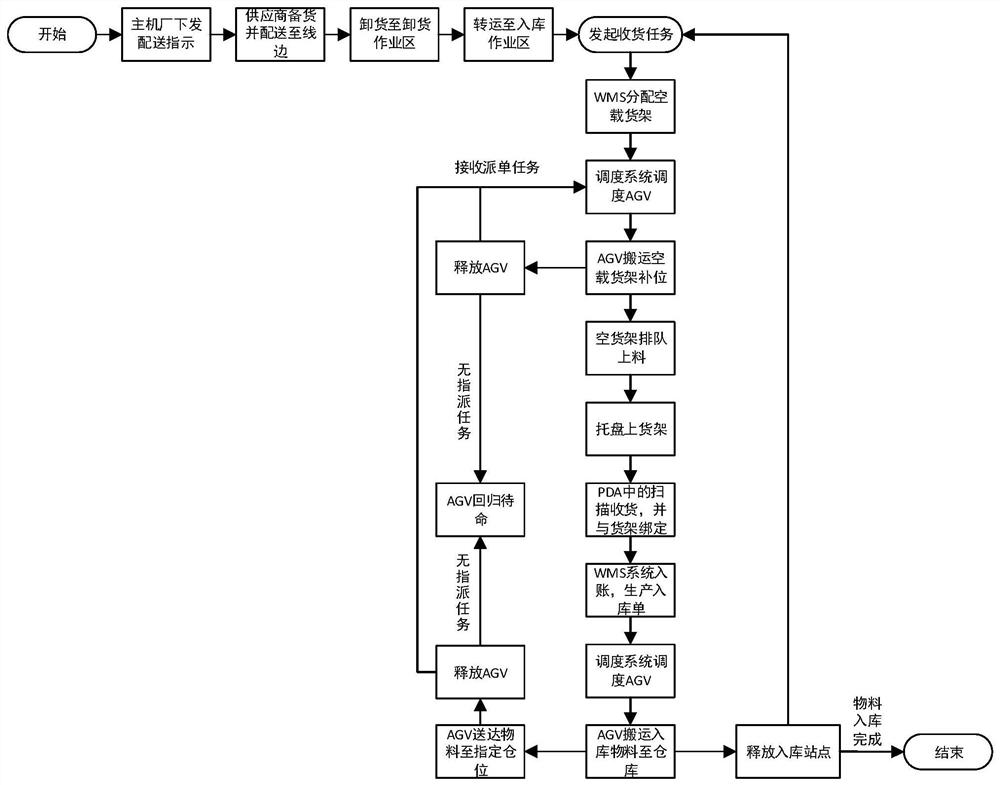

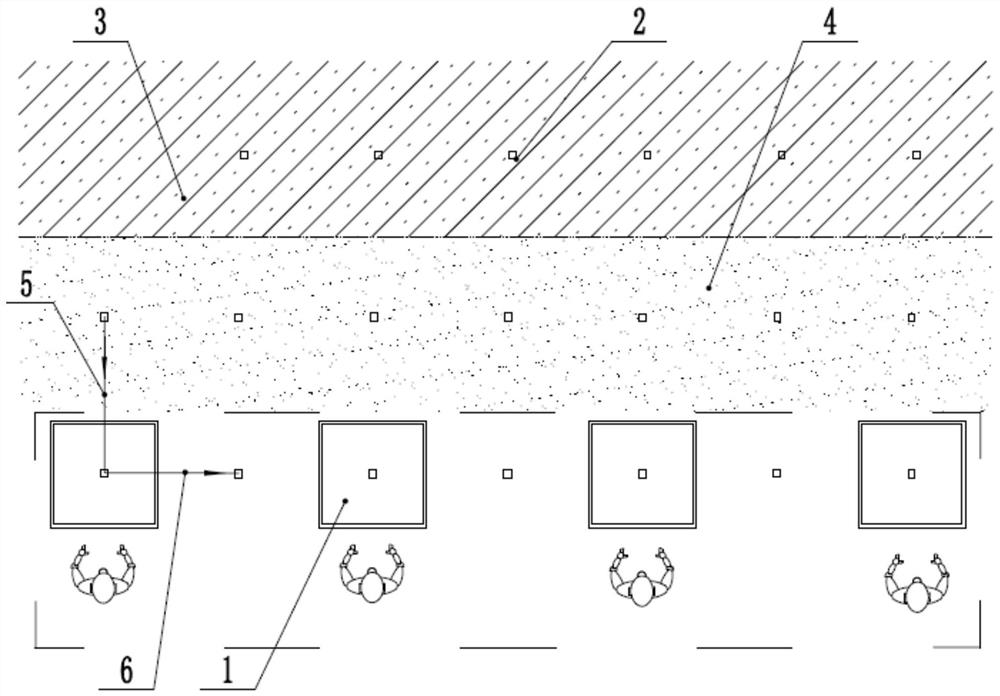

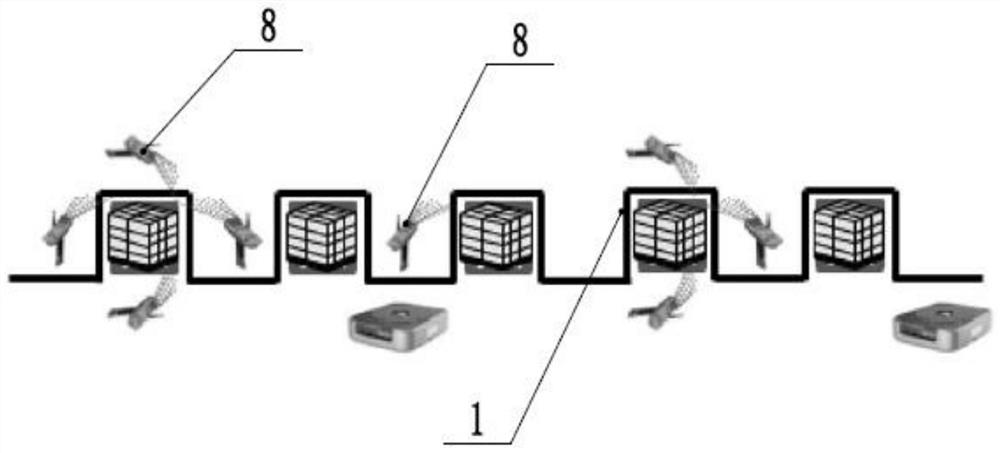

[0028] It should be noted that the present invention is a method for automatic storage of auto parts realized jointly by a storage site, a WMS system, a scheduling system, and an AGV. Among them, the WMS system is a commonly used term in the production and logistics industries, referring to the warehouse management system, which is mainly used to manage warehouses, record inventory information, allocate warehouse locations, manage inbound and outbound warehouses, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com