Variable-temperature variable-pressure curing device for well cementing slurry test mold

A technology for cementing cement slurry and mold testing, which is applied in the preparation of test samples, ceramic molding machines, manufacturing tools, etc., can solve the problems of high cost, complicated operation process, complicated structure, etc., and achieves low production cost and measurement results. Accurate and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

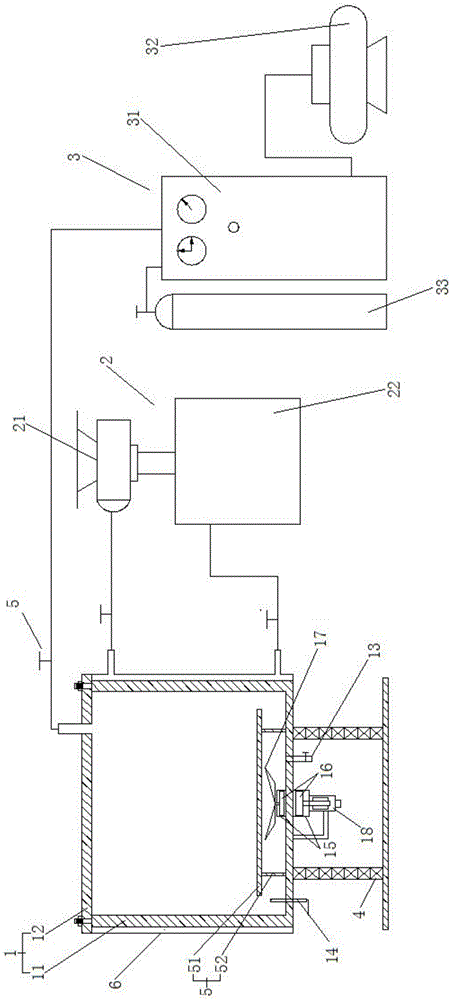

[0034] Example: such as figure 1 As shown, the variable temperature and variable pressure curing device of the cement slurry trial mold in this embodiment includes a curing box 1, a temperature control circulation system 2 and a pressurization system 3;

[0035] The above-mentioned curing box 1 is installed on the ground through the support base 4, and the inner bottom of the above-mentioned curing box 1 is equipped with a mold trial bracket 5;

[0036] The side wall of the above-mentioned curing box 1 is surrounded by a temperature-controlled circulating bath cover 6. A closed cavity is formed between the above-mentioned temperature-controlled circulating bath cover 6 and the side wall of the curing box 1. The above-mentioned temperature-controlled circulating bath cover 6 is respectively A water inlet and a water outlet connected to the above-mentioned cavity are provided, and the above-mentioned water inlet and water outlet are respectively connected to the temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com