Automatic assembly production line device of disposable sterile infusion sets

A production line equipment, automatic assembly technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of non-compliance with the sterile production requirements of medical appliances, large occupied area of the assembly site, low assembly efficiency, etc., to reduce High-speed and multi-DOF motion, high assembly efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

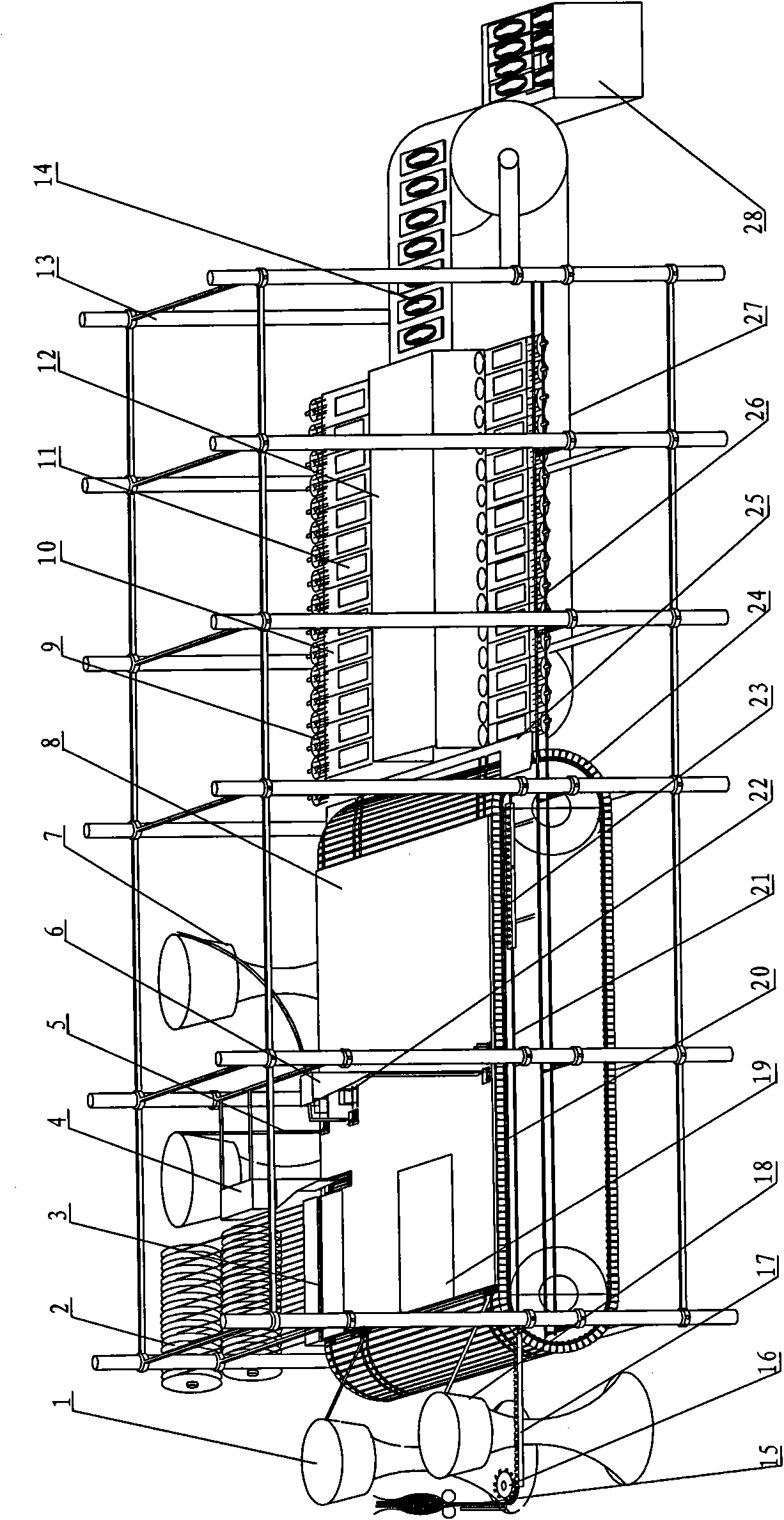

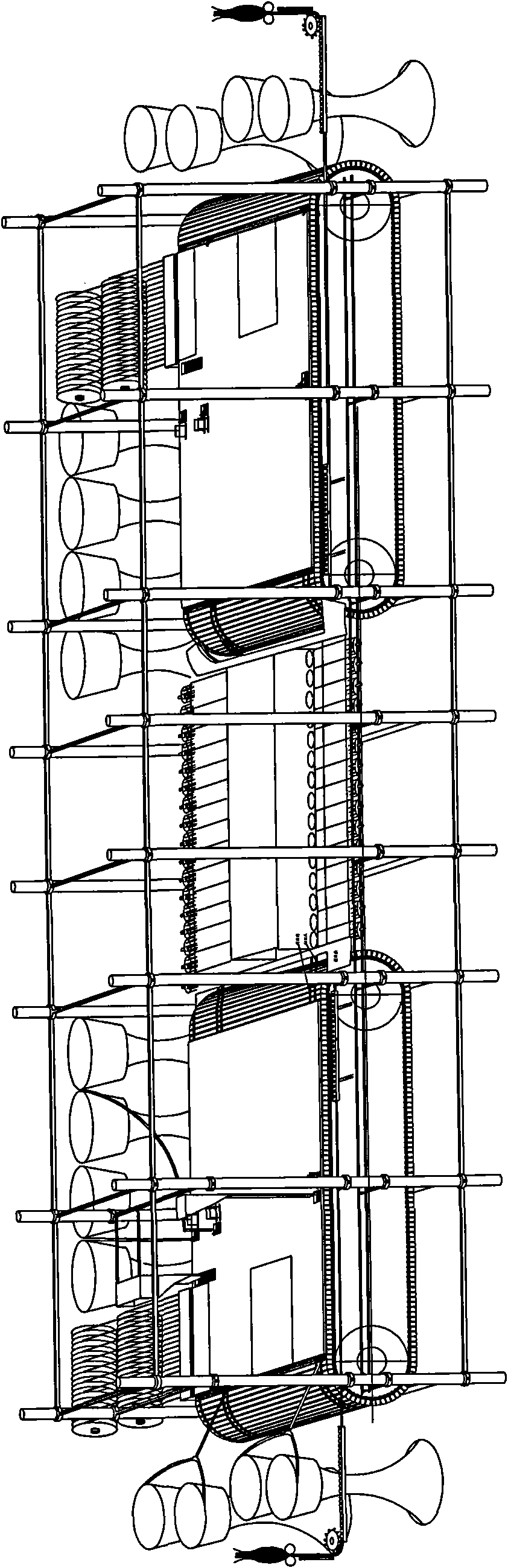

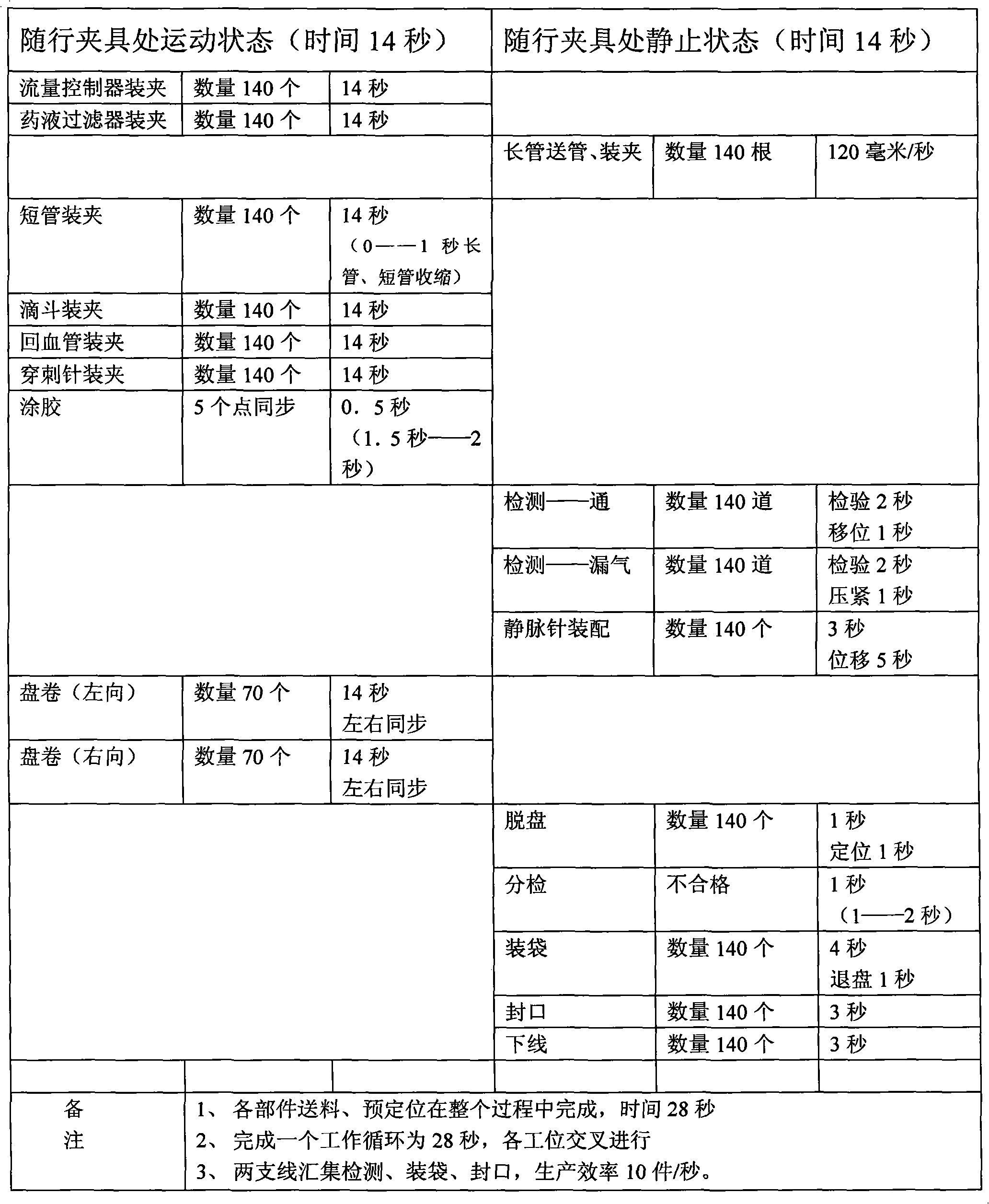

[0017] As shown in the figure, the equipment for the automatic assembly production line of disposable sterile infusion sets includes a feeding mechanism, an assembly testing mechanism, and a sorting and bagging mechanism. The feeding mechanism includes an accompanying clamp group 24, which is composed of several accompanying clamps fixedly arranged in parallel on the conveyor chain 20. The conveyor chain 20 is fixed on the support 13 and is an endless conveyor chain. The conveyor chain 20 engages the sprockets. The sprocket is connected with the external power mechanism, so that the pallet set 24 can do circular motion.

[0018] A guide plate is arranged on the upper part of the accompanying fixture group 24, and the left and right sides of the guide plate are respectively a component feeding area 19 and a component assembly area 8. The component feeding area 19 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com