A kind of preparation method of transparent flame retardant PC composite material

A composite material and transparent technology, which is applied in the field of preparation of transparent flame-retardant PC composite materials, can solve the problems of insufficient drying, easy stress cracking, and reduced drying effect of transparent flame-retardant PC composite materials, and achieve the effect of enhancing the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

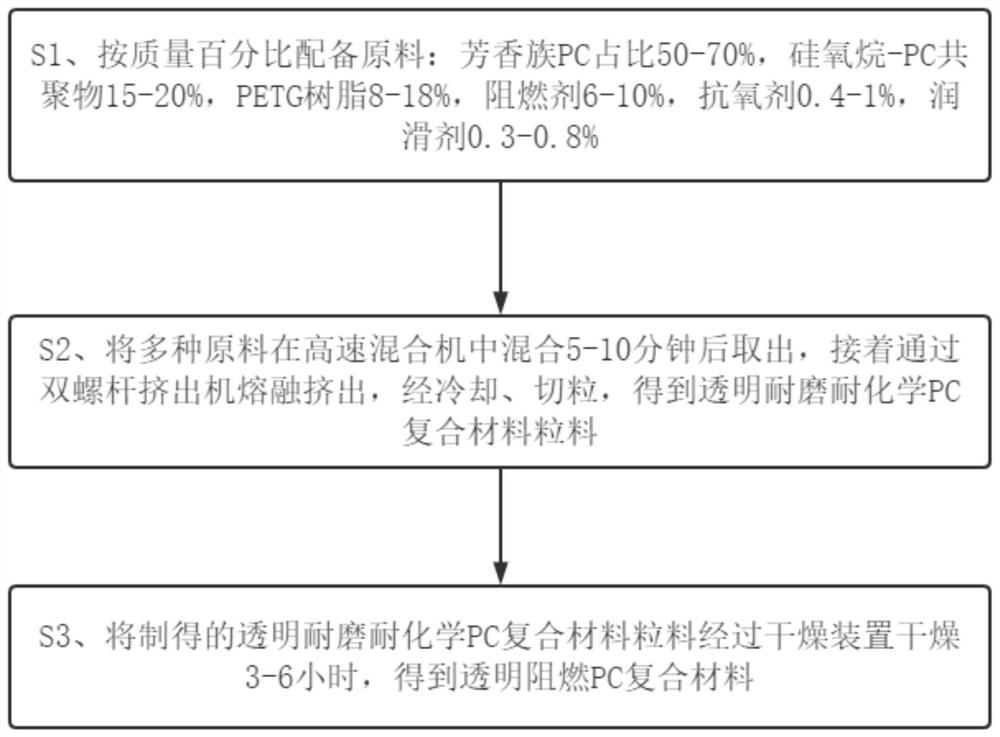

[0036] see figure 1 , a preparation method of transparent flame retardant PC composite material, comprising the following steps:

[0037] S1. Prepare raw materials by mass percentage: aromatic PC accounts for 50-70%, siloxane-PC copolymer 15-20%, PETG resin 8-18%, flame retardant 6-10%, antioxidant 0.4- 1%, lubricant 0.3-0.8%;

[0038] S2. Mix a variety of raw materials in a high-speed mixer for 5-10 minutes, take out, then melt and extrude through a twin-screw extruder, cool and pelletize to obtain transparent wear-resistant and chemical-resistant PC composite material pellets;

[0039] S3, drying the prepared transparent wear-resistant and chemical-resistant PC composite material pellets through a drying device for 3-6 hours to obtain a transparent flame-retardant PC composite material.

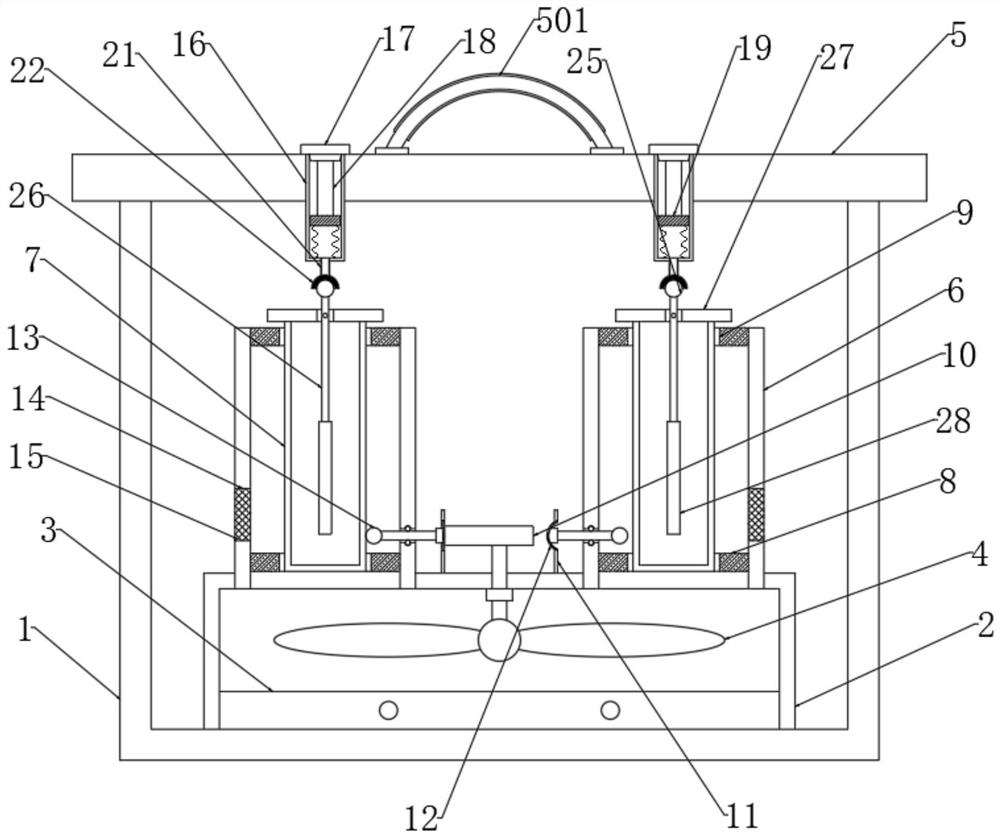

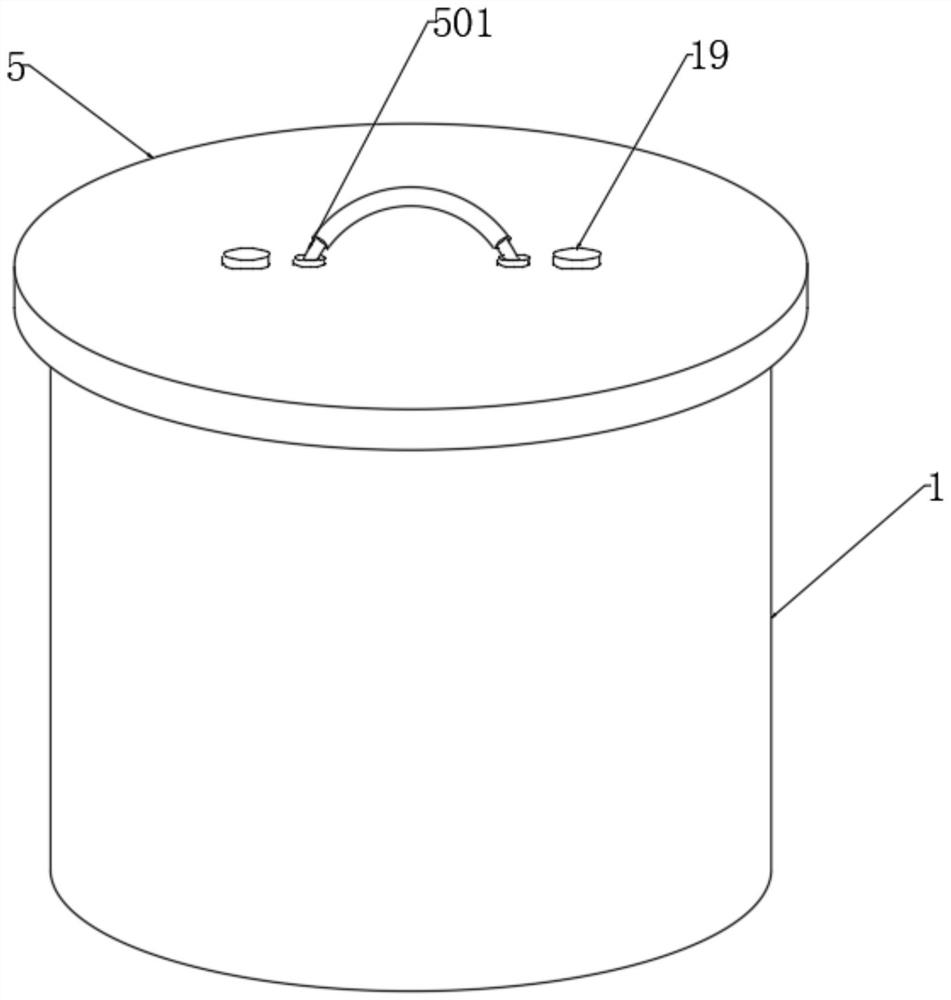

[0040] see Figure 2-5 , the drying device in S3 includes a drying cylinder 1, the upper end of the drying cylinder 1 is provided with a sealing cover plate 5, the inner bottom end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com