A combustible garbage disposal device

A waste treatment device and a treatment system technology, applied in the field of combustible waste treatment devices, can solve the problems of excessive manpower, difficulty in reuse, unfavorable environment, etc., to improve the working environment, improve pyrolysis efficiency, and consume less energy. good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

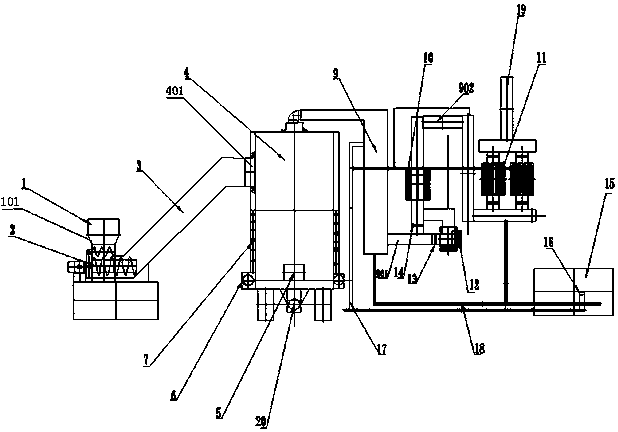

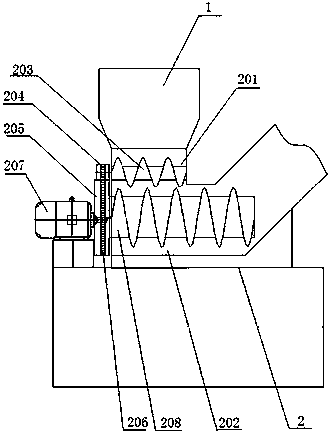

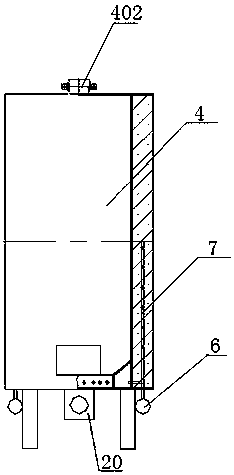

[0034] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a feed system, a pyrolysis treatment system, and a flue gas treatment system. The feed system includes a hopper 1, and the hopper 1 is connected to the upper feed port I101 of the pulverization and propulsion integrated machine 2; the pulverization and propulsion The all-in-one machine 2 is connected to the feed inlet II 401 of the pyrolysis furnace 4 through the feed pipe 3; the pyrolysis furnace 4 includes an inner wall, an outer wall, and an insulation layer between the inner wall and the outer wall; the front end and the rear end of the lower part of the pyrolysis furnace 4 Each is provided with a fire opening 5; the lower end of the pyrolysis furnace 4 is provided with an annular air inlet pipe 6, and the air inlet pipe 6 is provided with a thermal energy storage exchanger 7, and one end of the thermal energy storage exchanger 7 is connected to the air inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com