Patents

Literature

36results about How to "No other energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

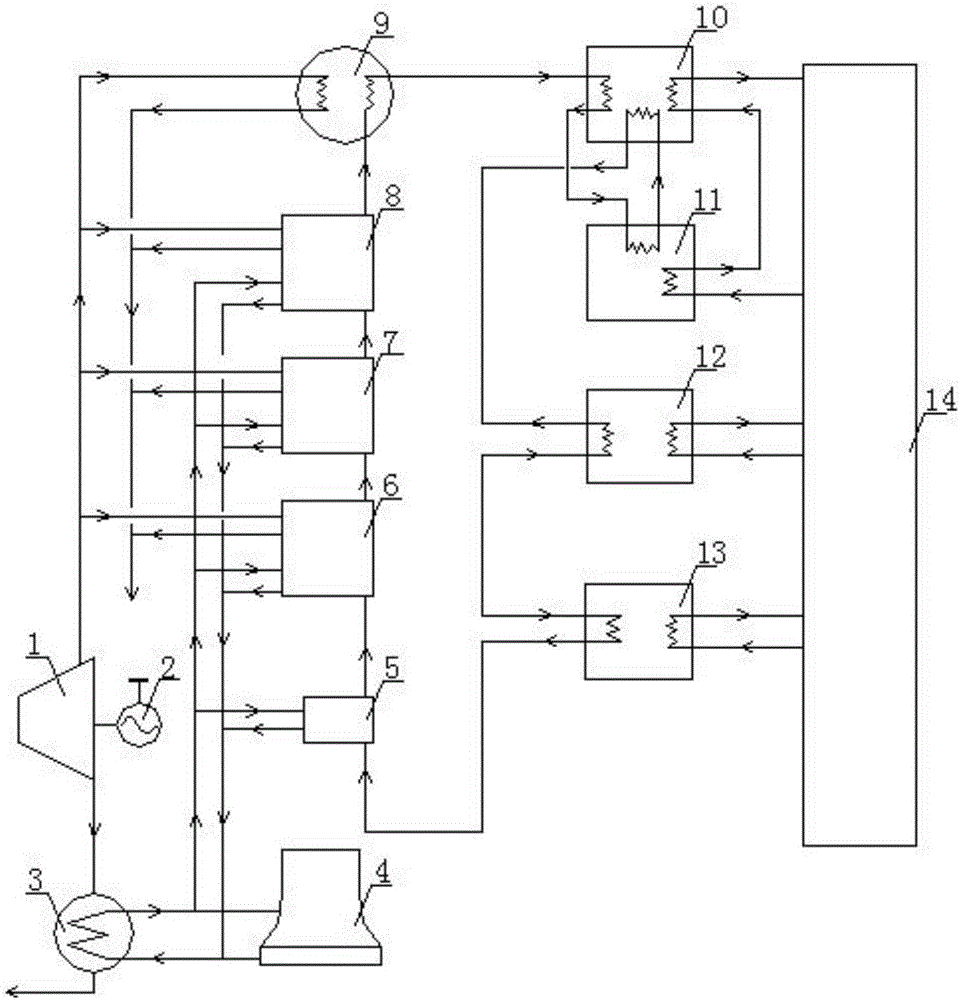

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

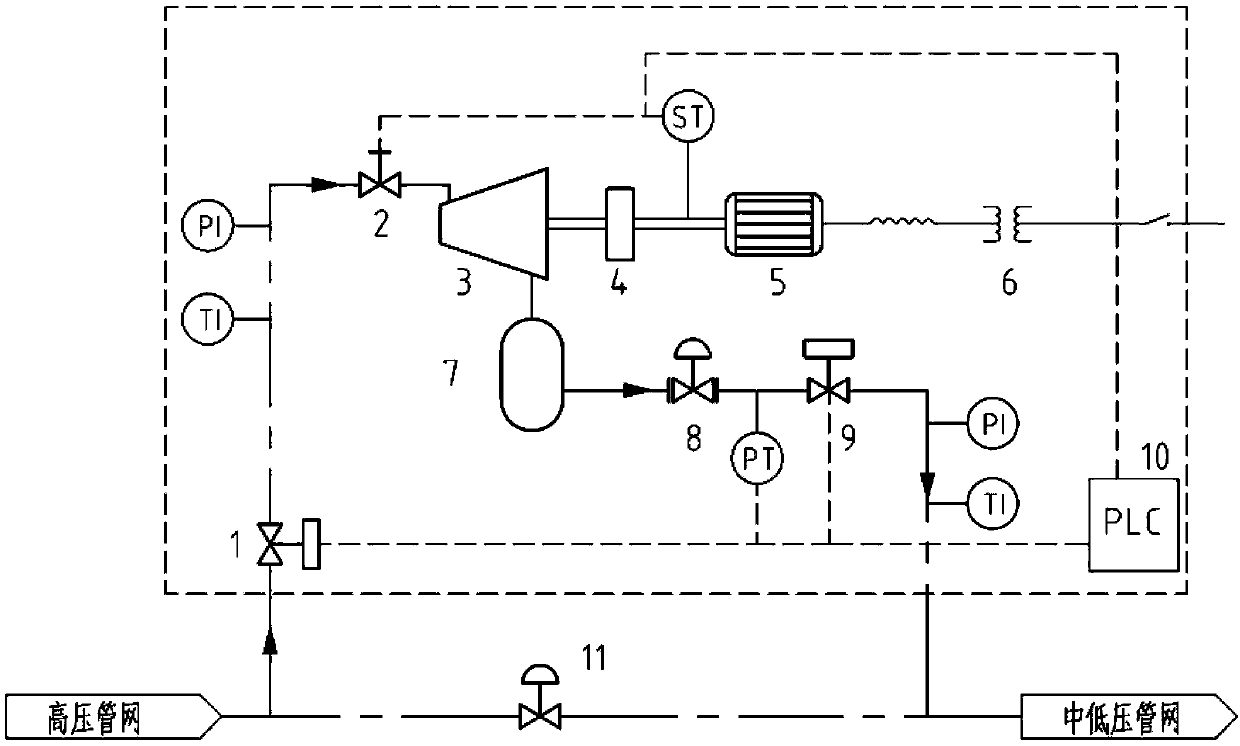

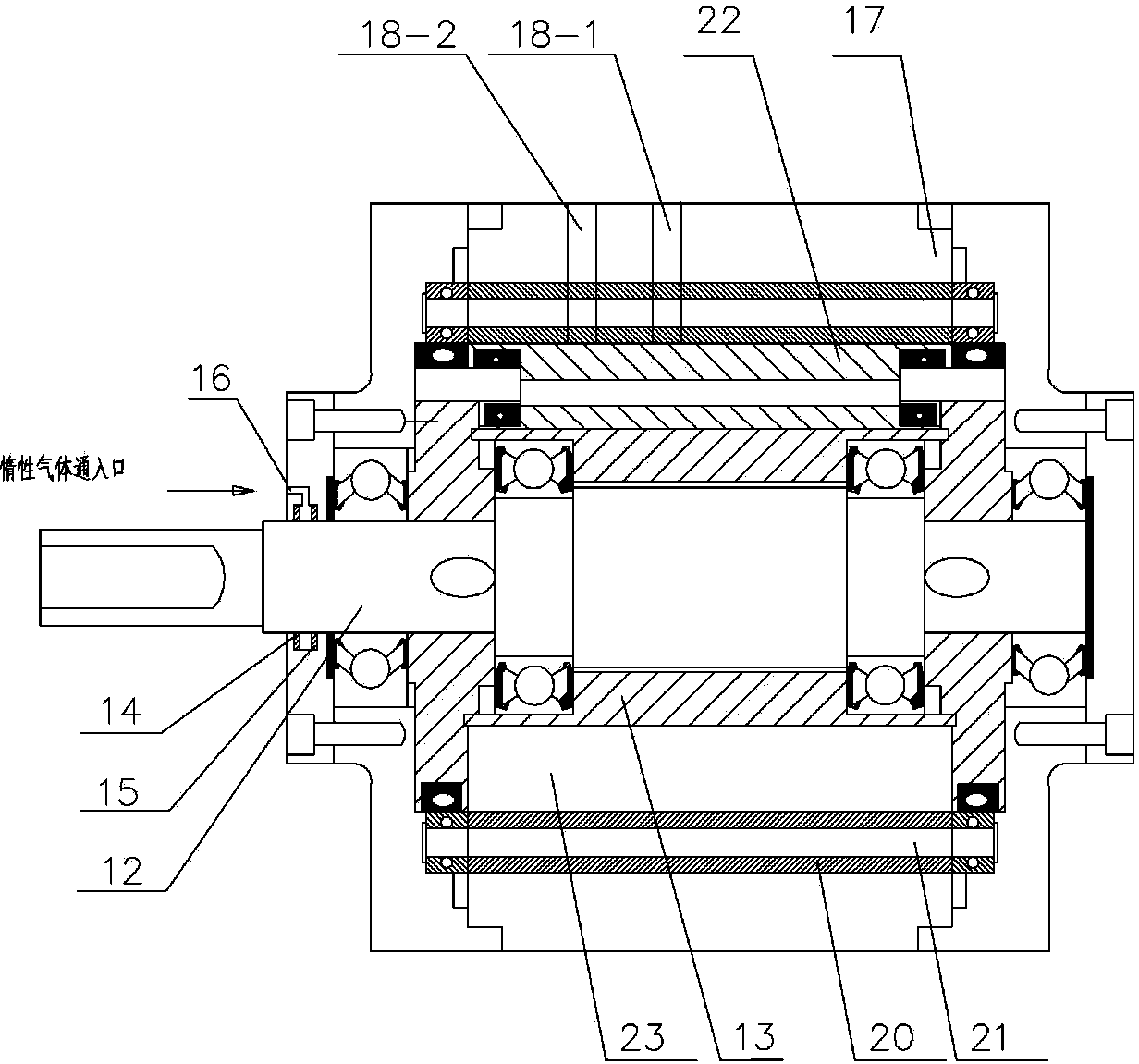

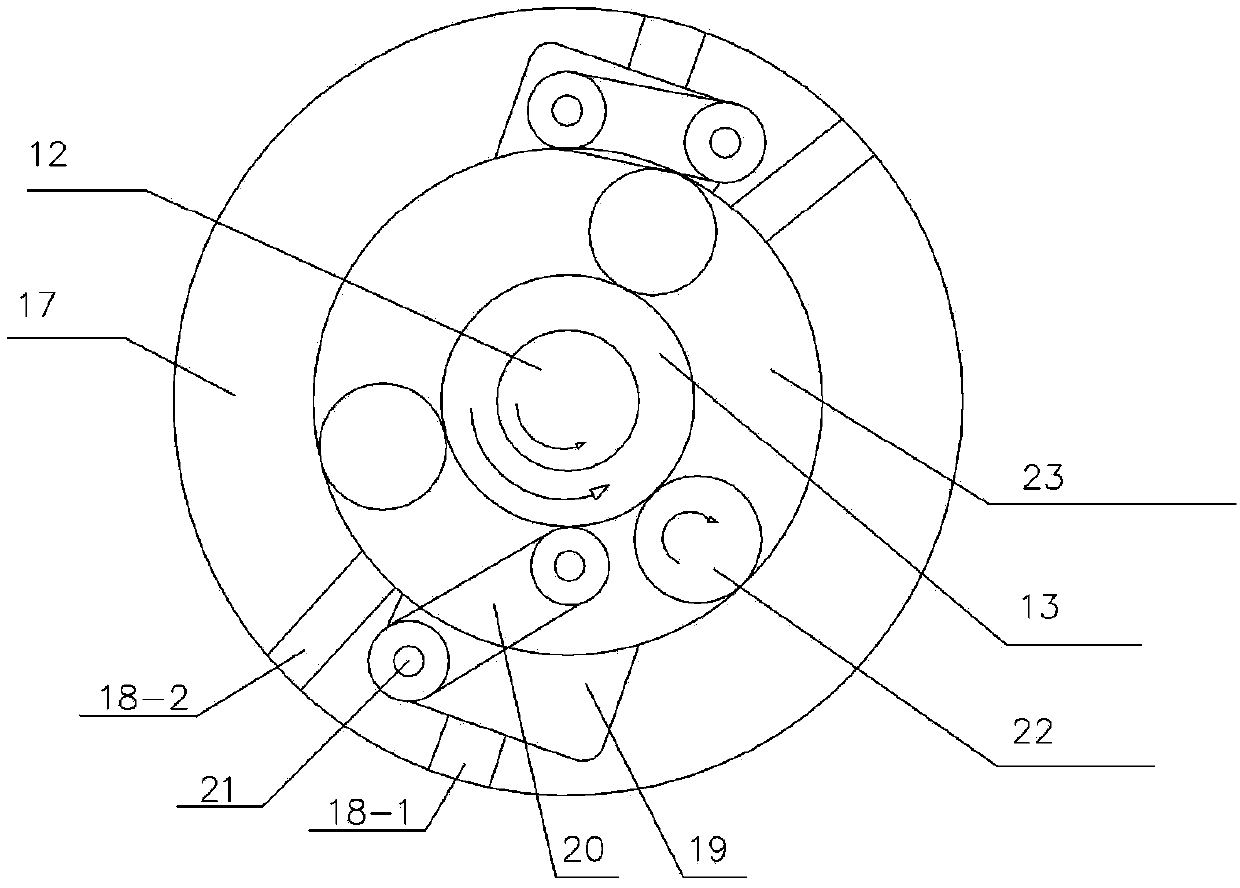

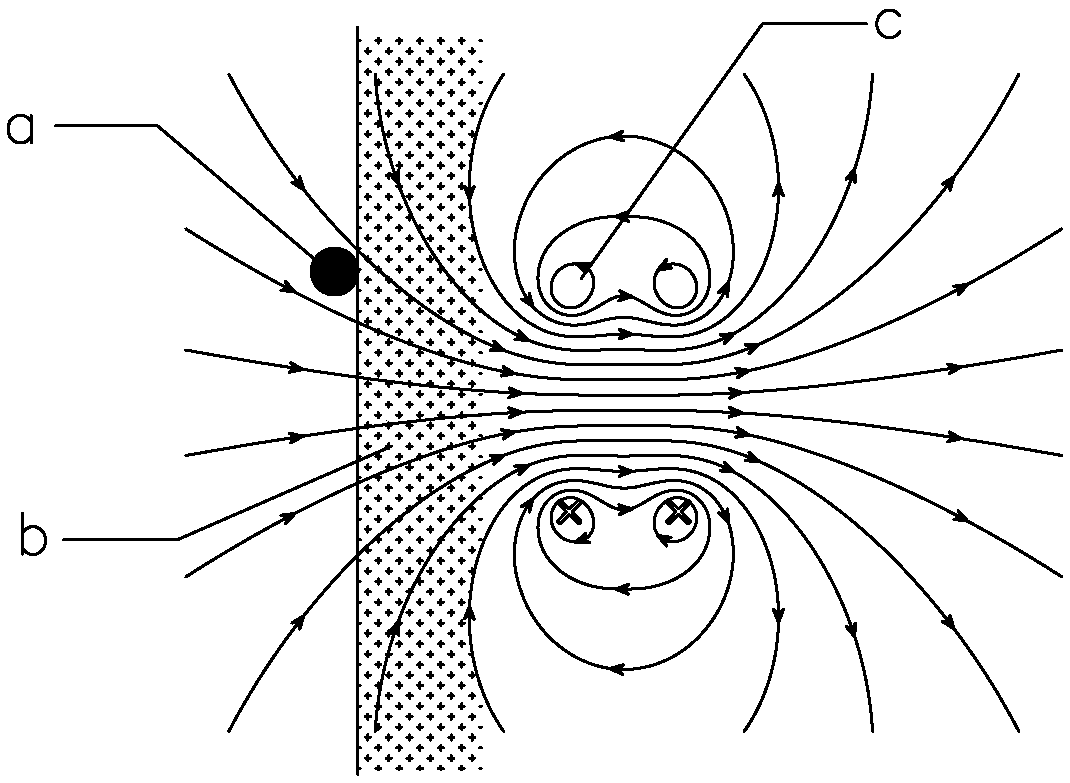

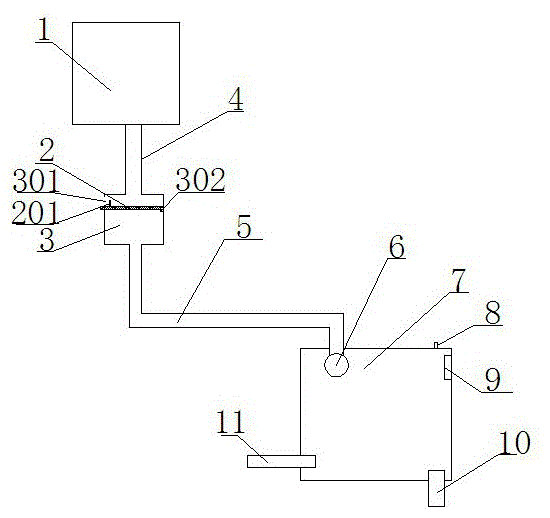

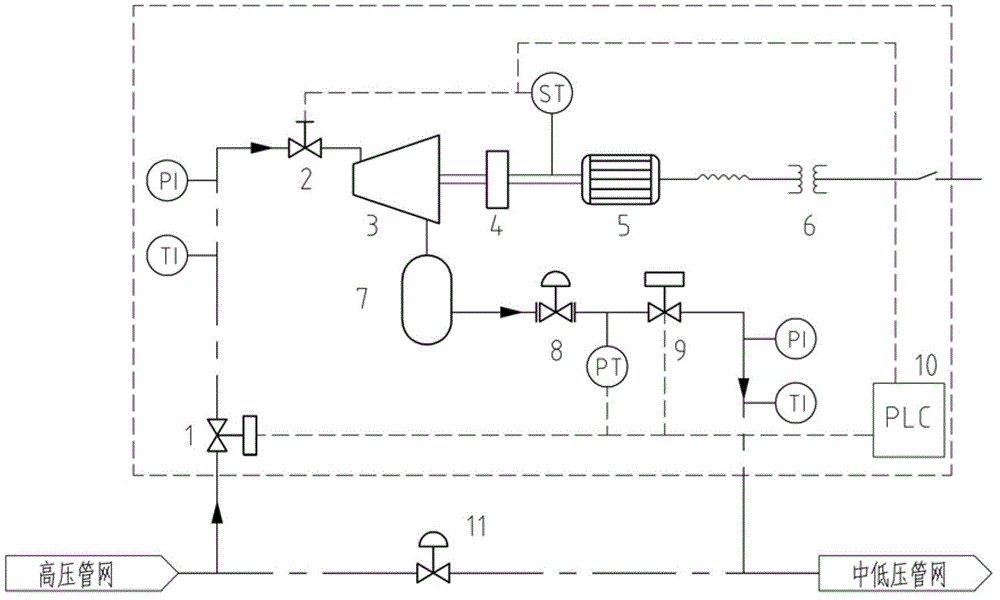

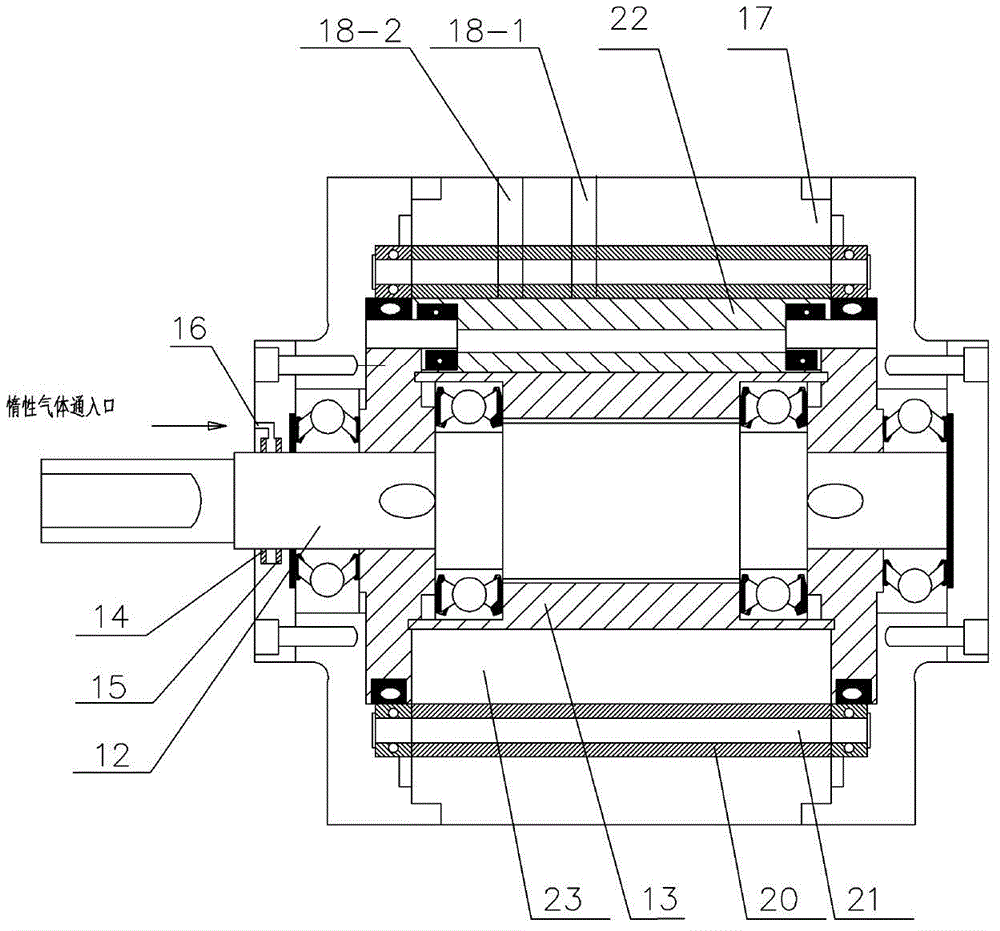

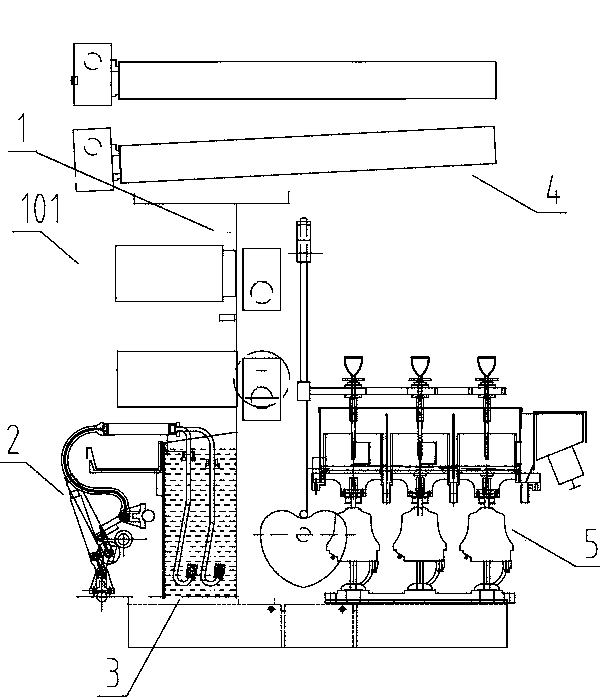

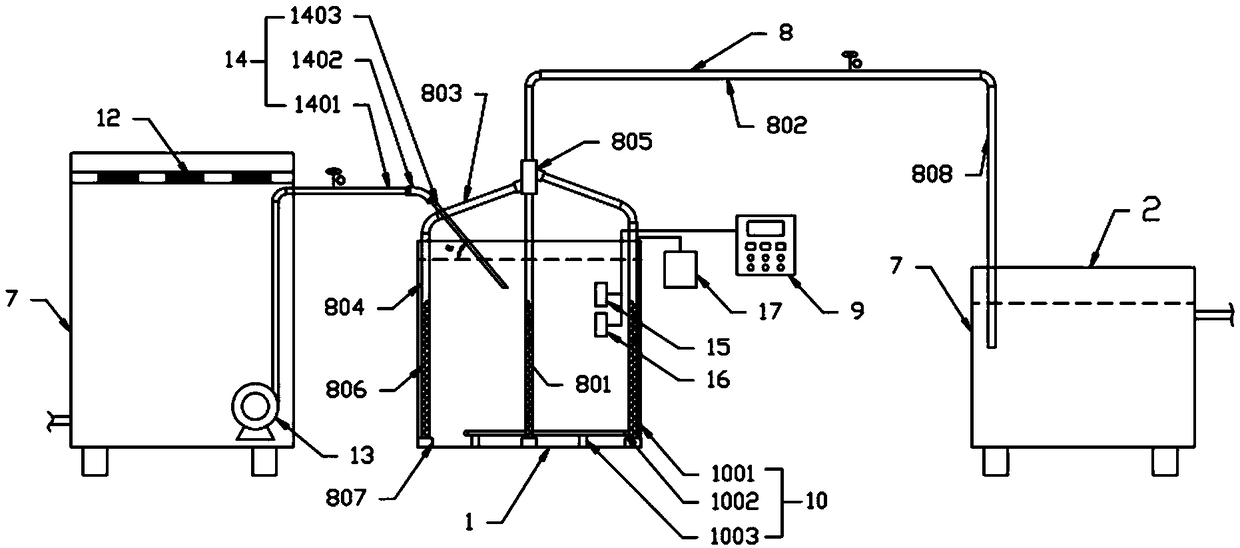

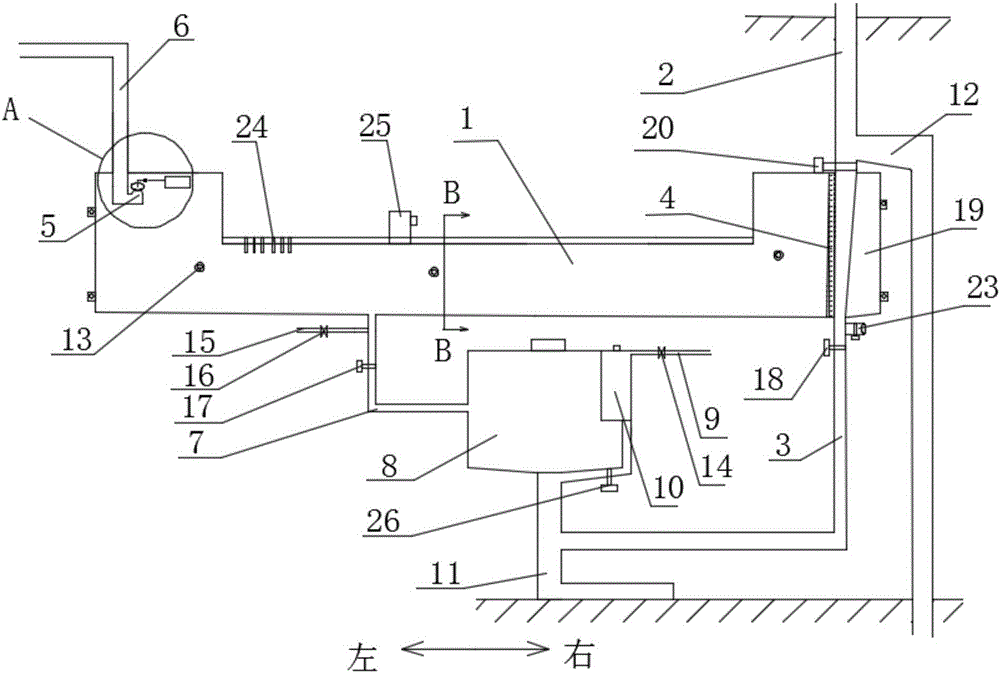

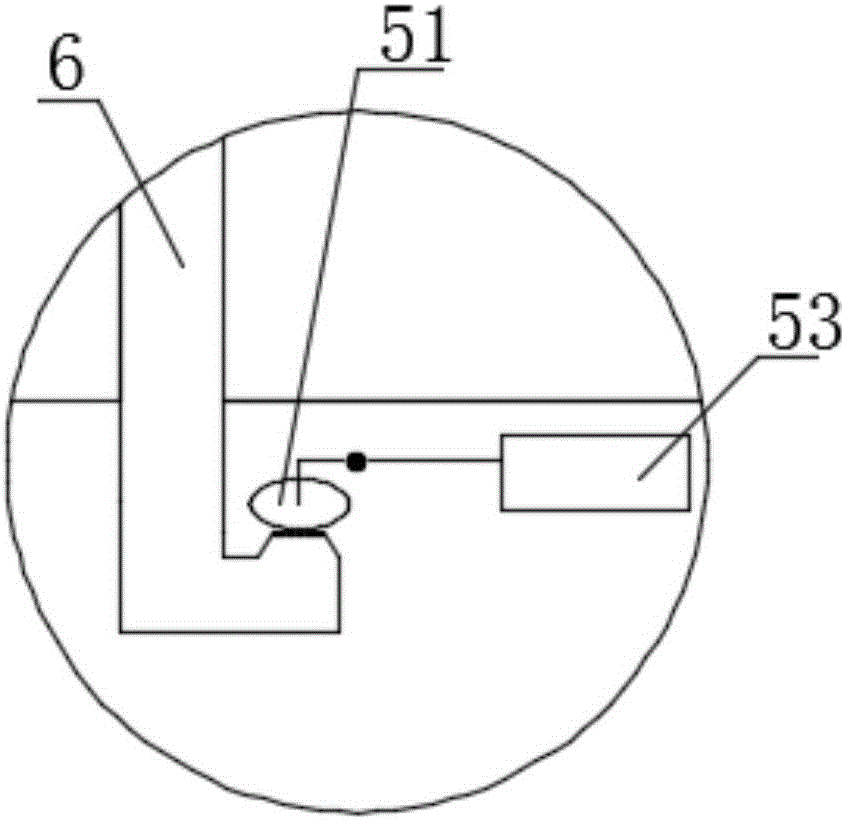

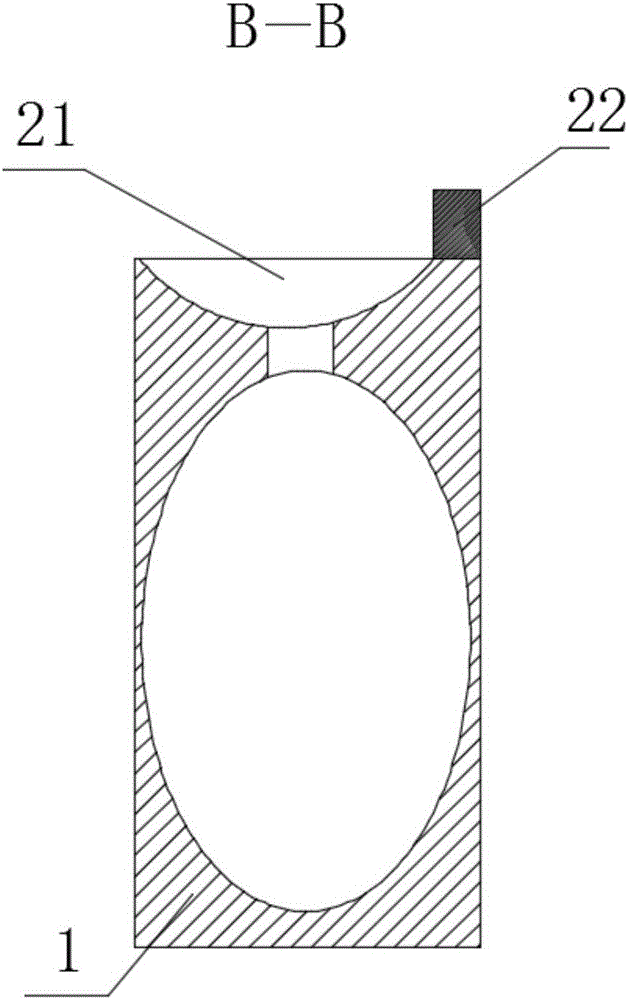

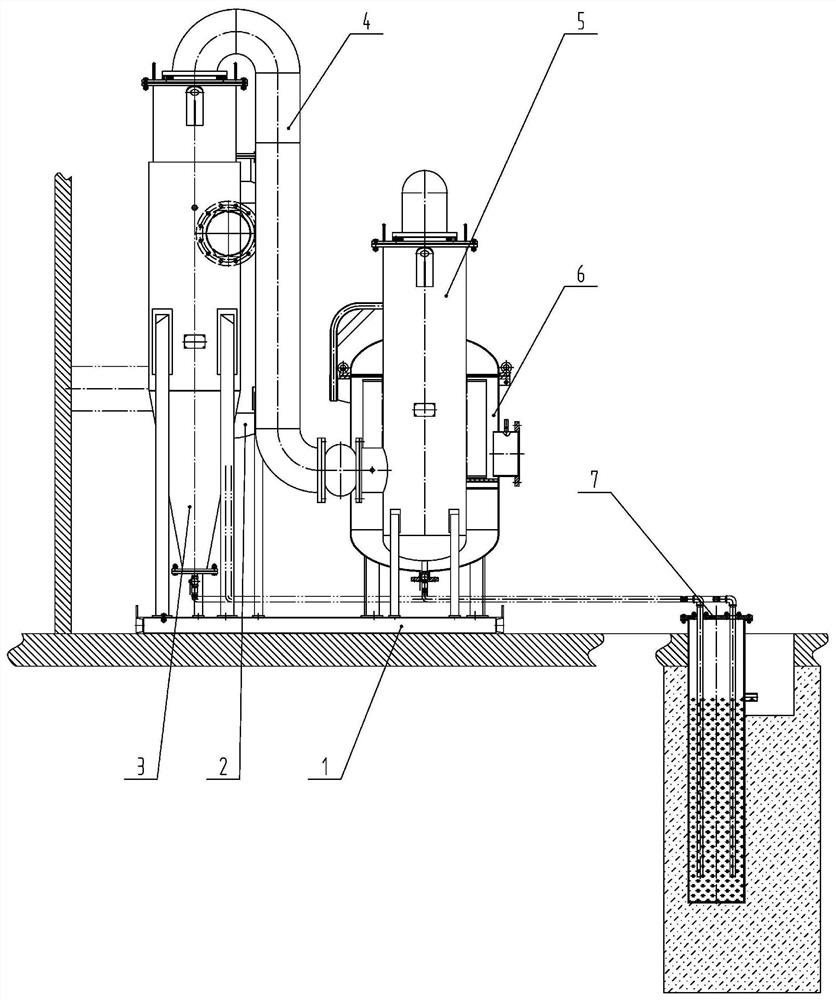

Process and device for generating power by pressure energy of small natural gas pipeline network

InactiveCN103422899ALeak will notSolve the problem that cannot be explosion-proofSealing arrangements for enginesMachines/enginesGas cylinderPower user

The invention discloses a process and a device for generating power by pressure energy of a small natural gas pipeline network. A high-pressure pipeline network of the device is connected with a gas inlet of an expansion machine through a pipeline; a gas outlet of the expansion machine is connected with a gas inlet of a temperature balancer through a pipeline; an outlet of the temperature balancer is connected with a low and medium-pressure gas pipeline network through a pipeline; a main shaft of the expansion machine is connected with a gearbox; the gearbox is connected with a power generator; the power generator is connected with a transformer synchronizer; the expansion machine adopts an improved AT15-65 type gas expansion machine; one end of the main shaft is connected with an air cylinder in a totally-closed way; a first seal ring and a second seal ring, which have sealing effects, are arranged between the other end of the main shaft and a wheel drum; a flow guide pipe is arranged in a closed cavity between the two seal rings; the flow guide pipe is connected with an inert gas bottle. The device can be used for continuously and stably providing a 220 V / 380 V stable power supply for an interruptible and closed 1-5 kW low-power user.

Owner:SOUTH CHINA UNIV OF TECH +1

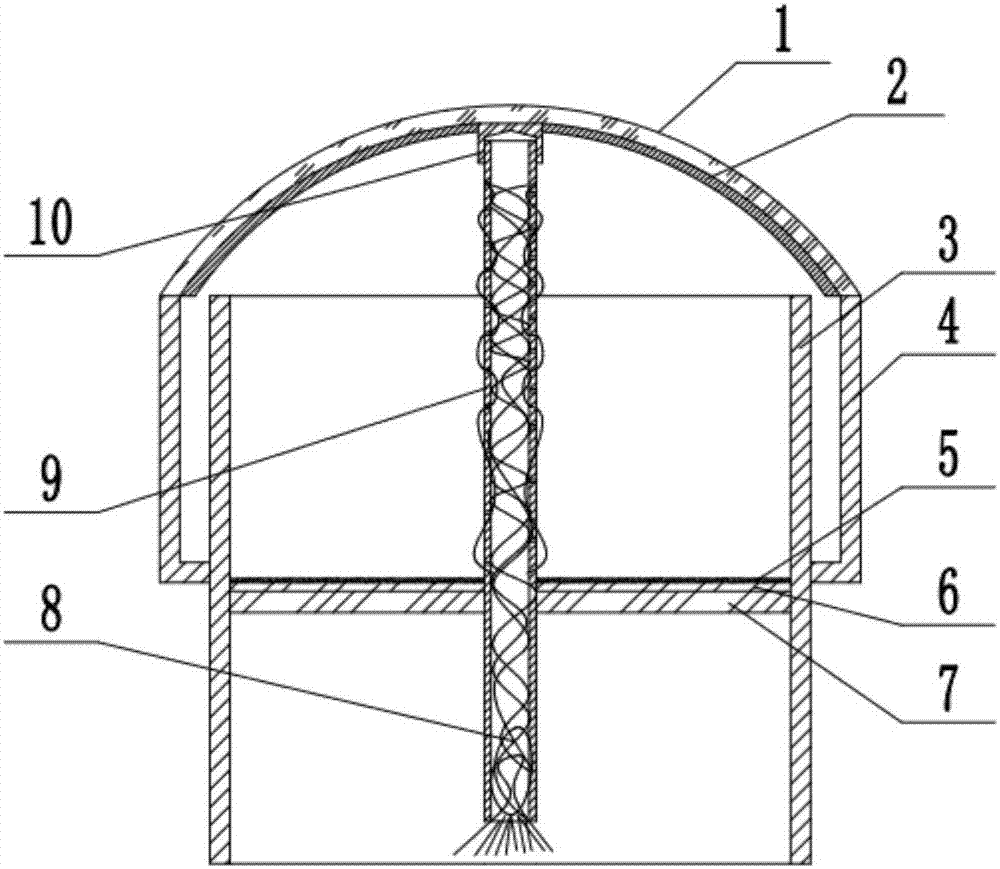

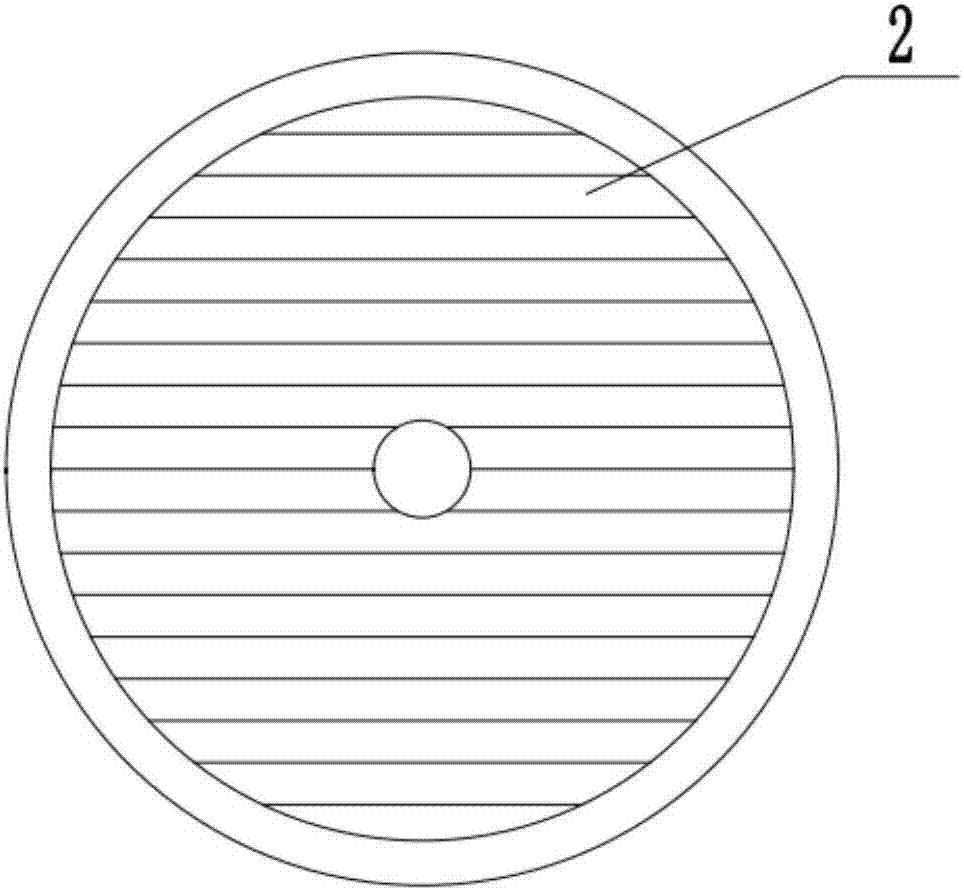

Seawater desalination device

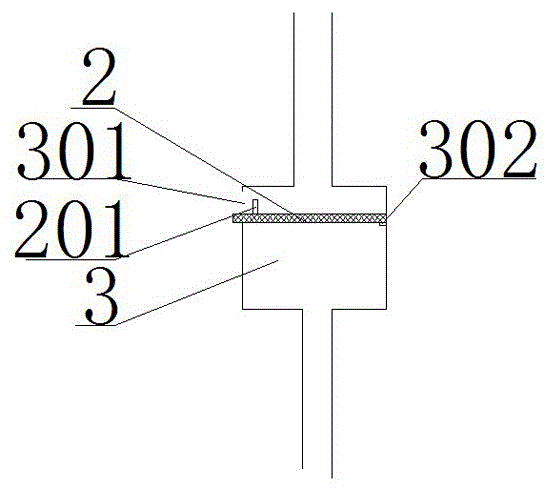

PendingCN106892476AEasy to disassembleEasy to cleanGeneral water supply conservationSeawater treatmentInterference fitFiber

The invention discloses a seawater desalination device which is mainly composed of a light-pervious heat-insulating cover, a seawater storage tank, a fresh water collection tank, a light-absorbing resin layer, a graphene layer, a heat-conducting silicon wafer, water delivery fiber, a hollow copper pipe with holes in the surface and an internal threaded ring. The light-pervious heat-insulating cover is connected to the fresh water collection tank through a hinge, the graphene layer deposits on the heat-conducting silicon wafer to form a graphene plate, the light-absorbing resin layer is coated on the graphene plate, the graphene plate is fixed in the middle of the seawater storage tank through interference fit, the hollow copper pipe with the holes in the surface is connected with the internal threaded ring through a thread, the internal threaded ring is welded on the light-pervious heat-insulating cover, the water delivery fiber is wound on the hollow copper pipe in an inside-outside alternating manner, and the other end of the fiber is soaked in seawater. The seawater desalination device is simple in structure, seawater can be delivered to an evaporation end by utilizing capillary principles of the high-performance water delivery fiber, and evaporation of water is accelerated by applying high specific surface area of the fiber, so that seawater desalination efficiency can be improved greatly.

Owner:BEIJING UNIV OF CHEM TECH

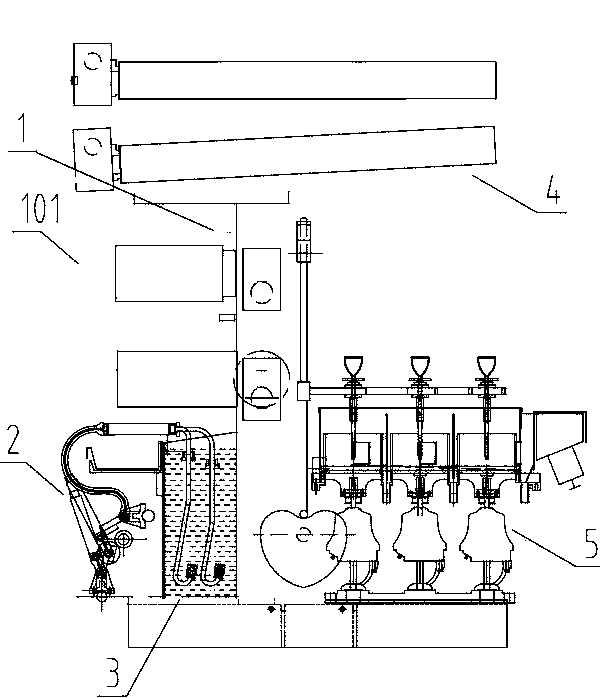

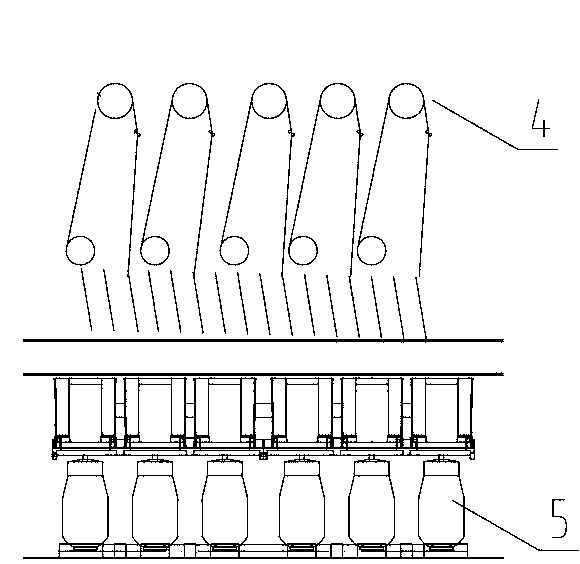

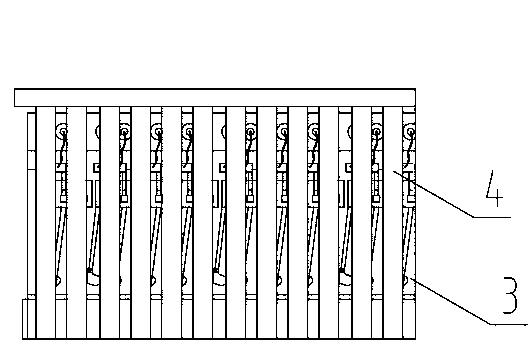

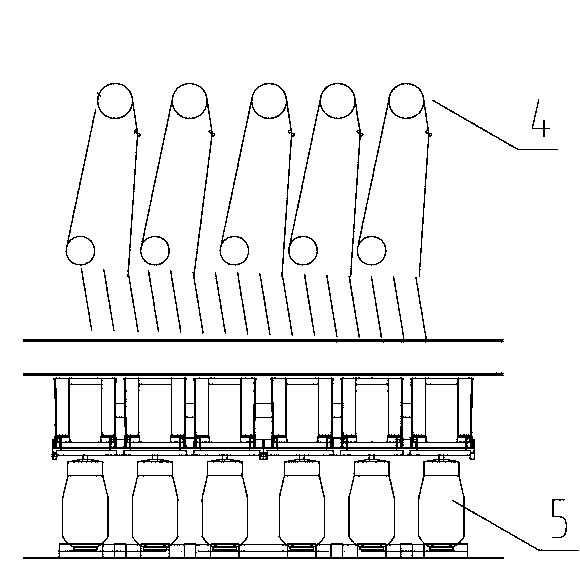

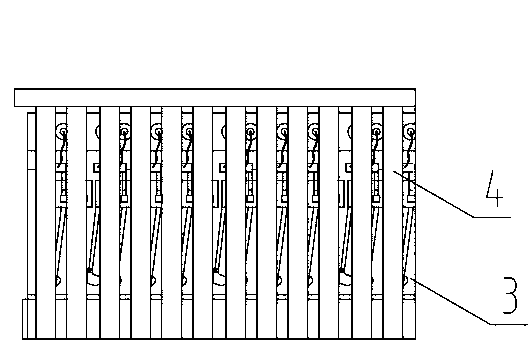

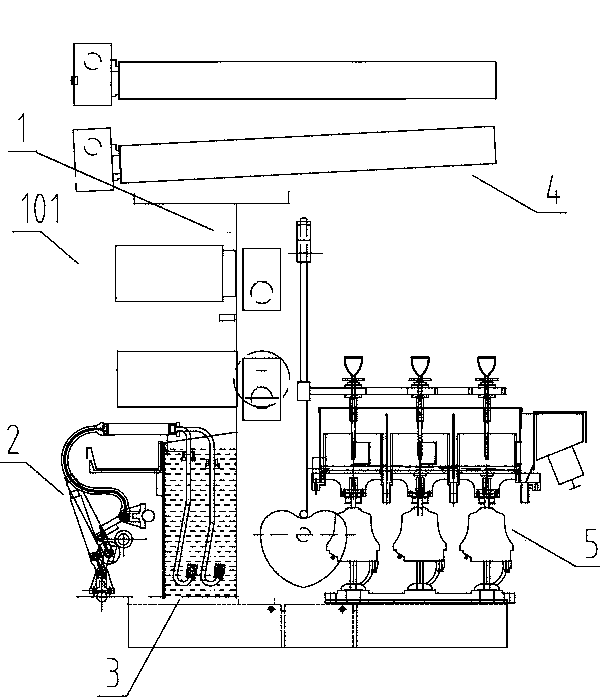

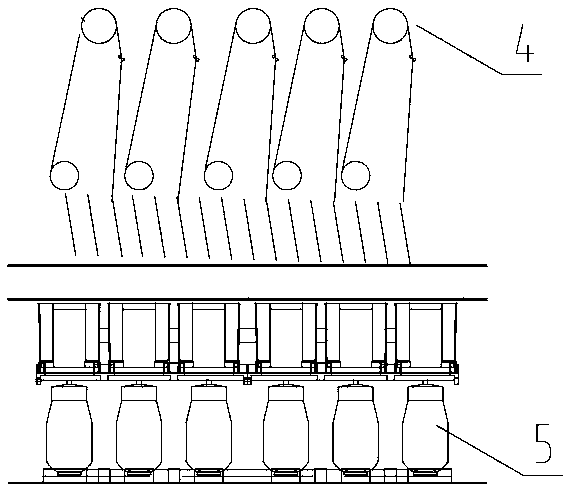

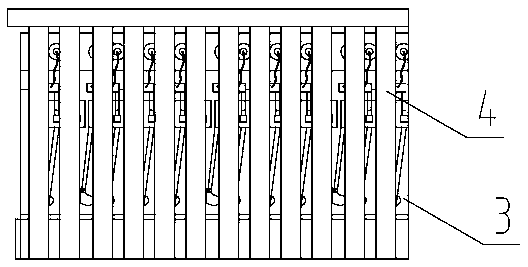

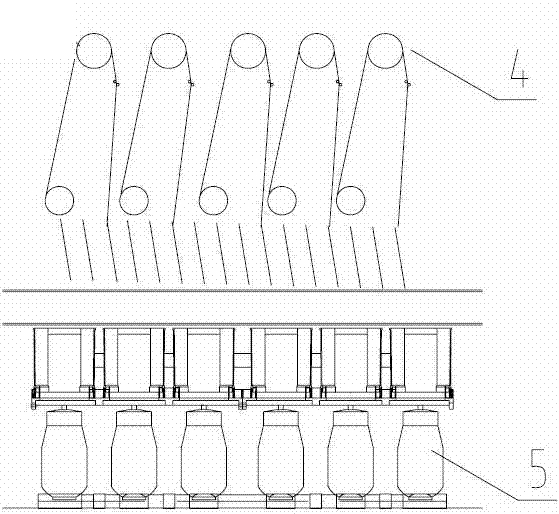

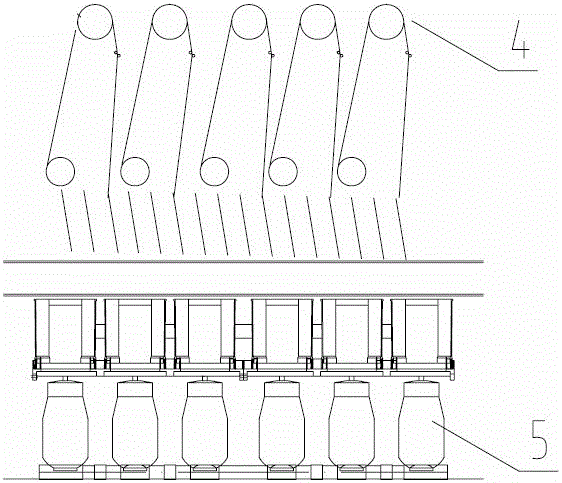

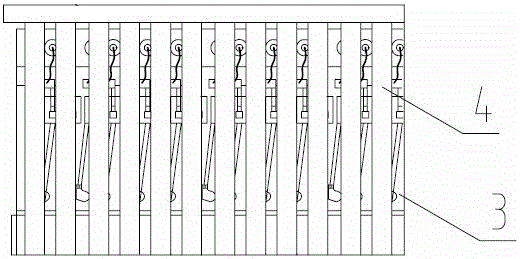

Spinning technology of a spinning machine

InactiveCN103643310AWind evenlySteady rotationArtificial filaments from viscoseWet spinning methodsSpinningControl system

The invention relates to a spinning technology of a spinning machine. The spinning technology of the spinning machine comprises the steps of glue supply, silk forming, spinning and winding. The forming portion of each winding device used in the step of winding is located outside an area between two side wall plates of a machine frame and is located on the other side opposite to a spinning face. Each winding device comprises a wet disk-shaped winding device, and / or a wet cylindrical winding device and / or a wet twisted winding device. Wet silk obtained after the step of glue supply, the step of silk forming and the step of spinning is wound through the winding devices, so that wet cylindrical silk and / or wet twisted silk and / or wet disk-shaped silk are / is formed. The winding devices are arranged externally, so that the corrosion of the silk, the winding devices and a control system of the winding devices is small in an acid environment, maintenance is convenient, and manual operation is convenient. Due to the fact that an existing centrifugal cylinder needs high-speed rotation, energy consumption is large. The winding devices adopted by the spinning machine just needs to meet the requirement for the speed of spinning rollers, no other energy consumption is needed, and therefore the overall power of the spinning machine is low.

Owner:YIBIN GRACE GROUP CO LTD +1

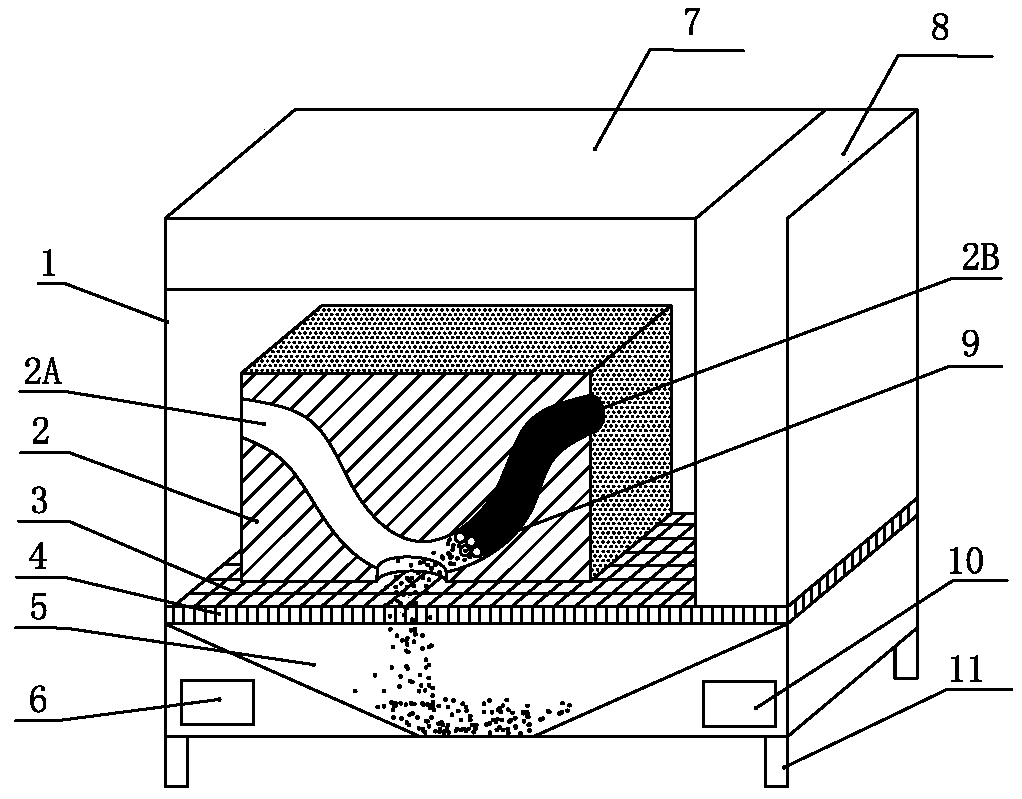

Device and method for removing redundant sand of 3D printing sand mould in magnetic control vibration mode

PendingCN108213341ARealize sand cleaningAutomate cleaningAdditive manufacturing apparatusFoundry mouldsSurface layerEngineering

The invention relates to technologies for clearing away redundant sand at a mould cavity portion of a 3D printing sand mould, in particular to a device and method for removing redundant sand of the 3Dprinting sand mould in a magnetic control vibration mode. The device for removing redundant sand of the 3D printing sand mould in the magnetic control vibration mode comprises a box; a supporting frame for storing the 3D printing sand mould is arranged in the box; a sand collecting device is arranged on the lower side of the supporting frame; the top and the side portion of at least one side of the box are provided with winding coils for generating an alternating magnetic field; a plurality of sand removing particles made of a magnetic material are arranged in the box; and under the action ofthe alternating magnetic field, the sand removing particles vibrate to impact the redundant sand of the 3D printing sand mould off gradually from the surface layer of the sand mould so that the mouldcavity of the sand mould can be formed, and the redundant sand is collected by the sand collecting device. According to the device, the alternating magnetic field is generated through the winding coils to control the sand removing medium particles made of the magnetic material to vibrate at a high frequency to impact the redundant sand in the mould cavity off layer by layer, and the efficiency and automation level of sand removing are greatly improved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Household waste water recycling device

InactiveCN104988964ACutting costsSimple structureDomestic plumbingWater supply installationWater savingFiltration

A household waste water recycling device comprises a water collecting tank, a connecting pipe and a water storing tank. The water storing tank is arranged below the water collecting tank. The connecting pipe is communicated with the water collecting tank and the water storing tank. A filtering device used for performing preliminary filtration, a U-shaped bend used for preventing odors and a spherical filtering bag used for removing water foam are further arranged on the connecting pipe. The filtering device is installed on the portion, on the outlet of the water collecting tank, of the connecting pipe. The spherical filtering bag is arranged in the water storing tank and connected with the tail end of the connecting pipe. The U-shaped bend is arranged on the portion, between the filtering device and the spherical filtering bag, of the connecting pipe. The filtering device comprises a box body and a filter screen arranged in the box body. The household waste water recycling device is simple in structure and reasonable in design, no other energy is consumed, waste water is recycled only through the gravity of the water, and popularization is convenient; besides, cost is low, and not only is water saved, but also family expenses are reduced.

Owner:HENAN UNIV OF SCI & TECH

Spinning process suitable for spinning machine with external winding device

InactiveCN103603073ALess corrosiveEasy to operateNew-spun product collectionSpinning head liquid feederYarnProcess engineering

The invention relates to a spinning process suitable for a spinning machine with an external winding device. The process comprises adhesive metering and supplying, filtering before spinning, silver forming, spinning and winding, wherein the moisture content of wet cake yarns or wet barrel yarns or wet twisted yarns in the winding process is 30-80%. The spinning process aims at the specific spinning machine with the external winding device, under the mutual action of all the processes and the control of process parameters, silvers can be wound into the wet cake yarns and / or the wet barrel yarns and / or the wet twisted yarns in the external winding device, the wet cake yarns, the wet barrel yarns and the wet twisted yarns can be directly used for yarn twisting, it is guaranteed that the spinning machine can reach high spinning speed, meanwhile, product quality can also be guaranteed, especially the silvers cannot be contaminated by water washing, acid liquor removal and falling oil in the winding process, a subsequent dyeing process is guaranteed, the worker operation is more convenient and easier, equipment maintenance is easier, energy consumption is lowered, production efficiency is effectively improved, and meanwhile product cost is greatly lowered.

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning process of spinning machine with novel single-spindle passive winding device

InactiveCN103628153ADip wellPrevent splashNew-spun product collectionArtificial thread manufacturing machinesControl systemEngineering

The invention relates to a spinning process of a spinning machine with a novel single-spindle passive winding device, and the process comprises the steps of adhesive feeding, filament forming, spinning and winding. The forming parts of the winding device are arranged on the outer side of an area between wall panels on both sides of a frame and on the other side which is opposite to a spinning surface; the winding device is the novel single-spindle passive winding device; due to the external winding device, the corrosion to filaments, the winding equipment and a control system thereof is low in an acid environment, so that the repair and the operation of a worker are convenient; due to the fact an existing centrifugal cylinder rotates at high speed, the energy consumption is high, while the winding device only needs to reach the speed of spinning rolls, no other energy is consumed, so the power of the whole machine is low.

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning process of spinning machine with active winding device

InactiveCN103628156APrevent splashEasy to cleanNew-spun product collectionArtificial thread manufacturing machinesPhysicsWall plate

The invention relates to a spinning process of a spinning machine with an active winding device, and the process comprises the steps of adhesive feeding, filament forming, spinning and winding. The forming parts of the winding device are arranged on the outer side of an area between wall panels on both sides of a frame and on the other side which is opposite to a spinning surface; the winding device is the active winding device; due to the external winding device, the corrosion to filaments, the winding equipment and a control system thereof is low in an acid environment, so that the repair and the operation of a worker are convenient; due to the fact an existing centrifugal cylinder rotates at high speed, the energy consumption is high, while the winding device only needs to reach the speed of spinning rolls, no other energy is consumed, so the power of the whole machine is low.

Owner:YIBIN GRACE GROUP CO LTD +1

Process and device for generating power by pressure energy of small natural gas pipeline network

InactiveCN103422899BLeak will notSolve the problem that cannot be explosion-proofSealing arrangements for enginesMachines/enginesGas cylinderEngineering

The invention discloses a process and a device for generating power by pressure energy of a small natural gas pipeline network. A high-pressure pipeline network of the device is connected with a gas inlet of an expansion machine through a pipeline; a gas outlet of the expansion machine is connected with a gas inlet of a temperature balancer through a pipeline; an outlet of the temperature balancer is connected with a low and medium-pressure gas pipeline network through a pipeline; a main shaft of the expansion machine is connected with a gearbox; the gearbox is connected with a power generator; the power generator is connected with a transformer synchronizer; the expansion machine adopts an improved AT15-65 type gas expansion machine; one end of the main shaft is connected with an air cylinder in a totally-closed way; a first seal ring and a second seal ring, which have sealing effects, are arranged between the other end of the main shaft and a wheel drum; a flow guide pipe is arranged in a closed cavity between the two seal rings; the flow guide pipe is connected with an inert gas bottle. The device can be used for continuously and stably providing a 220 V / 380 V stable power supply for an interruptible and closed 1-5 kW low-power user.

Owner:SOUTH CHINA UNIV OF TECH +1

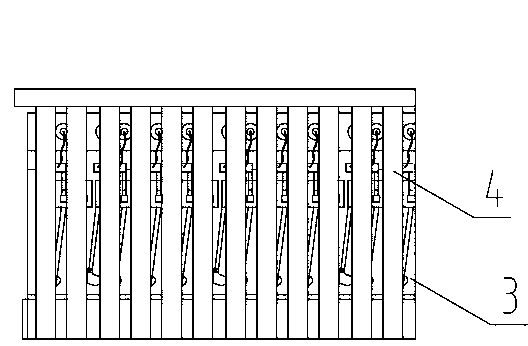

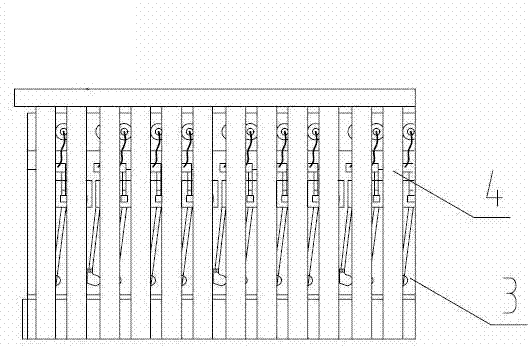

Spinning technology of spinning machine provided with a single spindle passive winding device

InactiveCN103643323ALess corrosiveLow powerNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning technology of a spinning machine provided with a single spindle passive winding device. The spinning technology comprises the steps of glue feeding, strand forming, spinning and winding. The forming part of the winding device is located on the outer side of the area between the two side wall plates of a rack and the other side opposite to a spinning surface, and the winding device is the single spindle passive winding device. Due to the fact that the winding device is arranged externally, corrosivity to strands, to the winding device and to a control system of the winding device is small under an acid environment, and maintenance and worker operation are convenient to carry out; due to the fact that an existing centrifugal cylinder needs to rotate at a high speed, energy consumption is high, the winding device only needs to meet the speed of spinning rollers, no other energy consumption is needed, and therefore the total power is small.

Owner:YIBIN GRACE GROUP CO LTD +1

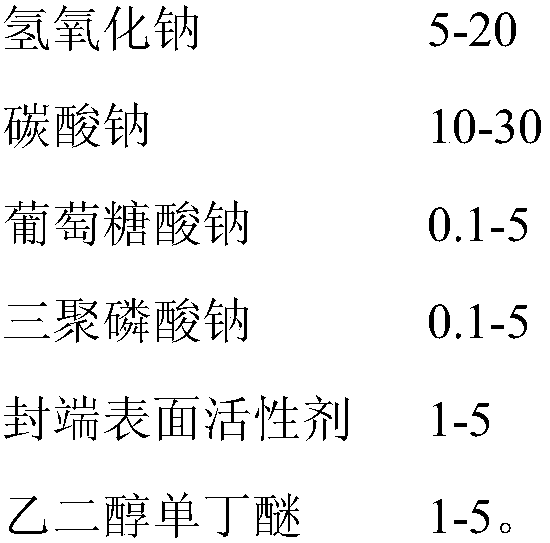

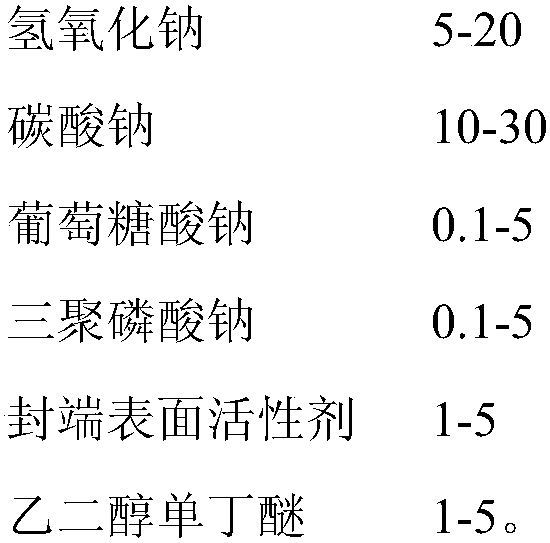

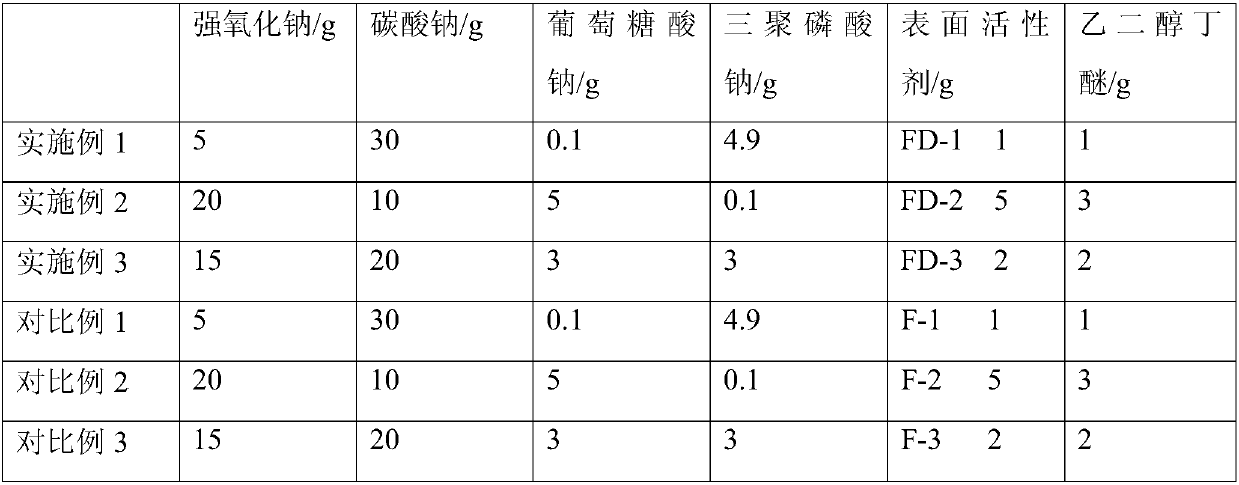

Stability-improved powdery metal degreasing agent

InactiveCN107587144AGood alkali resistanceHas the effect of dissolving oil stainsEtherSurface-active agents

A stable powdery metal degreasing agent is successfully developed in the invention. A surfactant is chemically modified to generate a new terminated surfactant, and the new terminated surfactant is used to prepare the powdery metal degreasing agent in order to improve the stability of the surfactant in the powdery degreasing agent in a strong alkali system. The powdery degreasing agent comprises,by weight, 5-20 parts of sodium hydroxide, 10-30 parts of sodium carbonate, 0.1-5 parts of sodium gluconate, 0.1-5 parts of sodium tripolyphosphate, 1-5 parts of the terminated surfactant and 1-5 parts of ethylene glycol monobutyl ether.

Owner:合肥普庆新材料科技有限公司

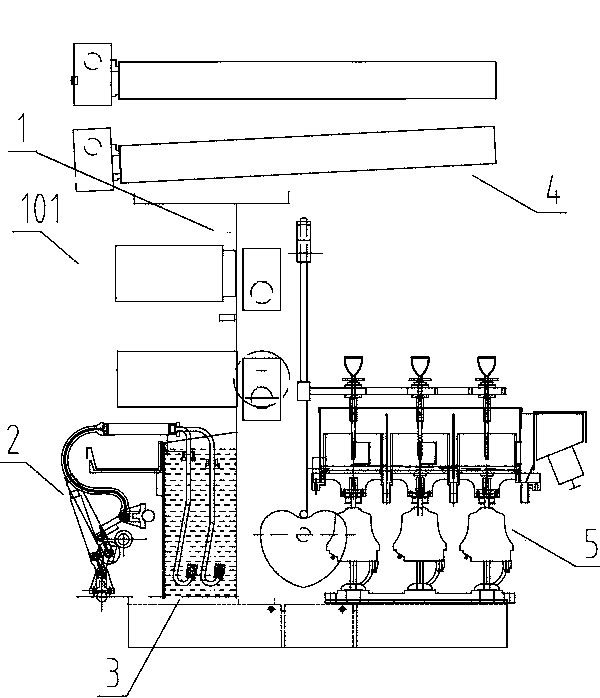

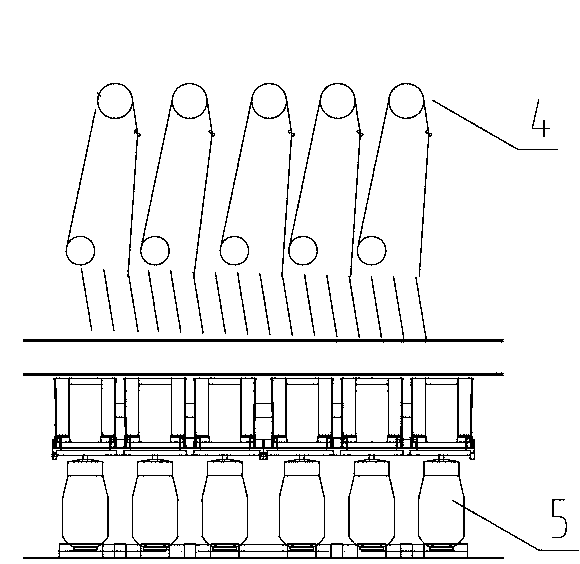

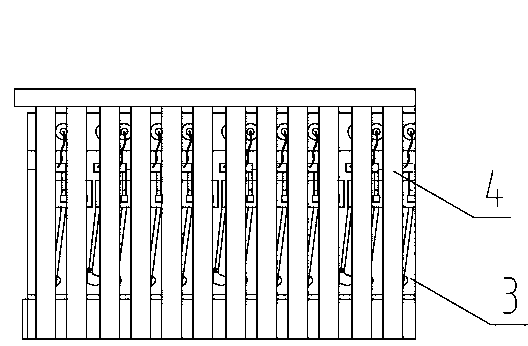

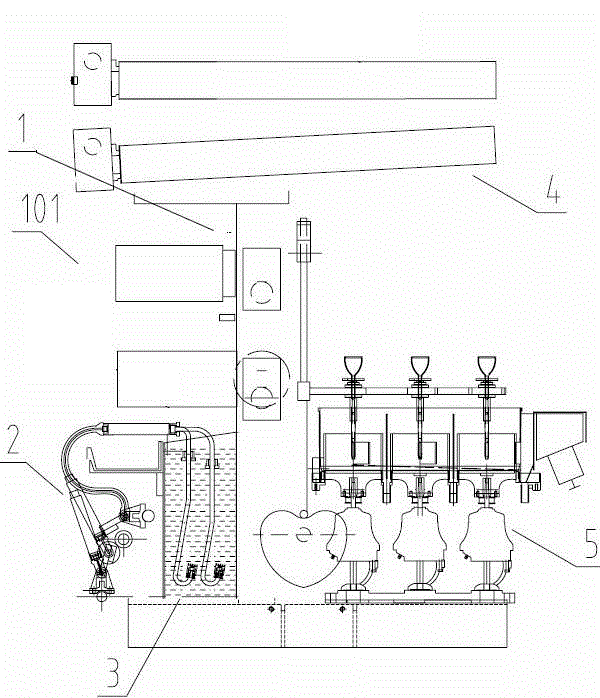

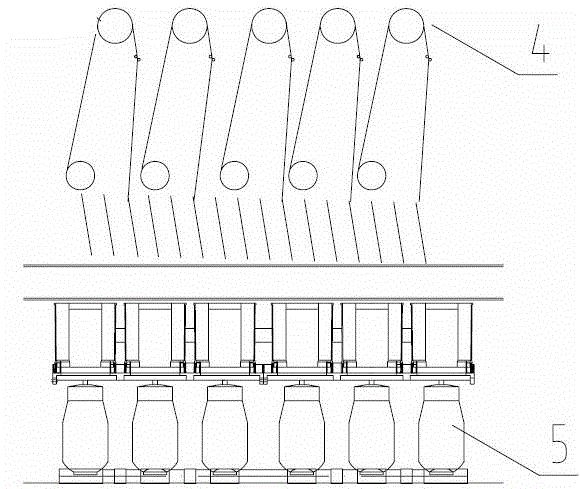

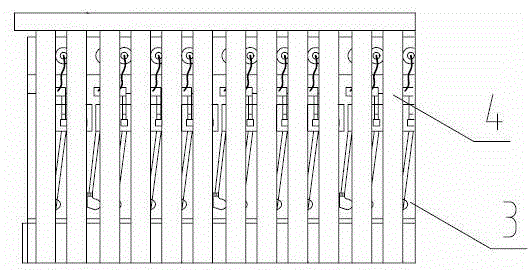

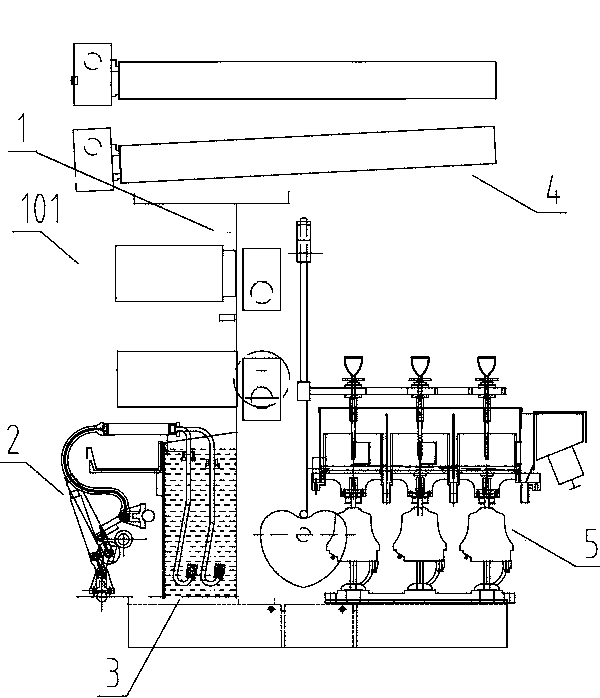

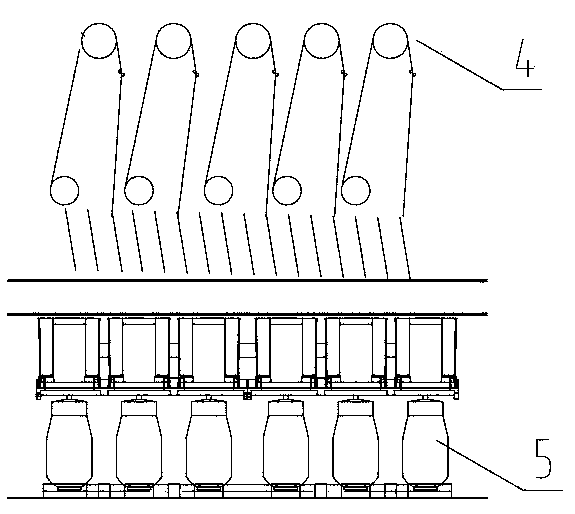

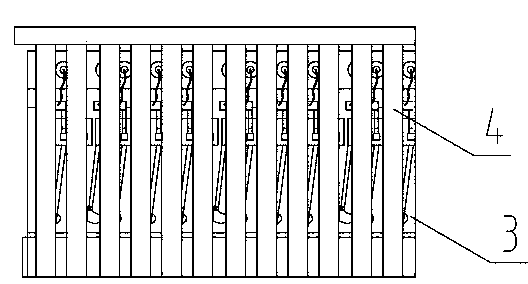

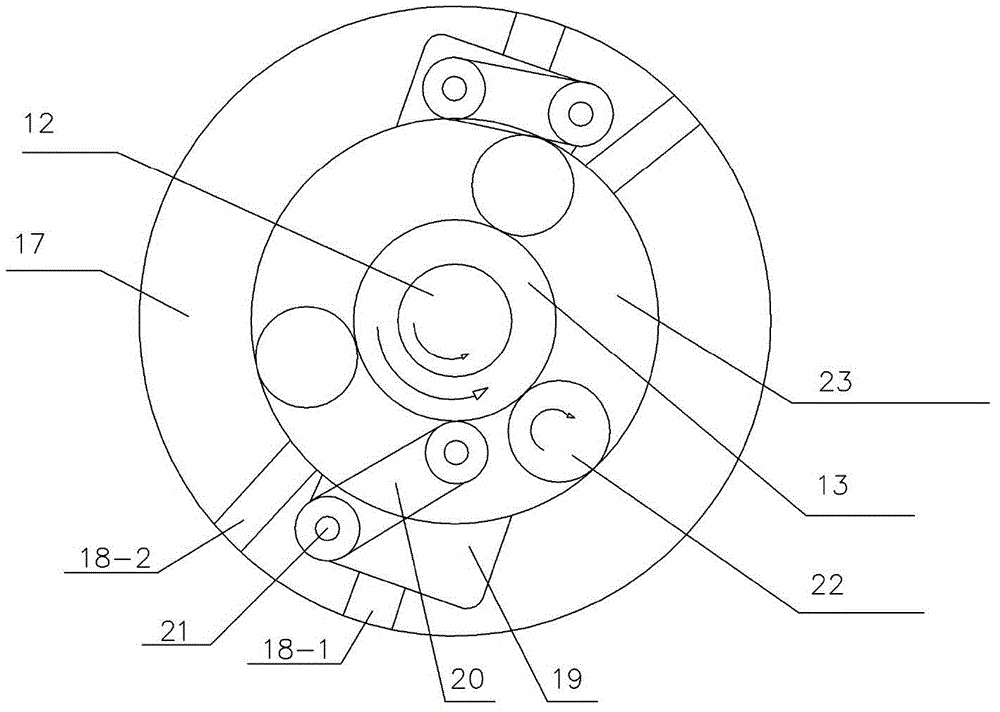

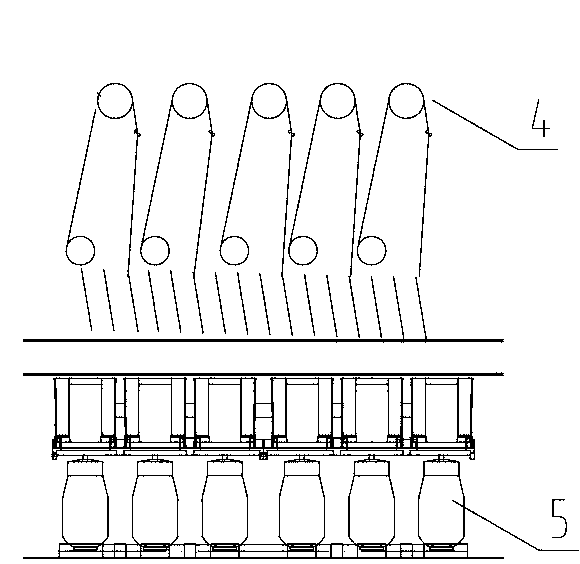

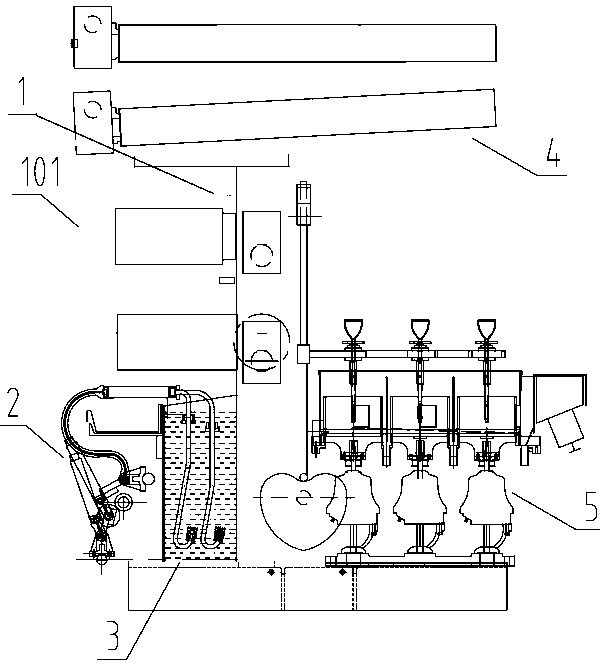

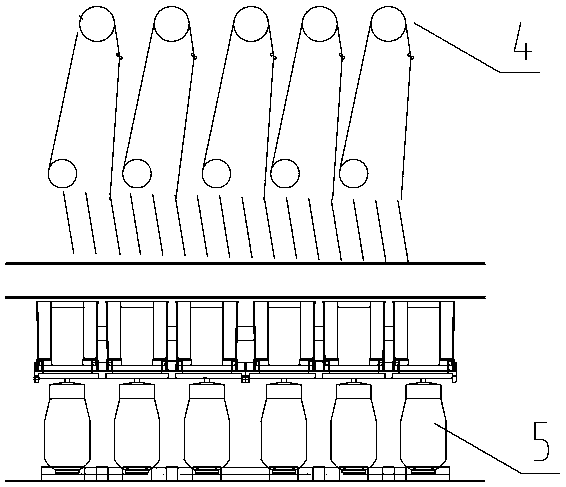

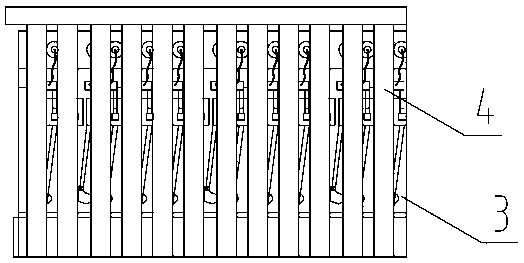

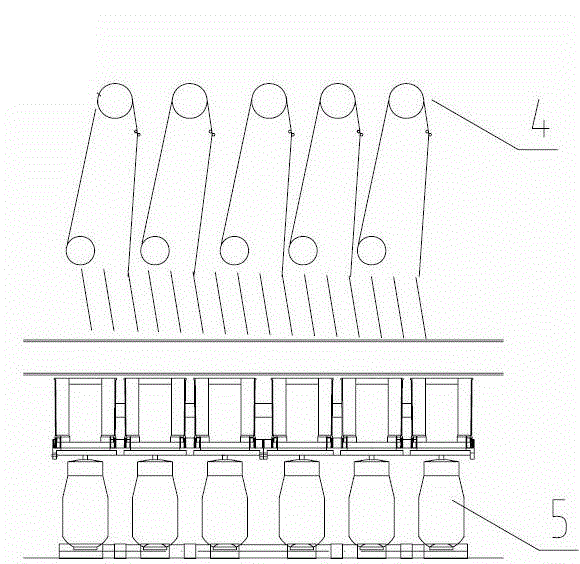

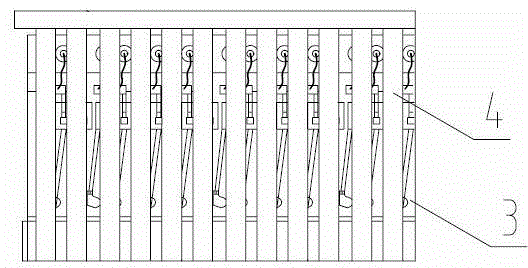

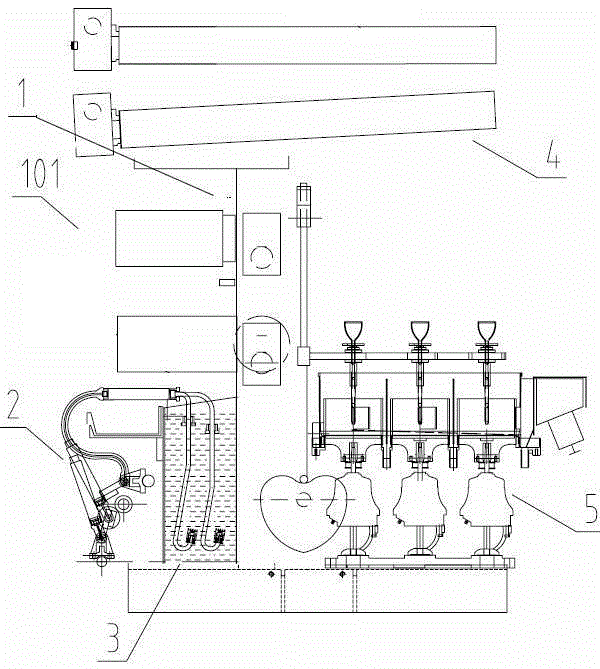

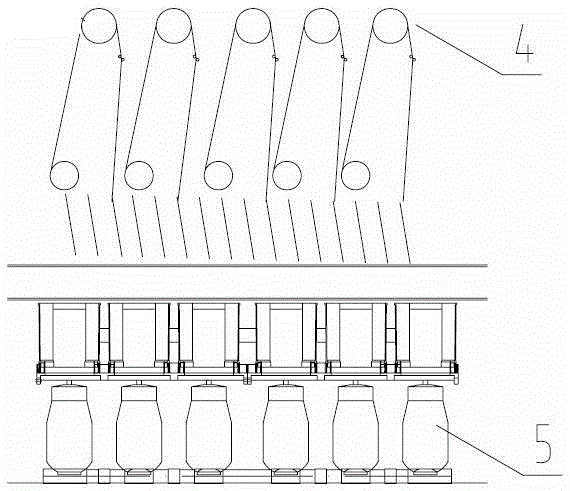

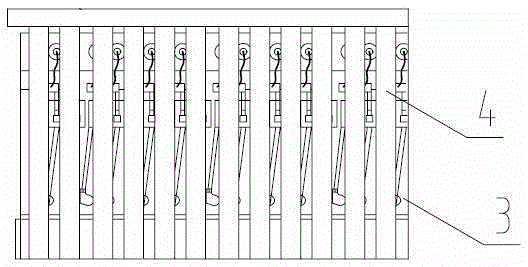

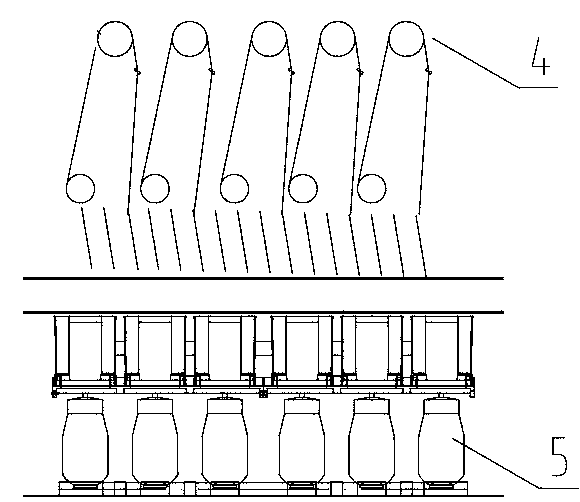

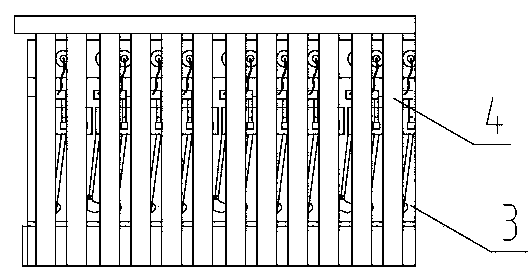

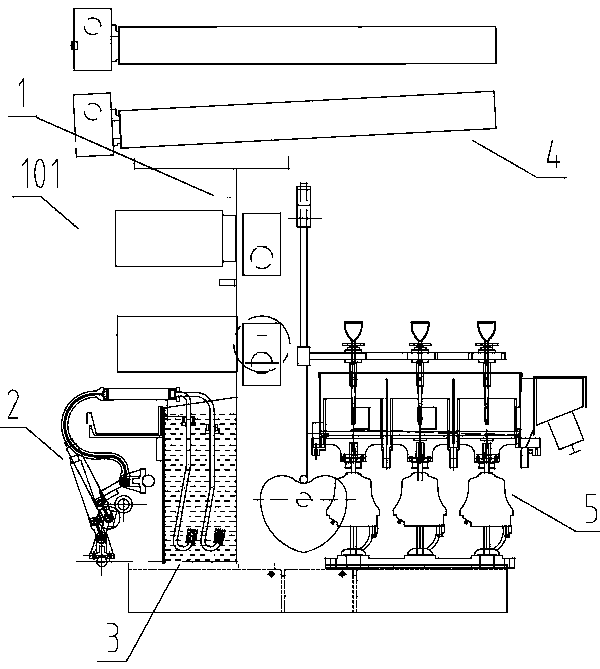

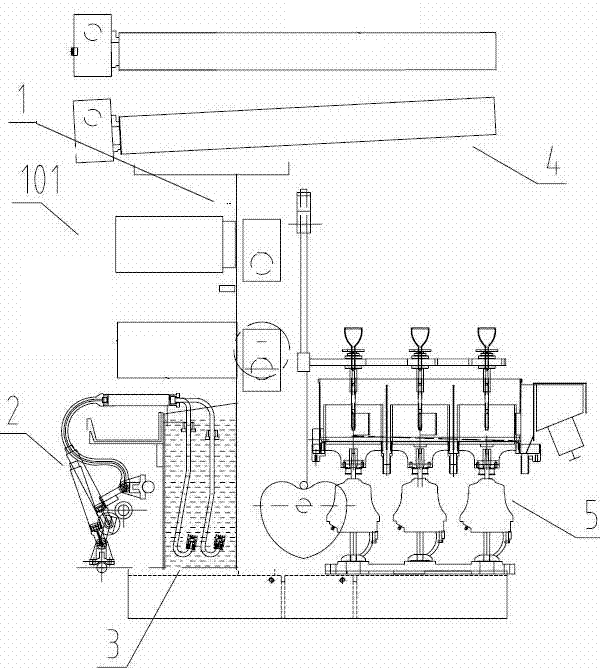

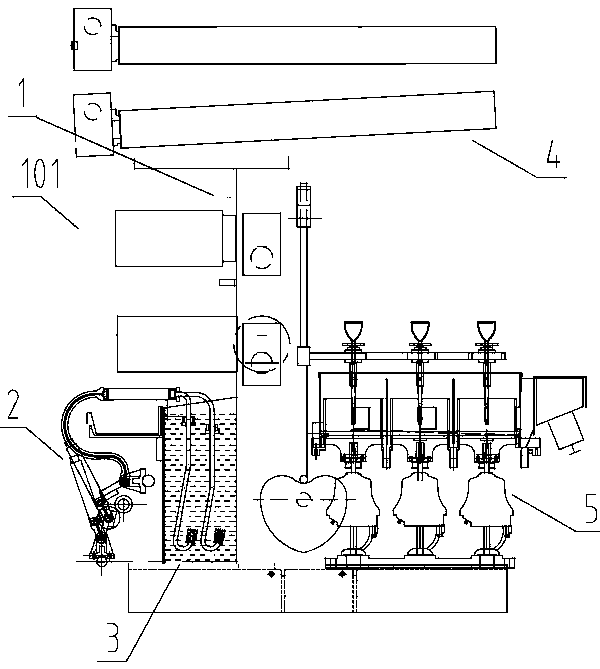

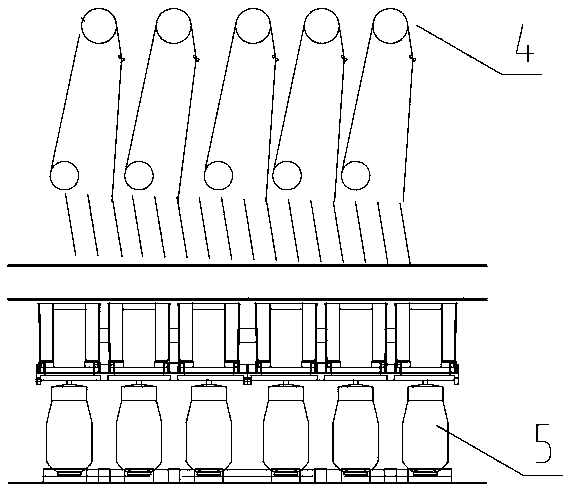

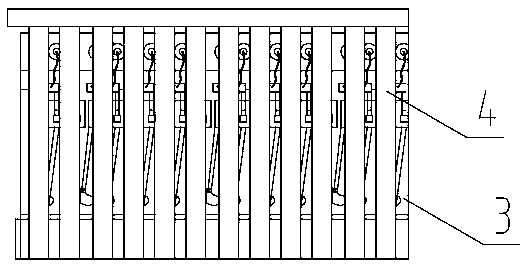

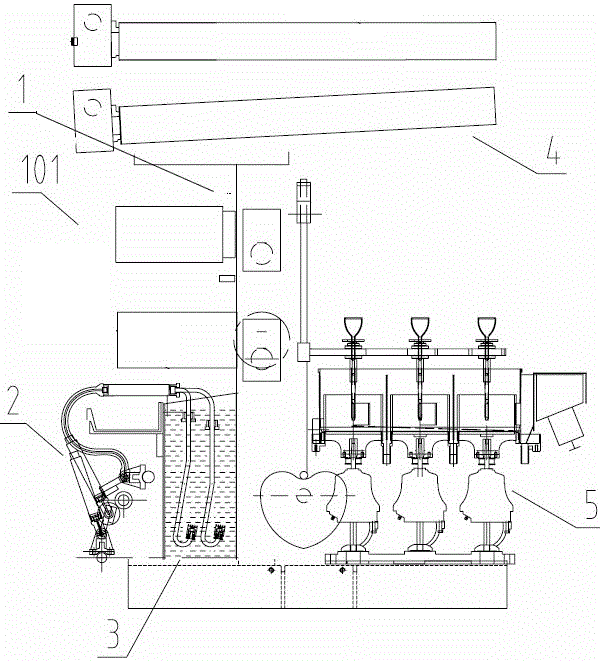

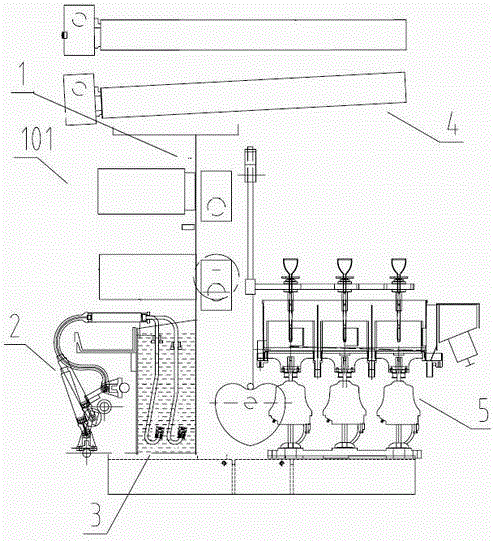

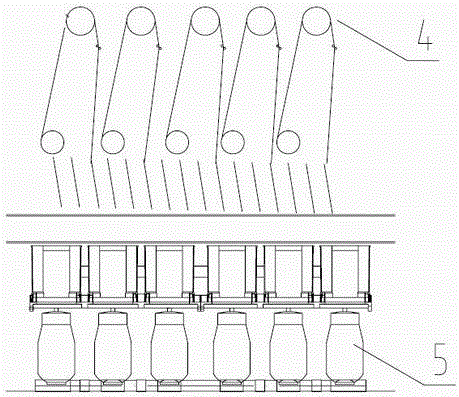

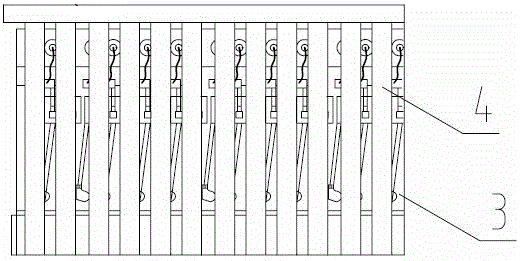

Spinning machine

InactiveCN103628163AWind evenlySteady rotationNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The utility model relates to spinning equipment, in particular to a spinning machine. The spinning machine comprises a stander, glue supply devices, strip forming devices, spinning devices and winding devices, wherein forming parts of the winding devices are positioned on the outer side of a region between wall plates on two sides of the stander; two ends of spinning rollers are fixed; the winding devices comprise wet cake winding devices and / or wet barrel winding devices and / or wet strand winding devices. The winding devices of the spinning machine are arranged outside, so that the corrosion to strips, the winding equipment and a control system of the winding equipment is low under an acidic environment, and maintenance and manual operation are facilitated; the conventional centrifugal cylinder needs to rotate at high speed, so that the energy consumption is high; however, the winding devices of the spinning machine only need to meet the speeds of the spinning rollers, and other energy consumption is zero, so that the whole spinning machine is low in power.

Owner:YIBIN GRACE GROUP CO LTD +1

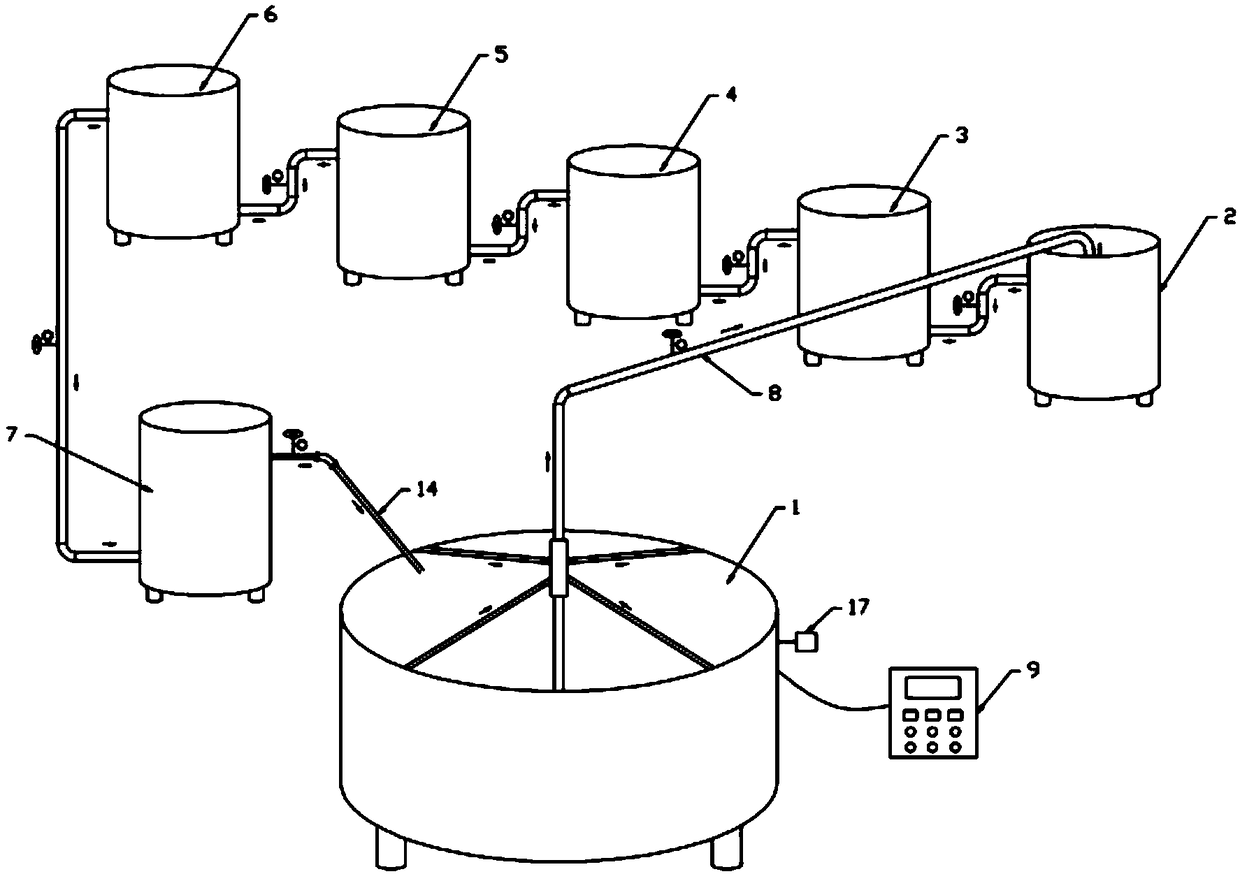

Cyclic ecological fish culture equipment

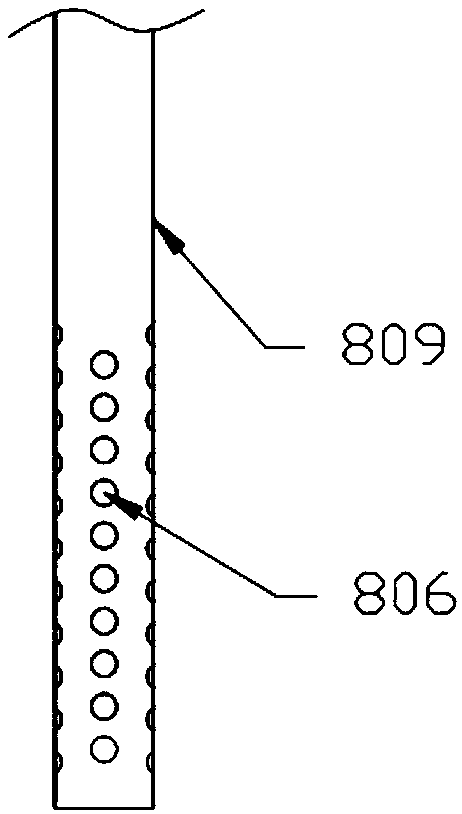

PendingCN109430151AImprove stabilityNo other energy consumptionPisciculture and aquariaControl modelsEngineering

The invention provides cyclic ecological fish culture equipment which comprises a fishpond and a settling pond. The cyclic ecological fish culture equipment is characterized in that a drainage deviceis arranged in the fishpond which is connected with the settling pond through the drainage device, the drainage device comprises a plurality of first drainage pipes arranged on the inner wall of the fishpond and a second drainage pipe arranged at the center of the fishpond, and one ends, close to the bottom of the fishpond, of each first drainage pipe and the second drainage pipe are provided witha first water absorbing section and a second water absorbing section respectively; each first water absorbing section comprises a plurality of first through holes, the second water absorbing sectioncomprises a plurality of second through holes, diameter of the first through holes is greater than that of the second through holes, and the lowest water level of the fishpond is higher than the highest water level of the settling pond. A closed cyclic control model is adopted for the whole system, and no waste and wastewater are discharged from all ponds, so that zero environment pollution is realized, and the cyclic ecological fish culture equipment is environment-friendly and simple in structure.

Owner:河北增硕农业技术开发有限公司

A spinning process of a spinning machine provided with a three-spindle passive winding device

InactiveCN103643322BEasy to operateImprove quality controlNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning process of a spinning machine provided with three passive winding devices. Including glue supply, thread forming, spinning and winding, the forming part of the winding device is located outside the area between the wallboards on both sides of the frame, on the other side opposite to the spinning surface, and the winding The winding device is a three-spindle passive winding device. Since the winding device of the present invention is externally installed, it is less corrosive to the thread, winding equipment and its control system in an acidic environment, and is convenient for maintenance and worker operation. The existing centrifugal cylinder needs to rotate at high speed, so the energy consumption is high, but the winding device of the present invention only needs to meet the speed of the spinning roller, without other energy consumption, so the power of the whole machine is small.

Owner:YIBIN GRACE GROUP CO LTD +1

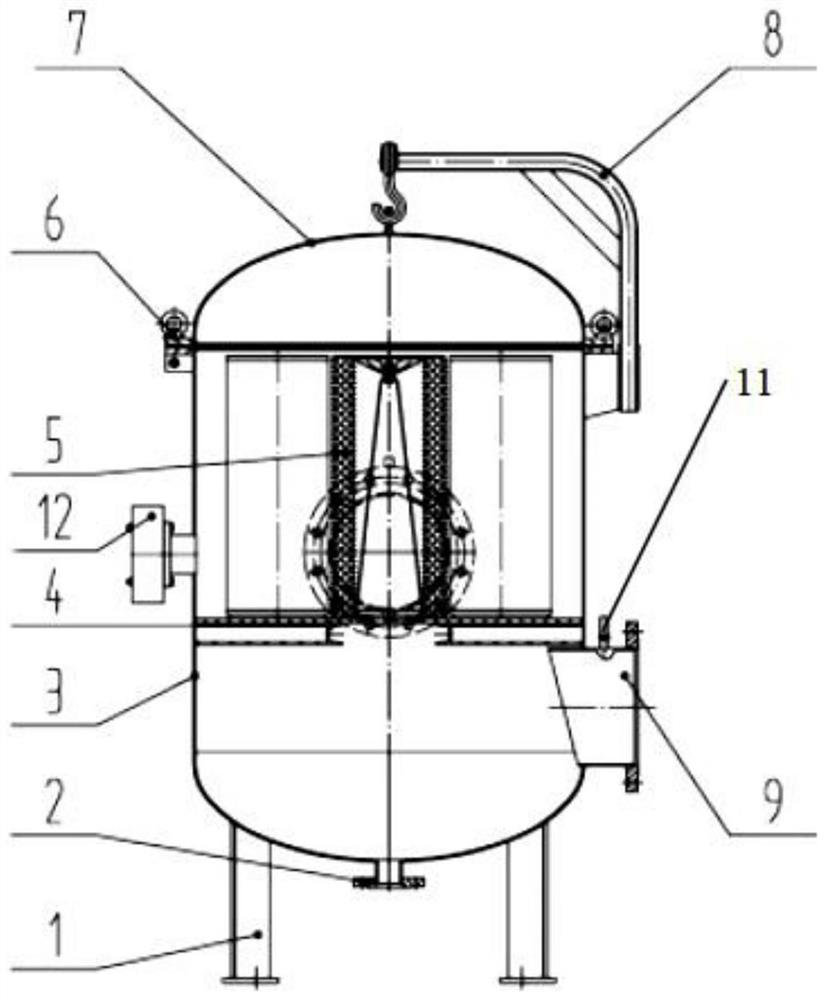

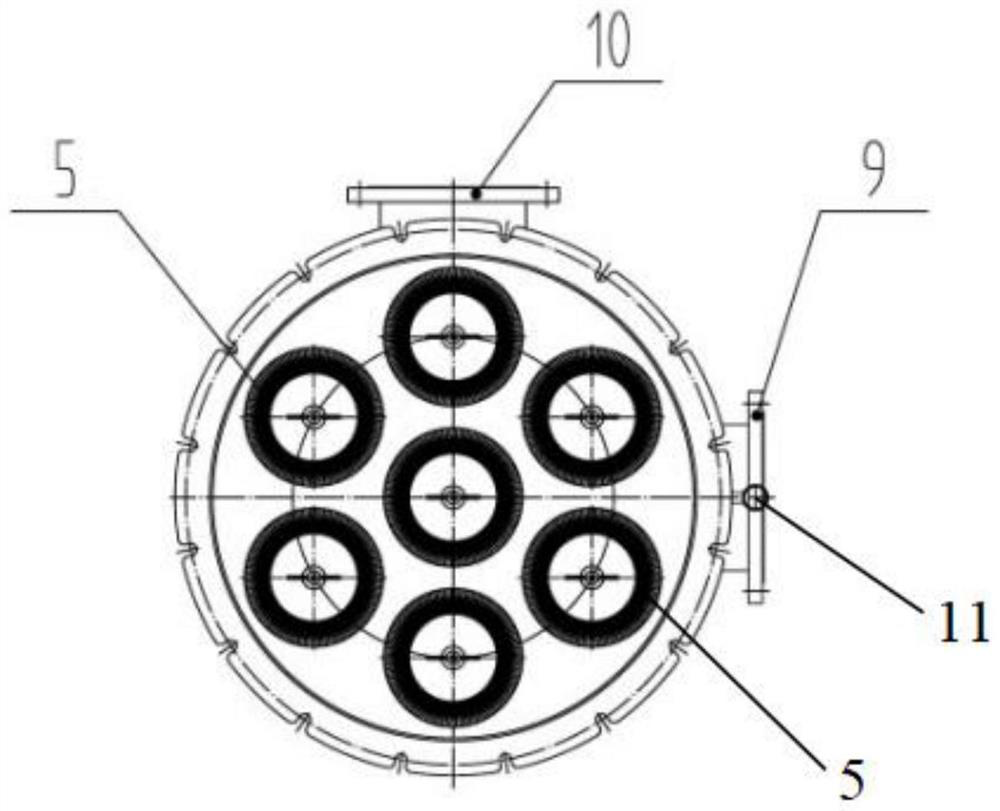

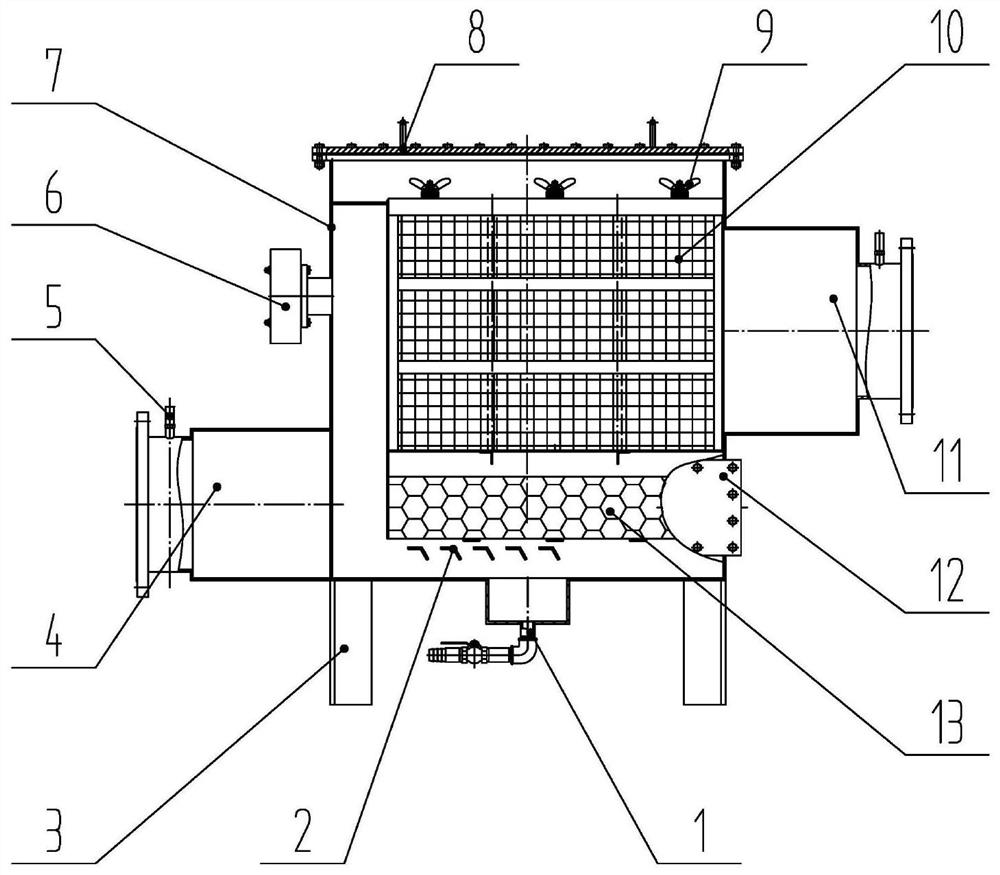

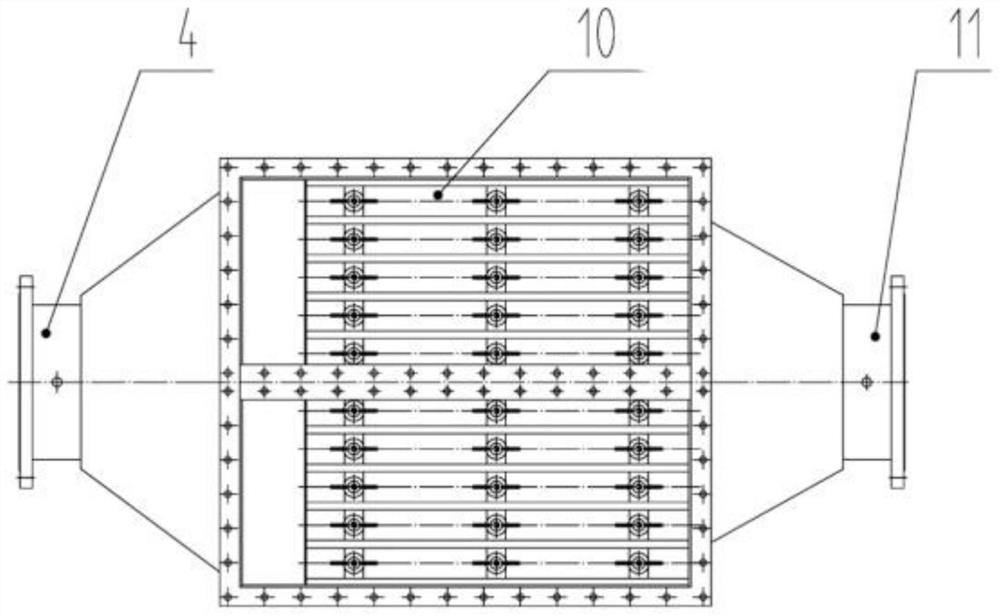

Gas dust removal device

InactiveCN111603860ALarge filter areaWide range of filtration accuracyDispersed particle filtrationGaseous fuelsDust controlEngineering

The invention discloses a gas dust removal device. The device comprises a shell, fixing bolts, a sealing plate used for sealing an upper opening of the shell and a support arranged at the bottom and used for supporting the shell, and the sealing plate is fixedly sealed to the upper opening of the shell through the fixing bolts; the shell is cylindrical, a bracket is further arranged in the shell,the interior of the shell is divided into an upper space and a lower space by the bracket, and a through hole is further formed in the bracket; a filter element is further arranged in the upper spacein the shell; and the filter element is detachably communicated to the bracket. The device is installed in front of a generator set, plays a role in fine filtering, is large in filtering area and small in pressure drop, is suitable for filtering gas with large gas amount and high filtering precision requirements, and is simple in structure, convenient to install and capable of saving cost.

Owner:西安科美动力科技有限公司

Spinning technology suitable for spinning machine with winding device externally arranged

InactiveCN103603077ALess corrosiveEasy to operateNew-spun product collectionSpinning head liquid feederSpinningViscose

The invention relates to a spinning technology suitable for a spinning machine with a winding device externally arranged. The spinning technology suitable for the spinning machine with the winding device externally arranged comprises the procedures of mucilage glue metering and supplying, filtering before spinning, silk forming, spinning and winding. The spinning technology aims at specific spinning machines with the winding device externally arranged, under the mutual action of all the procedures and the control of technological parameters, the fact that silk can be wound into wet-state cake packed silk and / or wet-state barrel packed silk and / or wet-state twisting packed silk which can be used for thread twisting directly in the externally arranged winding device can be achieved, the product quality can be guaranteed when the spinning machine reaches high spinning speed, and especially the silk cannot be polluted due to acid liquor removing by water cleaning and drippage of oiling agents in the final winding and forming procedure, a subsequent dyeing process is guaranteed, operation of workers is easier and more convenient, equipment is easier to maintain, energy consumption is lowered, production efficiency is improved effectively, and cost of products is lowered greatly.

Owner:YIBIN GRACE GROUP CO LTD +1

Suitable for spinning process of spinning machine with external winding device

InactiveCN103603077BLess corrosiveEasy to operateNew-spun product collectionSpinning head liquid feederConductor CoilMechanical engineering

Owner:YIBIN GRACE GROUP CO LTD +1

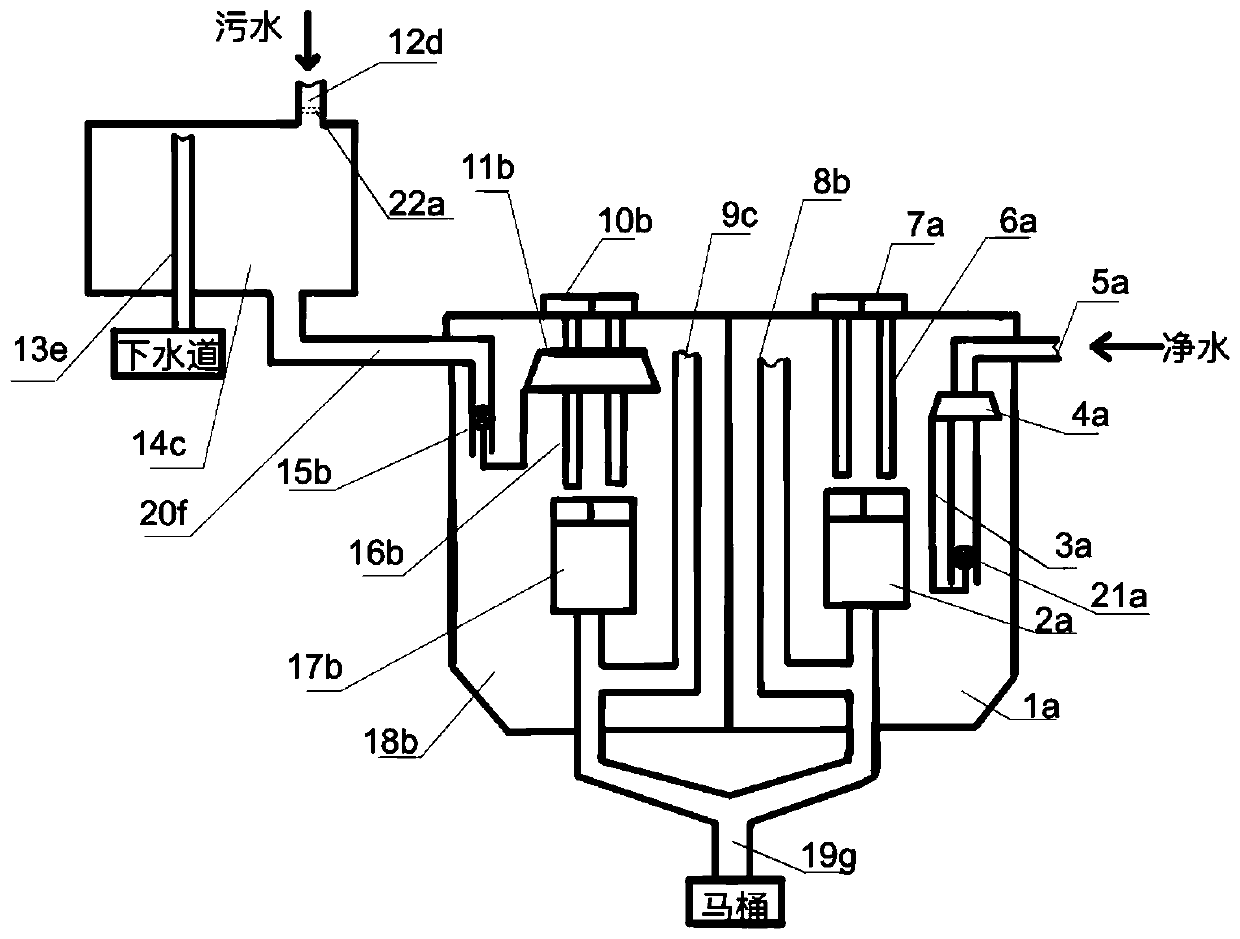

Water-saving water tank utilizing domestic sewage

PendingCN110607826ALarge water storage capacitySimple structureFlushing devicesWater supply installationWater savingSewage

The invention discloses a water-saving water tank utilizing domestic sewage. The water-saving water tank is characterized in that the water tank is divided into two parts of a clear water tank and a sewage tank, the left side of the water tank is the sewage tank, and the right side of the water tank is the clear water tank. Sewage enters the sewage tank from a sewage storage tank on the left through a sewage inlet pipe after being filtered through a filter screen, when the sewage quantity reaches the limit water level of the sewage tank, a sewage tank flushing button rises to the highest point, a sewage inlet pipe valve is closed and the sewage is stopped from flowing into the sewage tank due to rising linkage of a float, at the moment, the sewage flushing button is in a state capable of being pressed, and the sewage flushing button is pressed down so that flushing can be realized. Clear water enters the clear water tank from a clear water pipe, when the water level of the clear watertank reaches the limiting water level, the clear water tank stops inflow of water, and during use, a clear water tank flushing button is pressed so that flushing can be realized. The water in the sewage tank and the water in the clear water tank which are higher than the limiting water level can both be discharged from respective overflow ports. According to the water-saving water tank utilizing domestic sewage in the invention, most sewage of a washing sink and a kitchen can be effectively utilized, and energy conservation and environmental protection are achieved.

Owner:XI AN JIAOTONG UNIV

Spinning technology of spinning machine provided with novel through going shaft passive winding device

InactiveCN103643327ALess corrosiveLow powerArtificial thread manufacturing machinesArtificial filaments from viscoseControl systemProcess engineering

The invention relates to a spinning technology of a spinning machine provided with a novel through going shaft passive winding device. The spinning technology comprises the steps of glue feeding, strand forming, spinning and winding. A forming part of the winding device is located on the outer side of the area between the two side wall plates of a rack and the other side opposite to a spinning surface, and the winding device is the novel through going shaft passive winding device. Due to the fact that the winding device is arranged externally, corrosivity on strands, on the winding device and on a control system thereof is small under an acid environment, and maintenance and worker operation are convenient to carry out; due to the fact that an existing centrifugal cylinder needs to rotate at a high speed, energy consumption is high, the winding device only needs to meet the speed of spinning rollers, no other energy consumption is needed, and therefore the total power is small.

Owner:YIBIN GRACE GROUP CO LTD +1

Water-saving flushing system

InactiveCN106337468AAchieve recyclingCutting costsLevel controlIndustrial water supply conservationWater savingWater storage tank

The invention discloses a water-saving flushing system which comprises a water storage tank, wherein the water storage tank is connected with an upstairs sewer pipe, a blow-off pipe and an exhaust pipe and is connected with a flushing tank through a connection pipe; a detachable filter screen is arranged in the water storage tank; a clean water tank is arranged in the flushing tank; the lower ends of the flushing tank, the clean water tank and the blow-off pipe are connected with a flush urinal through a flushing pipe; an overflow pipe is arranged at a position, close to the water storage tank, of the upstairs sewer pipe; the overflow pipe and a water level limiting device are located at the same horizontal position; a high-pressure universal spraying device is arranged in the water storage tank; start and stop switches are arranged on all the pipes; water drainage switches are arranged on the flushing tank and the clean water tank; a transparent window is arranged at the right end part of the water storage tank. The water-saving flushing system recycles and reuses upstairs waste water by using the dead weight of water, so that money and water are saved; the water-saving flushing system is simple in structure, reasonable in design, low in cost and convenient to popularize.

Owner:李其焕

spinning machine

InactiveCN103628163BLess corrosiveLow powerNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

Owner:YIBIN GRACE GROUP CO LTD +1

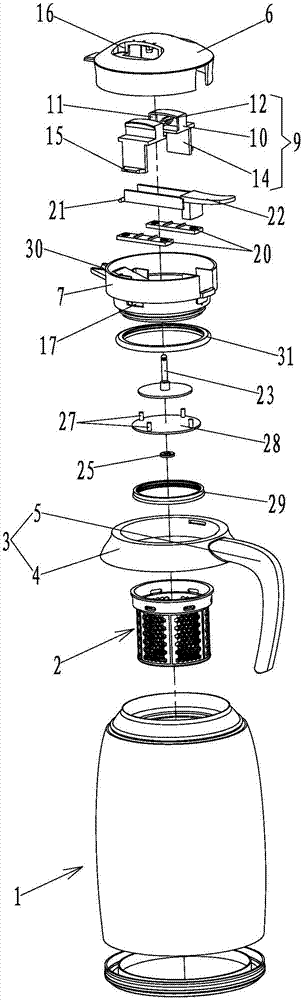

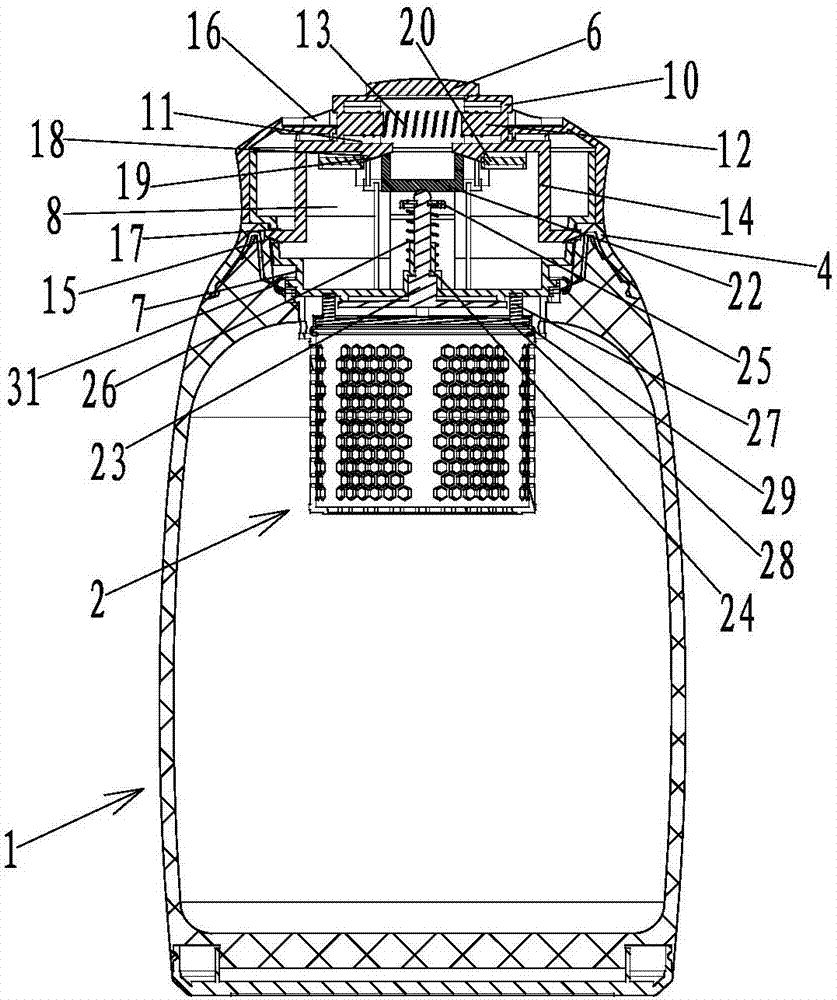

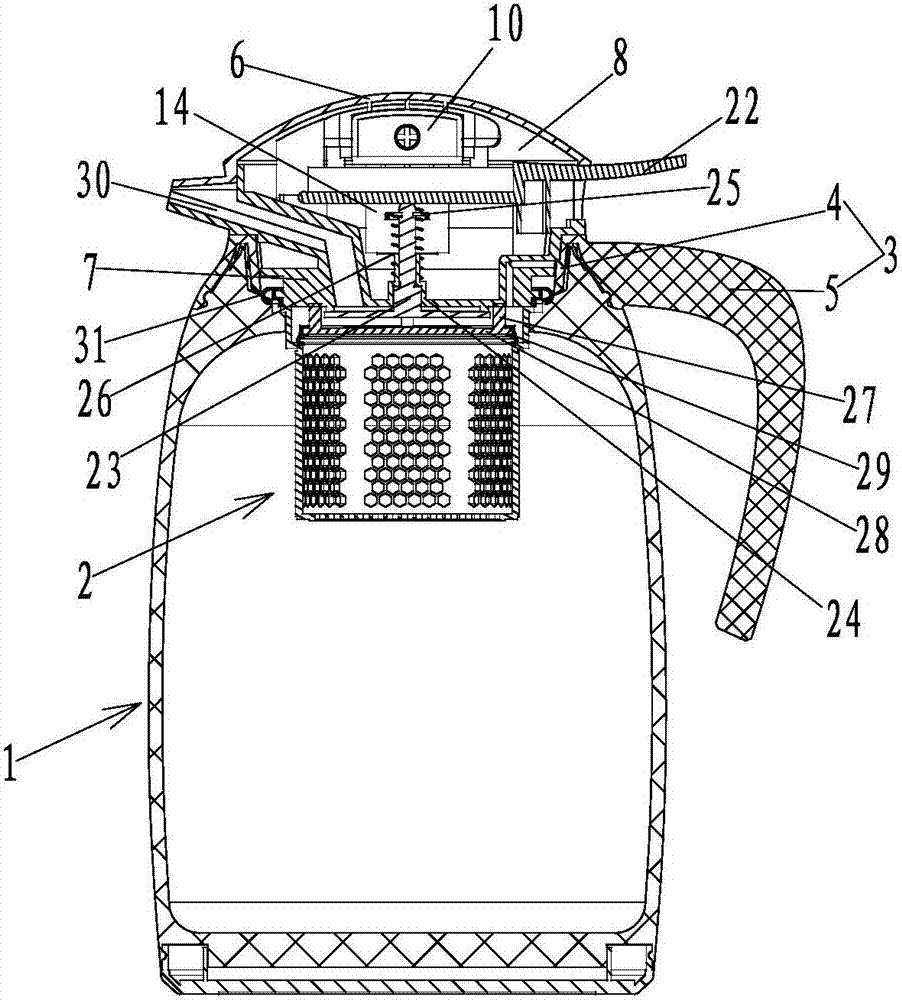

Boiled water purifying kettle

PendingCN107007167AReduce heavy metal contentReduce hardnessWater/sewage treatment bu osmosis/dialysisWater treatment locationMicroorganismFiltration

The invention discloses a boiled water purifying kettle which comprises a kettle body, wherein the upper end of the kettle body is connected with a kettle handle; a kettle cover structure is detachably mounted at the upper end of the kettle handle; a water outlet channel is formed in the kettle cover structure; and a nuclear pore membrane filter cartridge structure is connected between the kettle body and the kettle cover structure in a sealed manner. According to the boiled water purifying kettle disclosed by the invention, 99% of water scales, 98% of bacteria, dead microbes and other harmful impurities in boiled water can be removed, the content of heavy metals in water and the total hardness of water are greatly reduced, most of ions beneficial to a human body in water are remained, front-end filtration is not needed, the boiled running water can be directly filtered to be drunk, the kettle is safe and healthy, is convenient to use and extremely low in using cost and can be reused without secondary pollution after a blocked filter membrane is repeatedly cleaned to eliminate blockage.

Owner:上海谷奇核孔膜科技股份有限公司

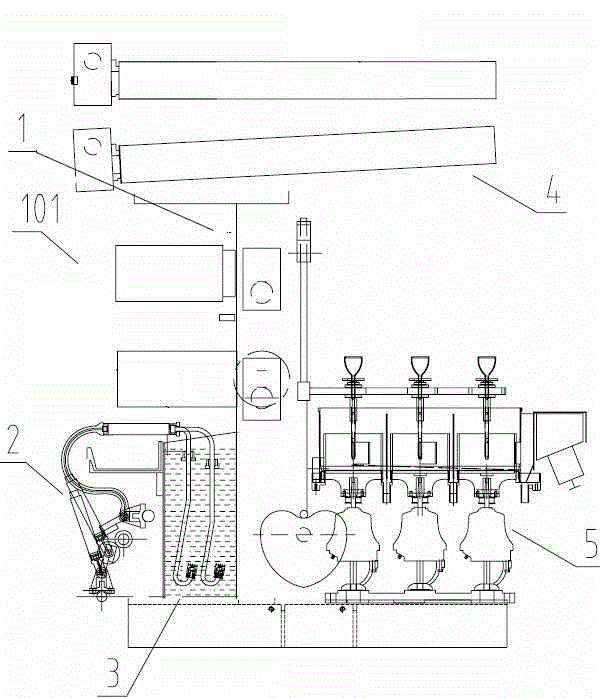

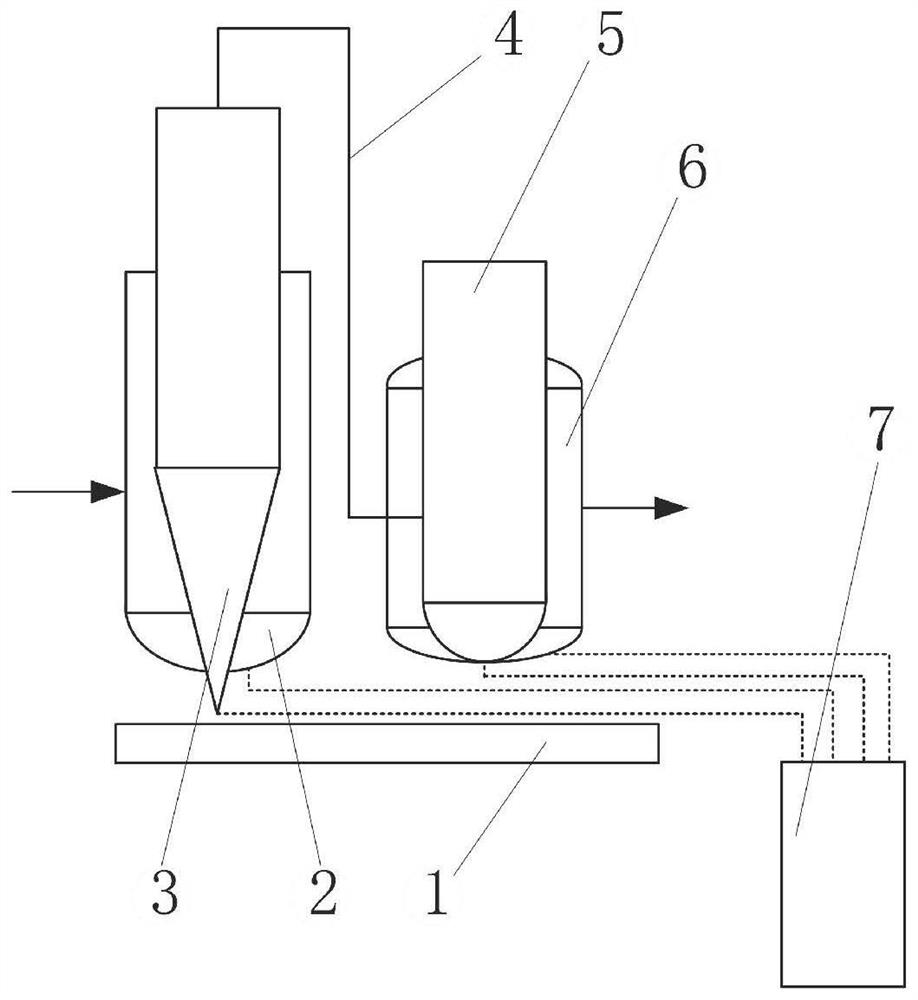

Gas conveying free water removal device

InactiveCN111603877AImprove dehydration efficiencySystem pressure loss is smallCombination devicesGaseous fuelsProcess engineeringEnvironmental geology

The invention discloses a gas conveying free water removal device. The device comprises a dehydrator, a gas dust remover, an automatic drainer, a connecting pipeline and a skid-mounted chassis, the dehydrator and the dust remover are fixedly arranged on the skid-mounted chassis, and the dehydrator comprises a coarse dehydrator, a cyclone dehydrator and a fine dehydrator; the coarse dehydrator, thecyclone dehydrator and the fine dehydrator are sequentially communicated through a connecting pipeline, and a flexible rubber joint is further arranged on the connecting pipeline; the automatic drainer is respectively communicated with the dehydrator and the gas dust remover; and gas containing moisture enters from the coarse dehydrator and sequentially enters the cyclone dehydrator, the fine dehydrator and the gas dust remover through the connecting pipeline, and the removed moisture is discharged through the automatic drainer. Effective measures for separation are taken according to the particle size of the free water, the removal process is complete and reliable, the efficiency is high, overall hoisting can be achieved, and moving is flexible and convenient.

Owner:西安科美动力科技有限公司

Spinning technology of spinning machine with externally-mounted winding device

InactiveCN103643314ALess corrosiveEasy to operateNew-spun product collectionArtificial thread manufacturing machinesEngineeringConductor Coil

The invention relates to a spinning technology of a spinning machine with an externally-mounted winding device. The process of the spinning technology comprises the following steps of mucilage glue metering and supplying, filtering before spinning, silk forming, spinning and winding. The spinning technology is specially applied to the specific spinning machine which is provided with the externally-mounted winding device, silk can be actively wound and / or passively wound into wet barrel contained silk capable of being directly used for thread twisting in the externally-mounted winding device under the mutual action of all processes and the control of technological parameters, the spinning machine can achieve high spinning speed, meanwhile, product quality can be guaranteed, the silk cannot be contaminated by dropping washing acid removal liquid and oiling agents in the final winding forming process, the subsequent dyeing process is guaranteed, the worker operation is simpler and more convenient, equipment maintenance is easier, energy consumption is lowered, production efficiency is effectively improved, and meanwhile product cost is greatly lowered.

Owner:YIBIN GRACE GROUP CO LTD +1

A spinning process of a spinning machine equipped with a through-shaft passive winding device

InactiveCN103628154BLess corrosiveLow powerNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning process of a spinning machine provided with a through-shaft passive winding device. Including glue supply, thread forming, spinning and winding, the forming part of the winding device is located outside the area between the wallboards on both sides of the frame, on the other side opposite to the spinning surface, and the winding The winding device is a through-axis passive winding device. Because the winding device of the present invention is externally installed, it is less corrosive to the thread, winding equipment and its control system in an acidic environment, and is convenient for maintenance and worker operation. The existing centrifugal cylinder needs to rotate at high speed, so the energy consumption is high, but the winding device of the present invention only needs to meet the speed of the spinning roller, without other energy consumption, so the power of the whole machine is small.

Owner:YIBIN GRACE GROUP CO LTD +1

A spinning process of a spinning machine equipped with a new type of through-shaft passive winding device

InactiveCN103643327BLess corrosiveLow powerArtificial thread manufacturing machinesArtificial filaments from viscoseSpinningControl system

The invention relates to a spinning process of a spinning machine provided with a novel through-shaft passive winding device. Including glue supply, thread forming, spinning and winding, the forming part of the winding device is located outside the area between the wallboards on both sides of the frame, on the other side opposite to the spinning surface, and the winding The winding device is a new type of through-shaft passive winding device. Since the winding device of the present invention is externally installed, it is less corrosive to the thread, winding equipment and its control system in an acidic environment, and is convenient for maintenance and worker operation. Because the existing centrifugal cylinder needs to rotate at high speed, the energy consumption is high, but the winding device of the present invention only needs to meet the speed of the spinning roller, without other energy consumption, so the power of the whole machine is small.

Owner:YIBIN GRACE GROUP CO LTD +1

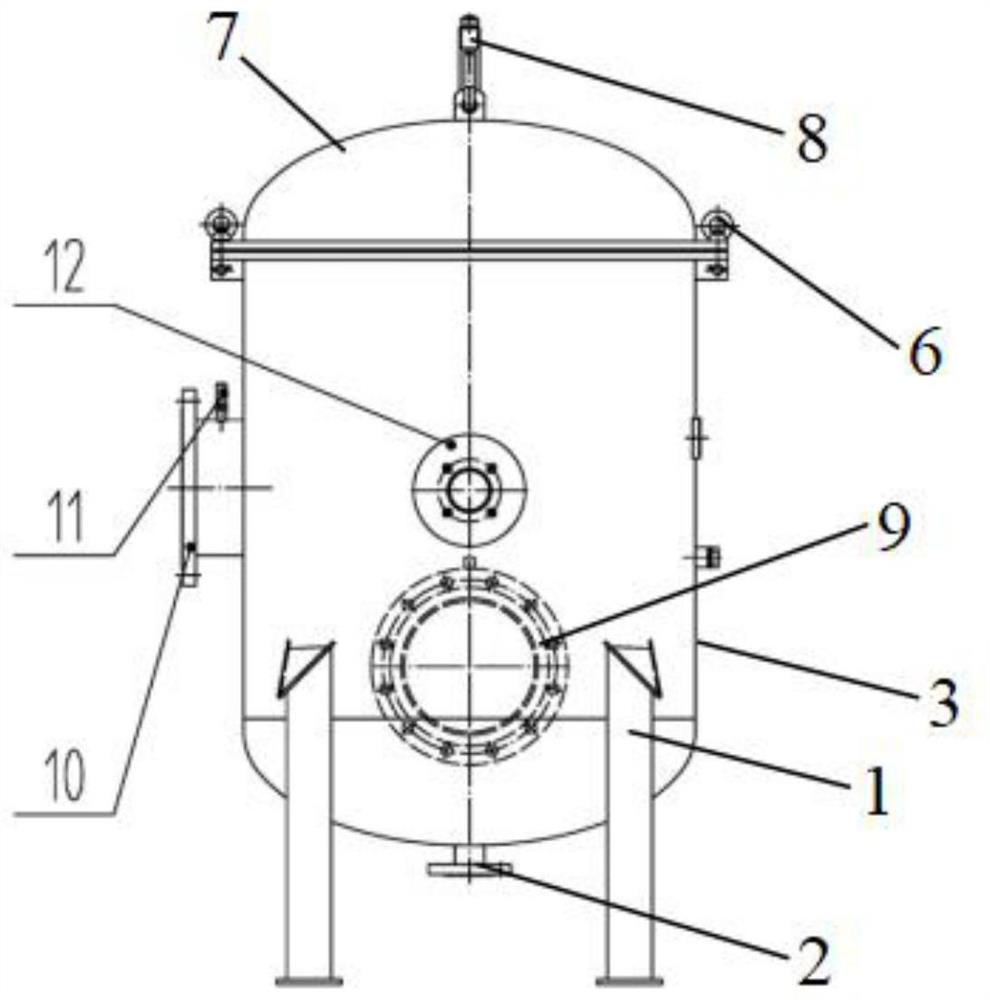

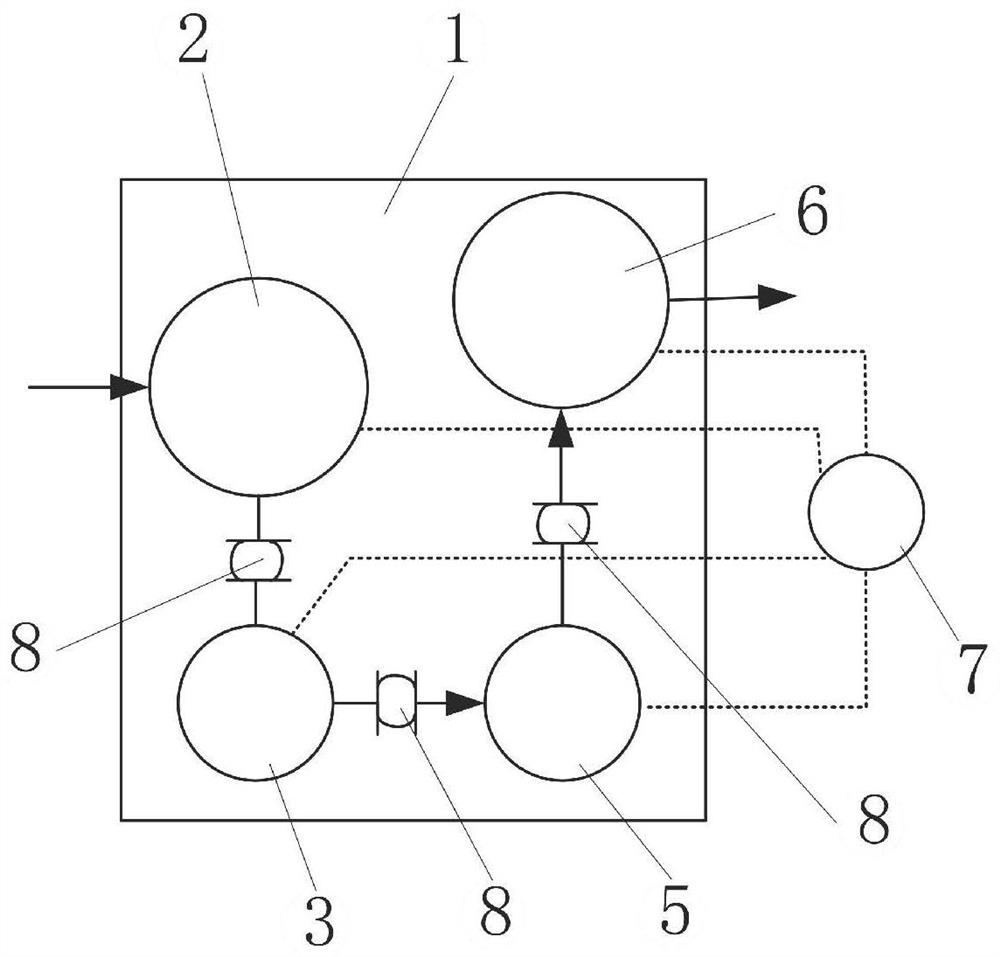

Gas dehydration and dust removal device

InactiveCN111603852AFunctionalLarge filter areaDispersed particle filtrationTransportation and packagingDust controlSewage outfall

The invention discloses a gas dehydration and dust removal device. The device comprises a shell (7), the top of the shell (7) is opened and is provided with a cover plate (8) for sealing the opening,a dirt draining exit (1) is formed in the bottom of the shell (7), a gas inlet (4) communicated with the inside is formed below the outer side of the shell (7), a gas outlet (11) communicated with theinside is formed above the outer side of the shell (7), the shell (7) is of a square structure, the caliber of the gas inlet (4) is of a divergent structure, and the caliber of the gas outlet (11) isof a convergent structure; and an explosion venting valve (6) communicated with the inside is further arranged on the outer side of the shell (7). According to the technical scheme, dehydration and dust removal are integrated, the filtering area is large, the gas application amount is large, the filtering precision is high, the pressure drop is small, the structure is simple, installation is convenient, and cost is saved.

Owner:西安科美动力科技有限公司

A kind of spinning process of spinning machine with external winding device

InactiveCN103643312BLess corrosiveEasy to operateArtificial thread manufacturing machinesFilament handlingSpinningViscose

The invention relates to a spinning technology of a spinning machine with an external winding device. The processes of the spinning technology comprise viscose metering, viscose supplying, filtering before spinning, silk strip forming, spinning and winding, wherein the moisture content of wet tube packed silk in the winding process is 30-80%. For the specific spinning machine with the external winding device, under the mutual effect of all the processes and the control of technological parameters, the purpose that the silk strips are wound into the wet tube packed silk which is directly used for twisting threads in the external winding device in an active winding mode and / or in a passive winding mode can be achieved, the fact that the spinning machine achieves high spinning speed is guaranteed, the quality of products can also be guaranteed at the same time, particularly, the silk strips can not be contaminated by dropping of water washing acid removing liquid and an oiling agent in the last winding forming process, a subsequent dyeing technology is guaranteed, operation of workers is simpler and more convenient, equipment maintaining is easier, energy consumption is lowered, and product cost is greatly lowered while the production efficiency is effectively improved.

Owner:YIBIN GRACE GROUP CO LTD +1

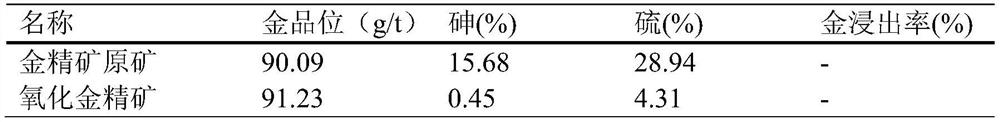

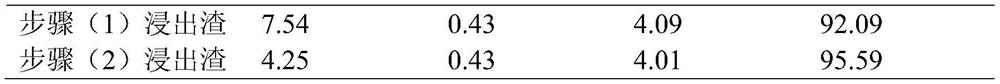

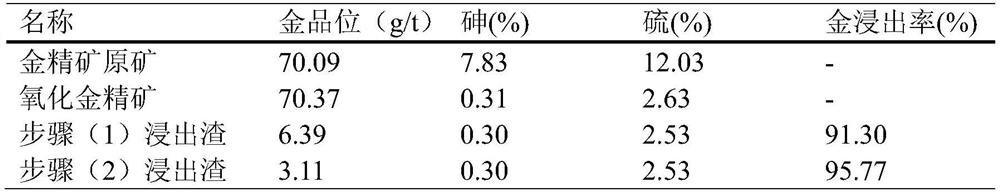

Gold concentrate oxidizing slag gold leaching process

PendingCN113981238ALarge amount of resourcesNo other energy consumptionProcess efficiency improvementActivated carbonPregnant leach solution

The invention discloses a gold concentrate oxidizing slag gold leaching process, which comprises the following steps: firstly, leaching the gold concentrate oxidizing slag for the first time by using a leachate and activated carbon to obtain gold-loaded carbon and mixed ore pulp; then supplementing activated carbon and the leachate into the mixed ore pulp, adjusting the pH value, and then carrying out secondary leaching to obtain a leaching solution, gold-loaded carbon and tailings; finally, recycling the leaching solution for continuous leaching; wherein the leachate is ammonium thiocyanate. The process is used for the high-arsenic sulfur gold concentrate with the arsenic content exceeding 15%, the leaching rate is 95% or above, other energy consumption is avoided, the leaching condition is simple, and the industrial realizability is high; the leaching solution is recycled and re-leached, so that the dosage of chemicals and water is saved, and meanwhile, the two-stage leaching ensures that the gold leaching rate is high and the index is stable; ammonium thiocyanate is adopted as the leachate, the leachate is easy to obtain, low in cost, safe and non-toxic, the gold leaching speed is high, the leaching period is short, leaching waste liquid and waste residues are easy to treat, and the cost is low.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com