Device and method for removing redundant sand of 3D printing sand mould in magnetic control vibration mode

A 3D printing and sand material technology, applied in the field of sand 3D printing, can solve the problem of inconvenient removal of excess sand material, improve sand cleaning efficiency and sand cleaning automation level, easy to program control, easy and efficient mass production operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

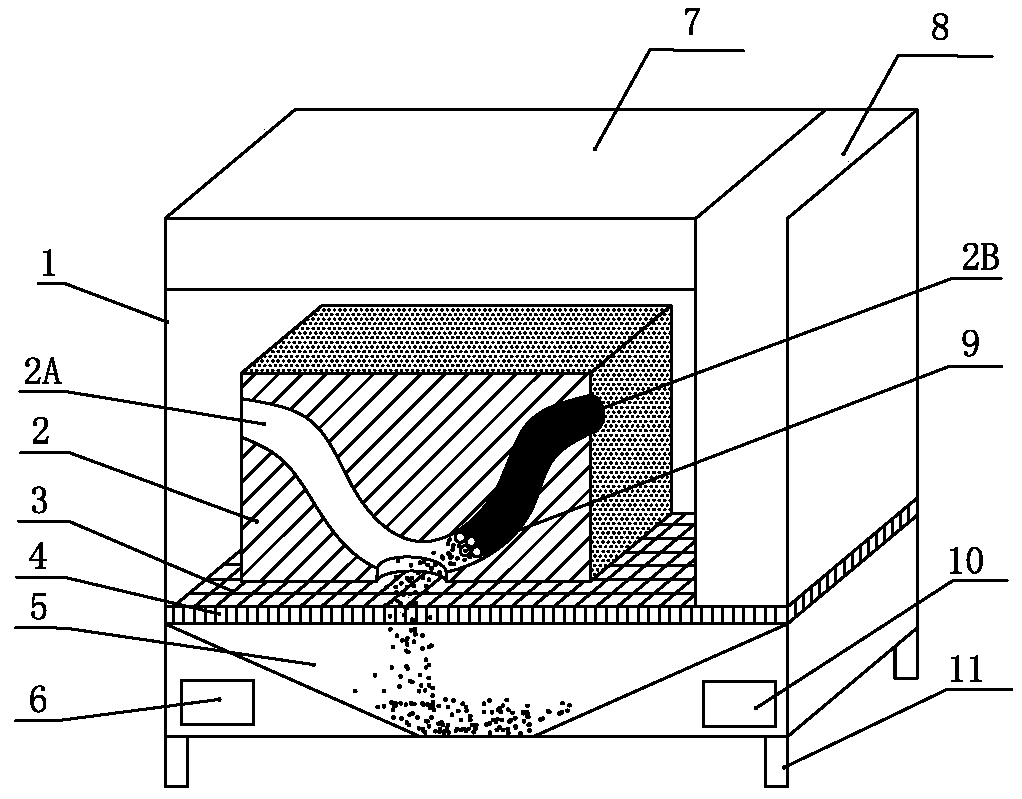

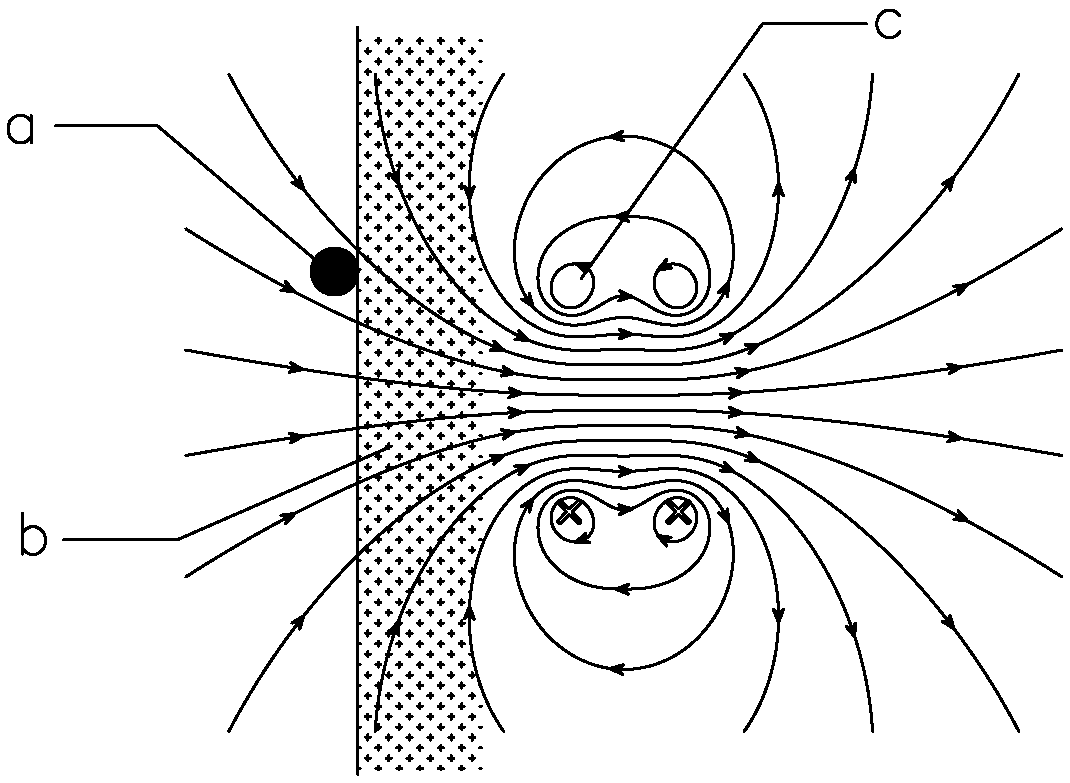

[0025] like figure 1 As shown, it is a device for removing excess sand material from 3D printing sand molds by magnetic control vibration according to the present invention, which includes a box body 1, and a support frame 3 for placing a 3D printing sand mold 2 is provided inside the box body 3, and sand is provided on the lower side of the support frame 3. Material collection device, the top of the box body 1 is provided with a winding coil 7 and at least one side is provided with a winding coil 8, the above-mentioned winding coils can generate an alternating magnetic field by alternating electricity with a certain current at a set frequency, and the box body 1 is provided with a number of sand cleaning particles 9 made of magnetic materials. The sand cleaning particles 9 can vibrate at high frequency in a certain space under the action of the above-mentioned alternating magnetic field. The surface layer of the sand mold begins to vibrate gradually to knock down the mold cav...

Embodiment 2

[0039] This embodiment specifically illustrates the method for removing excess sand material from 3D printing sand molds using the above-mentioned device, which specifically includes the following steps: A) According to the minimum diameter of the narrowest part of the mold cavity after the sand mold needs to remove excess sand material, select an appropriate amount of cleaning material with a particle size Sand particles; the number of sand cleaning particles should not be less than three. During the sand cleaning process, the number of sand cleaning particles can be increased or decreased according to the size of the cavity channel being cleaned. The particle size of each sand cleaning particle should be smaller than the 3D printing sand mold 1 / 3 of the minimum diameter of the narrowest small cavity after sand cleaning; then proceed to step B), place the 3D printed sand mold 2 on the support frame 3 in the box body 1, and make the excess sand material corresponding to the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com