Spinning technology of a spinning machine

A technology of spinning process and spinning machine, which is applied in the field of spinning process of spinning machine, and can solve the problems of broken viscose filaments, low filament strength, and insufficient reaction time of viscose filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

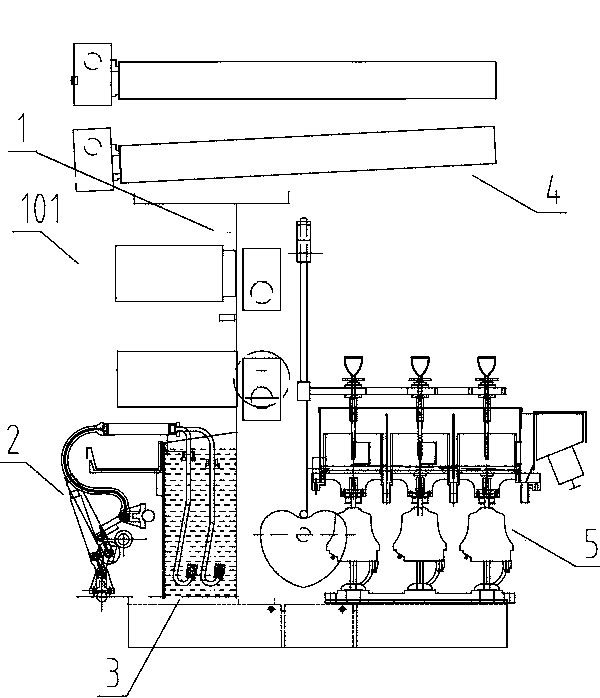

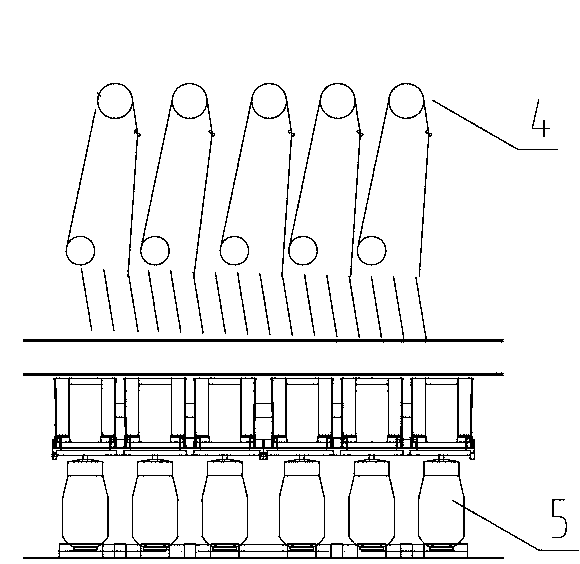

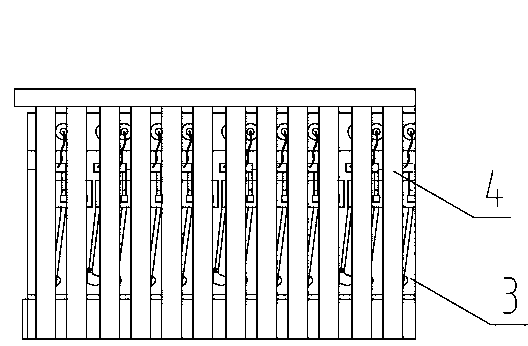

[0225] A spinning process of a spinning machine, comprising glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3, The spinning is completed by the spinning device 4, and the winding is completed by the winding device 5. The spinning device 4 includes a plurality of spinning rollers, and the two ends of the spinning rollers are fixed. The forming part of the winding device 5 is located on the outside of the area between the wallboards 6 on both sides of the frame 1, on the other side opposite to the spinning surface 101, and the spinning surface 101 refers to the outer side of the wallboard 6 outside the frame 1. 1. The area where the filament forming device 3 is provided, the other side opposite to the area is called the winding surface 7, and the winding device 5 includes a wet cake winding device 51, and / or a wet cylinder Packing winding device 52 ...

Embodiment 2

[0231]A spinning process of a spinning machine, comprising glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3, The spinning is completed by the spinning device 4, and the winding is completed by the winding device 5. The spinning device 4 includes a plurality of spinning rollers, and the two ends of the spinning rollers are fixed. The forming part of the winding device 5 is located on the outside of the area between the wallboards 6 on both sides of the frame 1, on the other side opposite to the spinning surface 101, and the spinning surface 101 refers to the outer side of the wallboard 6 outside the frame 1. 1. The area where the filament forming device 3 is provided, the other side opposite to the area is called the winding surface 7, and the winding device 5 includes a wet cake winding device 51, and / or a wet cylinder Packing winding device 52 a...

Embodiment 3

[0237] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area on the outside of the frame 1 wallboard 6 that is provided with a filament forming device 3, and the other side opposite to the area is called the winding surface 7, and the spinning device 4 includes a plurality of spinning rollers, Both ends of the spinning roll are fixed, and the winding device 5 includes a wet cake winding device 51 . The frame 1 includes at least two uprights 1101 , and the wall panels 6 are installed on the upr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Inner diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com