Spinning machine

A spinning machine and spinning roller technology, applied in the direction of filament generation, textile and papermaking, filament/thread forming, etc., can solve the pollution of water and acid solution in the winding device, increase energy consumption, and cannot obtain wet filaments And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

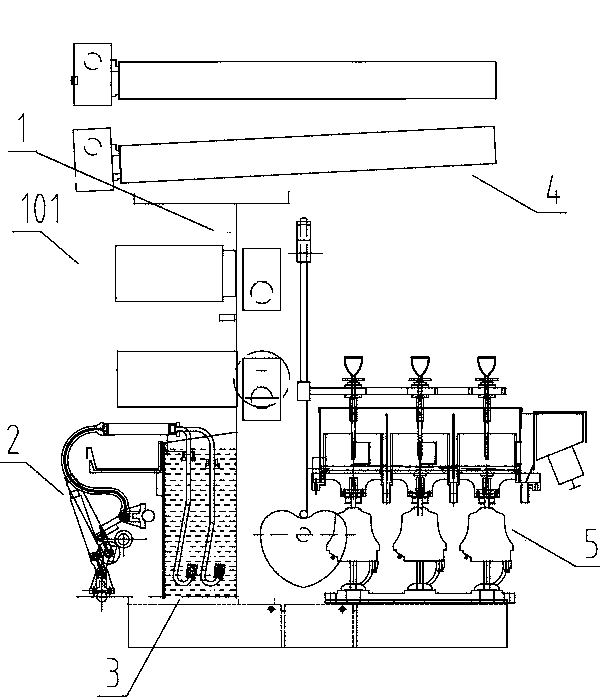

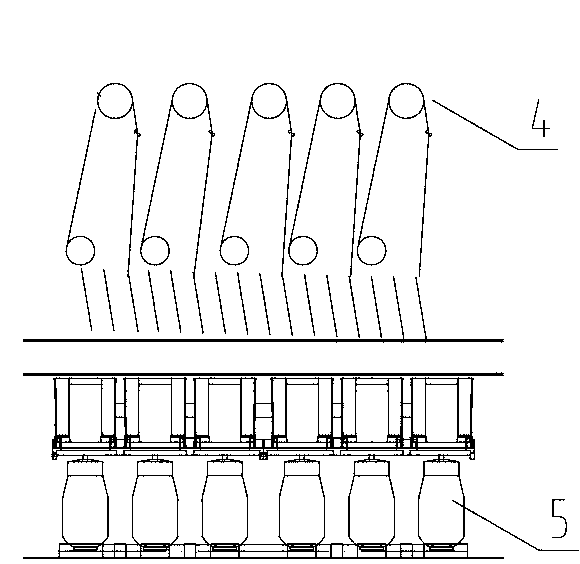

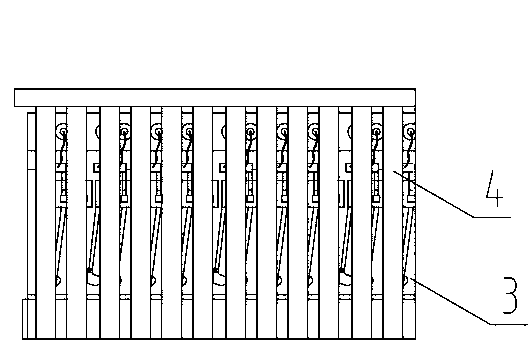

[0219] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area on the outside of the frame 1 wallboard 6 that is provided with a filament forming device 3, and the other side opposite to the area is called the winding surface 7, and the spinning device 4 includes a plurality of spinning rollers, Both ends of the spinning roll are fixed, and the winding device 5 includes a wet cake winding device 51 , and / or a wet package winding device 52 , and / or a wet skein winding device 53 . The frame 1 incl...

Embodiment 2

[0223] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area on the outside of the frame 1 wallboard 6 that is provided with a filament forming device 3, and the other side opposite to the area is called the winding surface 7, and the spinning device 4 includes a plurality of spinning rollers, Both ends of the spinning roll are fixed, and the winding device 5 includes a wet cake winding device 51 , and / or a wet package winding device 52 , and / or a wet skein winding device 53 . The frame 1 incl...

Embodiment 3

[0227] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area on the outside of the frame 1 wallboard 6 that is provided with a filament forming device 3, and the other side opposite to the area is called the winding surface 7, and the spinning device 4 includes a plurality of spinning rollers, Both ends of the spinning roll are fixed, and the winding device 5 includes a wet cake winding device 51 . The frame 1 includes at least two uprights 1101 , and the wall panels 6 are installed on the upr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com