Method for overcoming feeding difficulty of mirabilite gypsum as cement retarder

A technology of cement retarder and gypsum, applied in the field of cement production, can solve the problems of excessive powdery materials, difficulty in feeding mirabilite gypsum, affecting the production and use of mirabilite gypsum, etc., and achieve the effect of avoiding the increase of economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

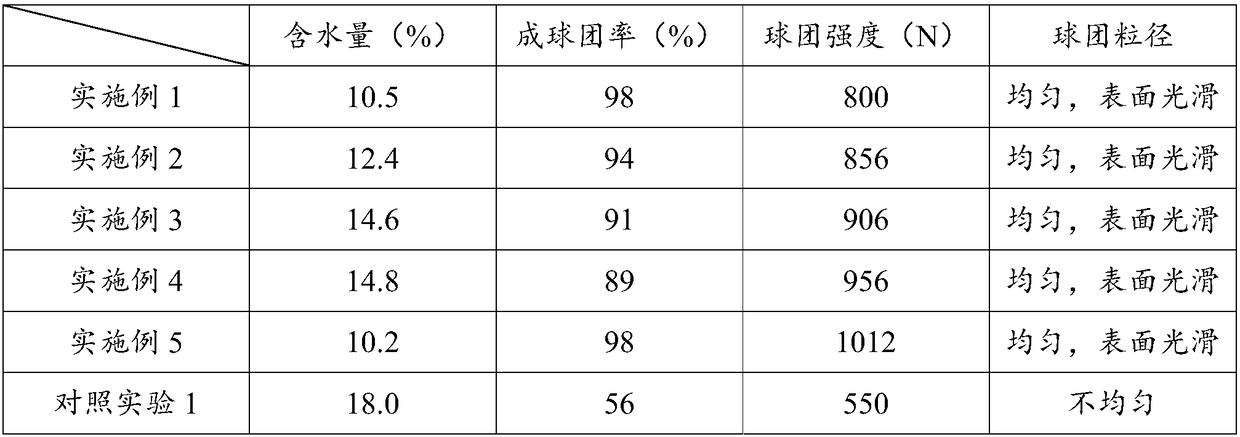

Examples

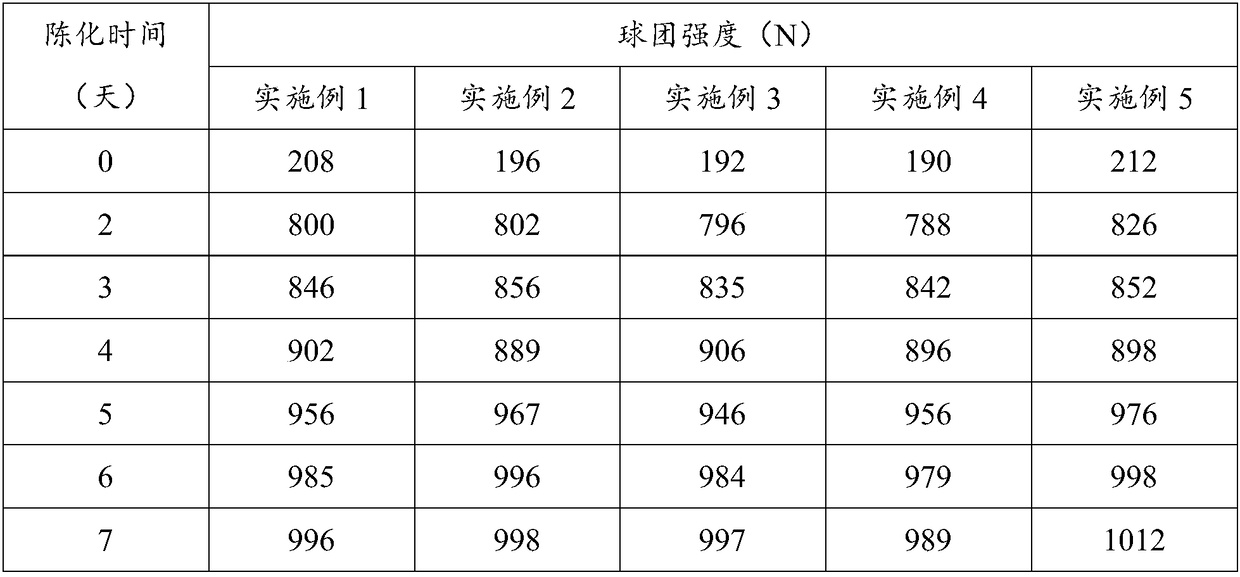

Embodiment 1

[0024] A method for solving the difficulty of feeding mirabilite gypsum as a cement retarder, comprising the following steps:

[0025] (1) Reduce the water content: The thenardite gypsum is transported to the gypsum storehouse, and stacked by a stacker, and is naturally stacked for 35 days at room temperature to reduce the water content by 6%;

[0026] (2) sieving: the mirabilite gypsum is sent to the belt according to the principle of first-in, first-out, and the thenardite gypsum is transported to the screening equipment through the belt, and the particle size of the thenardite gypsum is below 10 mm and 10 mm. The above are screened out respectively; the glauberite gypsum with a particle size of more than 10mm is directly transported to the aging warehouse by the belt, and aged for 2 days;

[0027] (3) briquetting: the mirabilite gypsum screened in step (2) with a particle size of less than 10 mm is sent to a high-pressure pelletizing machine through a belt for briquetting t...

Embodiment 2

[0031] A method for solving the difficulty of feeding mirabilite gypsum as a cement retarder, comprising the following steps:

[0032] (1) Reduce the water content: The thenardite gypsum is transported to the gypsum storehouse, and stacked by a stacker, and is naturally stacked for 25 days at normal temperature to reduce the water content by 4%;

[0033] (2) sieving: the mirabilite gypsum is sent to the belt according to the principle of first-in, first-out, and the thenardite gypsum is transported to the screening equipment through the belt, and the particle size of the thenardite gypsum is below 10 mm and 10 mm. The above are screened out respectively; the glauberite gypsum with a particle size of more than 10mm is directly transported to the aging warehouse by the belt, and aged for 3 days;

[0034] (3) briquetting: the mirabilite gypsum screened in step (2) with a particle size of less than 10 mm is sent to a high-pressure pelletizing machine through a belt for briquetting...

Embodiment 3

[0038] A method for solving the difficulty of feeding mirabilite gypsum as a cement retarder, comprising the following steps:

[0039] (1) Reduce the water content: The thenardite gypsum is transported to the gypsum storehouse, and stacked by a stacker, and is naturally stacked for 12 days at normal temperature to reduce the water content by 2.5%;

[0040] (2) sieving: the mirabilite gypsum is sent to the belt according to the principle of first-in, first-out, and the thenardite gypsum is transported to the screening equipment through the belt, and the particle size of the thenardite gypsum is below 10 mm and 10 mm. The above are screened out respectively; the glauberite gypsum with a particle size of more than 10mm is directly transported to the aging warehouse by the belt, and aged for 4 days;

[0041](3) briquetting: the mirabilite gypsum screened in step (2) with a particle size of less than 10 mm is sent to a high-pressure pelletizing machine through a belt for briquettin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com