Continuous wet-dry two-stage dynamic anaerobic fermentation equipment

A dry anaerobic fermentation and anaerobic fermentation technology, applied in the field of continuous wet-dry two-stage dynamic anaerobic fermentation equipment, can solve the problem of staying conceptual design or laboratory research stage, without involving dry fermentation biogas slurry reuse, It does not involve problems such as dry fermentation reactors, and achieves the effects of improving processing capacity and volumetric gas production rate, preventing local acidification, and reducing investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

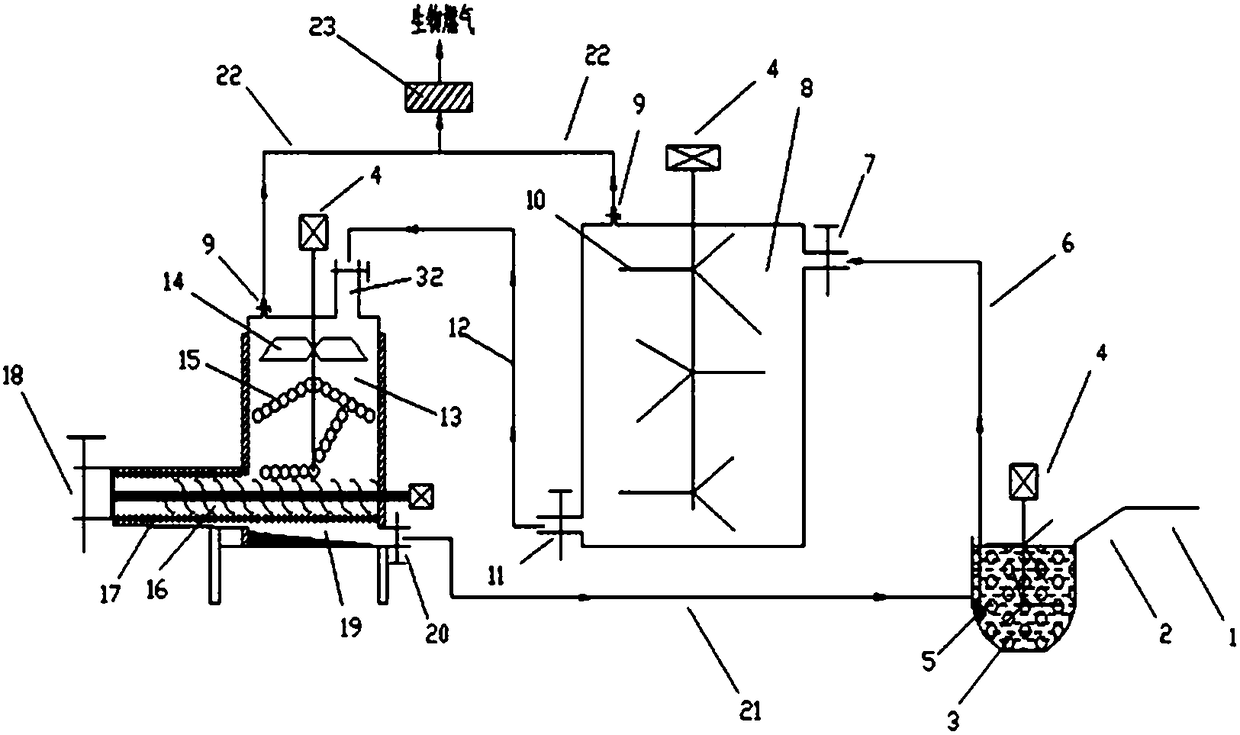

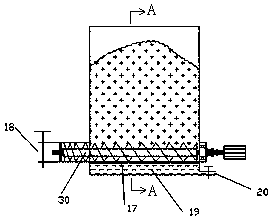

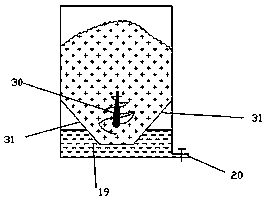

[0023] The accompanying drawings disclose the specific structure of the embodiment of the present invention without limitation, and this embodiment will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, a continuous wet-dry two-stage dynamic anaerobic fermentation equipment includes a mixing adjustment tank 3, a closed fermentation device and a fermentation residue dehydration discharge device 16. Material platform 1; Described airtight fermentation device comprises wet anaerobic fermentation device 8 and dry type anaerobic fermentation device 13, feed port 7 is positioned at the top of wet type anaerobic fermentation device 8, and feed port 32 is positioned at dry type anaerobic fermentation device 13. On the top of the fermentation device 13, the output end 11 is located at the bottom of the wet anaerobic fermentation device 8, and the output end 18 (big residue outlet) is located at the bottom of the dry anaerobic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com