Method for manufacturing copper-aluminum welded joint of capillary tube and copper end sleeved aluminum capillary tube

A technology for welding joints and capillaries, applied in the direction of pipes/pipe joints/fittings, welding equipment, welding/welding/cutting items, etc. The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preparation method for a capillary copper-aluminum welded joint, comprising the steps of:

[0024] (1) A high-temperature-resistant rod-shaped inner core that is harder than the copper capillary and exposed at both ends of the copper capillary is preset inside the copper capillary. The diameter of the inner core is smaller than the inner diameter of the aluminum capillary;

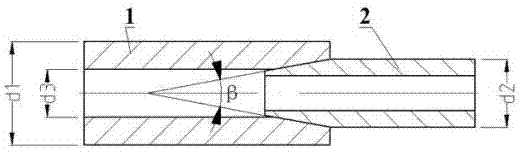

[0025] (2) Use a precision roll forging machine to taper one end of the copper capillary, and reduce the wall thickness of the copper capillary to form a welding surface with a certain taper taper b. At this time, the copper capillary shrinks in the inner diameter of the welding surface area, and the inner diameter after shrinkage is not smaller than the diameter of the inner core, and the inner core is stuck at the cone head;

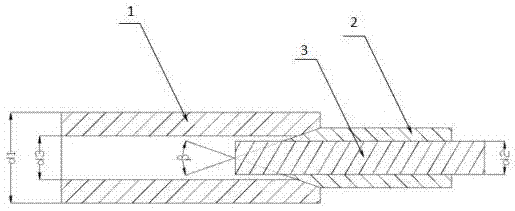

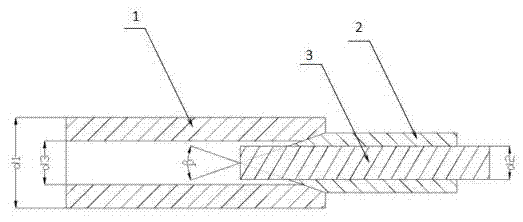

[0026] (3) if figure 1 Pre-assembled by inserting the tapered end of the copper capillary with the inner core into the aluminum capillary as shown;

[0027] (4) Place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com