Adjustable grinding device

A grinding device and adjustable technology, applied in the field of grinding rods, can solve the problems of shortening the service life of metal parts, accelerated wear of metal parts, etc., and achieve the effect of high surface roughness and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

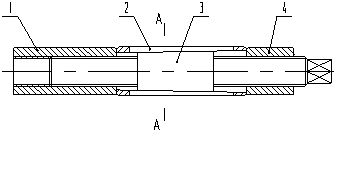

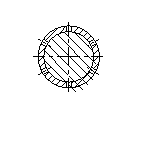

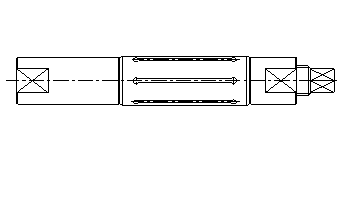

[0011] attached figure 1 The adjustable grinding device shown includes a left nut 1, an outer sleeve 2, an adjustment shaft 3 and a right nut 4. The inner conical hole on the outer sleeve 2 fits with the outer conical surface on the adjustment shaft 3, and the left nut 1 and the right nut 4 pass through The screws at both ends of the adjusting shaft 3 relatively fix the jacket 2 on the adjusting shaft 3; the circumference of the jacket 2 is provided with a plurality of straight grooves, and the outer wall is evenly bonded with diamond sand. During the adjustment of the present invention, the right nut 4 is loosened, and the left nut 1 is tightened to expand the outer diameter of the overcoat 2. After the outer diameter of the overcoat 2 is adjusted to the required size, the right nut 4 is tightened to fix the size; otherwise, Reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com