Preparation method of wear-resistant extrusion roller

The technology of squeezing roller and wear-resistant column is applied in the field of industrial crushing machinery preparation, which can solve the problems of long working cycle and high production efficiency, and achieve the effect of improving weldability, good weldability and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

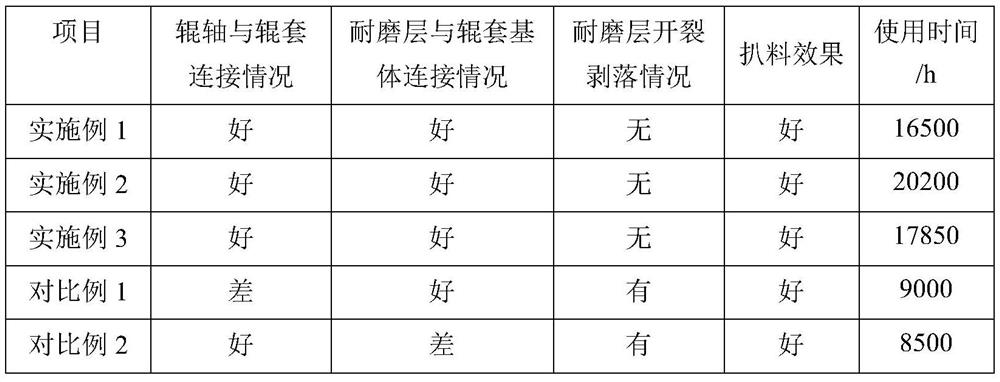

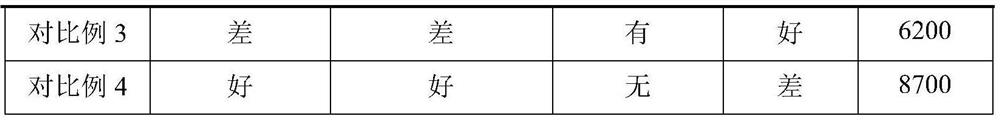

Embodiment 1

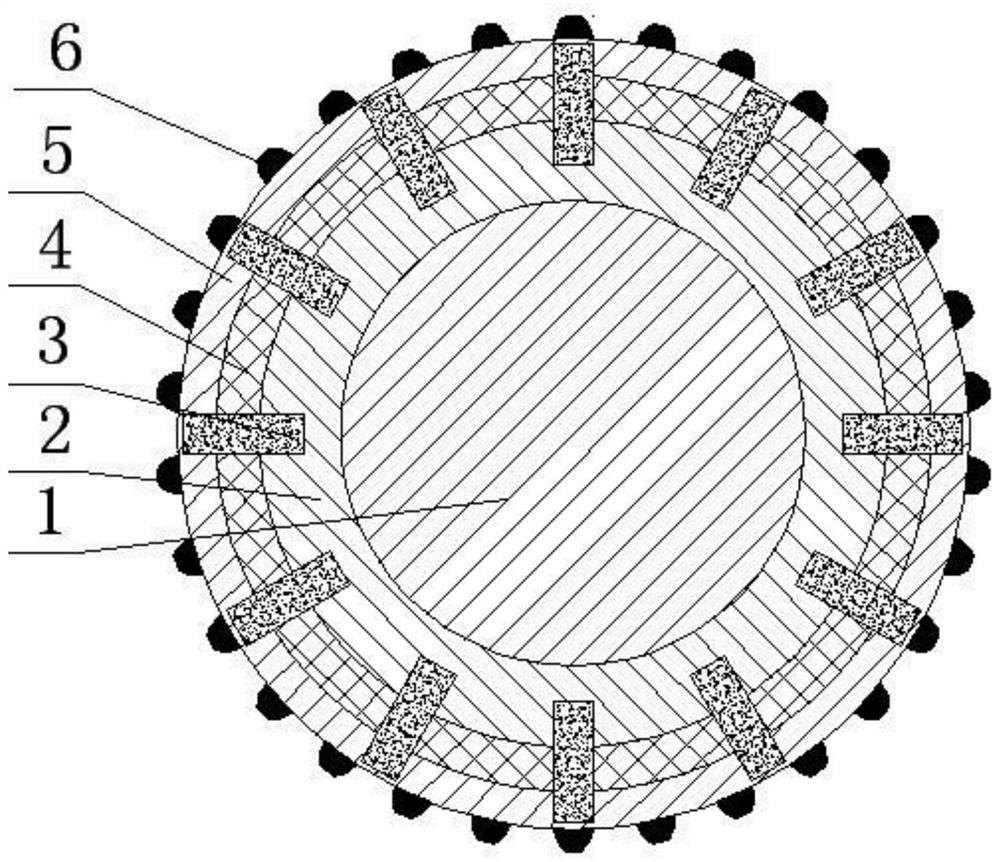

[0041] The wear-resistant extrusion roller includes a roller shaft 1, a roller sleeve base 2, a wear-resistant stud 3, a transition layer 4, a wear-resistant layer 5 and a wear-resistant pattern 6, and the roll shaft 1 and the roll sleeve base 2 are set together , the base body of the roller sleeve 2 is provided with wear-resistant studs 3, the outer ring surface of the roll sleeve base body 2 is provided with a transition layer 4, the outer ring surface of the transition layer 4 is provided with a wear-resistant layer 5, and the wear-resistant layer 5 A wear-resistant pattern 6 is provided on the outer ring surface, and its preparation method is as follows:

[0042] Step 1: Prepare the cavity.

[0043] Step 2: Put the wear-resistant stud 3 in the predetermined part of the cavity, and then pour the high manganese steel mother liquor into the cavity to form the roller sleeve matrix 2, the wear-resistant stud 3 and the roller sleeve base 2 are cast together, and the wear-resista...

Embodiment 2

[0059] The wear-resistant extrusion roller includes a roller shaft 1, a roller sleeve base 2, a wear-resistant stud 3, a transition layer 4, a wear-resistant layer 5 and a wear-resistant pattern 6, and the roll shaft 1 and the roll sleeve base 2 are set together , the base body of the roller sleeve 2 is provided with wear-resistant studs 3, the outer ring surface of the roll sleeve base body 2 is provided with a transition layer 4, the outer ring surface of the transition layer 4 is provided with a wear-resistant layer 5, and the wear-resistant layer 5 A wear-resistant pattern 6 is provided on the outer ring surface, and its preparation method is as follows:

[0060] Step 1: Prepare the cavity.

[0061] Step 2: Put the wear-resistant stud 3 in the predetermined part of the cavity, and then pour the high manganese steel mother liquor into the cavity to form the roller sleeve matrix 2, the wear-resistant stud 3 and the roller sleeve base 2 are cast together, and the wear-resista...

Embodiment 3

[0077] The wear-resistant extrusion roller includes a roller shaft 1, a roller sleeve base 2, a wear-resistant stud 3, a transition layer 4, a wear-resistant layer 5 and a wear-resistant pattern 6, and the roll shaft 1 and the roll sleeve base 2 are set together , the base body of the roller sleeve 2 is provided with wear-resistant studs 3, the outer ring surface of the roll sleeve base body 2 is provided with a transition layer 4, the outer ring surface of the transition layer 4 is provided with a wear-resistant layer 5, and the wear-resistant layer 5 A wear-resistant pattern 6 is provided on the outer ring surface, and its preparation method is as follows:

[0078] Step 1: Prepare the cavity.

[0079] Step 2: Put the wear-resistant nail 3 in the predetermined part of the cavity, and then pour the ultra-high manganese steel mother liquid into the cavity to form the roller sleeve base 2, and the wear-resistant stud 3 and the roll sleeve base 2 are inlaid and cast together, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com